A kind of rare earth ion co-doped aluminosilicate novel green light phosphor and preparation method thereof

A technology of aluminosilicate and rare earth ions, which is applied in the field of rare earth ion co-doped aluminosilicate new-type green phosphors and its preparation, to achieve fine and uniform particles, good surface morphology, and few powder surface defects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

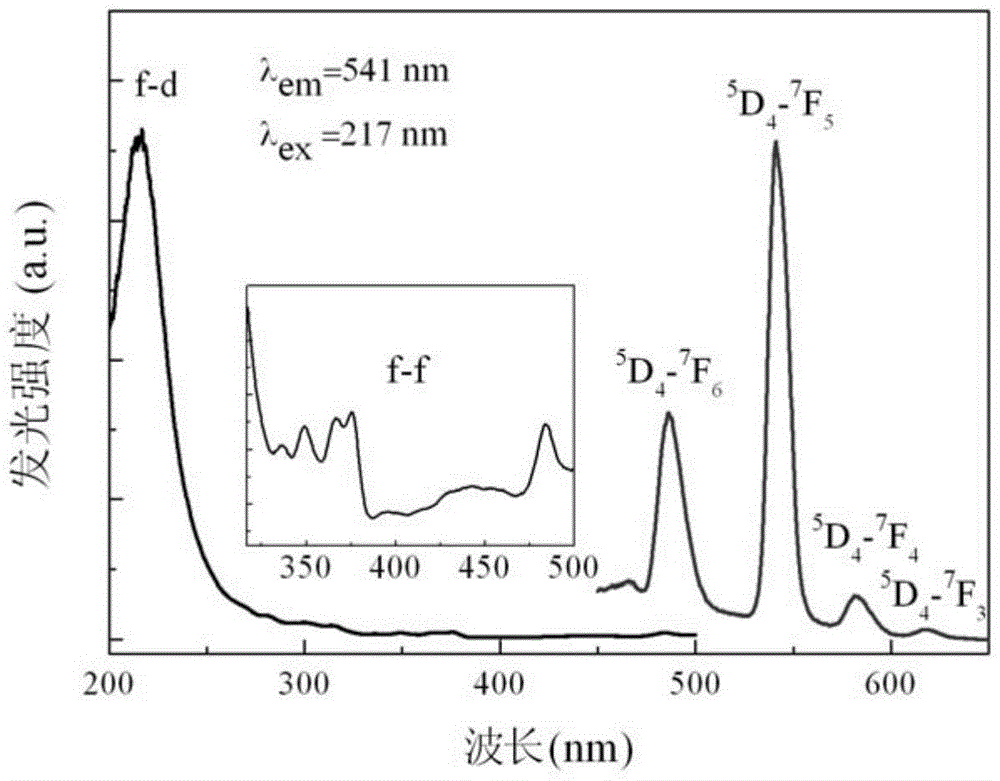

[0043] Weigh 5.998g (0.588mol) of alumina, 2.352g (0.392mol) of silicon dioxide, and 1.496g (0.02mol) of terbium oxide, mix them, and grind them in an agate mortar for 30 minutes. Pour the fully and uniformly mixed raw materials into a boron nitride crucible, place a corundum sheet under the crucible, put it into a high-temperature tube furnace for sintering, and introduce a reducing atmosphere of 95% N 2 +5%H 2 , set the sintering temperature to 1470°C, and the holding time to 5h. After the furnace cavity is cooled to room temperature, take out the sample and crush and grind for about 30 minutes to obtain Al 6 Si 2 o 13 : Tb phosphor. At this time Tb 3+ The doping concentration is 8mol%, the excitation and emission spectra are as figure 1 shown.

Embodiment 2

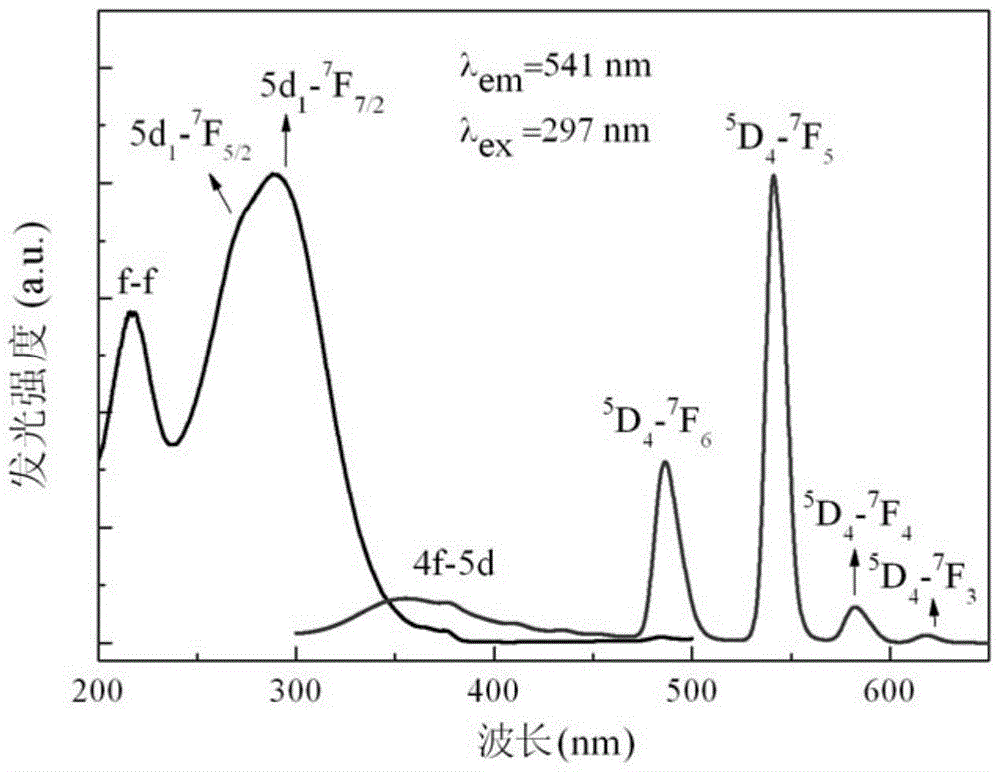

[0045] Weigh 5.918g (0.5802mol) of alumina, 2.321g (0.3868mol) of silicon dioxide, 1.496g (0.02mol) of terbium oxide, 0.2236g (0.013mol) of cerium oxide, mix them, and grind them in an agate mortar for 30min . Pour the fully and uniformly mixed raw materials into a boron nitride crucible, place a corundum sheet under the crucible, put it into a high-temperature tube furnace for sintering, and introduce a reducing atmosphere of 95% N 2 +5%H 2 , the sintering temperature is 1470°C, and the holding time is 5h. After the furnace cavity is cooled to room temperature, take out the sample and crush and grind for about 30 minutes to obtain Al 6 Si 2 o 13 : Tb, Ce green phosphor. At this time Ce 3+ and Tb 3+ The doping concentrations are 1.3mol% and 8.0mol%, respectively, and the excitation and emission spectra are as figure 2 shown. With 297nm as the excitation wavelength, the luminous quantum efficiency of the phosphor is 24.21%, and it has good thermal stability: the lumin...

Embodiment 3

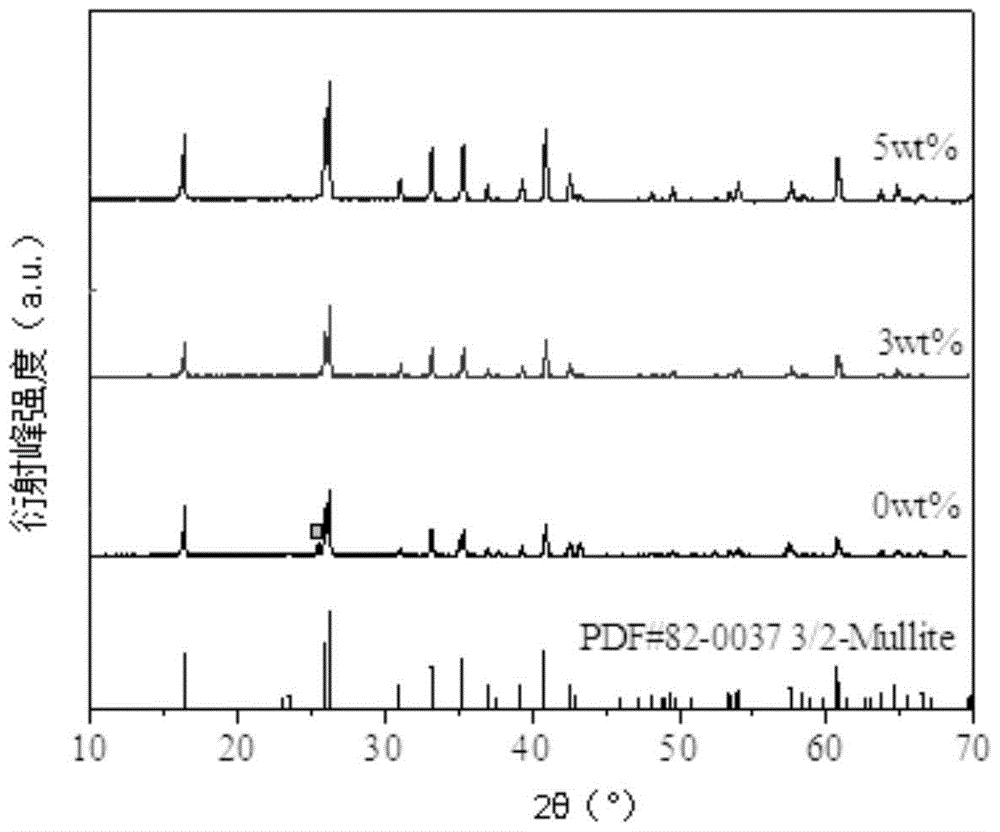

[0047] Weigh 5.918g (0.5802mol) of alumina, 2.321g (0.3868mol) of silicon dioxide, 1.496g (0.02mol) of terbium oxide, 0.2236g (0.013mol) of cerium oxide, mix them, and grind them in an agate mortar for 30min . Pour the fully and uniformly mixed raw materials into a boron nitride crucible, place a corundum sheet under the crucible, put it into a high-temperature tube furnace for sintering, and introduce a reducing atmosphere of 95% N 2 +5%H 2 , the sintering temperature is 1470°C, and the holding time is 5h. After the furnace cavity is cooled to room temperature, take out the sample and crush and grind for about 30 minutes to obtain Al 6 Si 2 o 13 : Tb, Ce green phosphor; followed by 15wt% SiO 2 Coating treatment: specifically use the hydrolysis of tetraethyl orthosilicate (TEOS) in acidic solution to produce Si(OH) 4 , and then heat treatment at 600°C for 2 hours, so that the Si(OH) on the surface of the phosphor particles 4 Transformation into continuous dense amorphou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com