Vanadate garnet type fluorescent material as well as preparation method and application thereof

A garnet-type, fluorescent material technology, applied in luminescent materials, chemical instruments and methods, lasers, etc., can solve problems such as limiting the application of fluorescent materials, and achieve the effect of widening application fields, wide application fields, and low furnace temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The preparation method of the vanadate garnet-type fluorescent material comprises the following steps:

[0039] 1) According to the chemical composition expression A 2-2x K 1+x N x m 2 V 3 o 12 The ratio of each element in the formula is weighed to take ammonium metavanadate NH 4 VO 3 and the nitrates of other metal elements, the total mass is W 1 , add water, and a co-solvent (citric acid), and stir well at 70-80°C to obtain a sol or gel (precursor);

[0040] 2) Put the above precursor into a high-temperature furnace preheated to 400-1000° C. for reaction; the reaction time is 10-120 minutes.

[0041] Specifically, the gel can be reacted at a temperature of 400-700°C for 10-60 minutes to obtain a product, and the sol can be reacted at a temperature of 600-1000°C for 60-120 minutes to obtain a product. Prolonging the reaction time can increase the crystallinity of the product, thereby increasing the luminous intensity.

[0042] 3) After the reaction is complet...

Embodiment 1

[0047] Example 1 Garnet-type fluorescent material Ca 2 KMg 2 V 3 o 12 preparation of

[0048] The preparation method is as follows:

[0049] 1) Take each reaction raw material by the following weight:

[0050] Table 1

[0051]

[0052] 2) Add 1200 grams of citric acid to the raw material of 1), and then add 700 grams of water, and stir thoroughly at a temperature of 75° C. to obtain a sol (precursor).

[0053] 3) Reacting the precursor obtained in 2) at a temperature of 900° C. for 60 minutes to obtain a reaction product.

[0054] 4) The reaction product obtained in 3) is taken out and cooled to room temperature.

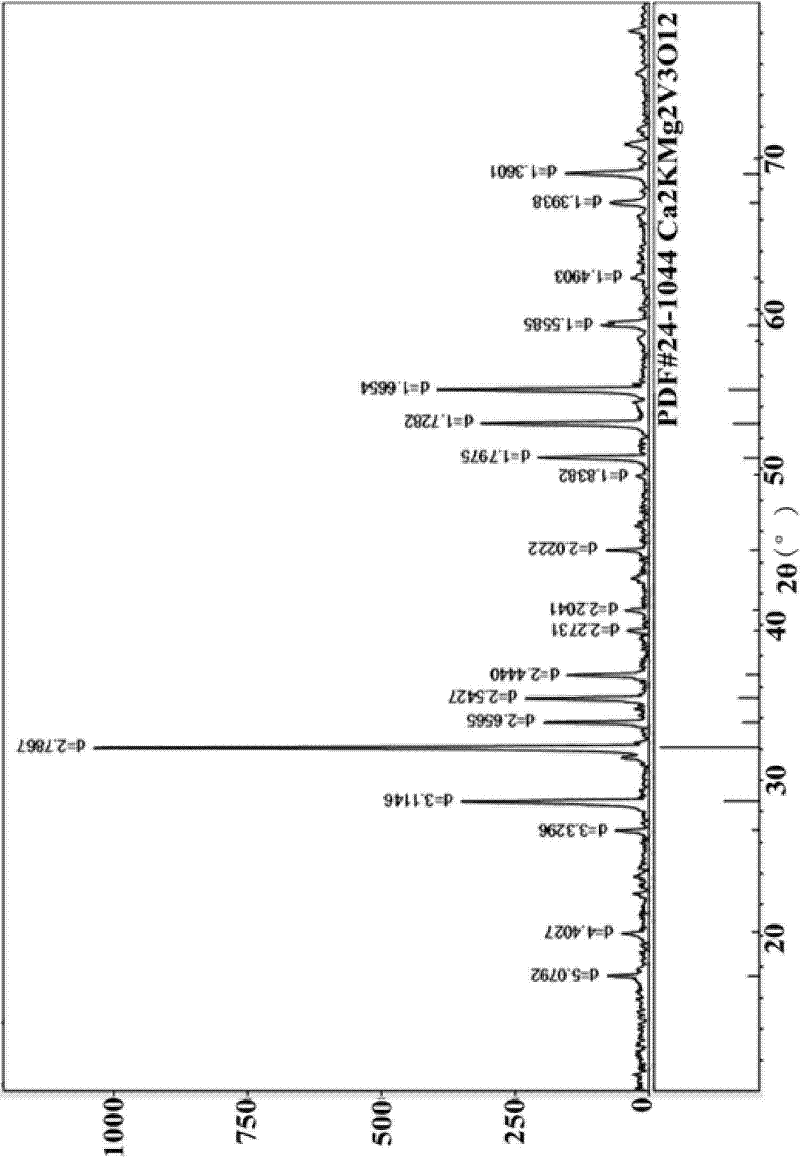

[0055] The XRD pattern and Ca of the obtained sample 2 KMg 2 V 3 o 12For the comparison chart of the standard phase PDF card, see figure 1 , as can be seen from the spectrum, the two are completely consistent, indicating that the phase of the sample in this example is a single phase of Ca 2 KMg 2 V 3 o 12 .

Embodiment 2

[0060] Example 2 Rare earth-doped garnet-type fluorescent material Ca 1.94 K 1.03 Eu 0.03 Mg 2 V 3 o 12 preparation of

[0061] The preparation method is as follows:

[0062] 1) Take each reaction raw material by the following weight:

[0063] Table 2

[0064]

[0065] 2) Add 1200 grams of citric acid to the raw material described in 1), and then add 700 grams of water, and fully stir at a temperature of 75° C. to obtain a sol (precursor).

[0066] 3) Reacting the precursor obtained in 2) at a temperature of 900° C. for 60 minutes to obtain a reaction product.

[0067] 4) The reaction product obtained in 3) is taken out and cooled to room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com