Nitride fluorescent powder material and preparation method thereof

A nitride phosphor and chemical technology, applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of unfavorable batch production, high cost, complicated process, etc., and achieve product cost reduction, high quantum efficiency, and wide process window Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

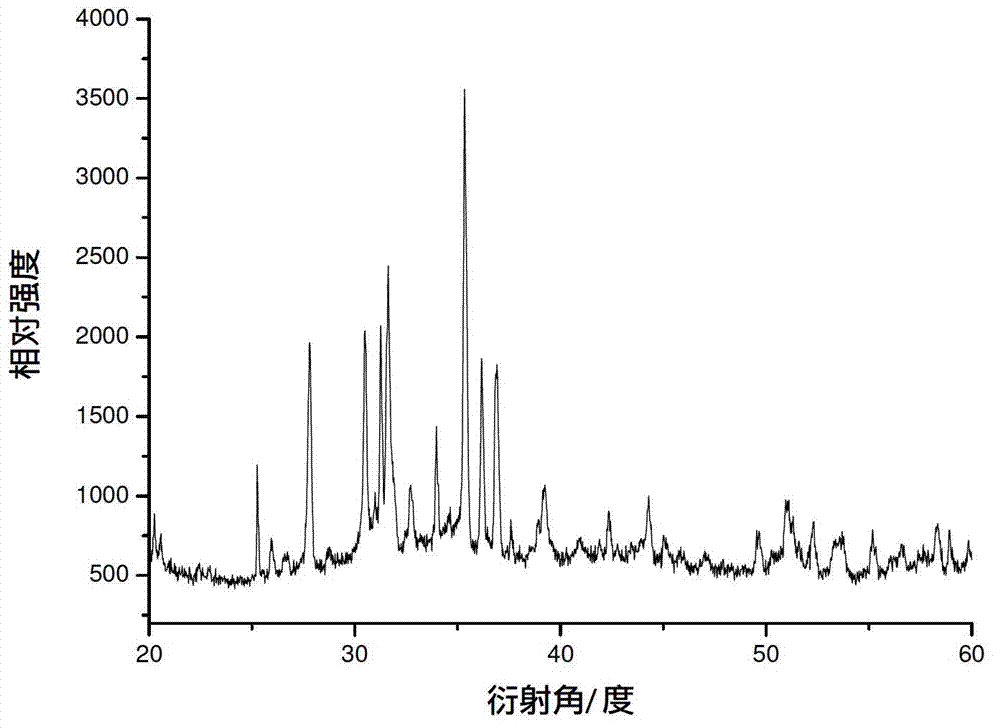

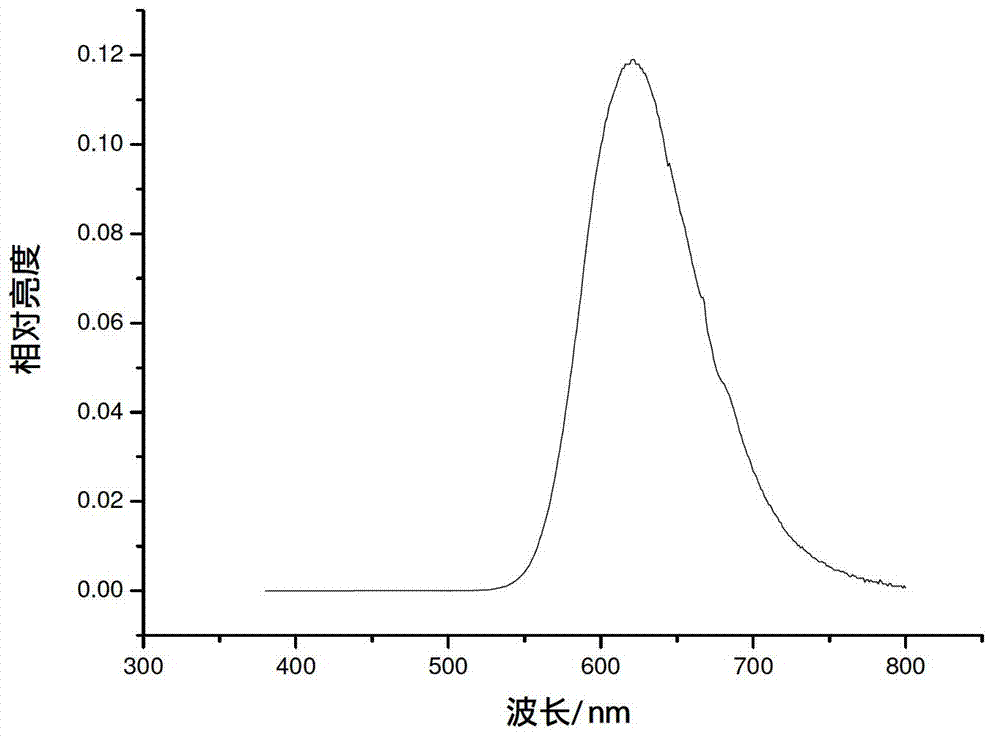

[0026] Sr 1.96 Si 4.5 Al 0.5 N 8 : Preparation of 0.04Eu phosphor.

[0027] Using Sr, Si, Al, Eu as raw materials, the ratio of the amount of the above substances is Sr: Si: Al: Eu=1.96: 4.5: 0.5: 0.04, and the above metals (or non-metals) are put into the arc melting furnace The alloy body is formed by instant arc high temperature in the process, the obtained alloy body is crushed and ball milled to obtain alloy powder, and the alloy powder is placed in a zirconia crucible. 2 Sinter at 1400°C for 10 hours, take it out after natural cooling, wash with deionized water until the pH value of the washing liquid is neutral, and then dry at 120°C for 2 hours to obtain Sr 1.96 Si 4.5 Al 0.5 N 8 : 0.04Eu phosphor.

Embodiment 2

[0029] Sr 1.95 Ca 0.04 Si 4.5 Al 0.5 N 8 : Preparation of 0.01Eu phosphor.

[0030] Using Sr, Ca, Si, Al, Eu as raw materials, the ratio of the amount of the above substances is Sr: Ca: Si: Al: Eu=1.95: 0.04: 4.5: 0.5: 0.01, and the above metal (or non-metal) , Put into the arc melting furnace for instant arc high temperature formation alloy body, the obtained alloy body is crushed and ball milled to obtain the alloy powder, the alloy powder is put into the zirconia crucible, the N 2 Sinter at 1500℃ for 8 hours, take it out by natural cooling, wash with deionized water, the pH value of the washing solution is neutral, and dry at 120℃ for 2 hours to obtain Sr 1.95 Ca 0.04 Si 4.5 Al 0.5 N 8 : 0.01Eu phosphor.

Embodiment 3

[0032] Sr 1.5 Ba 0.2 Si 5 N 8 : Preparation of 0.3Eu phosphor.

[0033] Using Sr, Ba, Si, Eu as raw materials, the ratio of the amount of the above substances is Sr: Ba: Si: Eu=1.5: 0.2: 5: 0.3, and the above metals (or non-metals) are put into the arc melting furnace The alloy body is formed by instant arc high temperature in the process, the obtained alloy body is crushed and ball milled to obtain alloy powder, and the alloy powder is placed in a zirconia crucible. 2 Sinter at 1800°C for 8 hours, take it out by natural cooling, wash with deionized water, the pH value of the washing solution is neutral, and dry at 120°C for 2 hours to obtain Sr 1.5 Ba 0.2 Si 5 N 8 : 0.3Eu phosphor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com