Patents

Literature

140results about How to "Large margin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

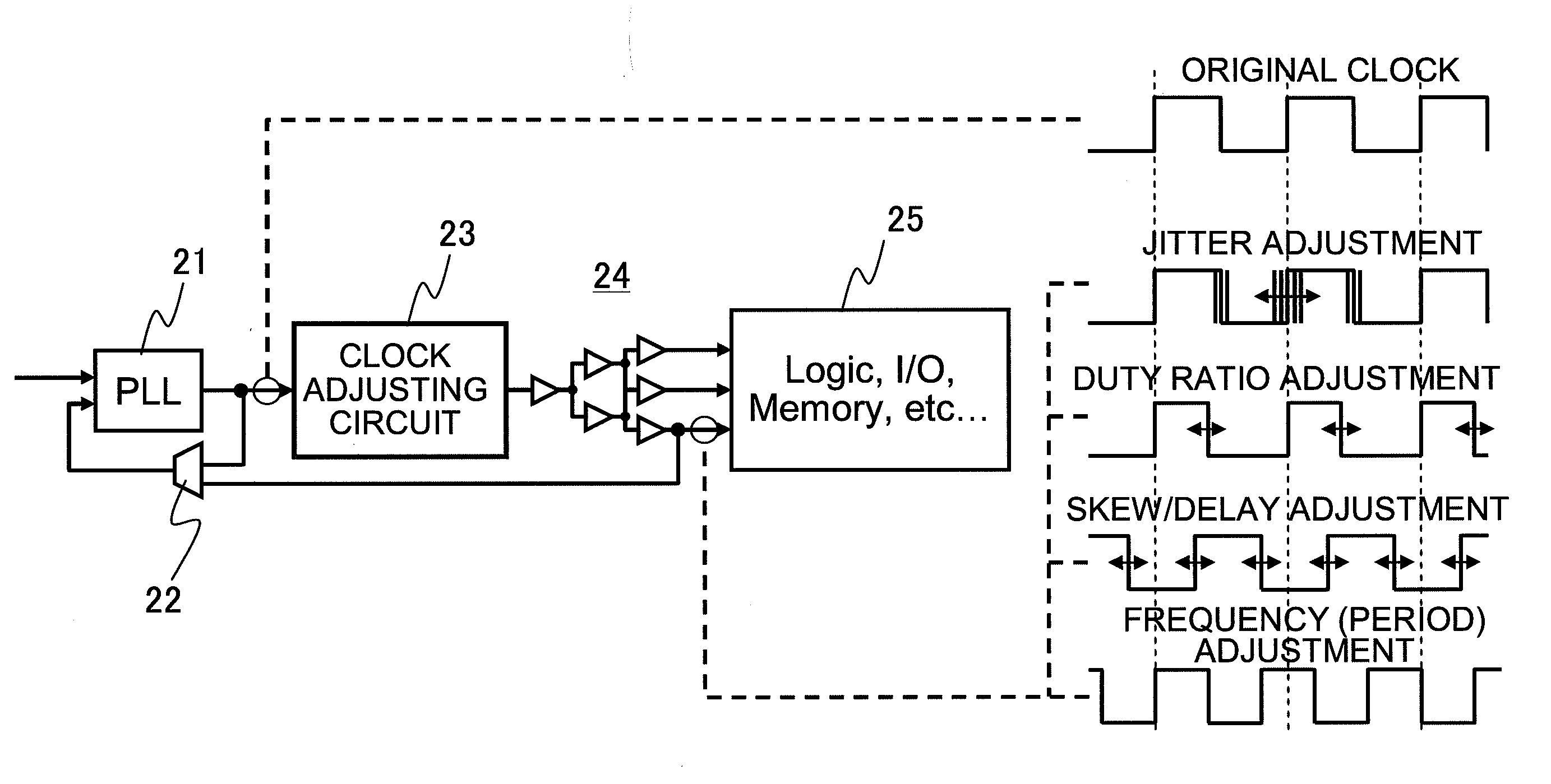

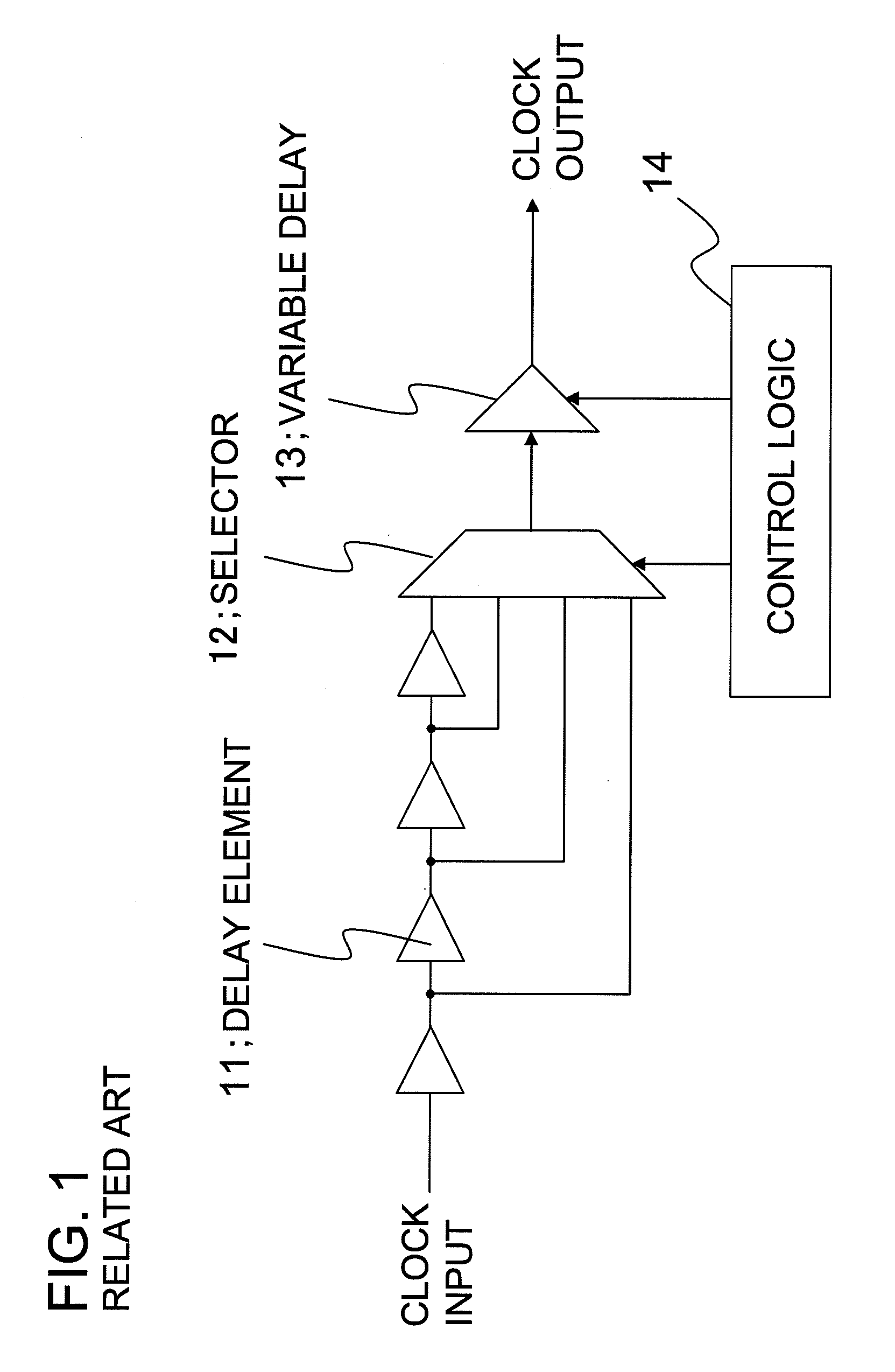

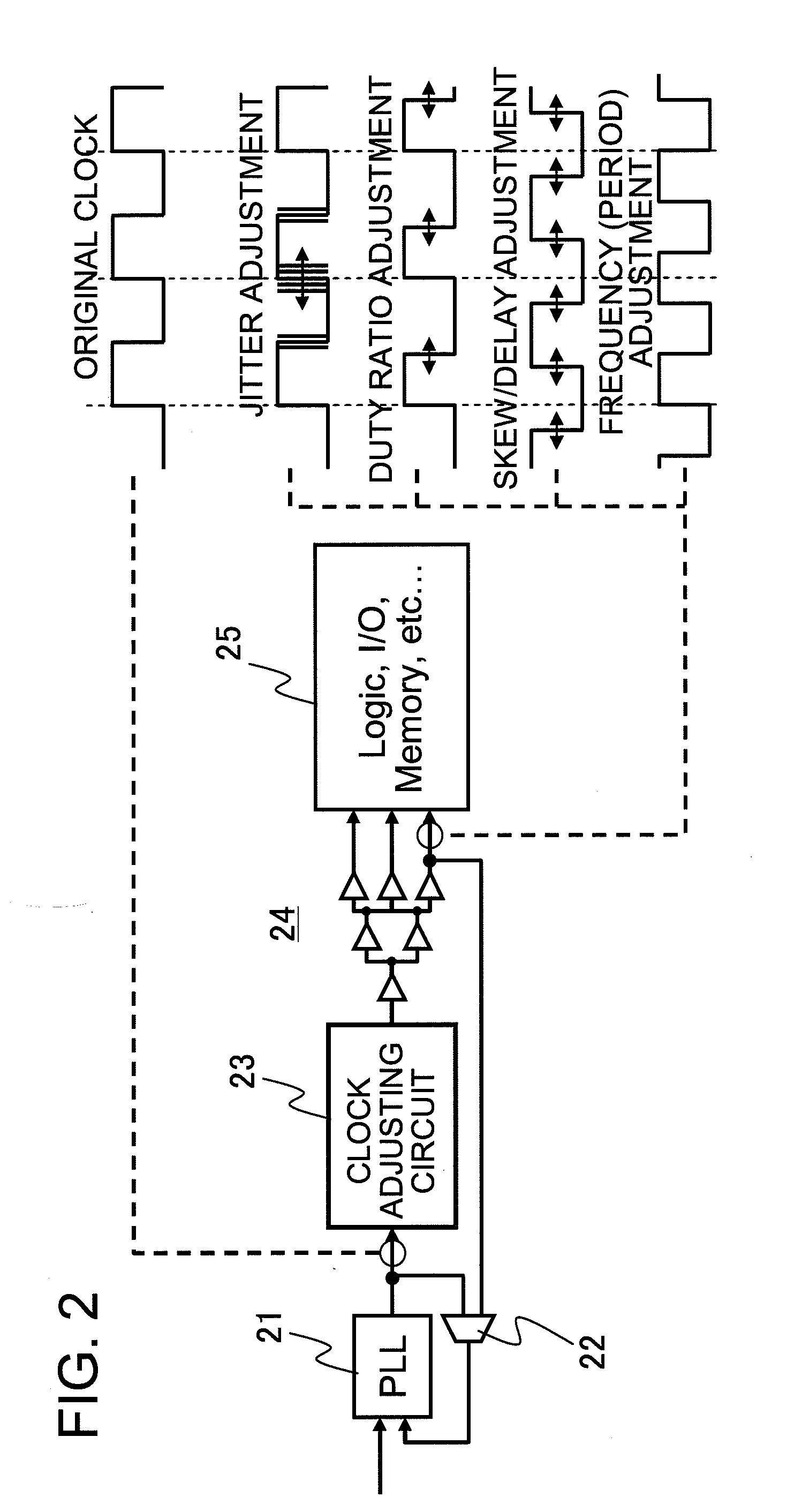

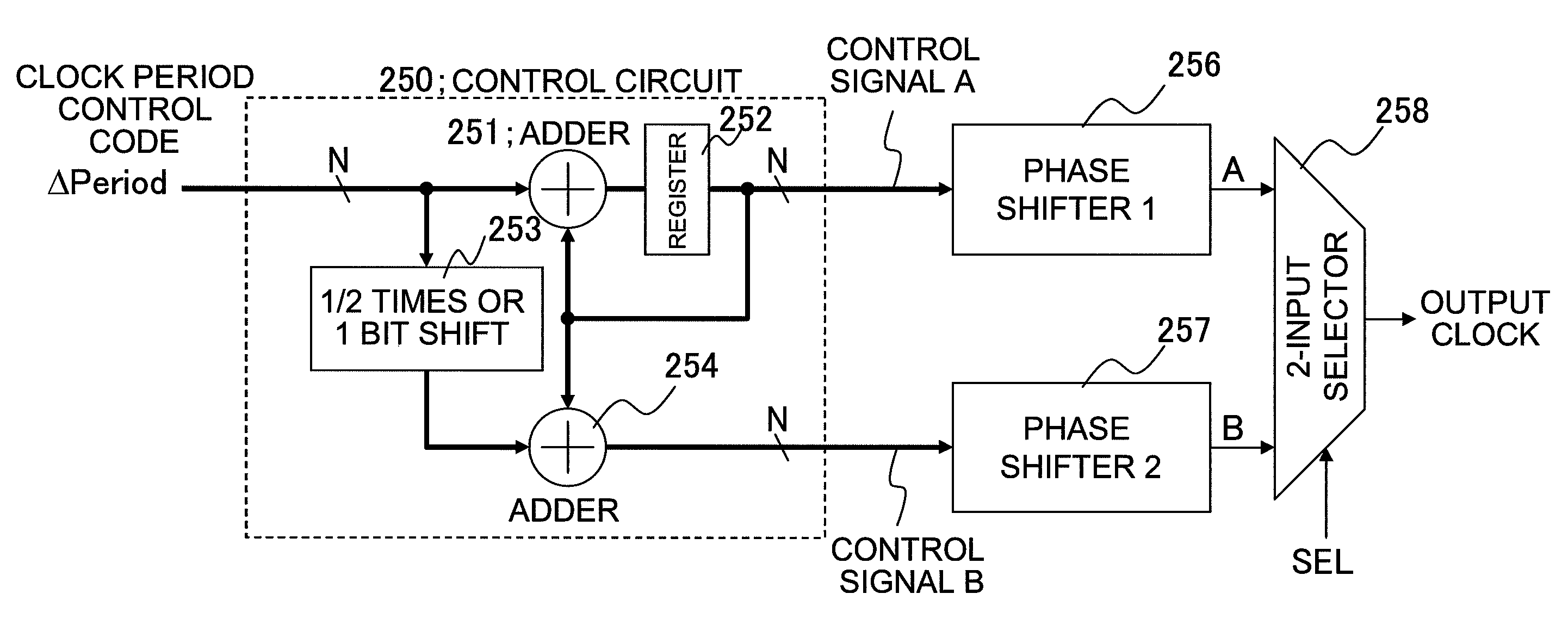

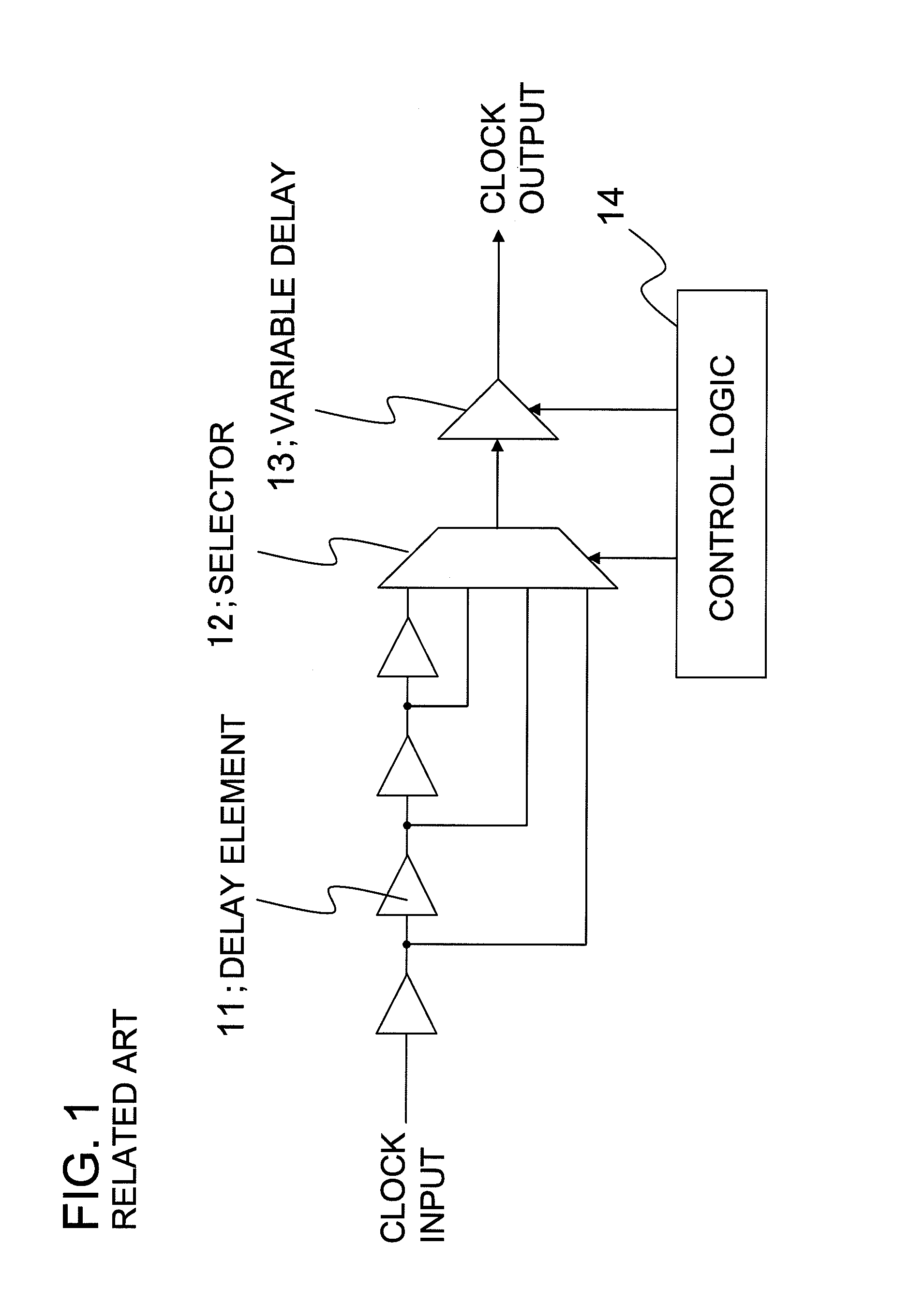

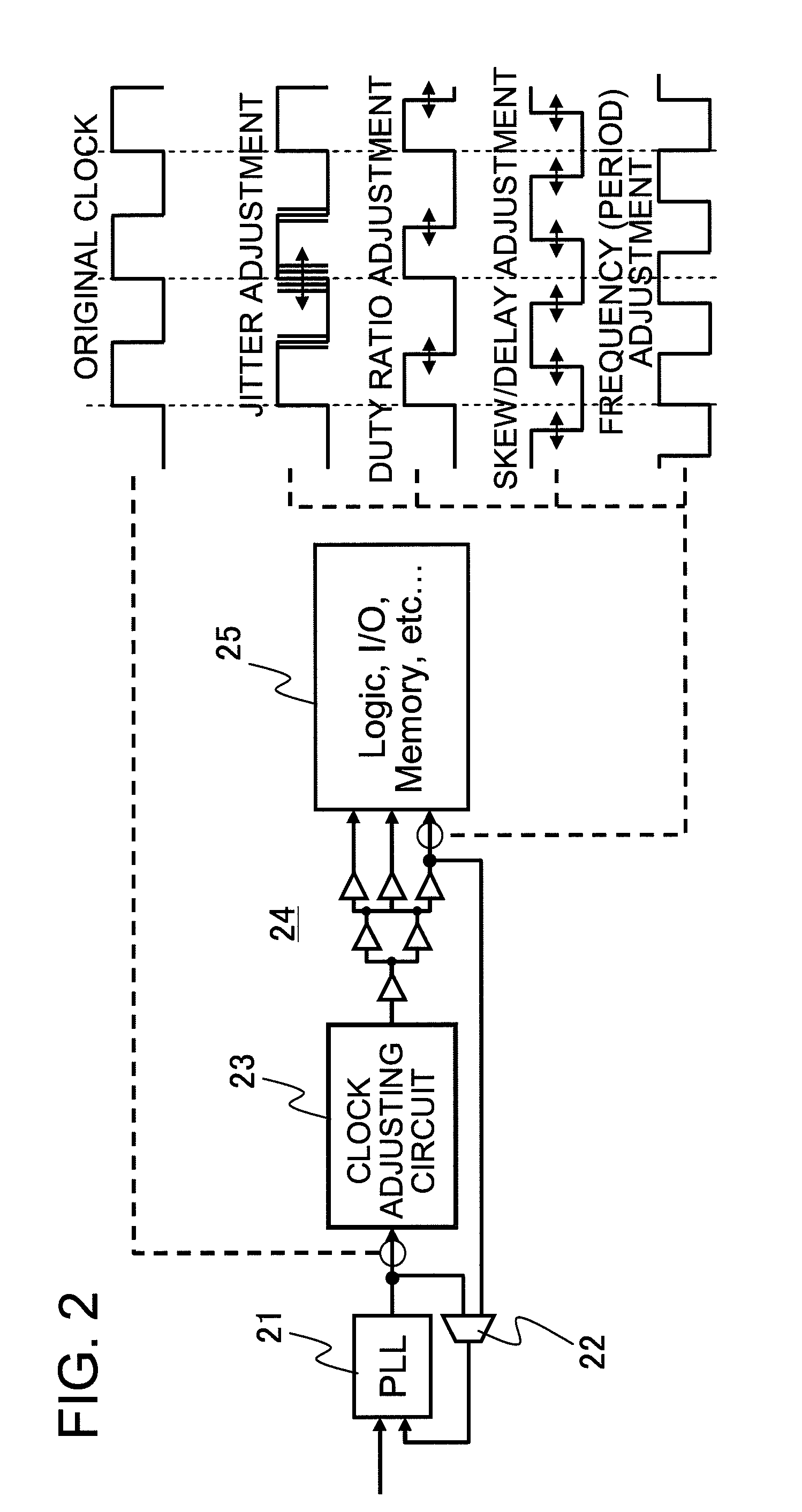

Clock adjusting circuit and semiconductor integrated circuit device

InactiveUS20100039157A1Improve reliabilityLarge marginPulse automatic controlSingle output arrangementsControl signalControl circuit

Disclosed is a clock adjusting circuit comprising a phase shifter that receives a clock signal and variably shifts, based on a control signal, respective timing phases of a rising edge and a falling edge of the clock signal; and a control circuit that supplies the control signal to the phase shifter circuit before each edge is output; wherein the clock signal, in which at least one of a period, a duty ratio, jitter and skew / delay of the input clock signal is changed over an arbitrary number of clock cycles, is output.

Owner:NEC CORP

Clock adjusting circuit and semiconductor integrated circuit device

InactiveUS8072253B2Improve reliabilityLarge marginPulse automatic controlSingle output arrangementsControl signalControl circuit

Owner:NEC CORP

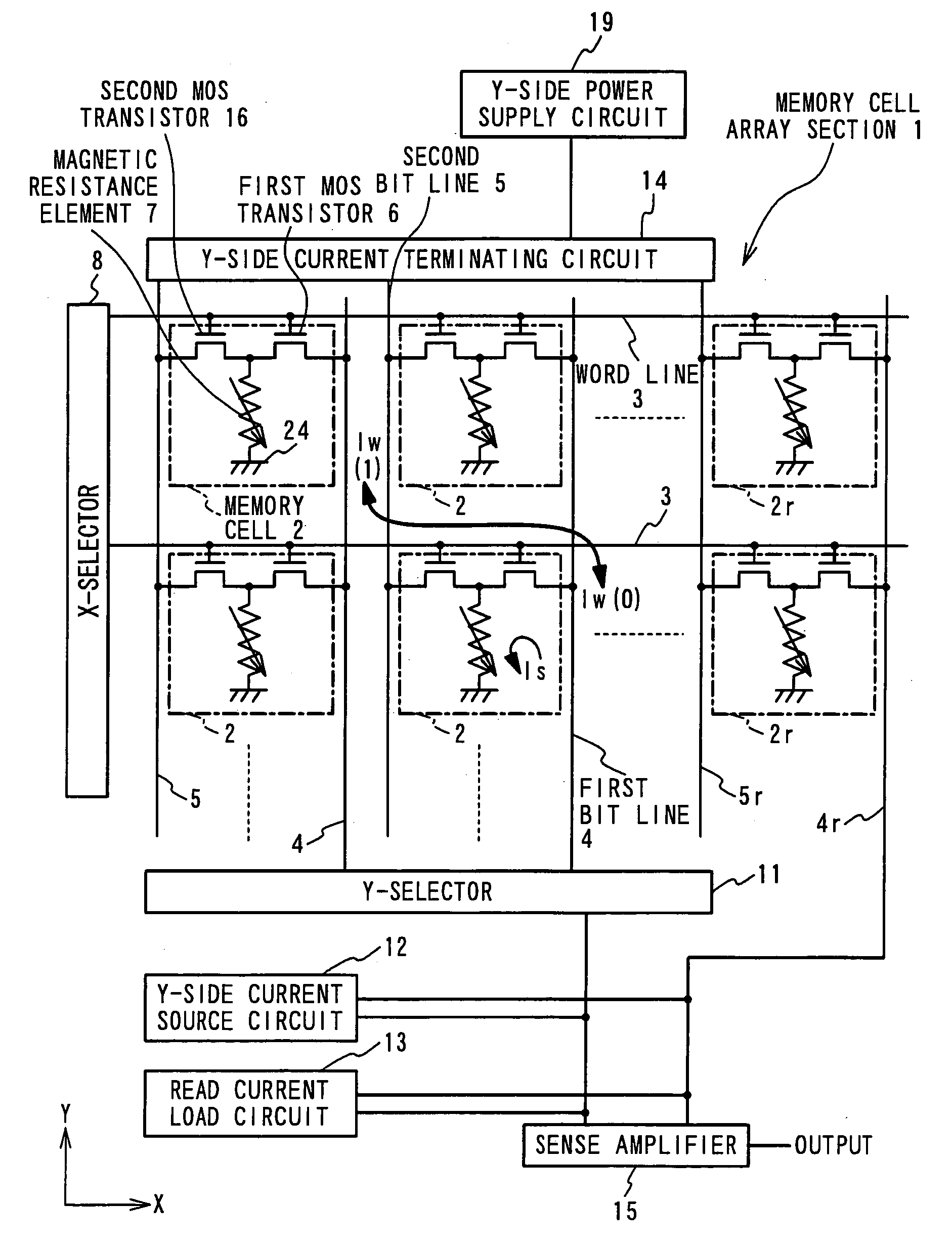

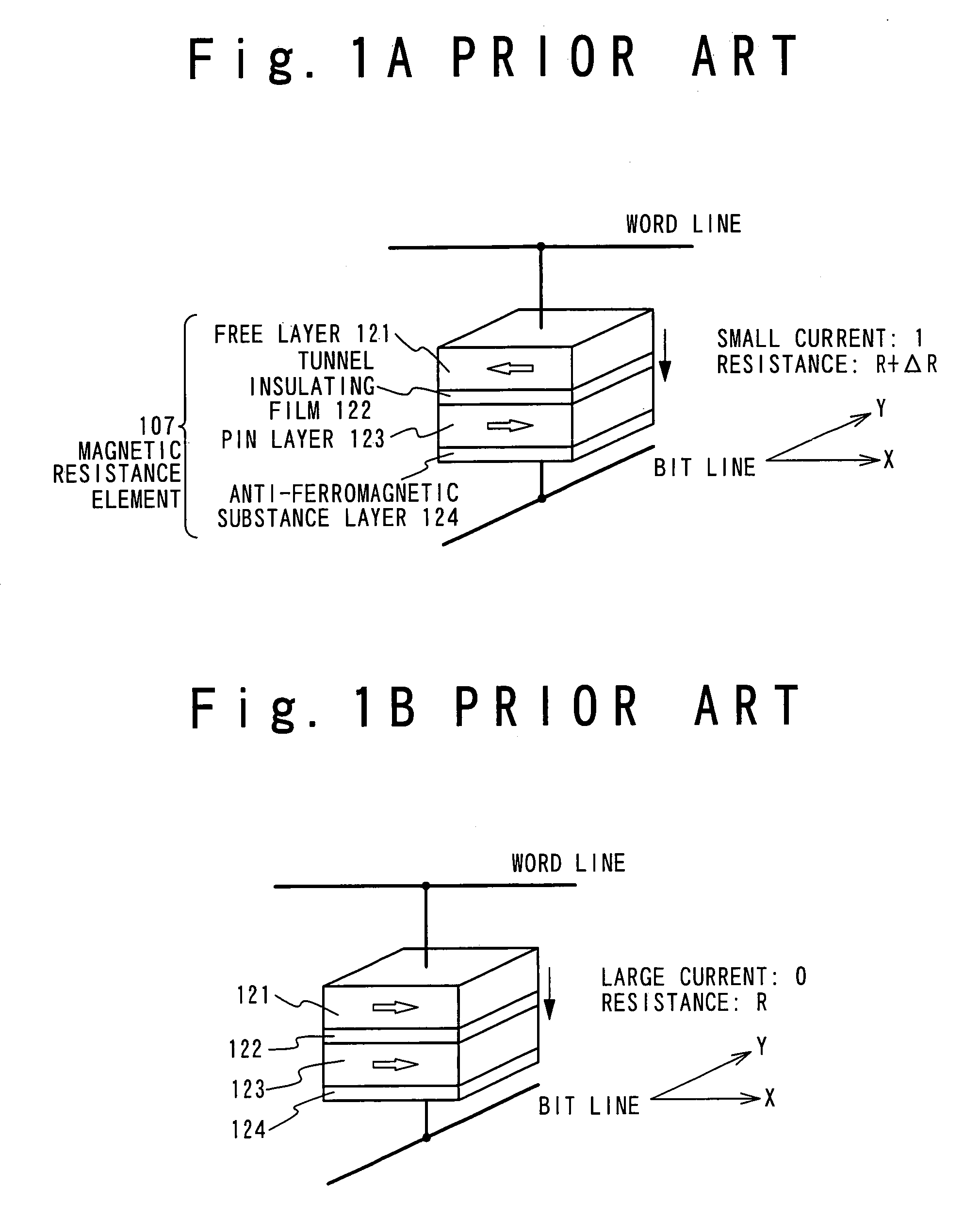

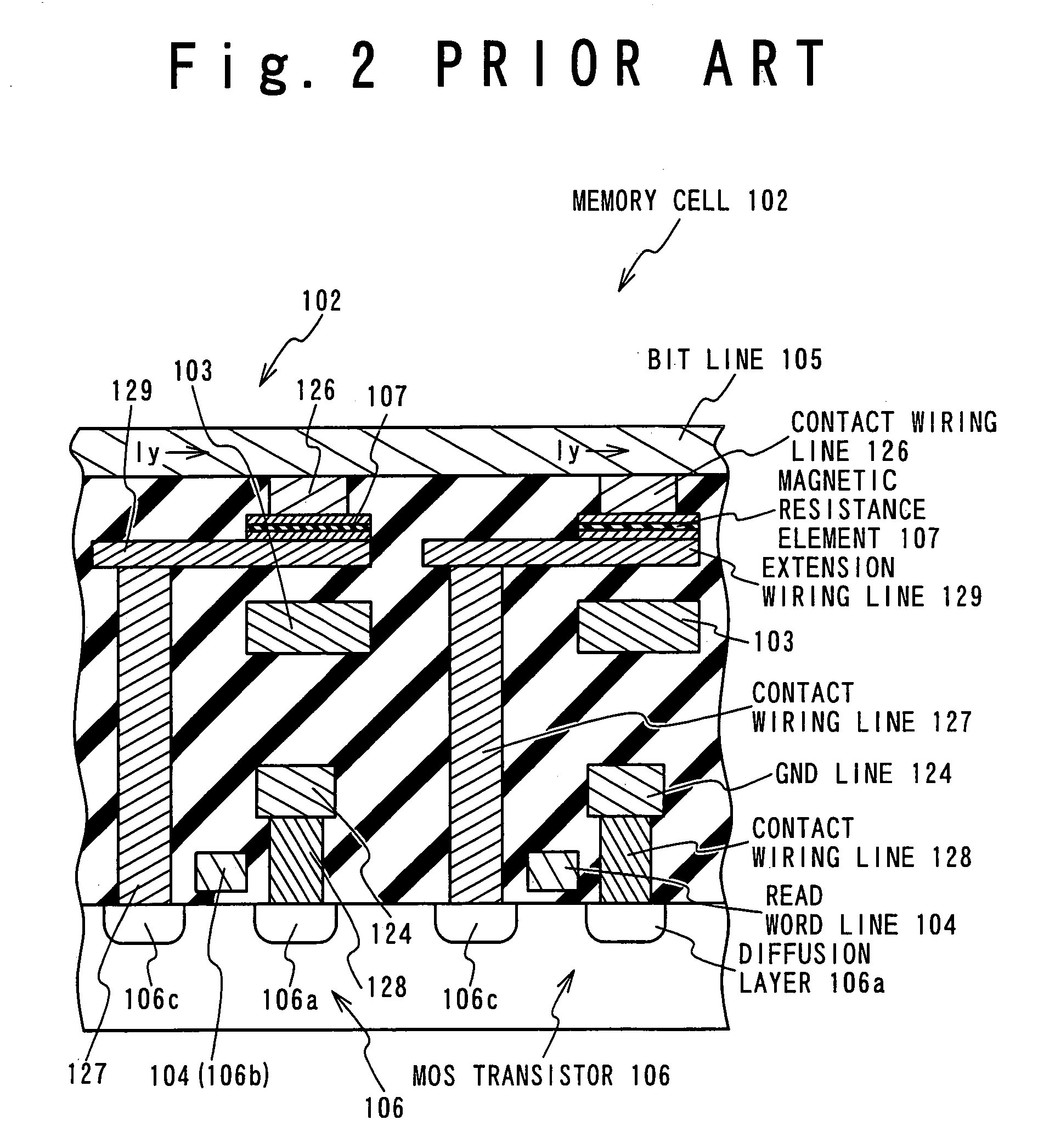

Magnetic memory cell and magnetic random access memory using the same

In a magnetic random access memory, a memory cell includes a magnetic field generating section having an extension wiring line, and connected with a first selected bit line, a conductive pattern, and a magnetic resistance element having a spontaneous magnetization, storing a data and connected between the extension wiring line and the conductive pattern. In a data write operation into the memory cell, a write data is written in the magnetic resistance element of the memory cell by a write electric current which flows through the extension wiring line of the magnetic field generating section of the memory cell, and a value of the write data is determined based on a direction of the write electric current. In a data read operation from the memory cell, a read electric current flows through the extension wiring line of the magnetic field generating section and the magnetic resistance element in the memory cell. A memory cell array section includes the memory cells arranged in a matrix, and each memory cell is connected with a first word line and a first bit line at least, the gate section.

Owner:NEC CORP

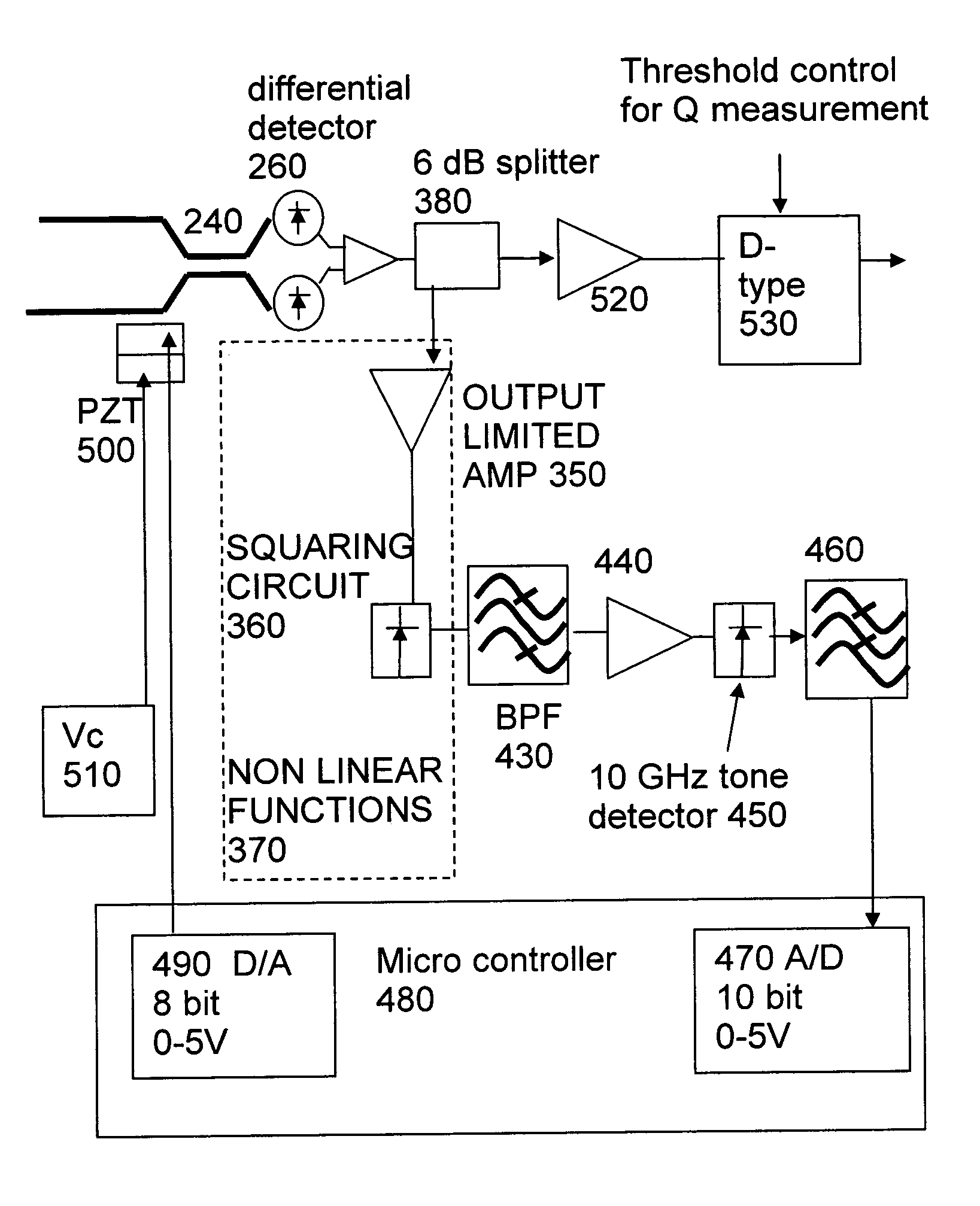

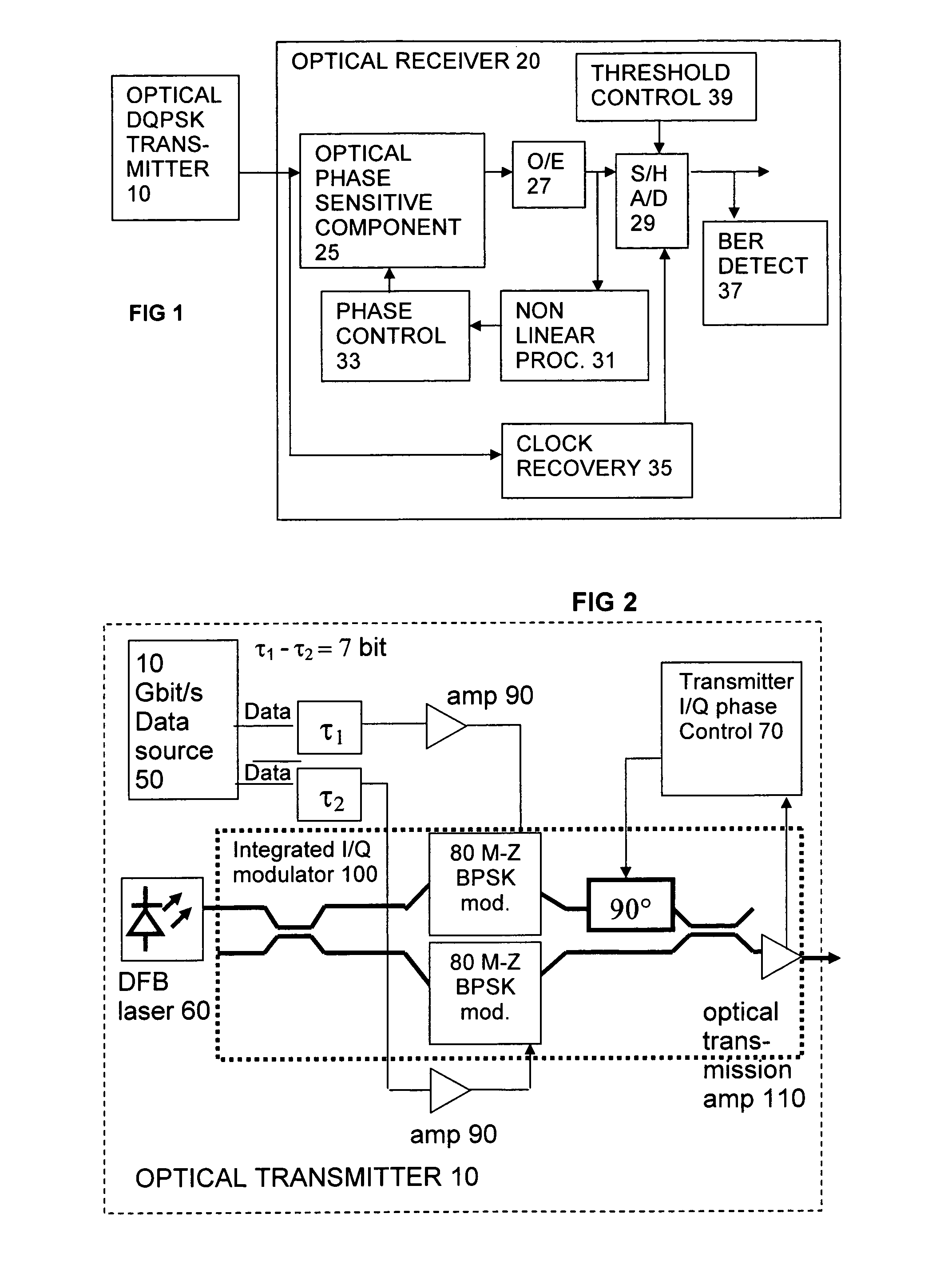

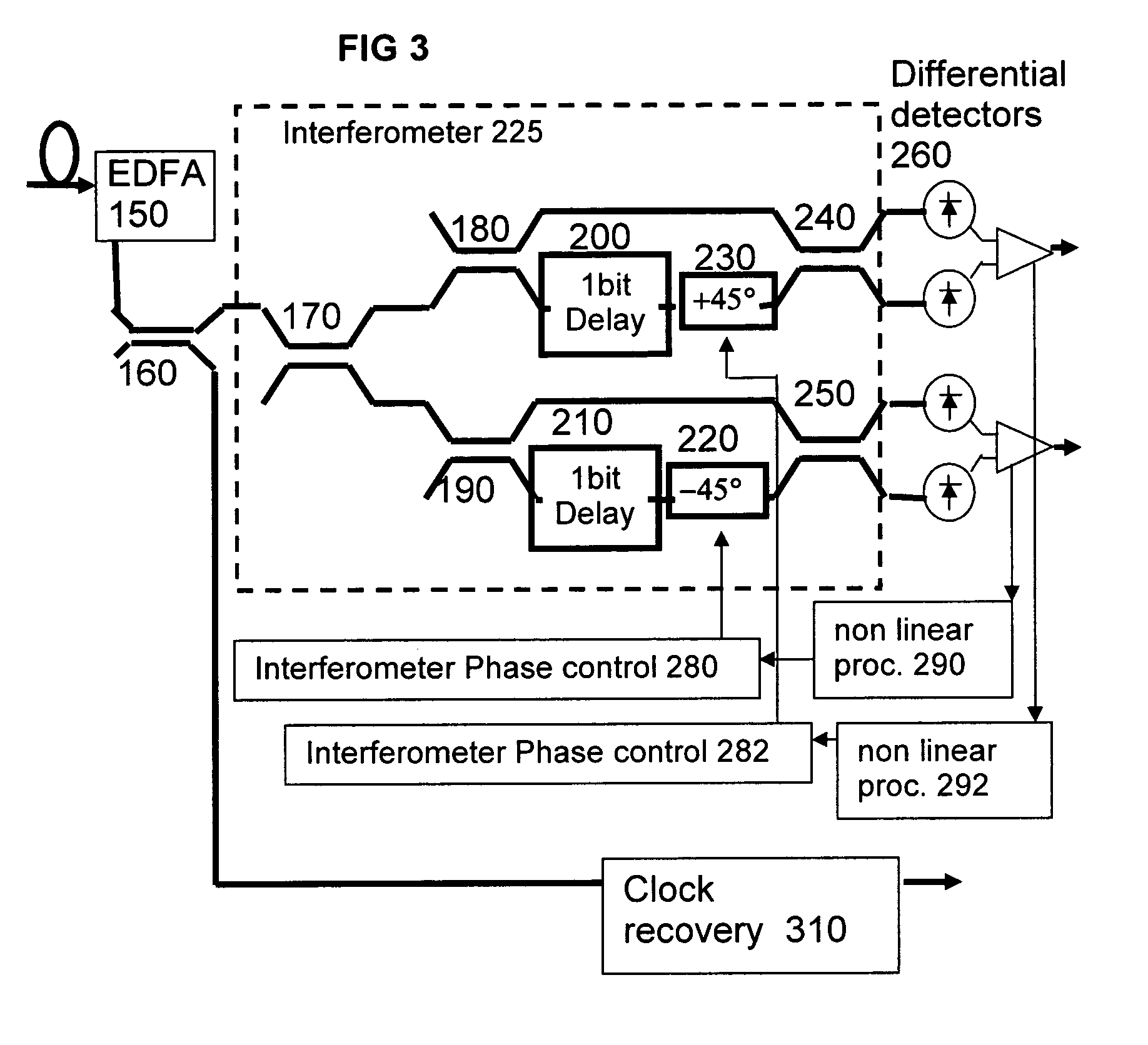

DQPSK receiver phase control

ActiveUS7389055B1Effective and reliable controlOptimal Rate of ChangeOptical multiplexElectromagnetic receiversPhase responseDifferential phase

An optical receiver for receiving an optical differential phase shift keyed signal has an optical component sensitive to the optical phase of the signal, such as an interferometer, a device arranged to generate a control signal by non linear limiting of an output of the optical component, such as an RF amplifier arranged to operate in a region near saturation point, and a phase controller for tuning a phase response of the optical component to the received signal according to the control signal.

Owner:CIENA

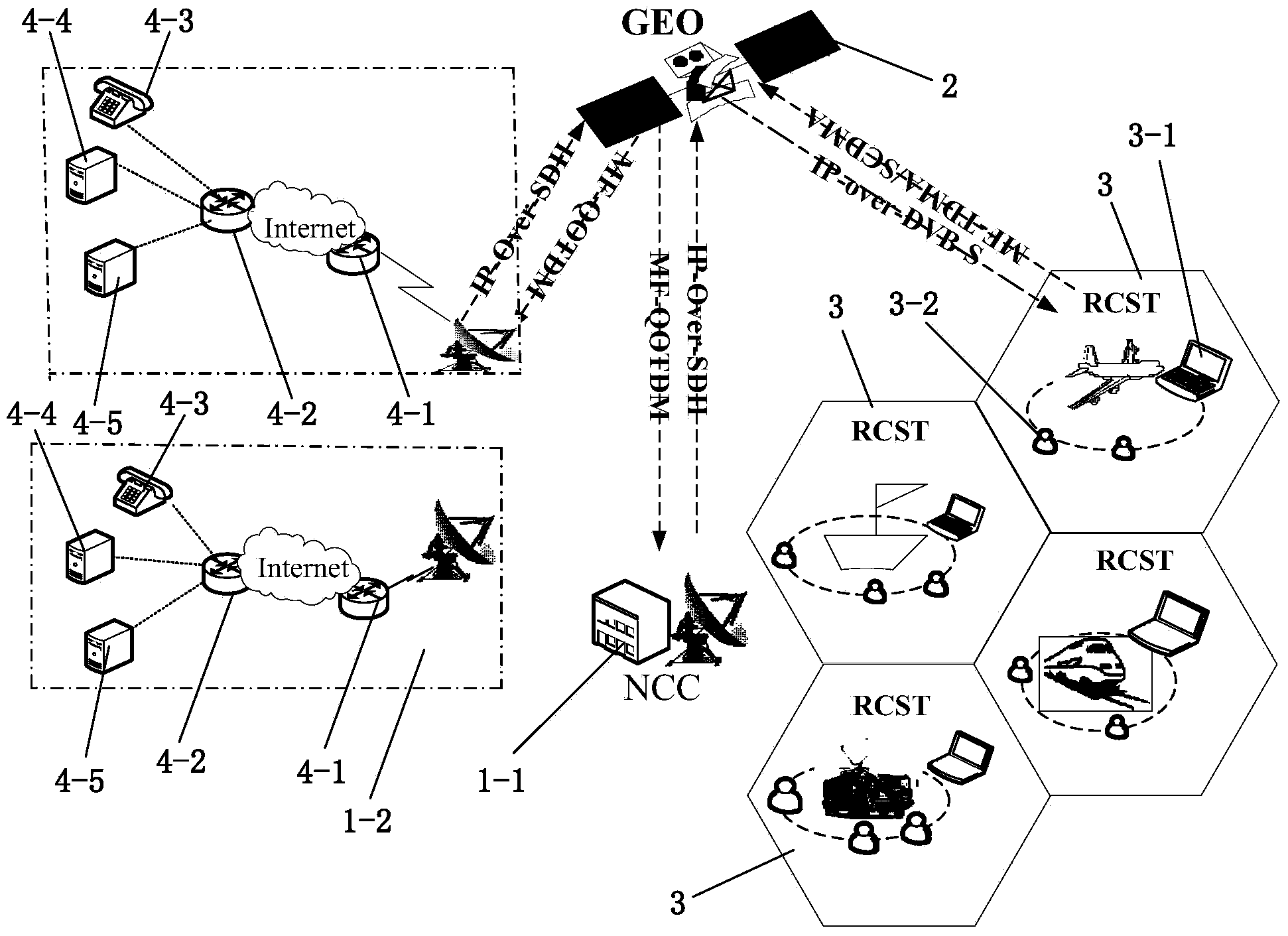

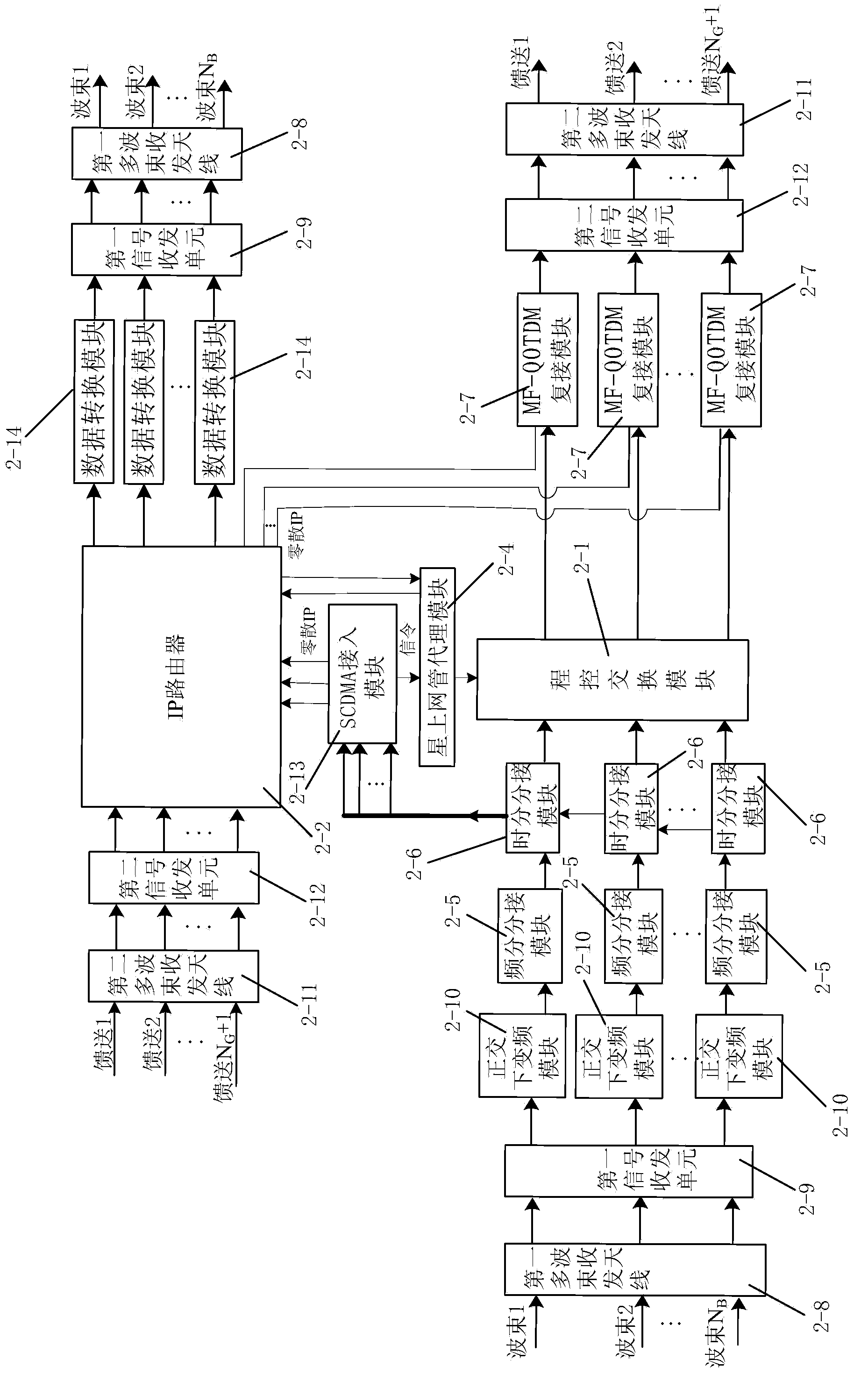

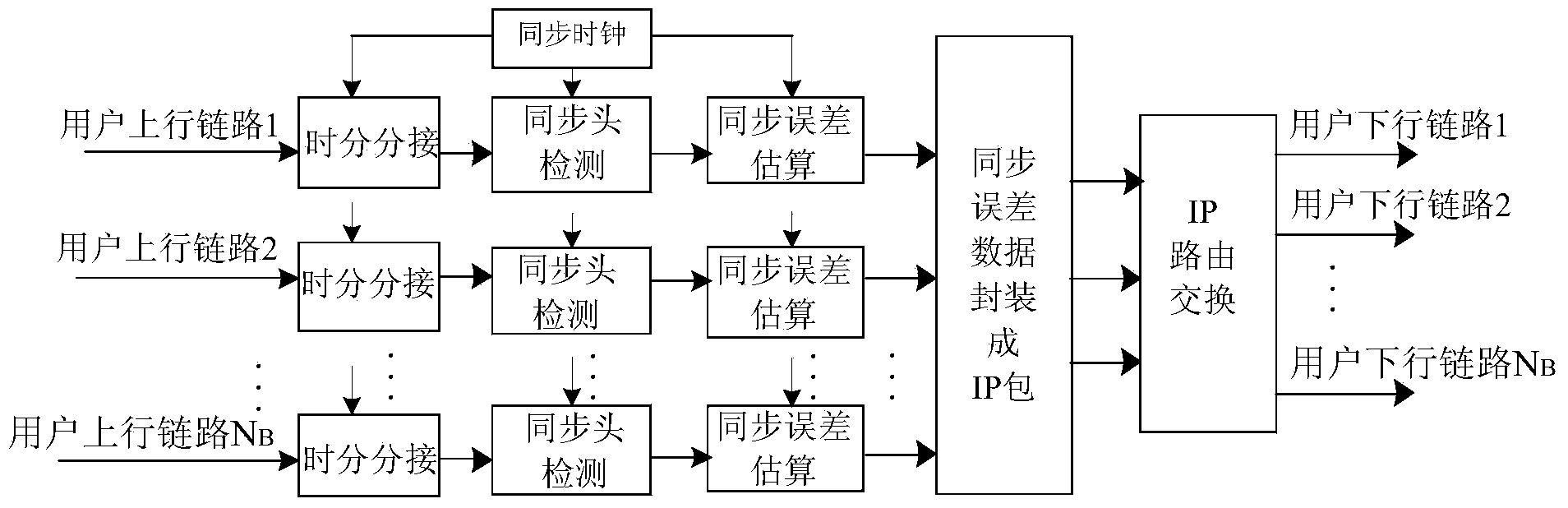

Broadband mobile communication method and system based on multi-beam GEO satellite

ActiveCN103929232ASimple structureReasonable designActive radio relay systemsCommunications systemBroadband

The invention discloses a broadband mobile communication method based on a multi-beam GEO satellite. The broadband mobile communication method based on the multi-beam GEO satellite mainly comprises the steps that spot beams at the Ka frequency band are adopted by NG+1 bidirectional feed links between a satellite-borne device and a ground station device, so that space division multiplexing is achieved for NG+1 times; a cellular network with NB cells is formed through NB bidirectional user links between the satellite-borne device and NT mobile user terminals based on an NB-beam satellite antenna, and space division multiplexing is achieved for NB / 4 times with every four cells as a group, so that a 260 MHz bandwidth resource can be shared. The invention further discloses a broadband mobile communication system based on the multi-beam GEO satellite. According to the broadband mobile communication method and system based on the multi-beam GEO satellite, any one of the NT mobile user terminals can serve as an independent multimedia communication terminal as well as a local area network connected with a public Internet and can have access to a remote URL through the satellite links of the system, and an Internet service on the level similar to the 4G mobile communication level can be provided for a large number of people on various vehicles.

Owner:XIDIAN UNIV

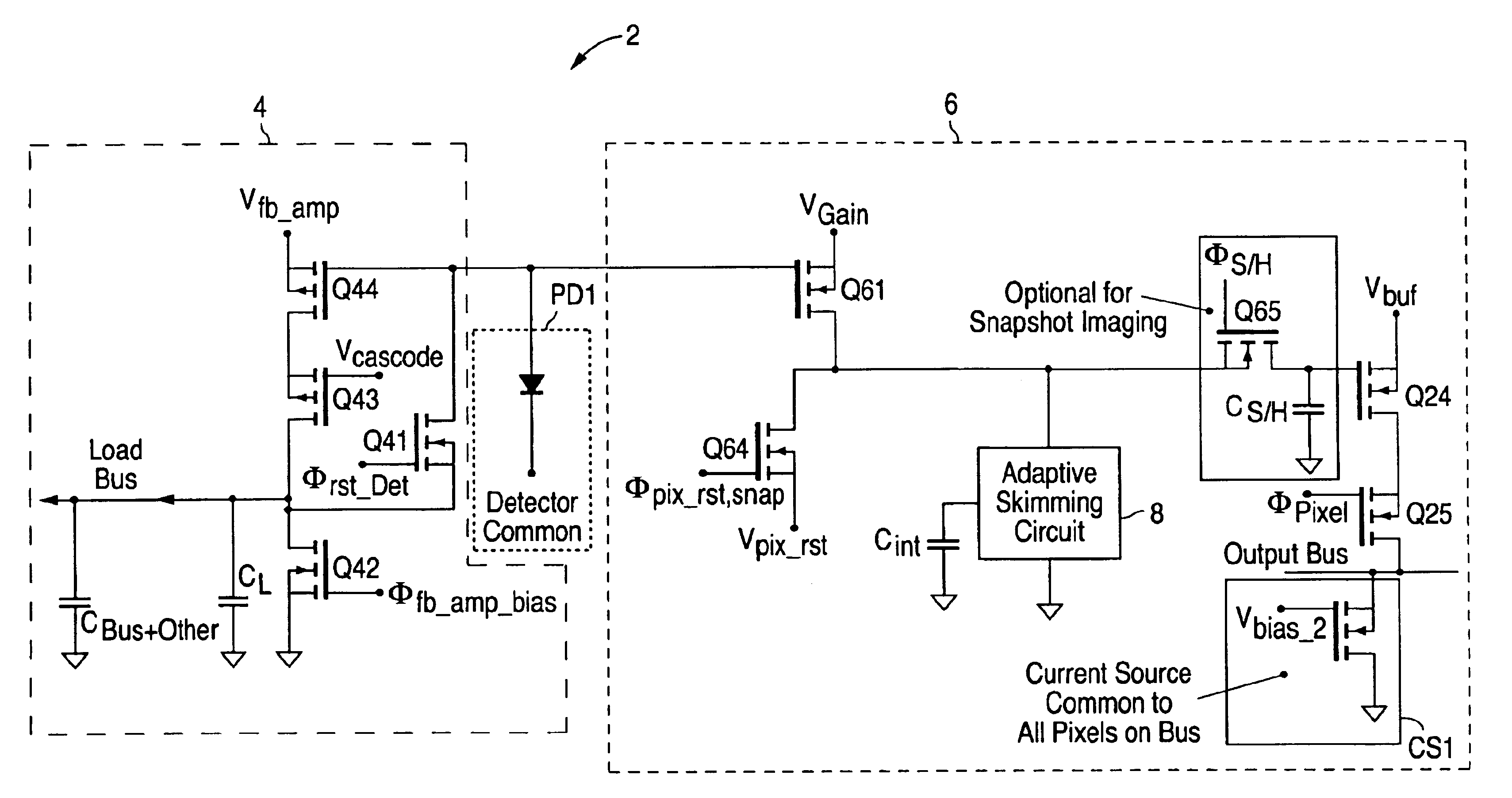

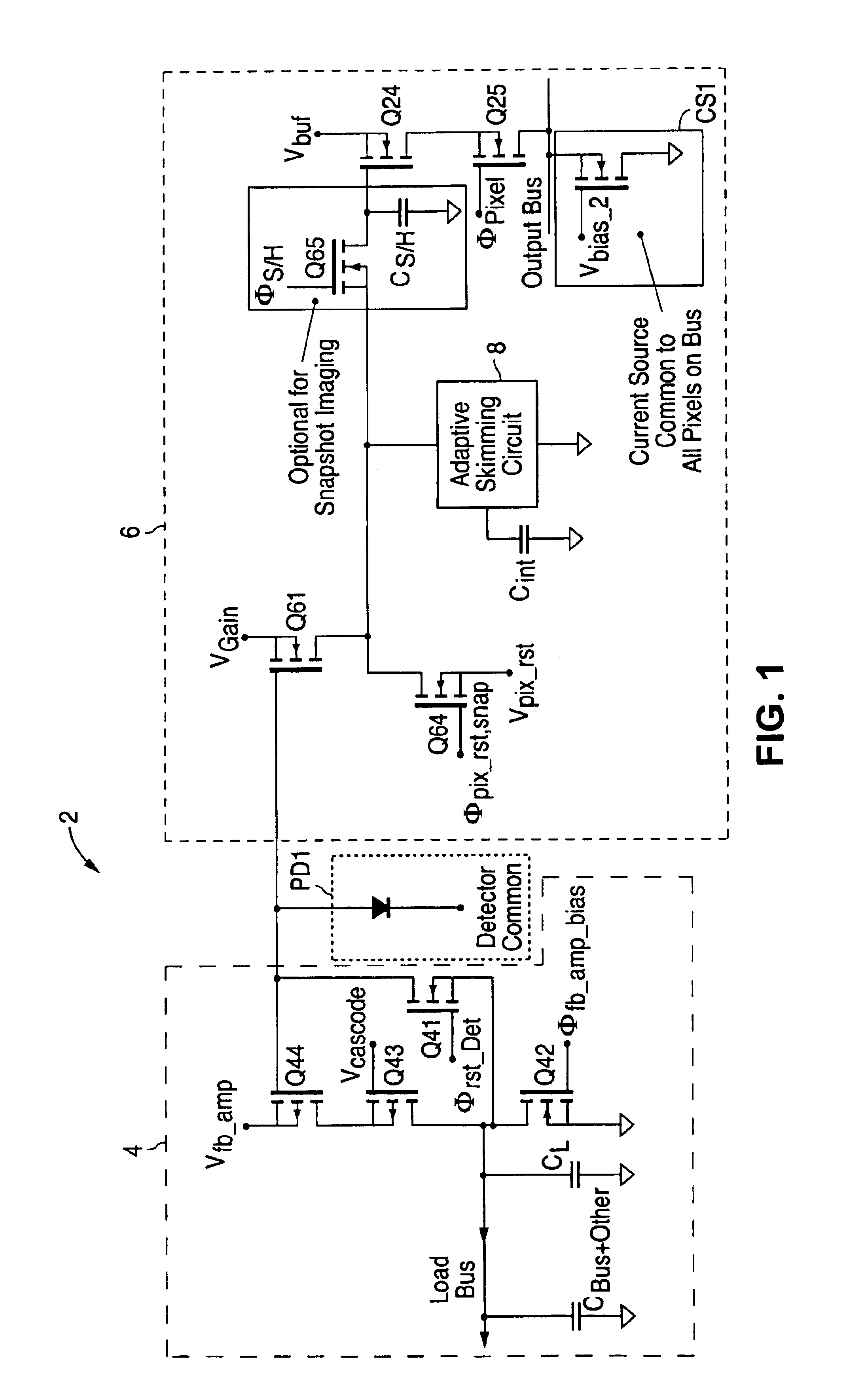

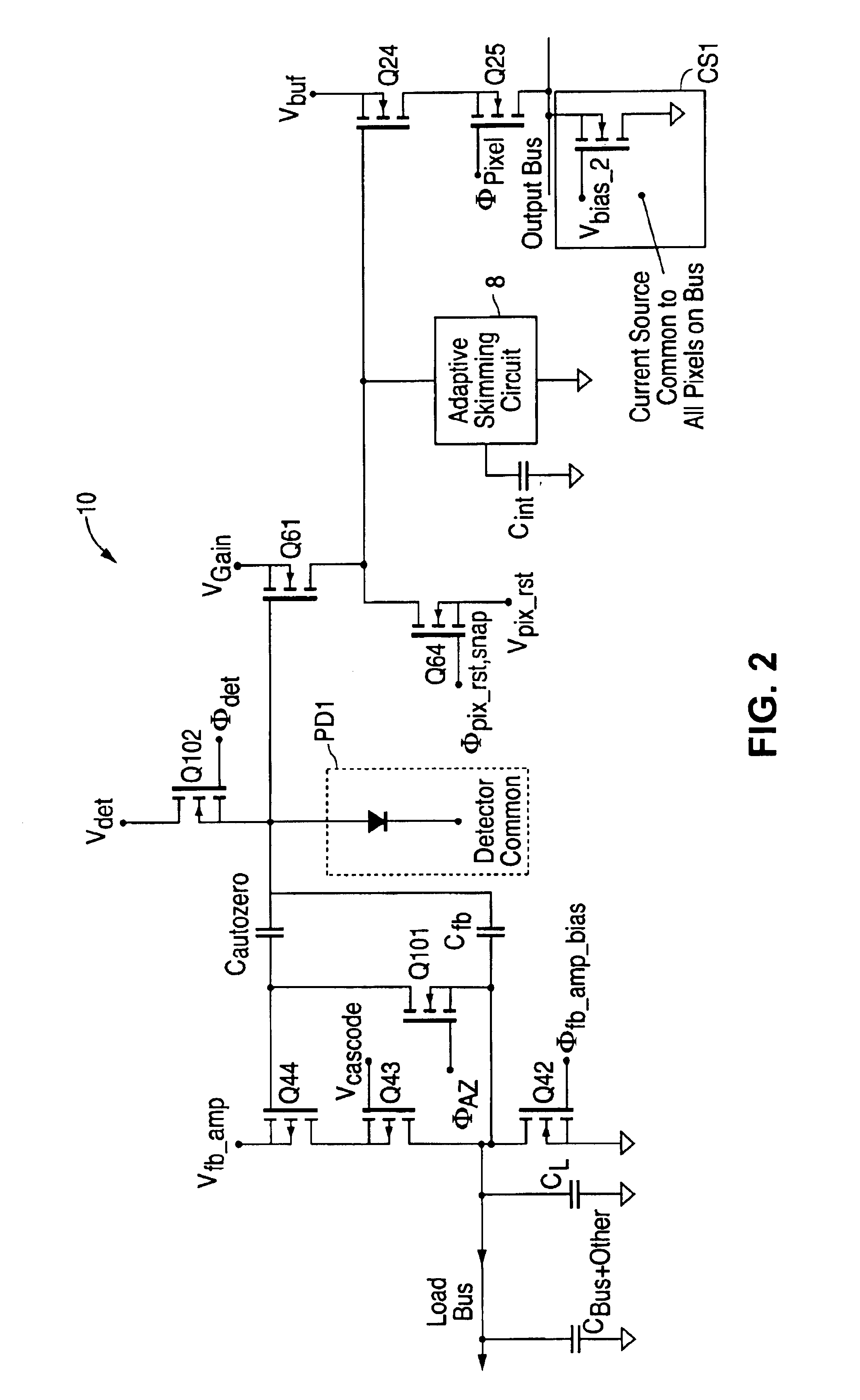

High gain detector amplifier with enhanced dynamic range for single photon read-out of photodetectors

InactiveUS6900839B1Facilitate single-photon read-outUltra-low noiseTelevision system detailsTelevision system scanning detailsLow noiseAudio power amplifier

An ultra-low noise, high gain interface pixel amplifier is provided with capability for single-photon readout of standard photodetectors at high electrical bandwidths for diverse spectral bandpass from the x-ray to long IR bands. The detector charge modulates a source follower whose output is double sampled to remove correlated noise by a compact stage that also provides optimum level shift for subsequent amplification of the full signal excursion. The level-shifted signal finally drives a compact amplifier that generates a robust end-to-end transimpedance. Single-photon readout of photodetectors at high electrical bandwidths in small pixel areas is thereby facilitated.

Owner:SAMSUNG ELECTRONICS CO LTD

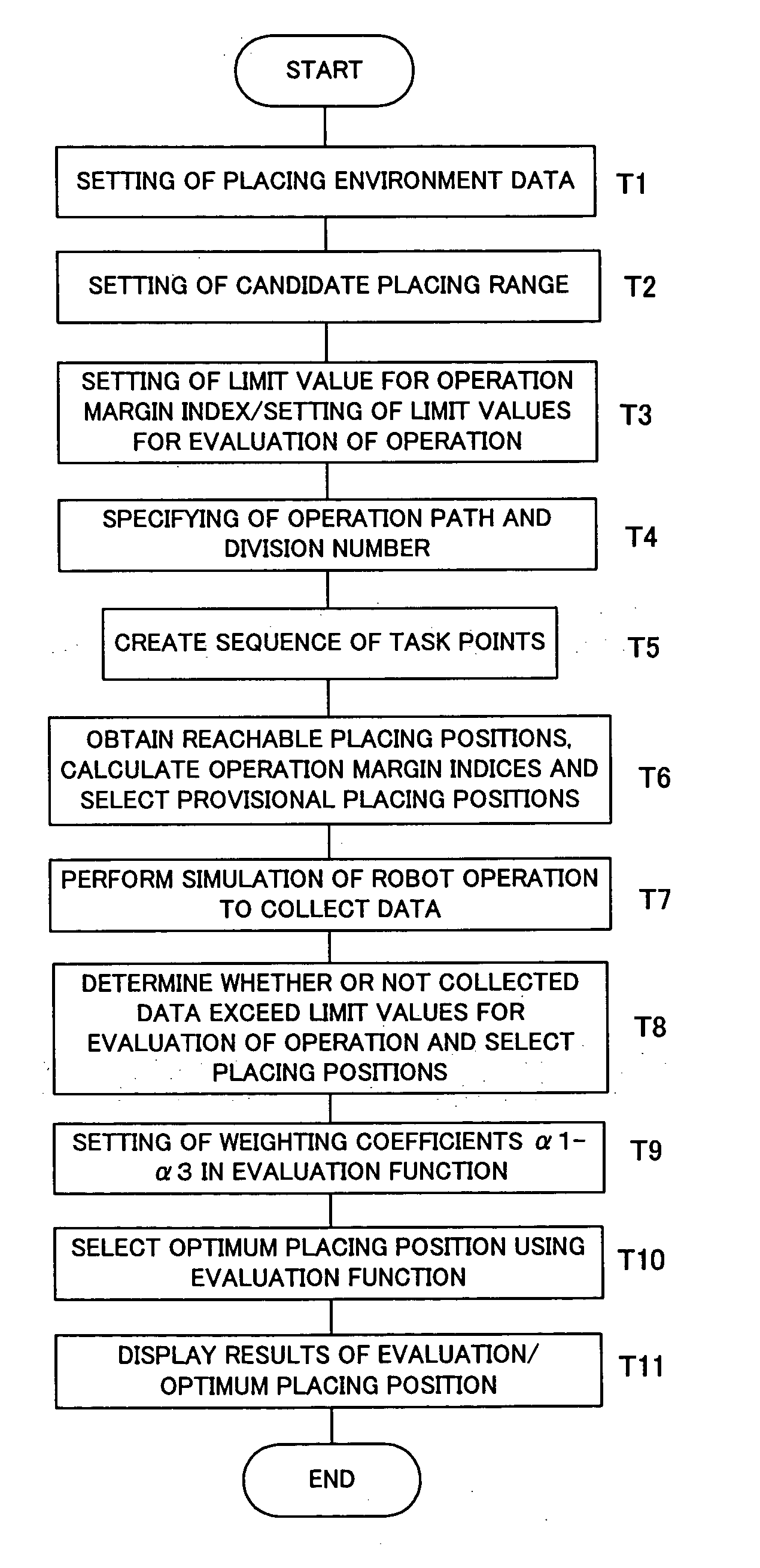

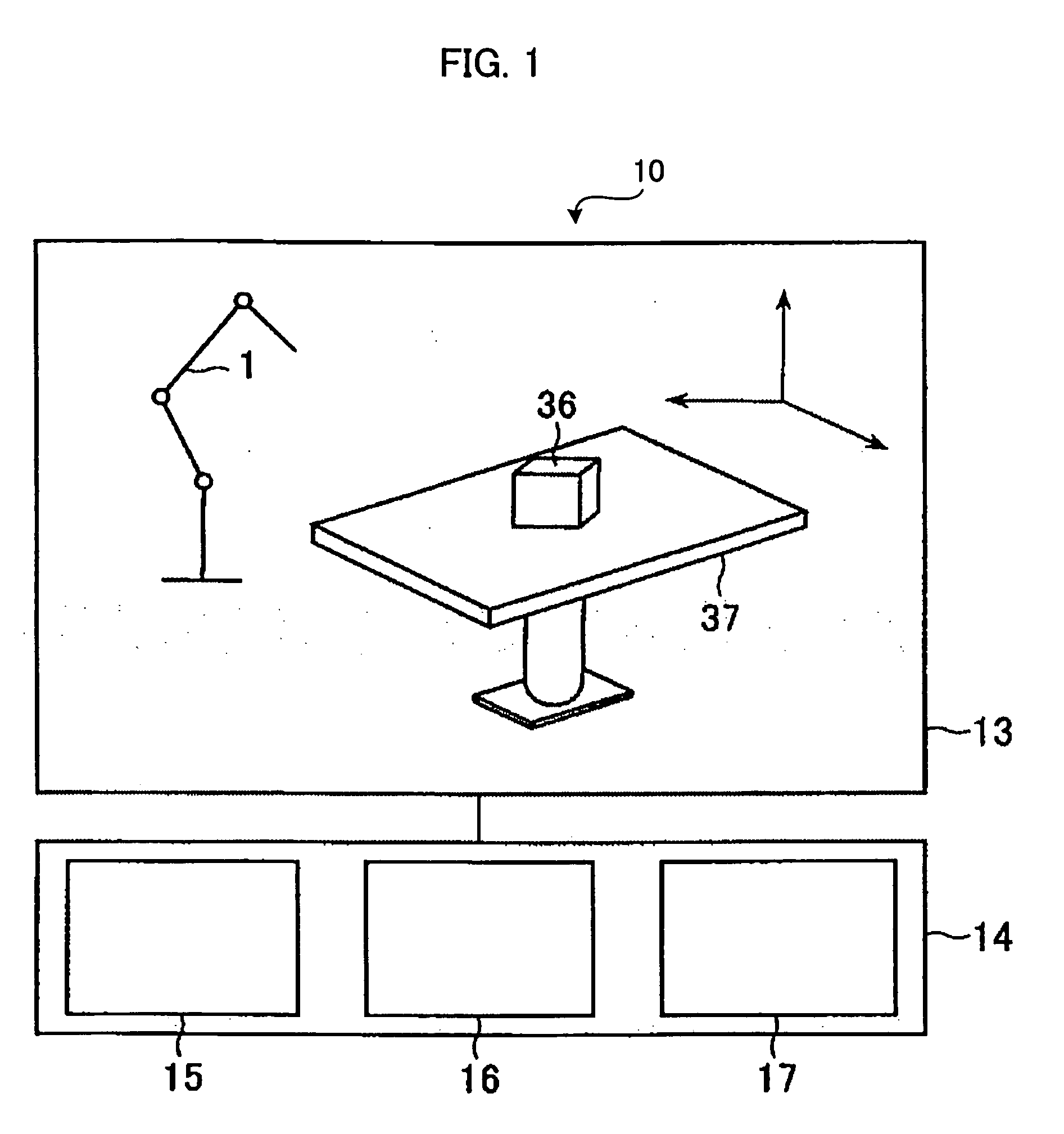

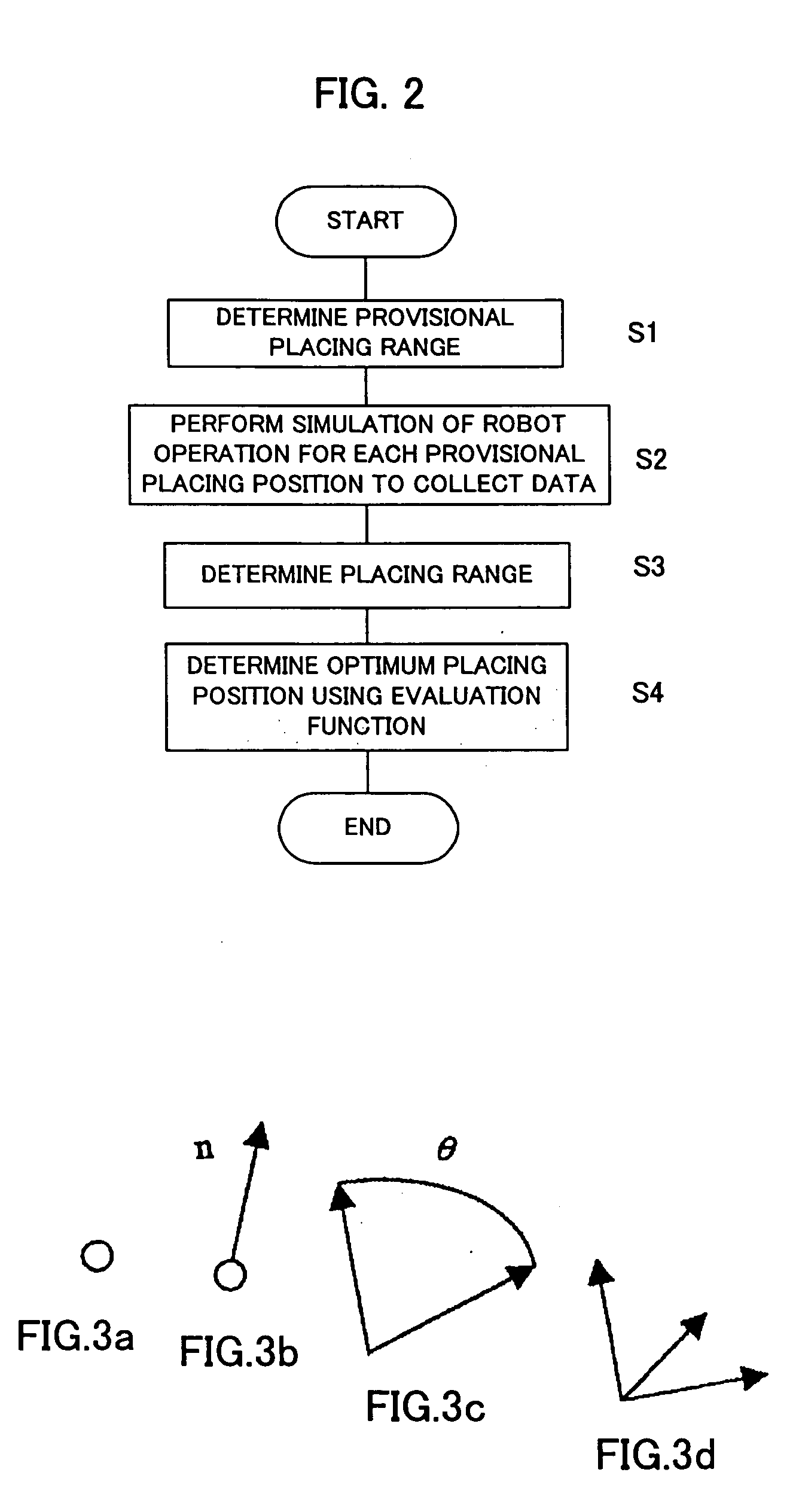

Robot off-line simulation apparatus

ActiveUS20050004709A1Easy to placeLow costProgramme controlProgramme-controlled manipulatorData selectionSimulation

A robot off-line simulation apparatus that allows a person to know an optimum placement for a robot, an operation margin index, etc. before going to an actual working site. Provisional robot placing positions are selected using data about a given sequence of task points (operation path), etc. The conditions for selection are (i) that solution to the inverse kinematics should be found regarding the entire sequence of task points, (ii) that the robot should not interfere with a peripheral device, and (iii) that regarding all the axes of the robot, the operation margin index should satisfy a criterion value. Simulation is performed according to operation programs under the condition that the robot is placed at each of the provisional placing positions, where data about cycle time, duty, energy value, change in acceleration / speed, etc. is collected. Using the collected data, evaluation of operation is performed regarding each of the provisional placing positions, and those provisional placing positions which allow good operation are identified as placing positions ensuring the robot operation. Further, using an evaluation function in which each aspect is given a weighting, the placing positions ensuring the robot operation are reduced to optimum placing positions ensuring the robot operation.

Owner:FANUC LTD

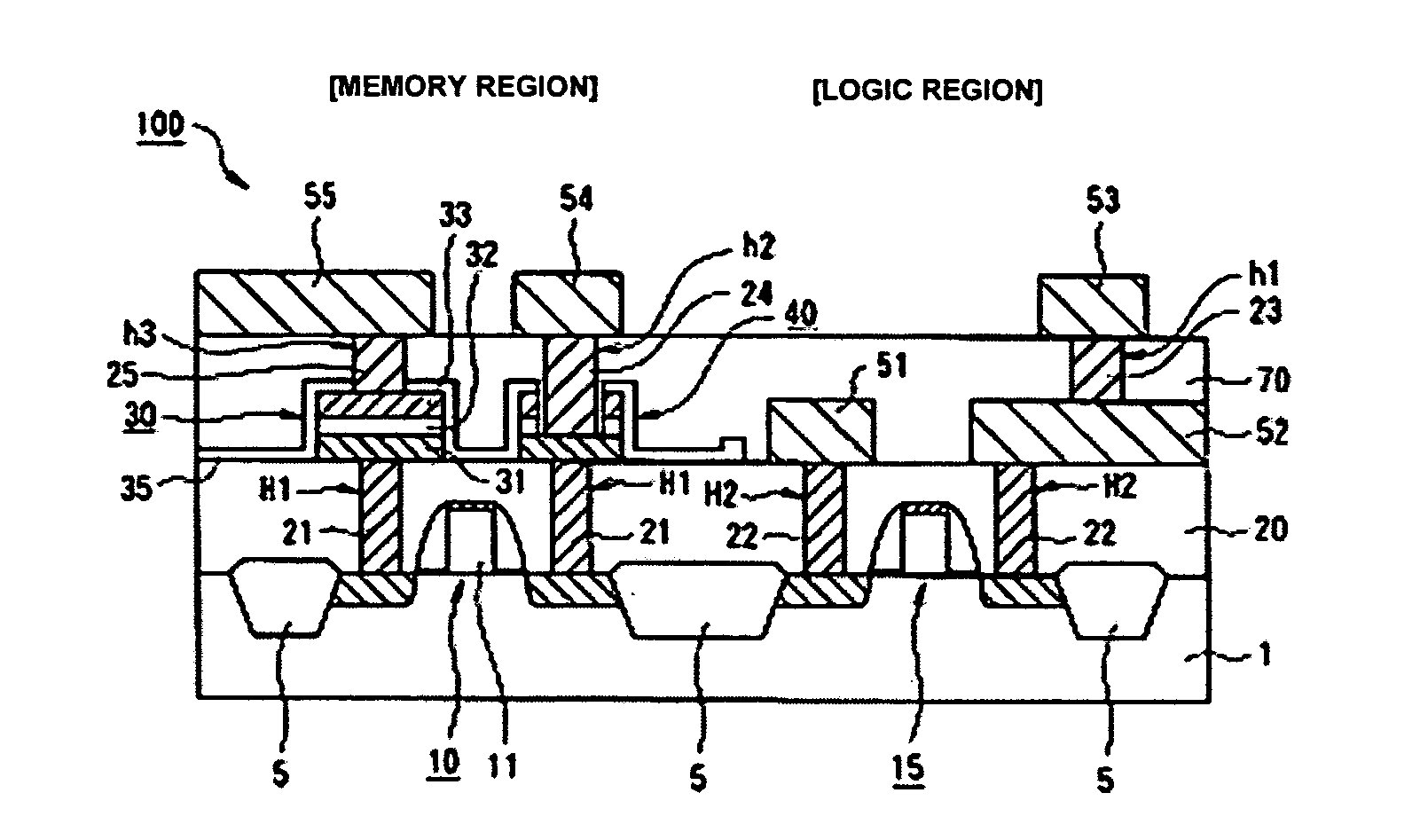

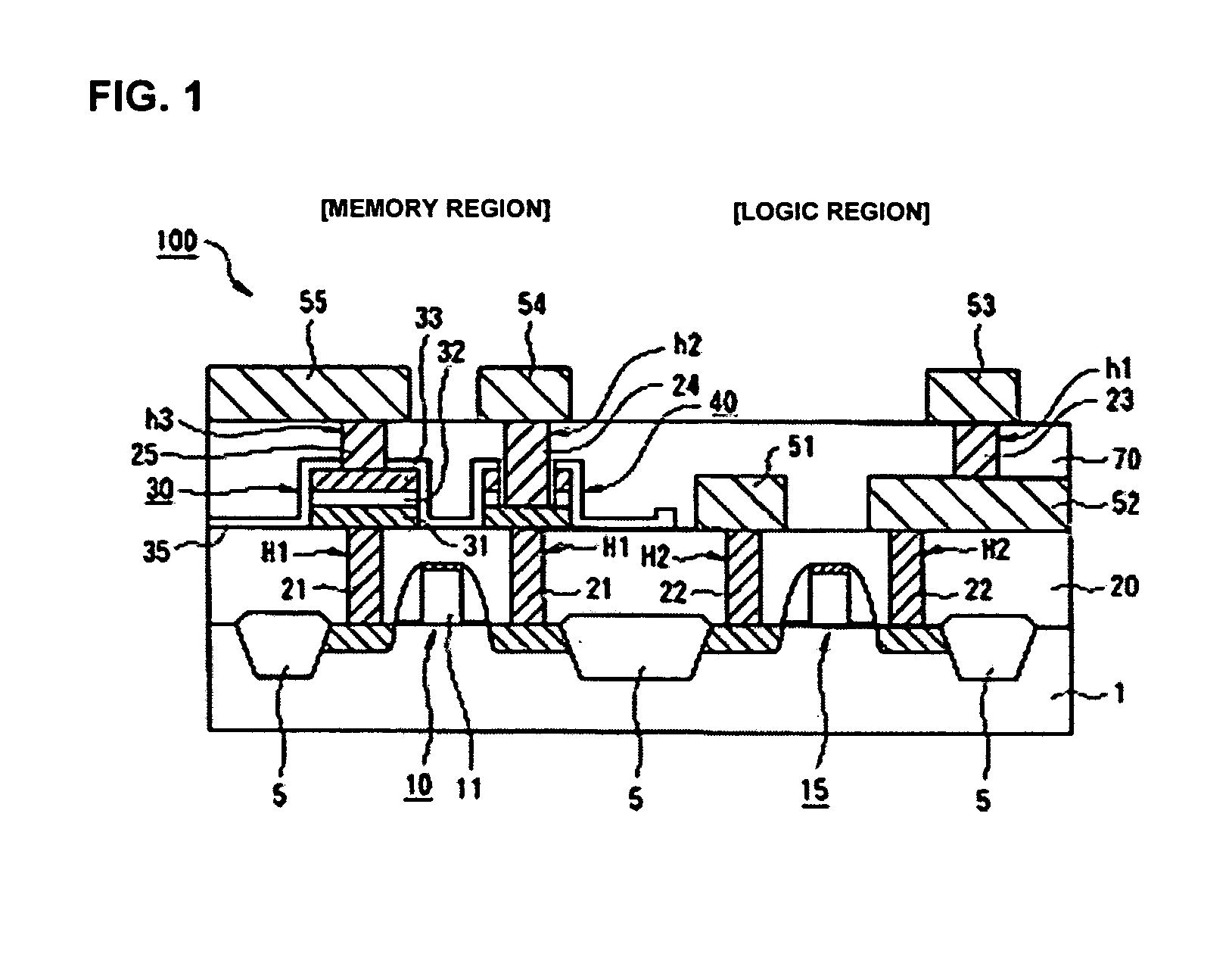

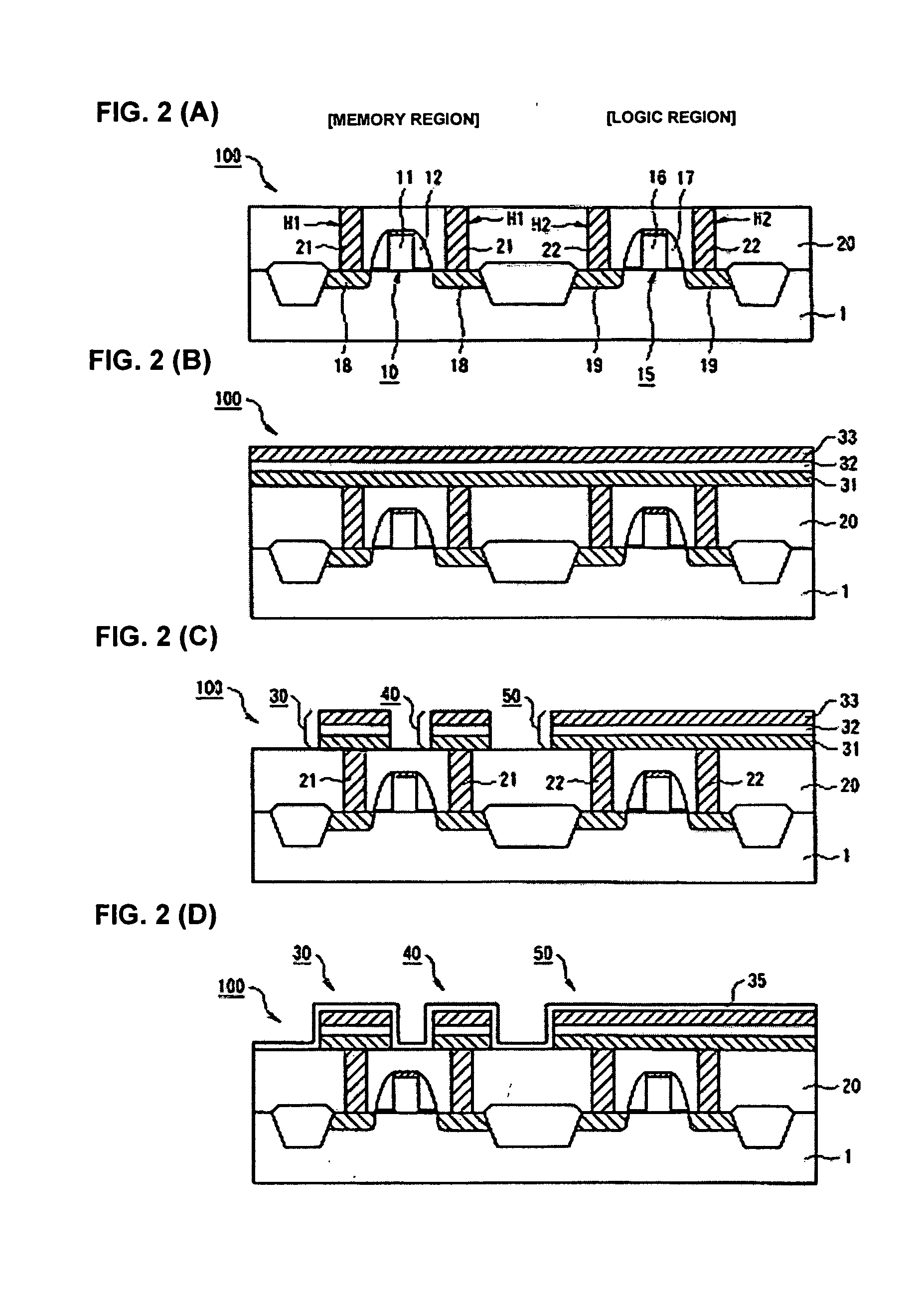

Method for manufacturing semiconductor device, and semiconductor device

InactiveUS20060033138A1Small occupancy areaResistanceTransistorSolid-state devicesDielectricDevice material

A manufacturing method for a semiconductor device that has a first region for memory elements and a second region for elements other than memory elements on a substrate, includes forming a first interlayer dielectric film on the substrate. A first opening section, which is made to reach the substrate, is formed in the first interlayer dielectric film over the first region. A second opening section, which also reaches the substrate, is formed in the first interlayer dielectric film over the second region. A first plug electrode is formed in the first opening section and a second plug electrode is formed in the second opening section. A ferroelectric capacitor is formed on the first interlayer dielectric film and made to cover and contact the first plug electrode. A first wiring pattern covering and contacting the second plug electrode is formed on the first interlayer dielectric film. A second interlayer dielectric film, which covers the ferroelectric capacitor and the first wiring pattern, is formed on the first interlayer dielectric film. A third opening section is then made in the second interlayer dielectric film over the second region and reaching the first wiring pattern. A third plug electrode is formed in the third opening section.

Owner:SEIKO EPSON CORP

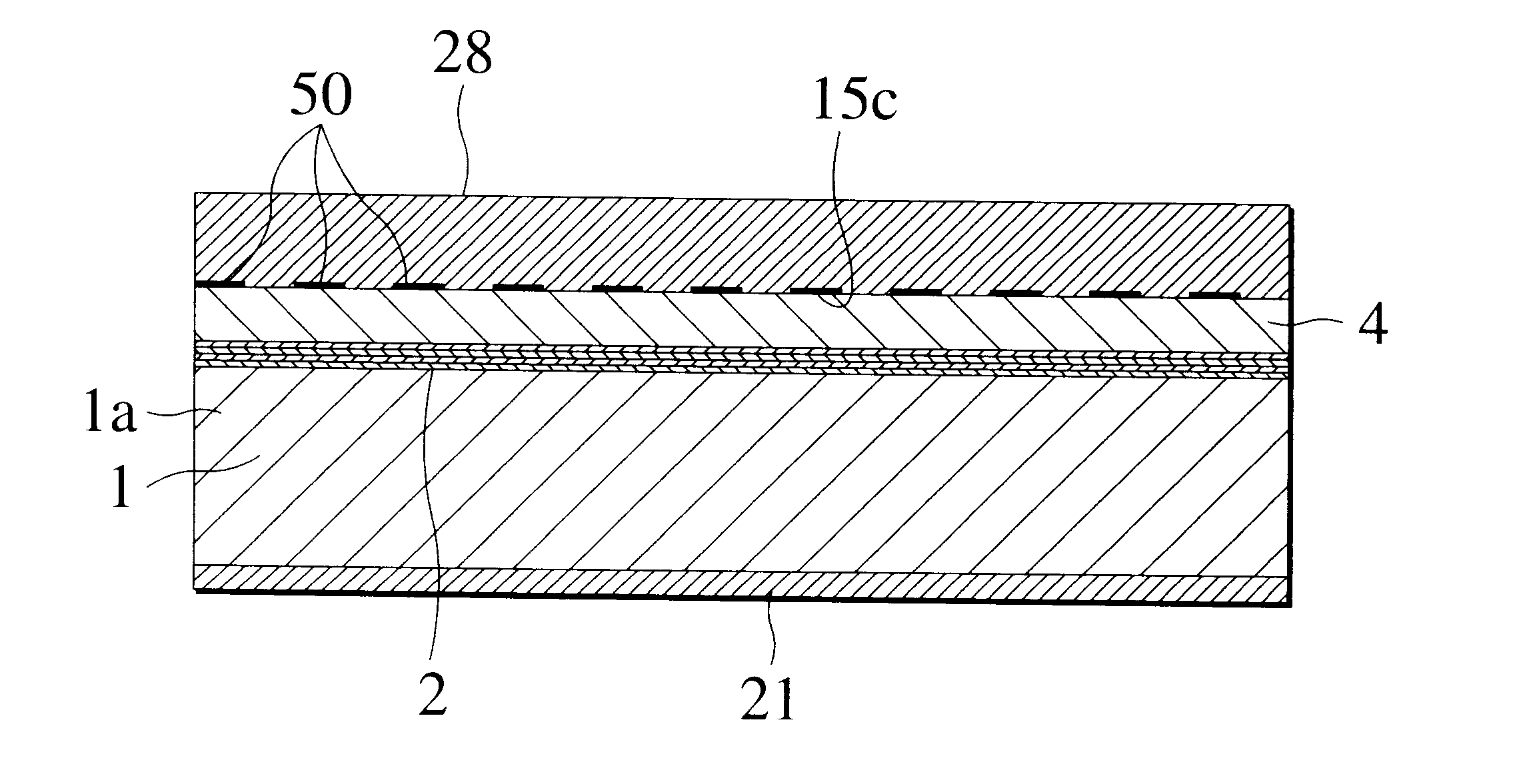

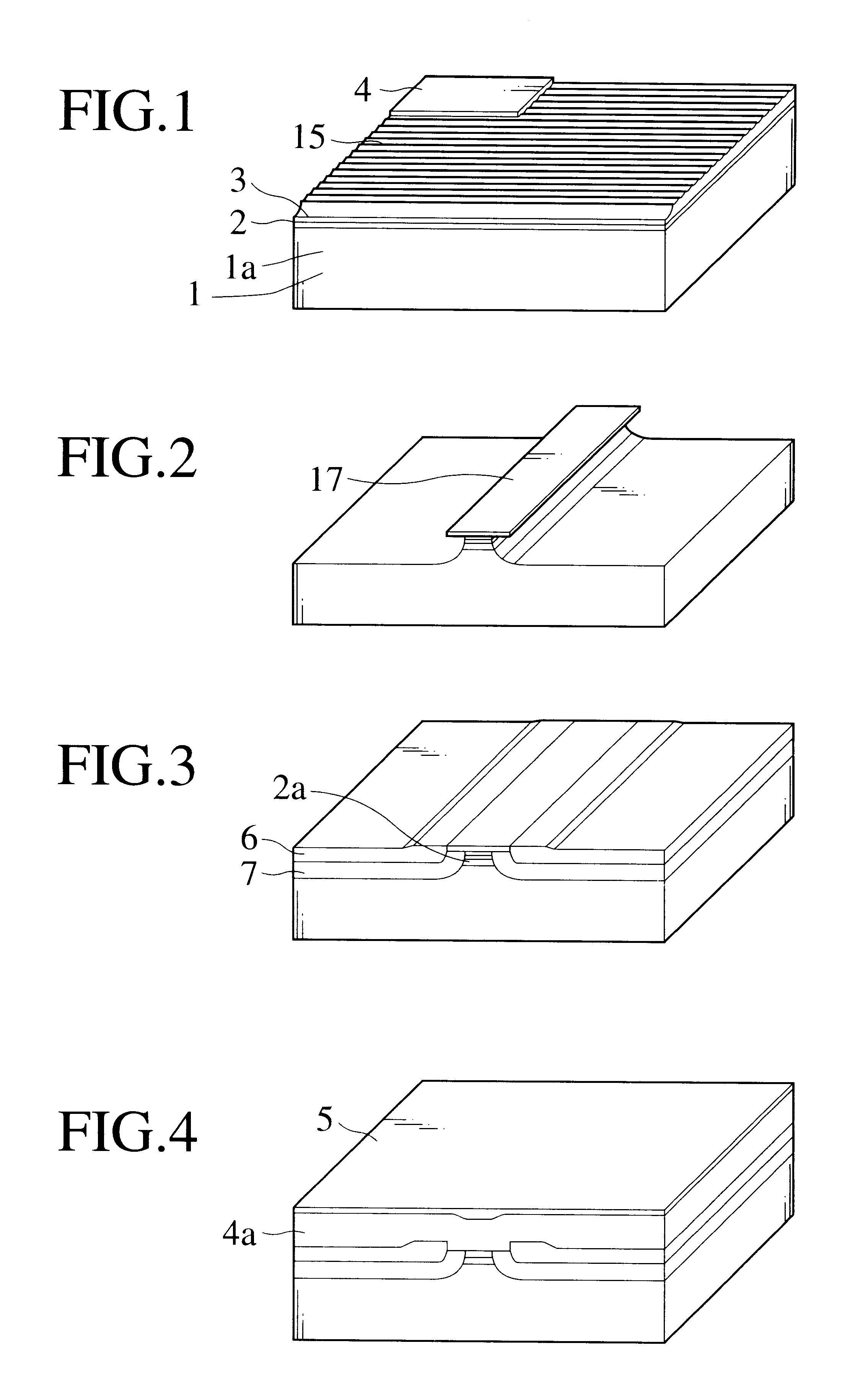

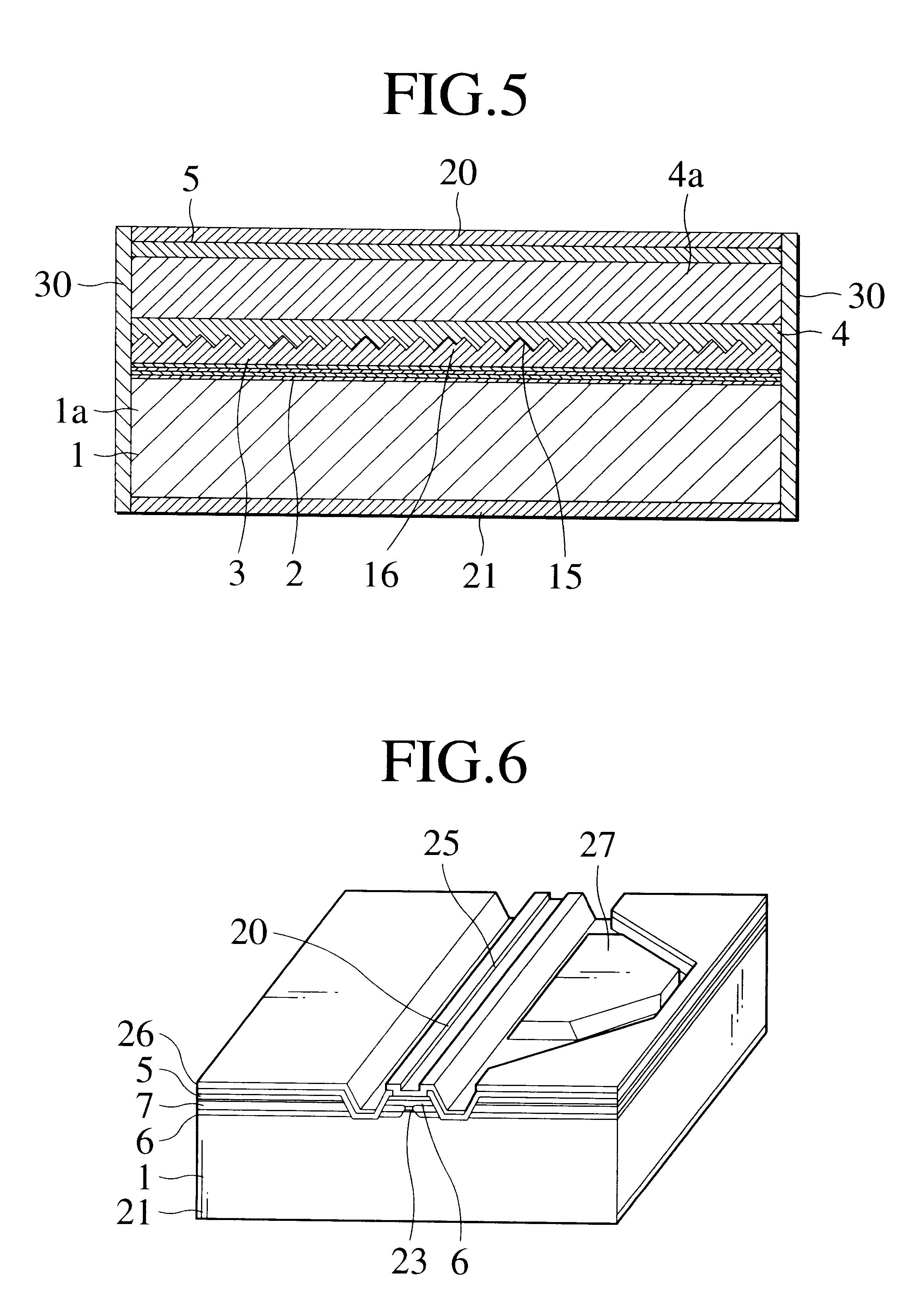

Optoelectronic device and laser diode

InactiveUS6327413B1Simple configurationReduce manufacturing stepsLaser detailsLaser optical resonator constructionWaveguideElectric field

Both an electric energy applying mechanism and an optical waveguide mechanism can be provided to an ITO layer (transparent electrode) by constituting an optical waveguide so as that the guided mode profile spread into the ITO layer. Also a bonding pad is provided to supply a power and apply an electric field onto the ITO layer. Accordingly, a device structure can be simplified and thus improvement in yield of the optoelectronic device having an optical waveguide and improvement in parameters of the optoelectronic device can be achieved.

Owner:KK TOSHIBA

Welding method of ultra-thick and high-strength water-power steel

ActiveCN101905365ATo achieve the welding effectReduce fillingArc welding apparatusWorkpiece edge portionsEngineeringWelding defect

The invention relates to a welding method of ultra-thick and high-strength water-power steel, belonging to the welding field. Welding is realized by adopting a mixed welding mode, i.e. hand welding is adopted as a basis for filling the bottom, and gas shielded welding is adopted for a middle layer and a cover part, multilayer and multi-pass welding are adopted, a carbon arc is cropped out after a single side is filled, and the input of welding heat is controlled within 65 kJ / cm. A welding bevel adopts an asymmetric U-shaped bevel, a thick steel plate of 145-155 mm is preheated to 100 DEG C before welding, the inter-layer temperature is kept between 100 DEG C to 160 DEG C, and heat treatment stress is not carried out after welding, and the problem of reheat embrittlement of a welding joint of the high-strength water-power steel is solved. The invention needs simple welding equipment, realizes welding through a combined welding process on the basis of the traditional equipment, reduces the filling amount of welding metal, and achieves the welding effect of a narrow gap. Compared with the hand arc welding, the invention greatly improves the welding efficiency of the thick steel plate and lowers the possibility of welding defects easily generated on the hand arc welding of an ultra-thick steel plate, such as cold cracks, incomplete fusion, crisp fusion, and the like.

Owner:SHOUGANG CORPORATION +1

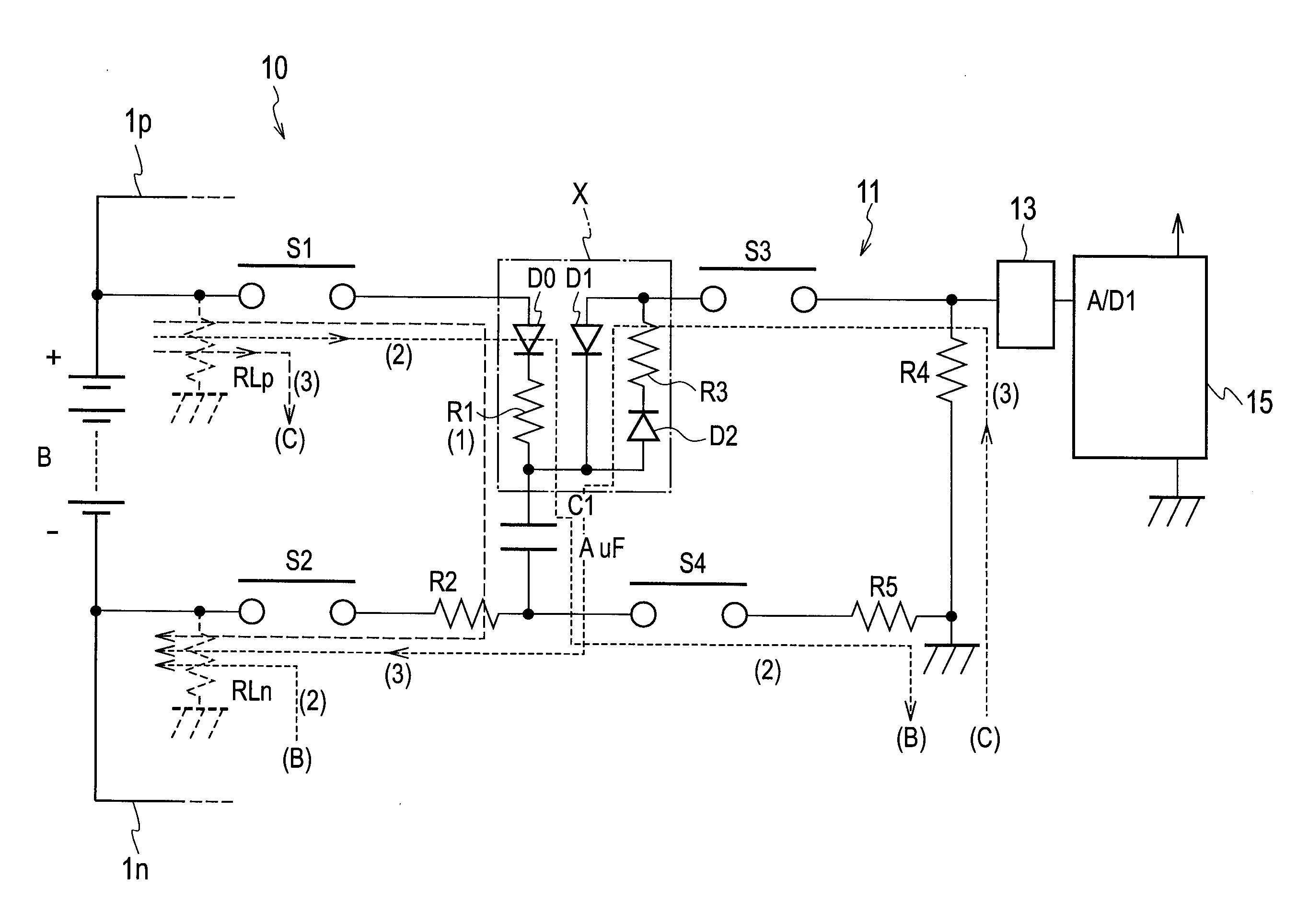

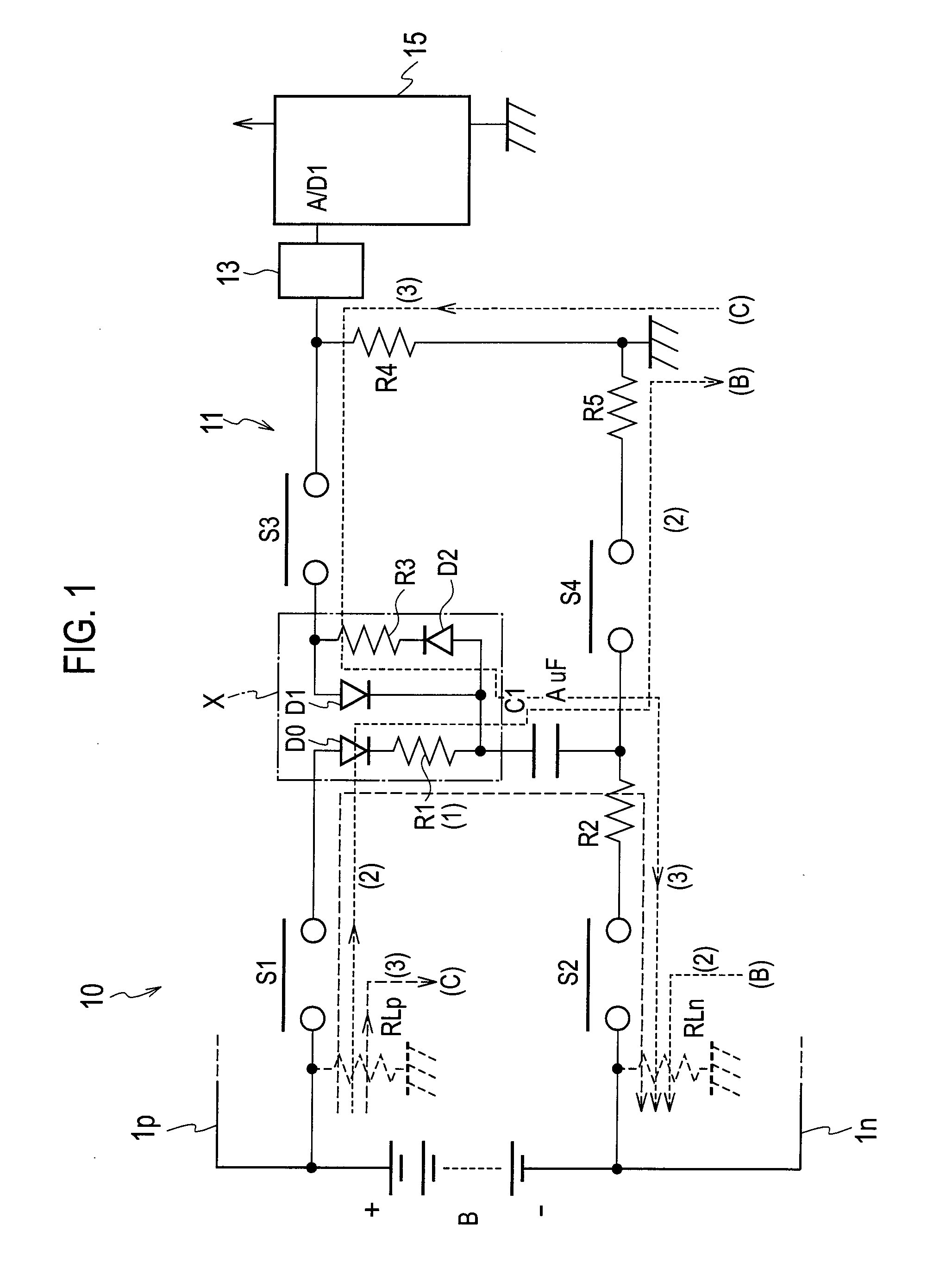

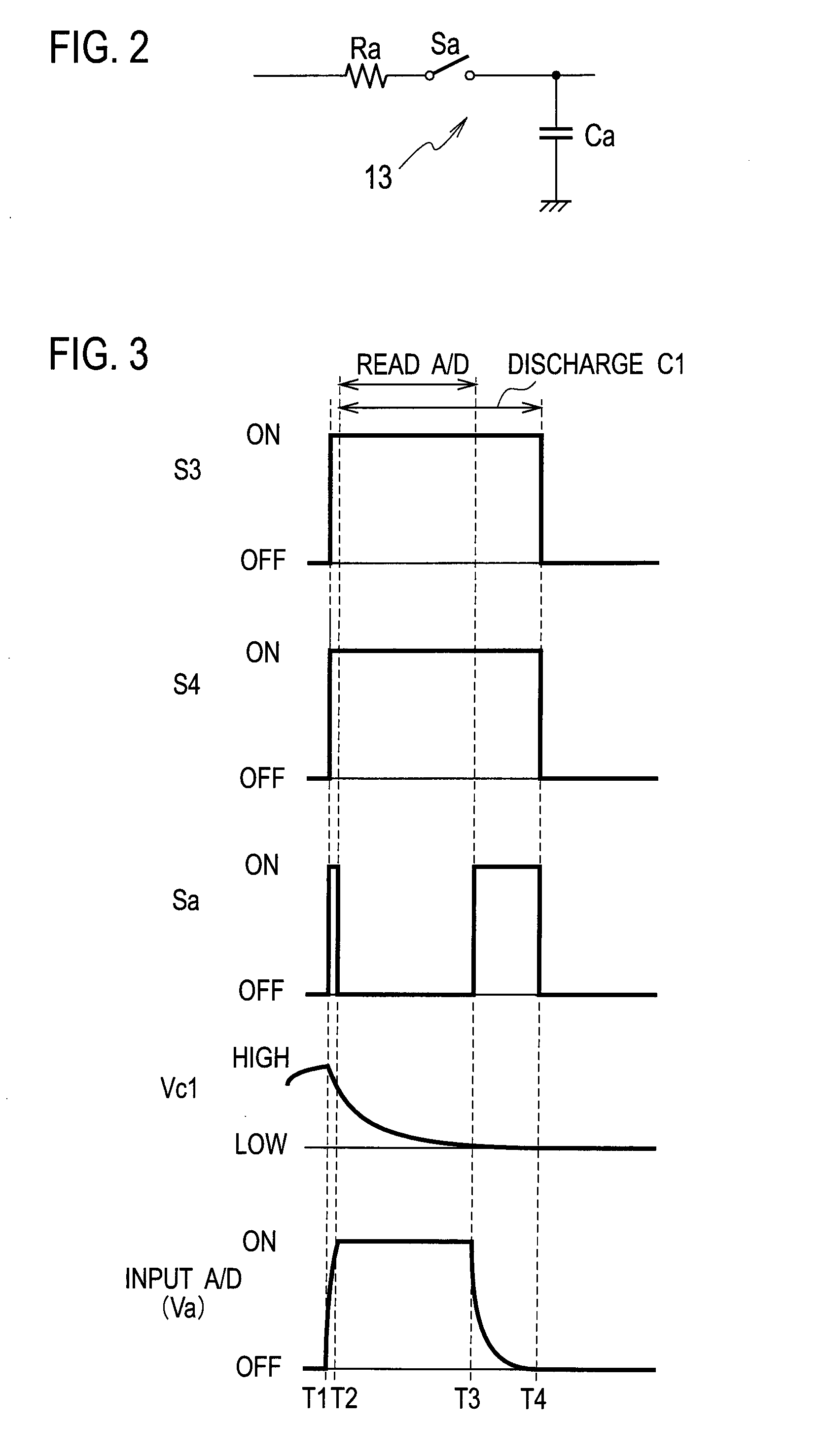

Insulating state detection unit having failure detector

ActiveUS20120262183A1Avoid misjudgmentAccurate detectionShort-circuit testingTesting circuitsCharge voltageFailure detector

An insulating state detection unit is configured to perform failure detection for switches, which connect a flying capacitor to a sample hold circuit for acquiring a charge voltage and a ground potential, by using a failure determination threshold value according to a variable value. That is to say, the insulating state detection unit is configured to decide the failure determination threshold value by taking, as a reference, a charge voltage of a capacitor of the sample hold circuit charged with electric charge amount corresponding to a charge voltage of the flying capacitor when the flying capacitor is charged with electric charge amount corresponding to an output voltage of a DC power supply.

Owner:YAZAKI CORP

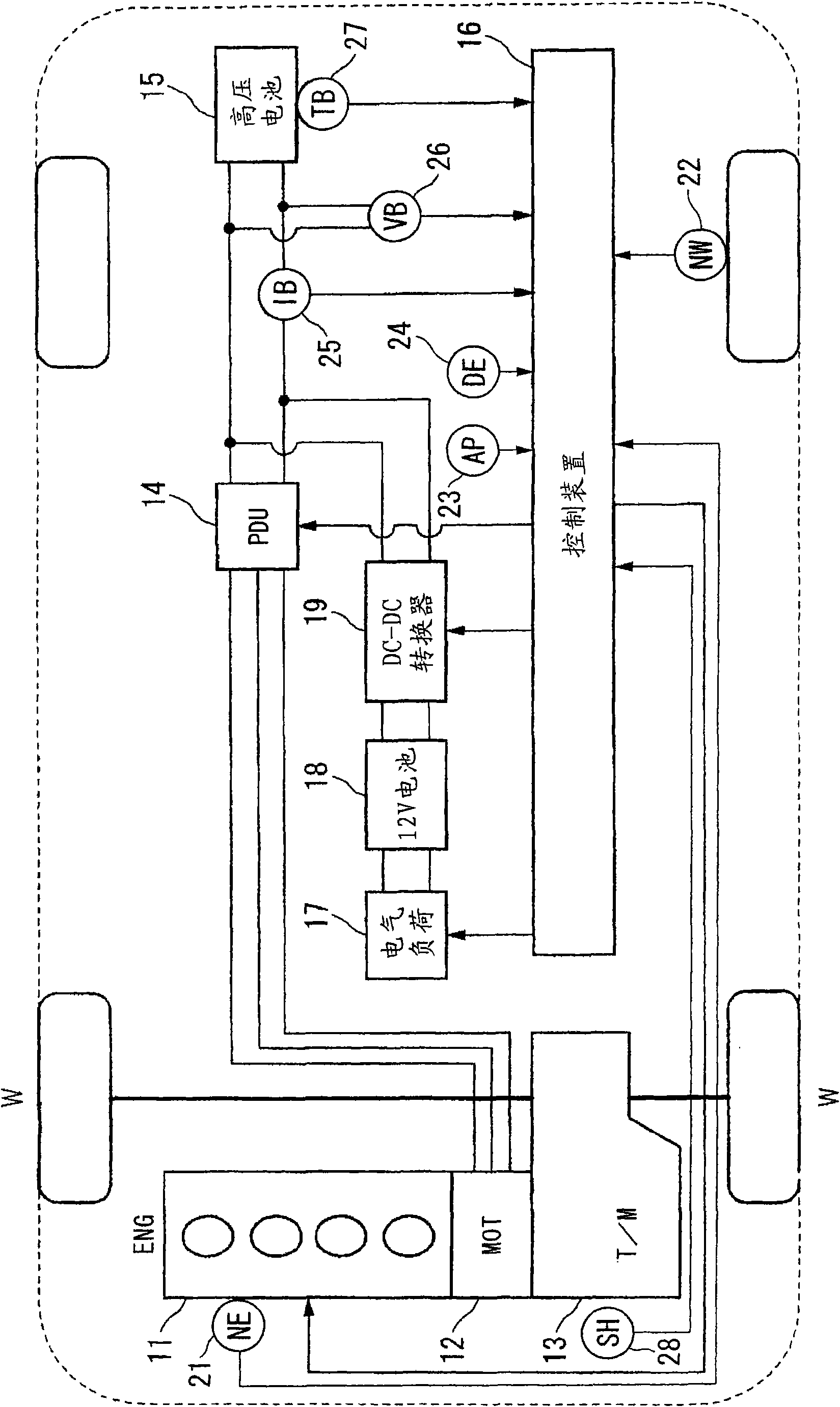

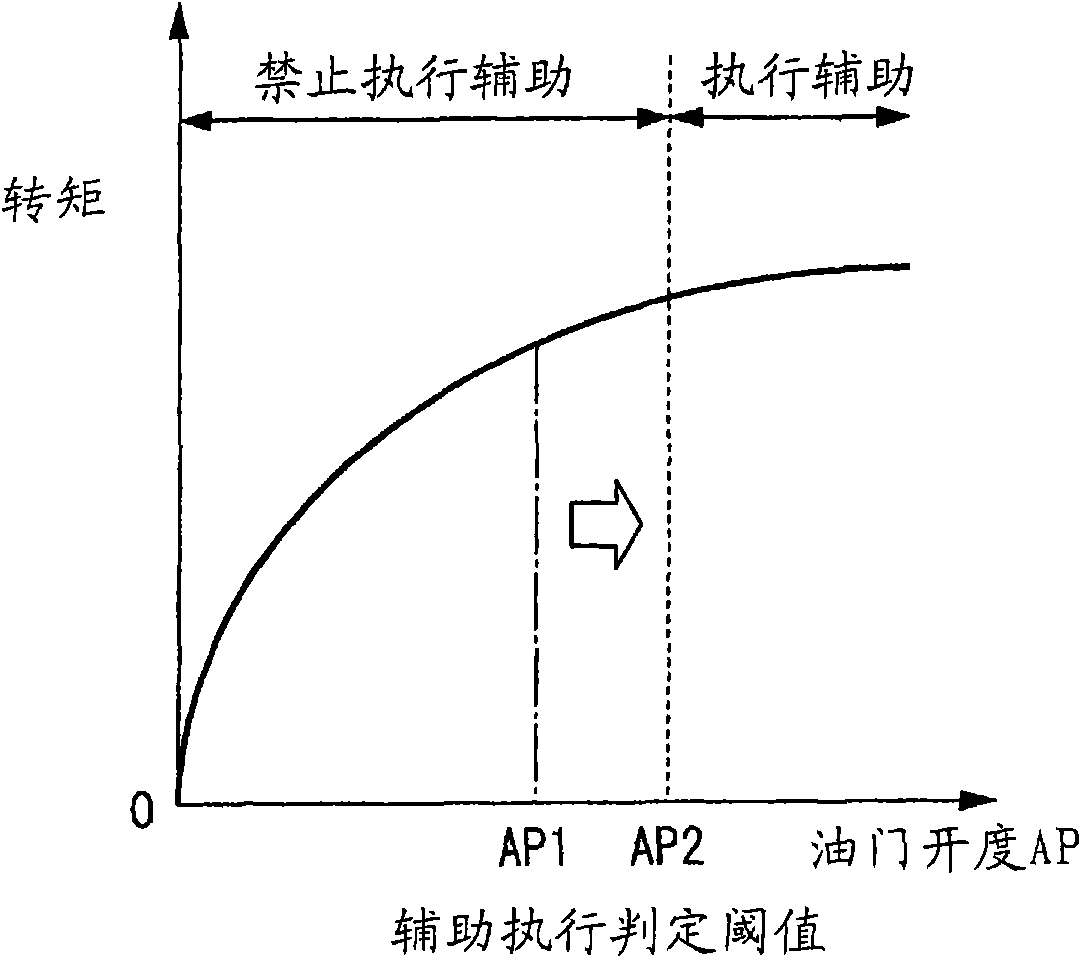

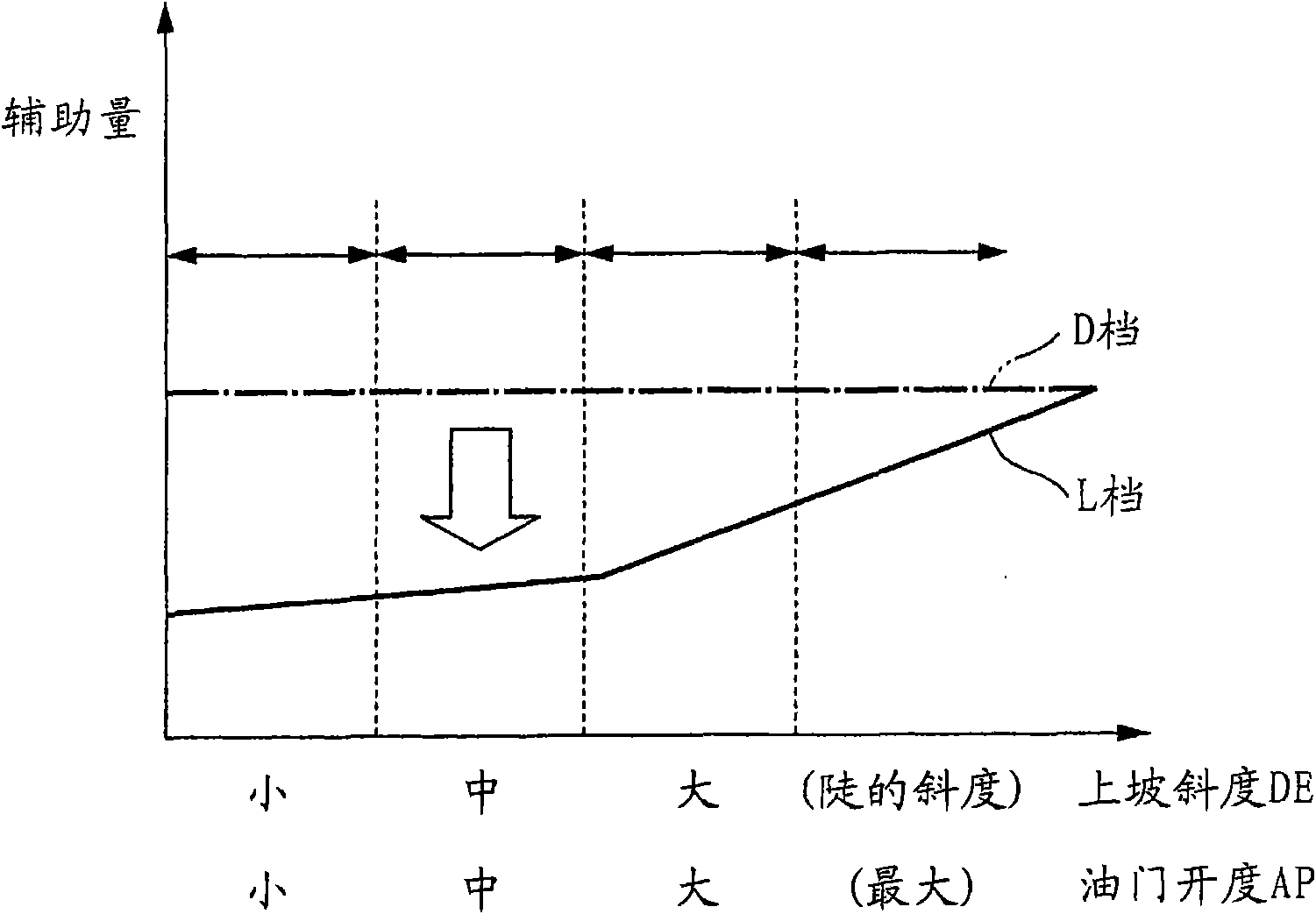

Control device for hybrid vehicle

ActiveCN101687505ADrive inhibitionDriving force inhibitionElectrical controlInternal combustion piston enginesElectricityInternal combustion engine

A control device for a hybrid vehicle having an internal combustion engine, a generator motor, an electricity storage device, and driving force assist means. The control device has switch means that appropriately selects from and switches between travel ranges including at least a normal travel range and a charge priority range in which charging to the electricity storage device is prioritized. The control device also has threshold value increasing means that, when the charge priority range is selected by the selection means, increases a specific determination threshold value to a level higherthan that when the normal travel range is selected by the switch means.

Owner:HONDA MOTOR CO LTD

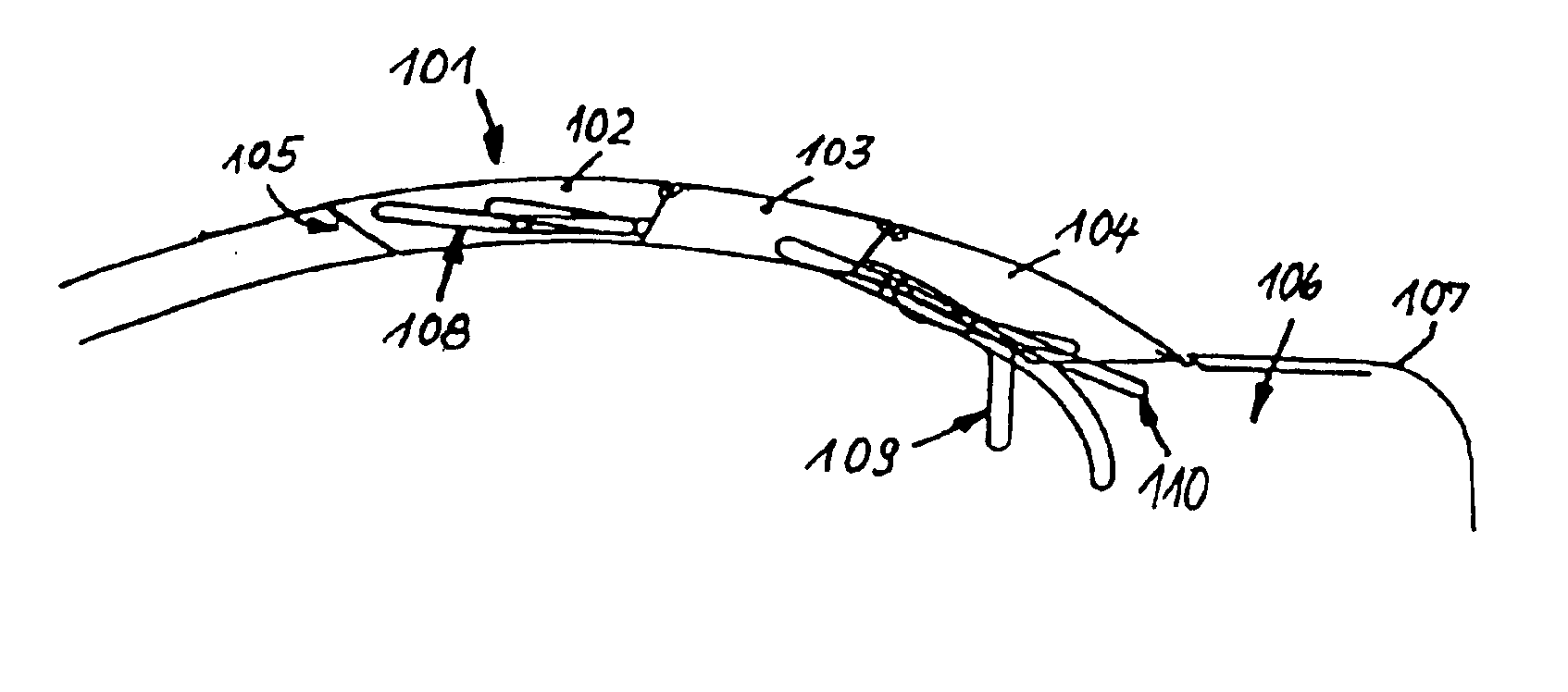

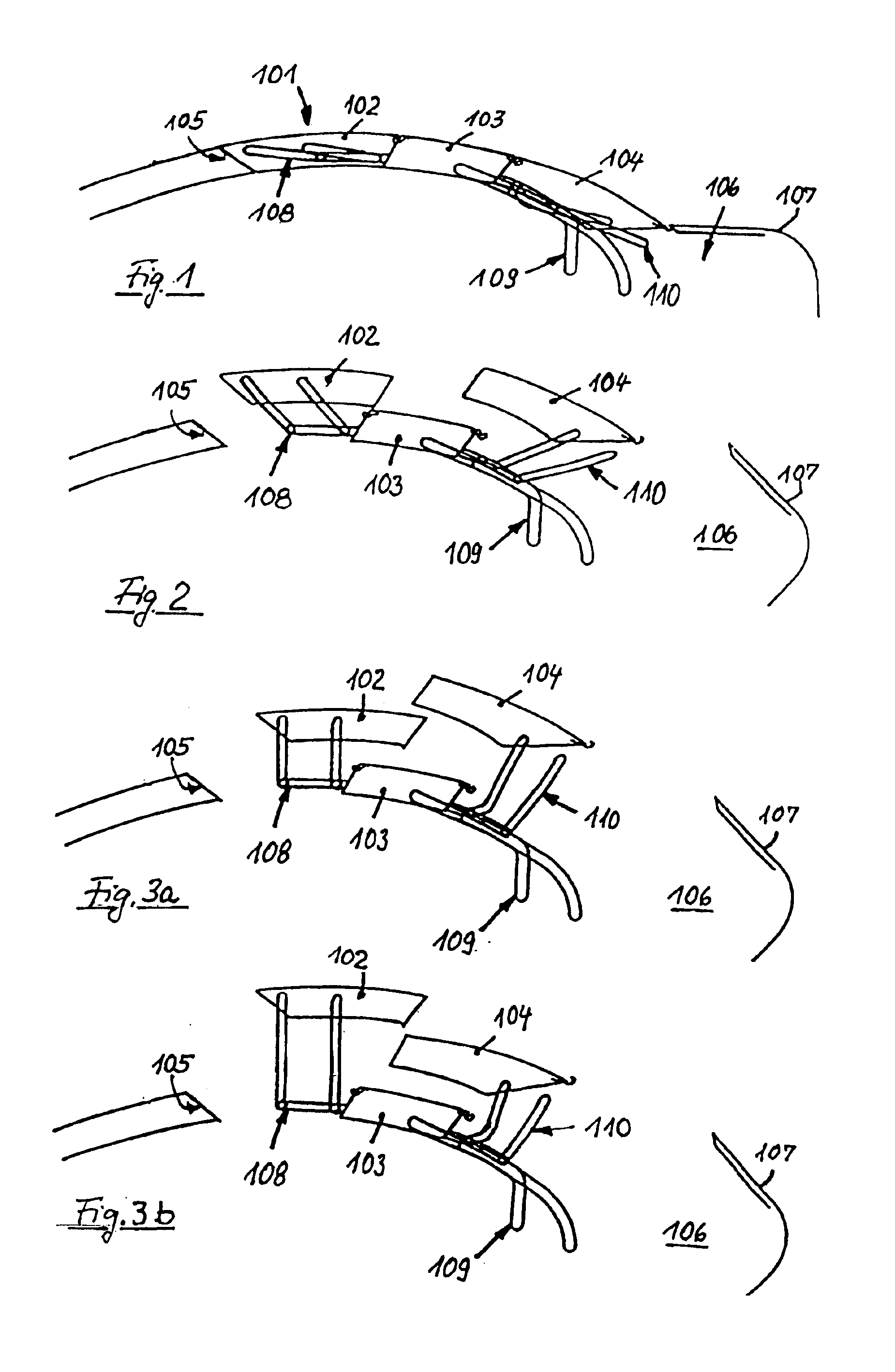

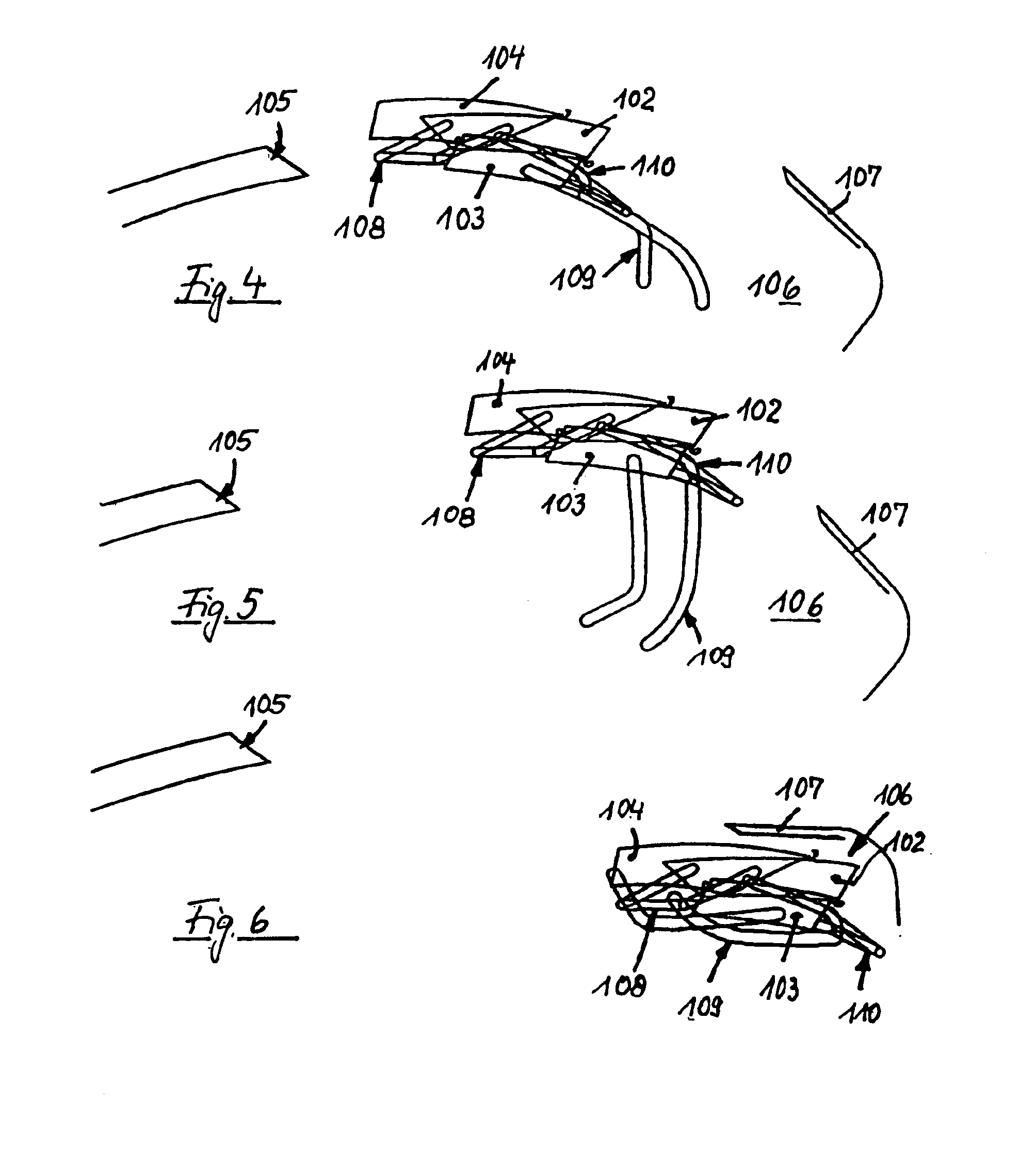

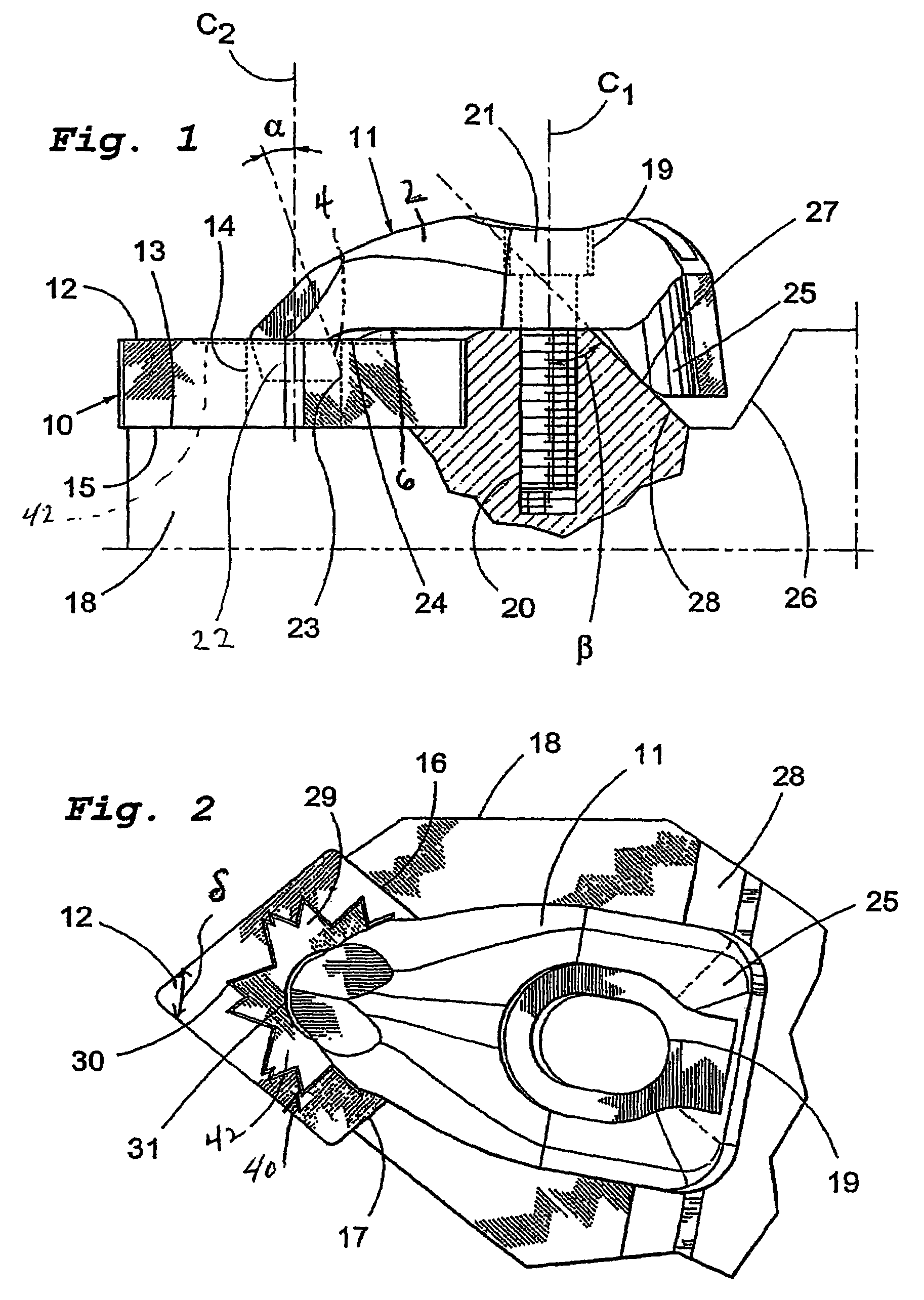

Hardtop vehicle roof with three rigid roof parts

InactiveUS6857687B2Small space requirementEasy to operateEngine sealsVehicle sealing arrangementsInterior spaceHolding room

In a hardtop vehicle roof comprising front, intermediate, and rear roof parts, which are movable between a closed position, in which they cover an interior vehicle space, and an open position, in which they are stacked in a storage compartment of the vehicle, and wherein the front and rear roof parts are supported on the intermediate roof part by a roof part operating mechanism, which is operatively connected to a support and operating mechanism by which the intermediate roof part is mounted on the body of the vehicle, the roof parts operating mechanisms for the front and rear roof parts are operatively connected to the support and operating mechanism of the intermediate part such that, when the roof is opened, the front and rear roof parts are moved on top of the intermediate roof part to form a packet in which the top sides of all roof parts face upwardly and which requires relatively little space on top of the vehicle and does not intrude in the vehicle interior during the transfer between the closed and the open positions.

Owner:CTS FAHRZEUG DACHSYST

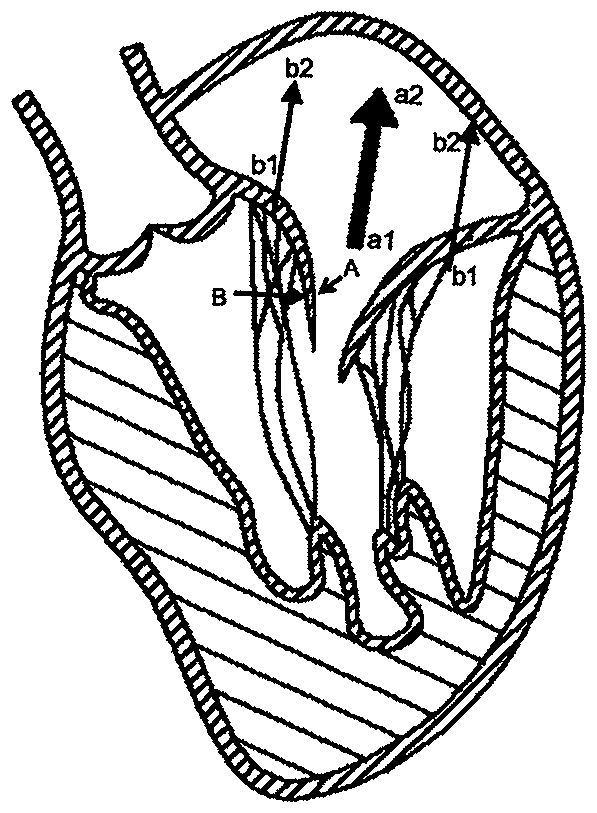

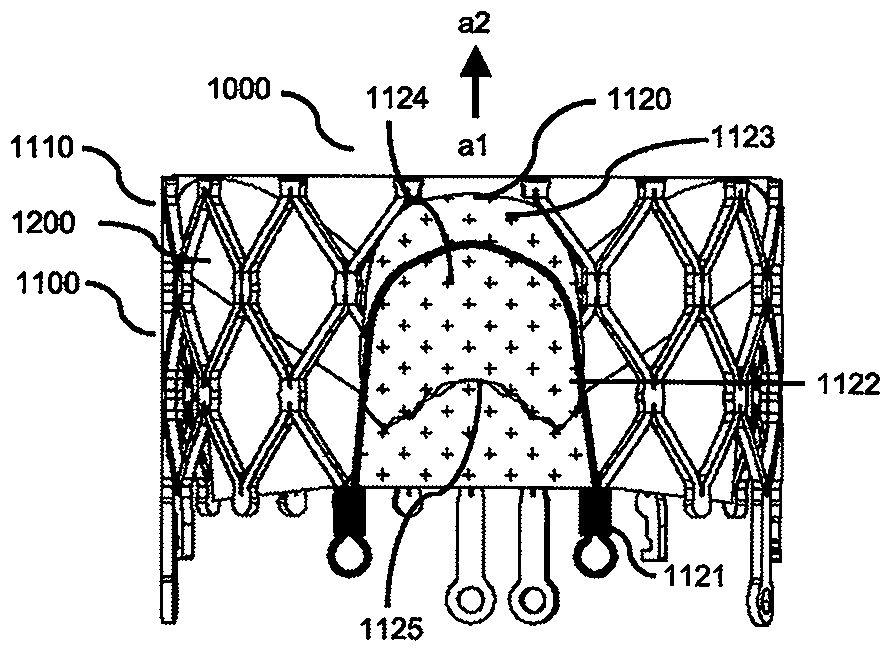

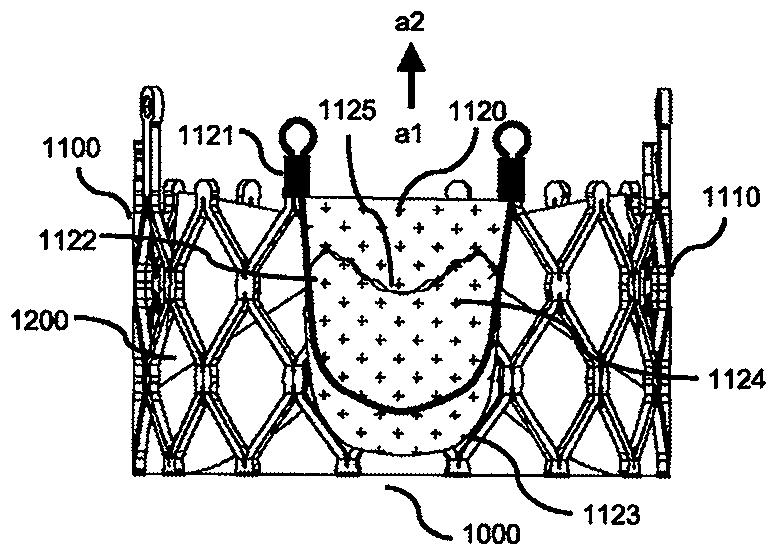

Prosthetic valve prosthesis

ActiveCN107260366AGood opening and closing functionStable supportHeart valvesInsertion stentMedicine

The invention relates to a prosthetic valve prosthesis. The prosthetic valve prosthesis comprises a stent and a prosthetic valve. The stent comprises a valve sewing section and at least one clamping device. The prosthetic valve is fixedly connected to the valve sewing section. The clamping device is composed of a connecting section, a clamping section and an adaptive section, wherein the connecting section is fixedly connected with a part of the valve sewing section, one end of the connecting section is fixedly connected with one end of the clamping section, the adaptive section is fixedly connected with the clamping section, and one end of the adaptive section is dissociated from the valve sewing section to serve as a free end. In the natural state, the clamping section approaches the outer surface of the valve sewing section, and the supporting force of the adaptive section in the direction of the axis line is smaller than that of the clamping section in the direction of the axis line. When the prosthetic valve prosthesis is released to a target position, the clamping device plays a fixing role, and the prosthetic valve replaces the native valve to achieve valve opening and closing.

Owner:NINGBO JENSCARE BIOTECHNOLOGY CO LTD

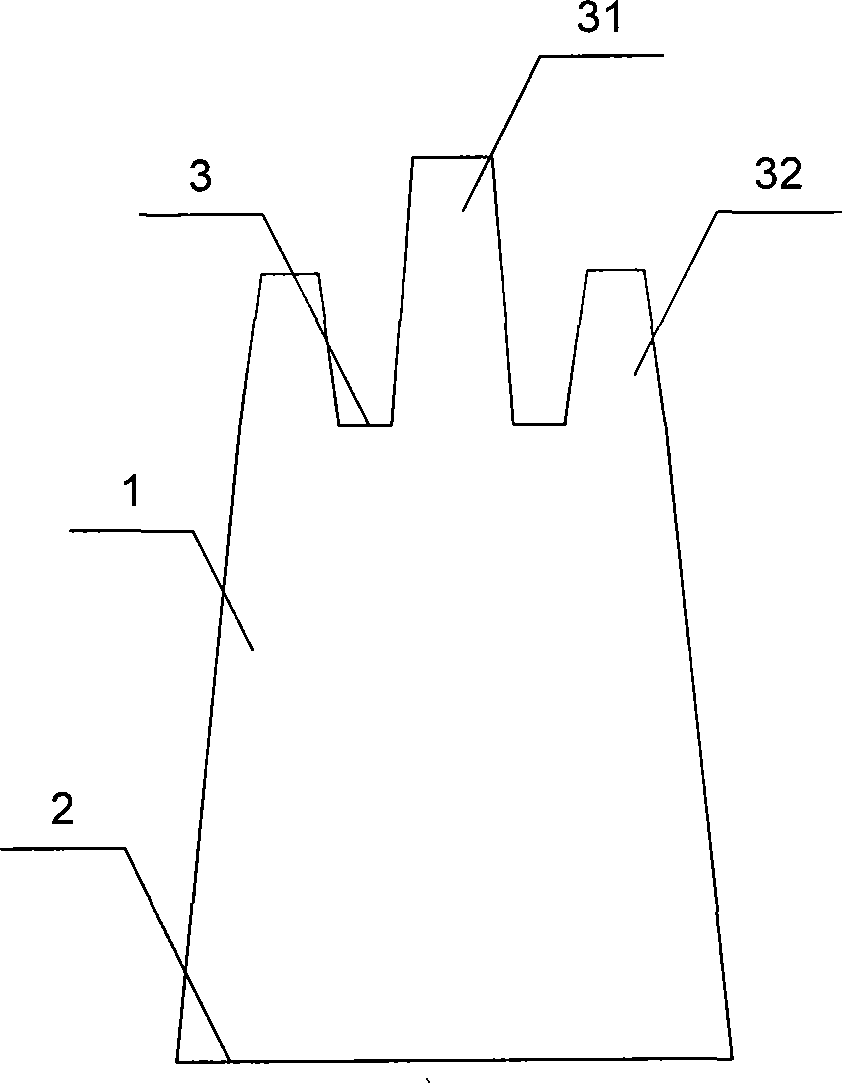

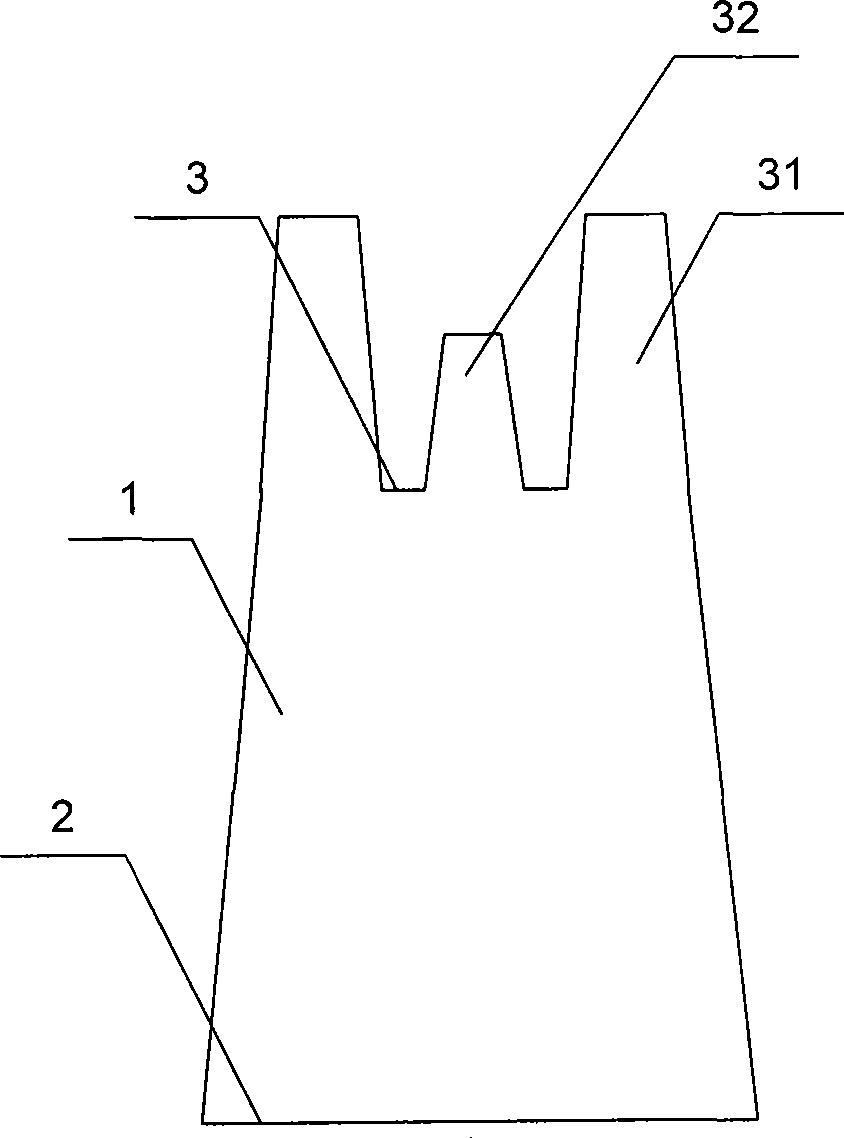

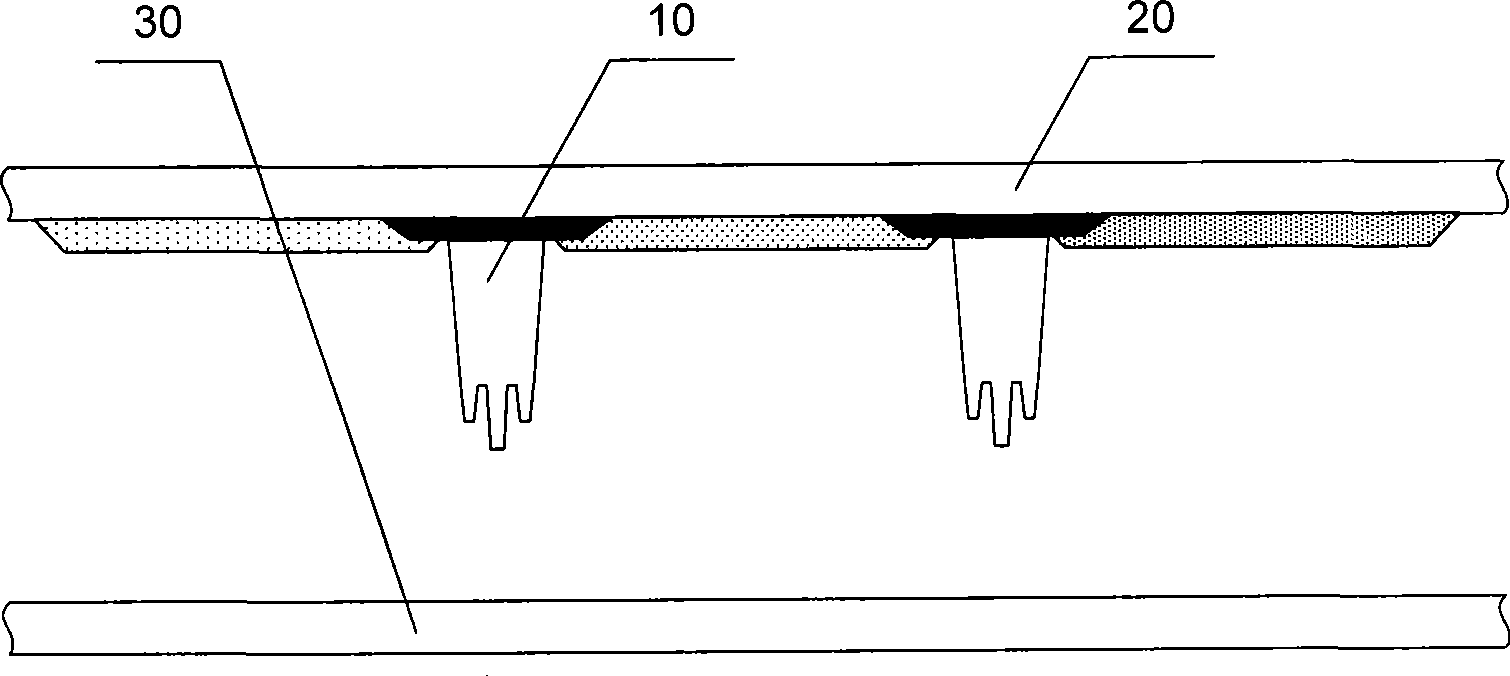

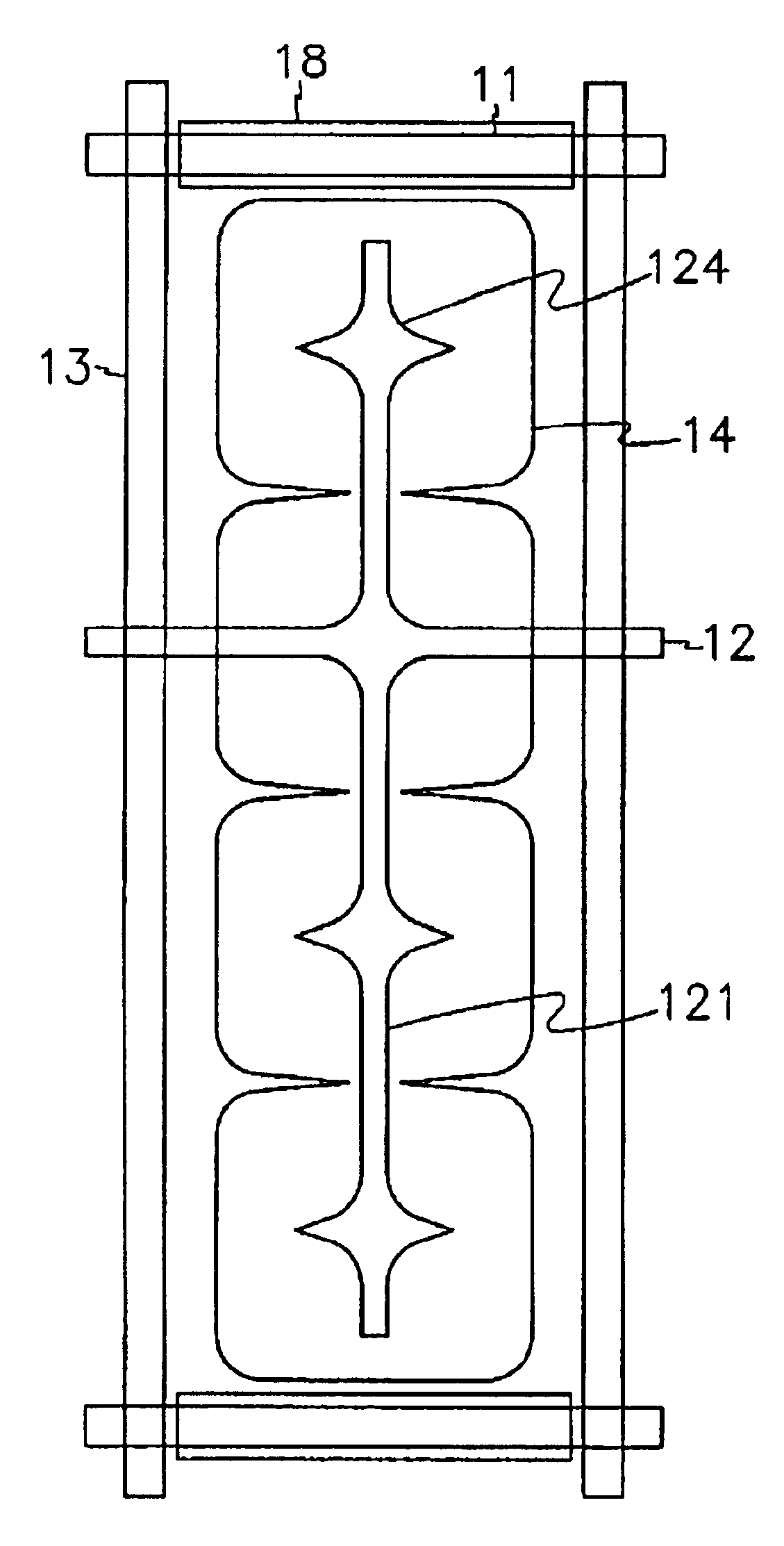

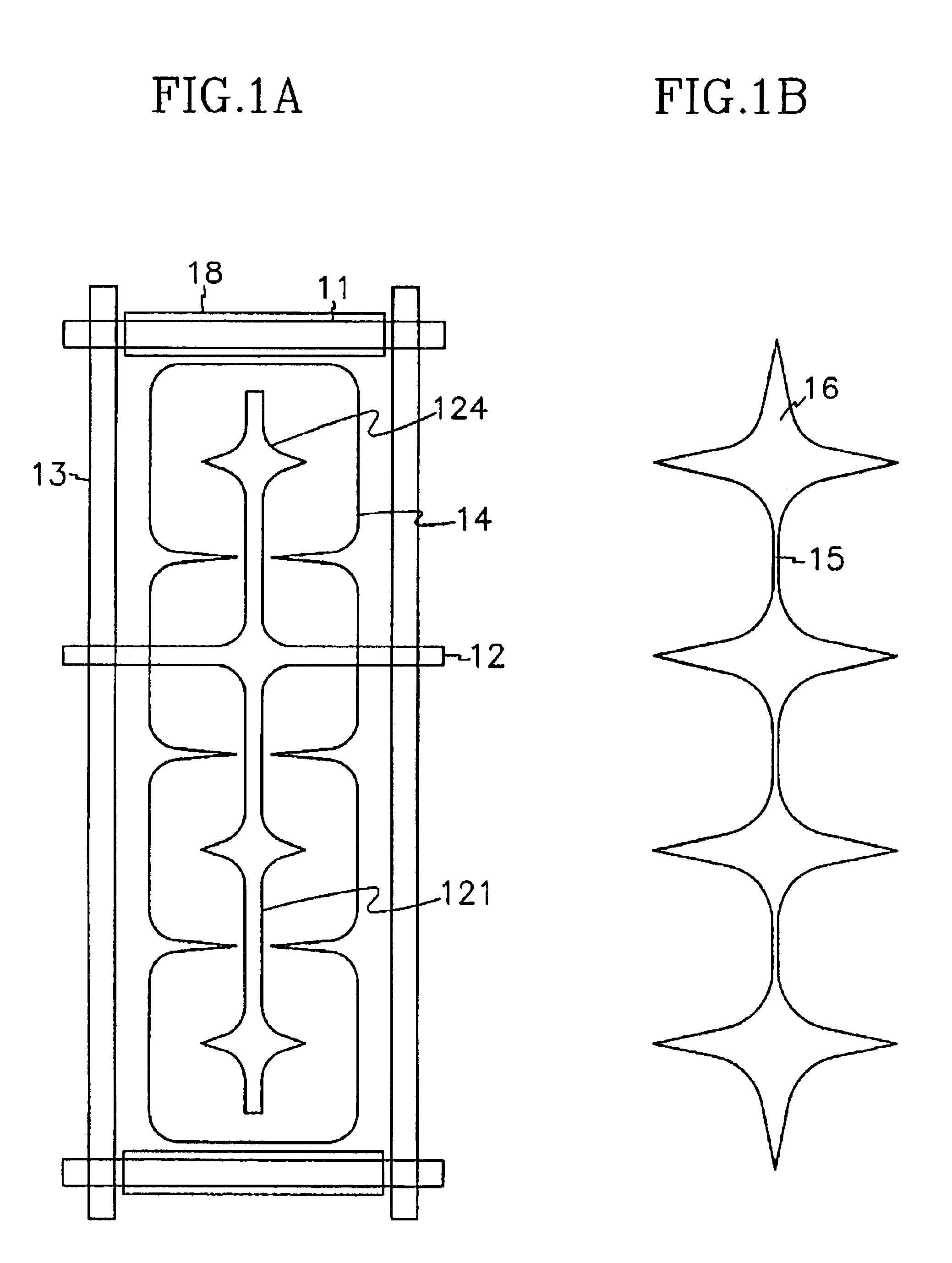

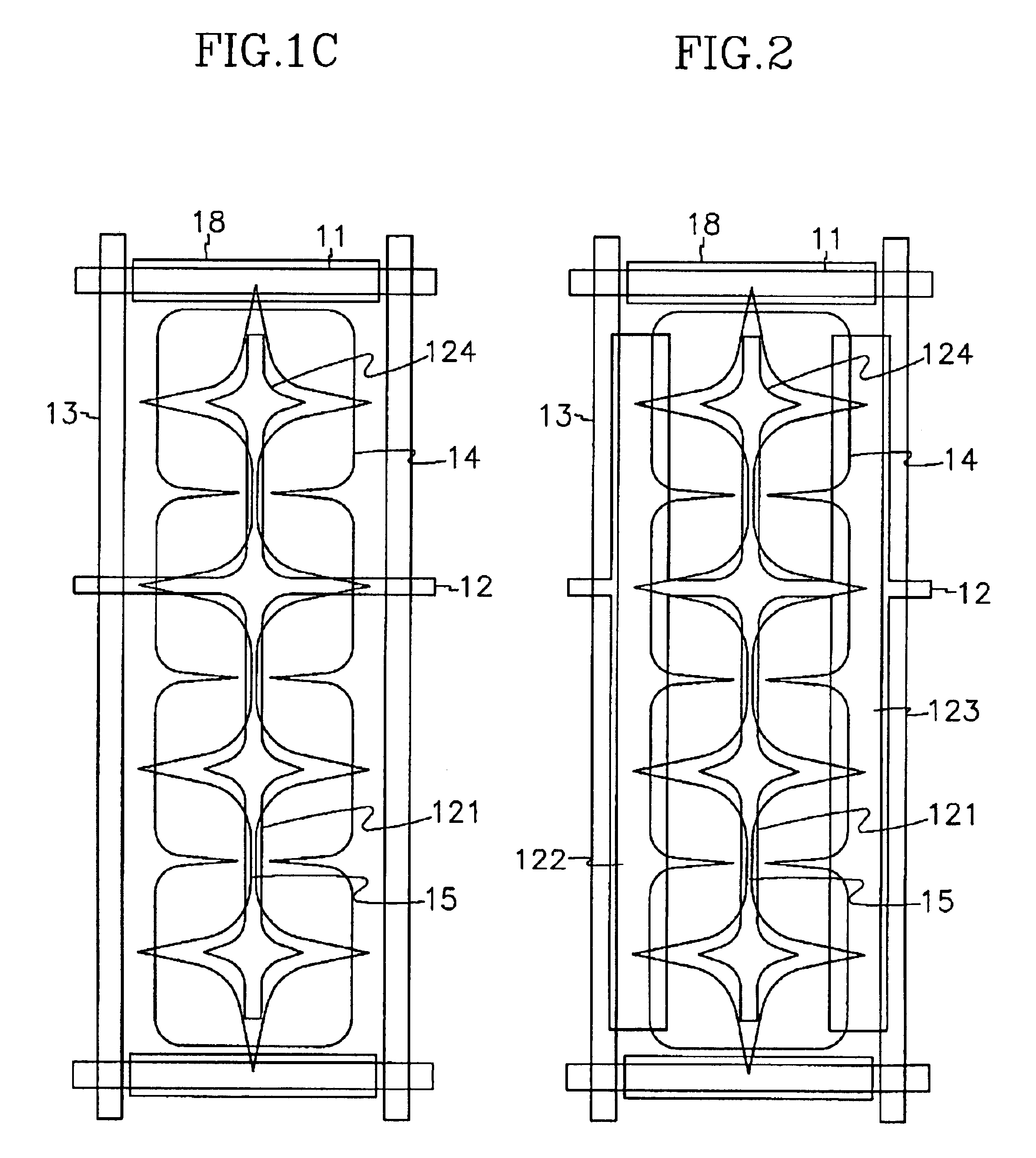

Column shaped spacer and LCD panel thereof

ActiveCN101452156AReduce processing requirementsImprove qualityNon-linear opticsLiquid-crystal displayLiquid crystal

The invention relates to a cylindrical spacer which comprises a cylindrical part that has a base end connected with a substrate of liquid crystal display panel and a top end supporting the other substrate of liquid crystal display panel. The top end of cylindrical part is a projection structure which is high at central part and low at external part, or a concave structure which is low at central part and high at external part. The invention also relates to a liquid crystal display panel which comprises a color film substrate and an array substrate, and a cylindrical spacer which has a base end connected with the color film substrate and a top end supporting the array substrate. The top end of cylindrical spacer is a projection structure or a concave structure which has larger preset deformation force and larger deformation allowance. The liquid crystal display panel according to the invention simultaneously increases the allowed filling high limit of liquid crystal and allowed filling lower limit of liquid crystal, can provide a liquid crystal layer allowance with larger range, reduce the technical requirement for the box, and increases the picture quality of liquid crystal display.

Owner:K TRONICS (SUZHOU) TECH CO LTD +1

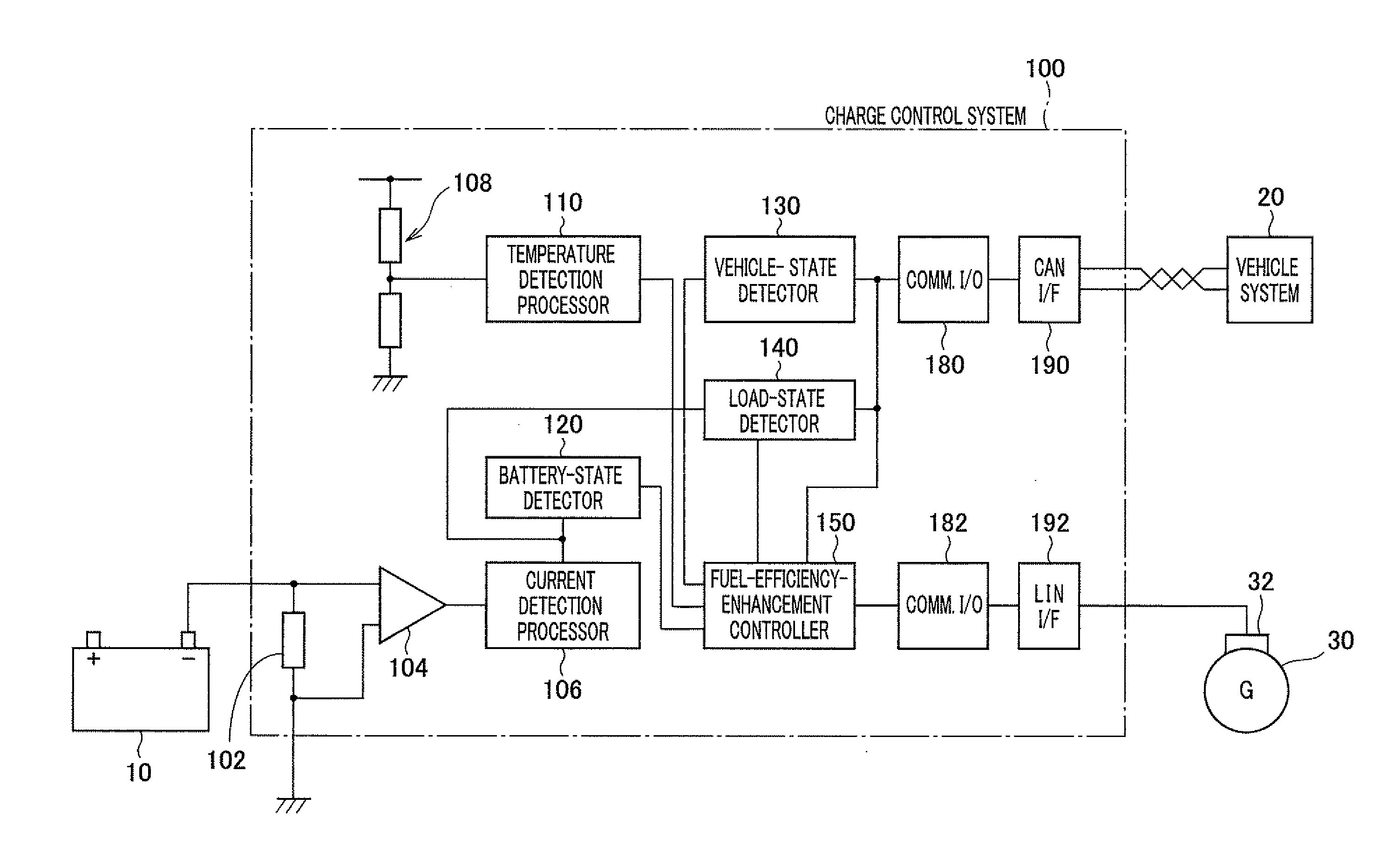

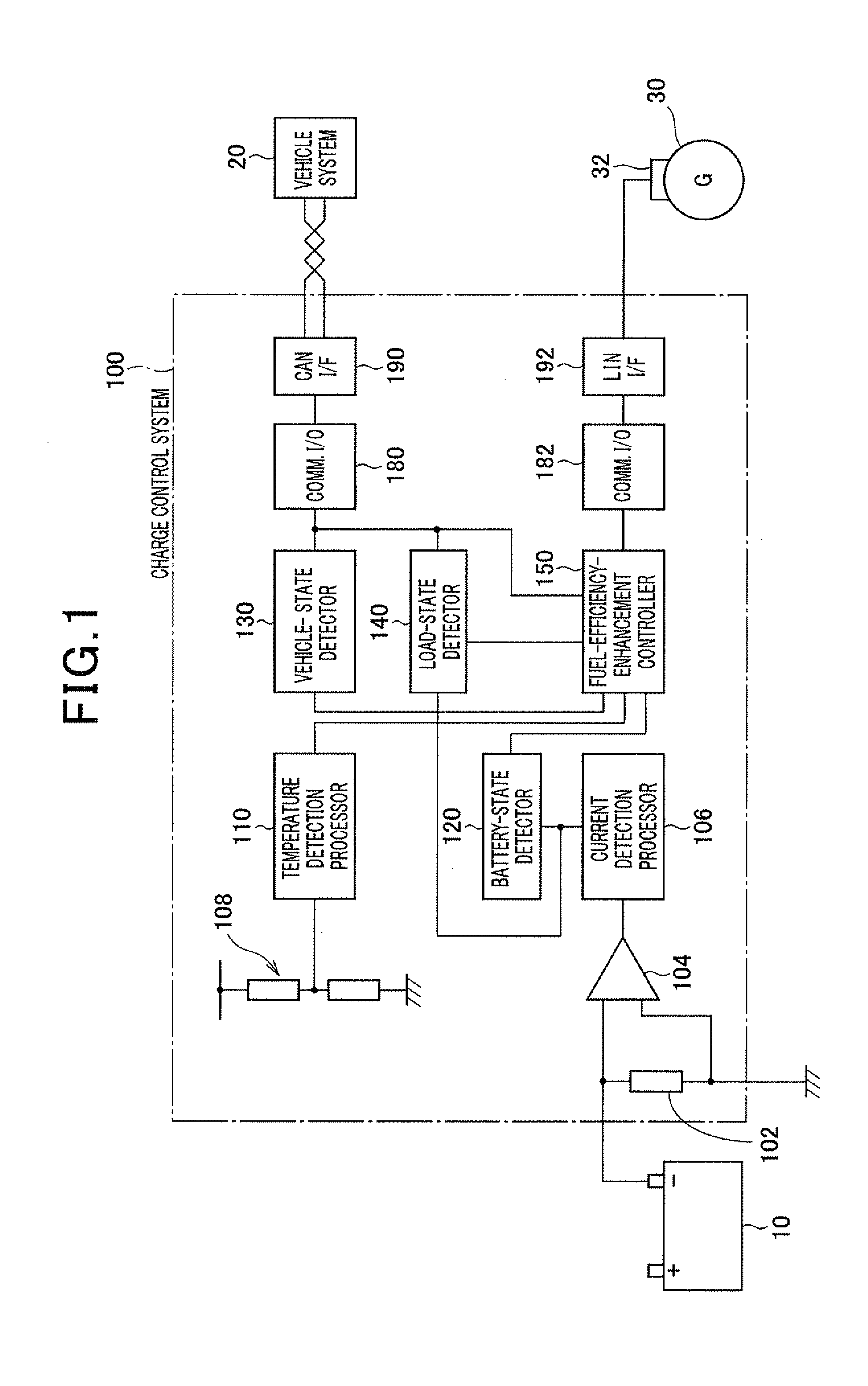

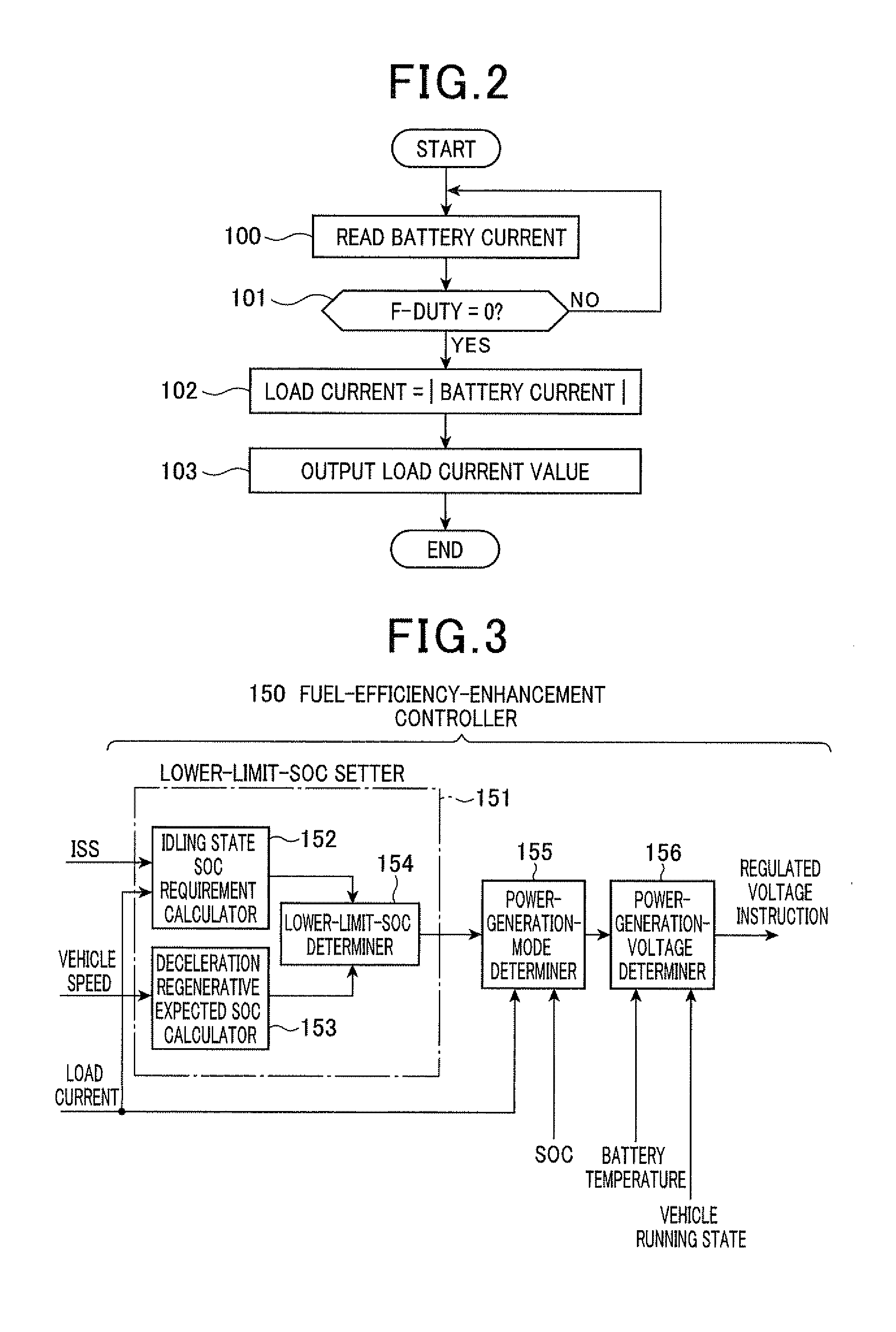

Charge control system

ActiveUS20110215764A1Improve fuel efficiencyEasy to useBatteries circuit arrangementsElectric powerLower limitBattery charge

An in-vehicle charge control system includes a vehicle-state detector that detects a running state of a vehicle, a battery-state detector that detects a charge level of an in-vehicle battery, a fuel-efficiency-enhancement controller that predicts a discharge amount to be discharged by the battery under a discharge condition, sets a lower limit of the battery charge level on the basis of the battery charge level detected by the detector such that the lower limit of the battery charge level is higher than a battery charge level at which the battery begins to degrade by the predicted discharge amount, and controls a power generation amount of a vehicle generator according to the vehicle state detected by the detector. The system with this configuration can maintain the battery charge level and enhance the fuel efficiency simultaneously under practical use conditions.

Owner:DENSO CORP

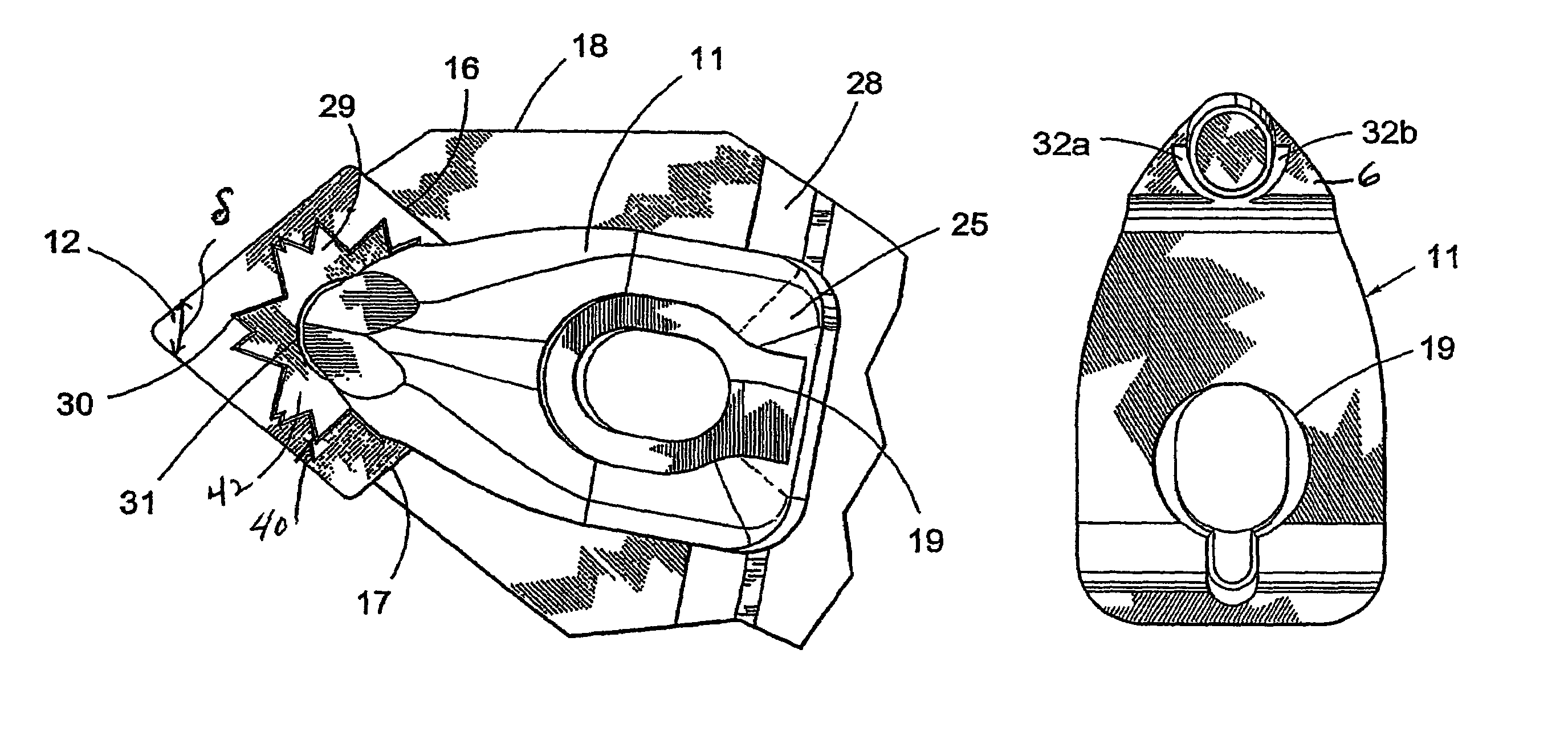

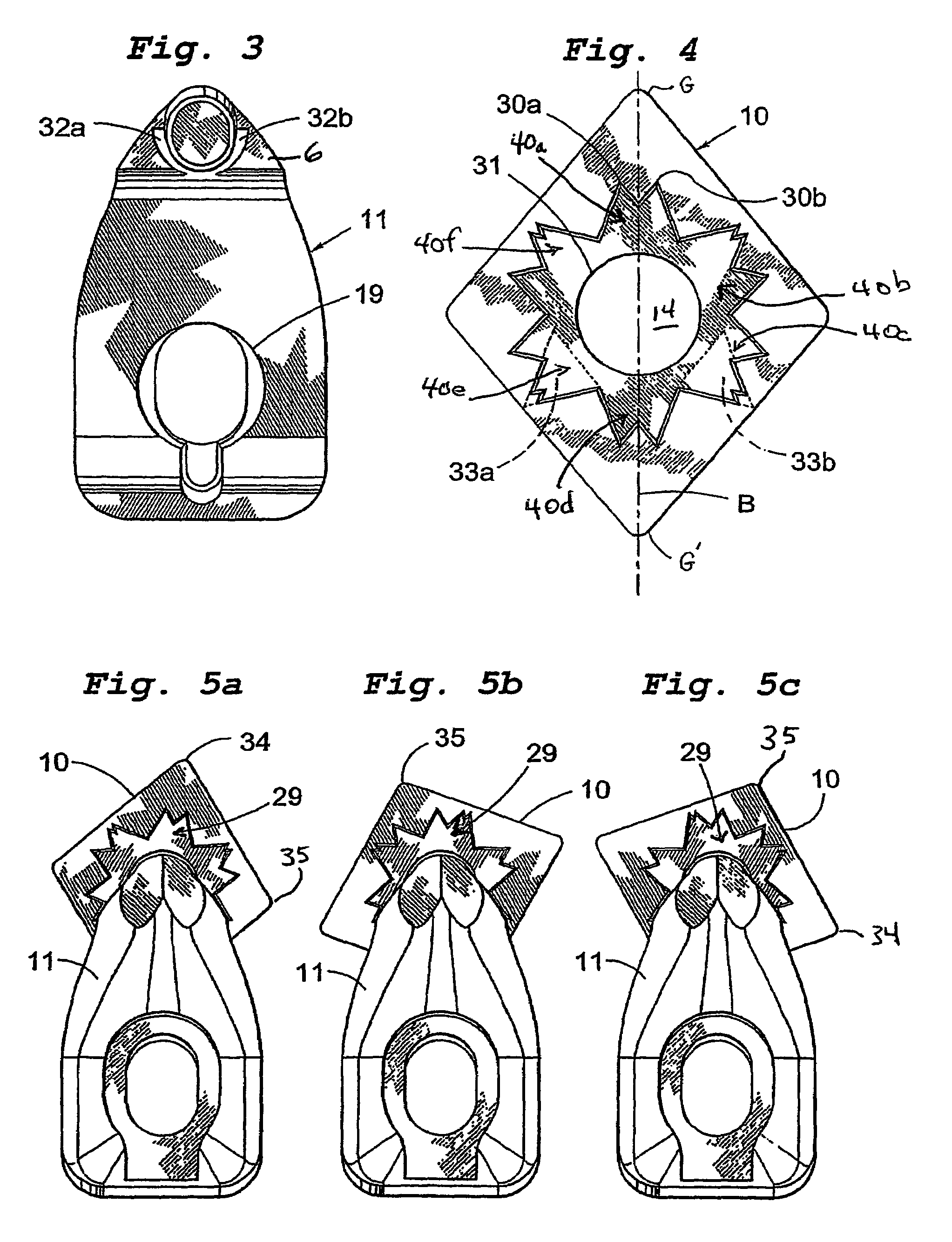

Cutting insert with an array of surfaces receiving clamping forces

A cutting insert includes a body that forms top and bottom surfaces, and a center hole intersecting at least the top surface (e.g., a through-hole). A portion of the top surface which extends around the center hole includes an array of projections radiating laterally outwardly around the center hole. A distal end of each projection disposed farthest from the center hole defines a tip of the projection. The projections form at least six tips spaced circumferentially apart. Each tip has a planar top face. A clamp has flat contact surfaces which press downwardly against the planar top faces of respective projections simultaneously as the clamp pulls the insert against an upstanding support surface.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

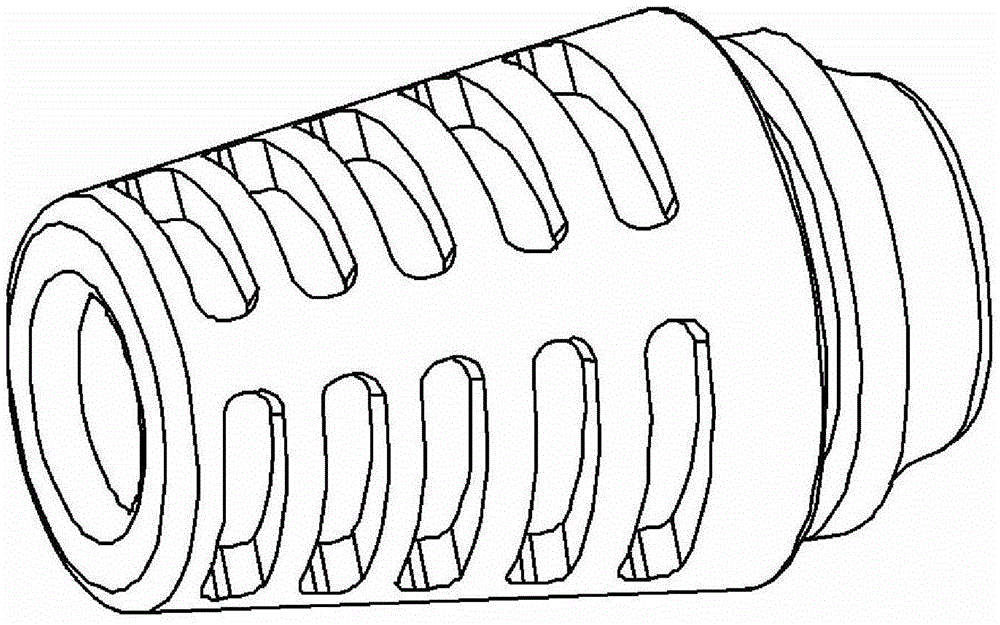

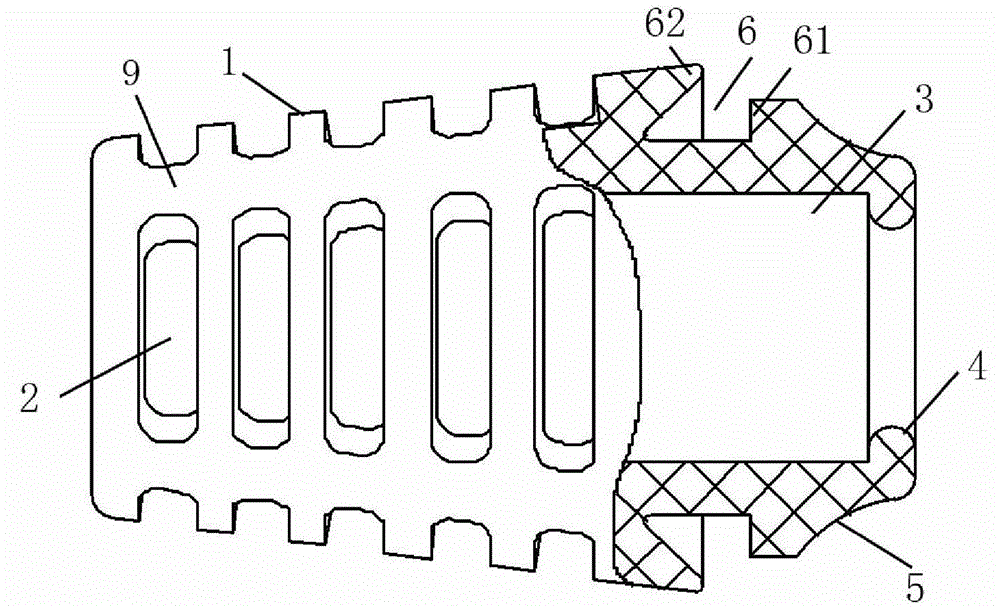

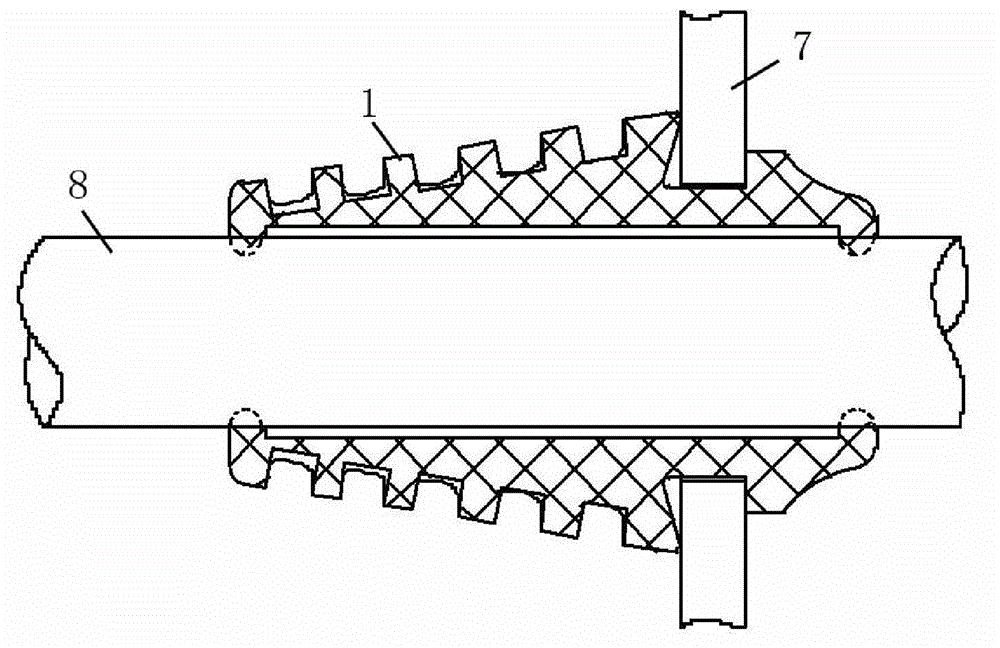

Cable protection sleeve and cable assembly

The invention provides a cable protection sleeve and a cable assembly. The cable protection sleeve includes a threading sleeve body, the periphery of the threading sleeve body is provided with a circular groove, at least one of two groove walls of the circular grove is provided with a sealing skirt edge extending towards the other groove wall opposite to the groove wall and used for pressing against a hole edge of a wire outlet hole, an outer circumferential surface or an inner circumferential surface of the sealing skirt edge is a conical surface used for being pushed by the hole edge of the wire outlet hole and clinging to the hole edge through radial slippage elastic deformation and axial compression elastic deformation so as to seal the wire outlet hole, and the conical surface gradually closes or opens in a direction from front to back. In use, radial and axial deformation of the sealing skirt edge on the groove wall of the circular groove occur when the sealing skirt edge is extruded by the hole edge of the wire outlet hole, and enable the sealing skirt edge to have a very large deformation amount, when deformation of the wall groove of the circular grove occurs due to a swing or bending of a cable, the sealing skirt edge does not completely disengage from the hole edge, thereby ensuring that the sealing skirt edge is capable of clinging to the hole edge at all times, and relatively high sealing waterproofness is achieved.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

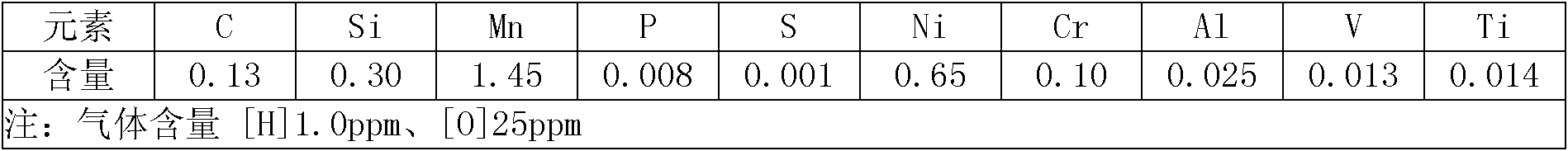

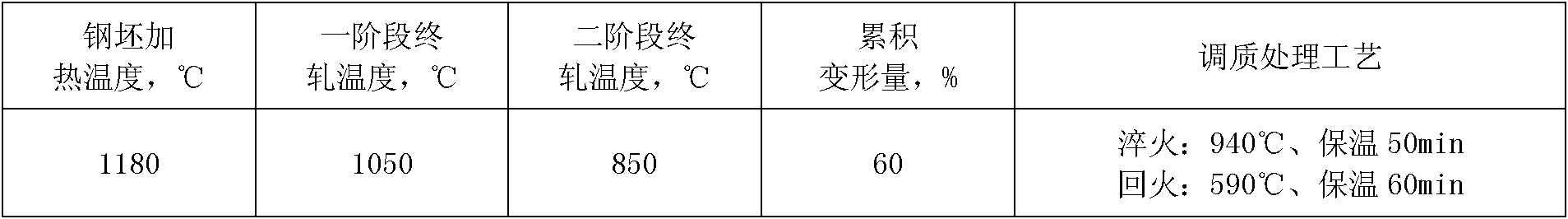

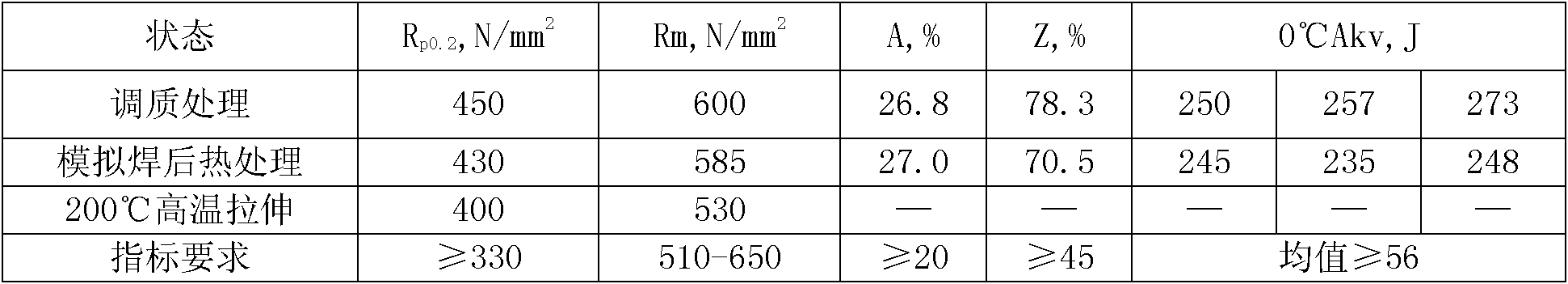

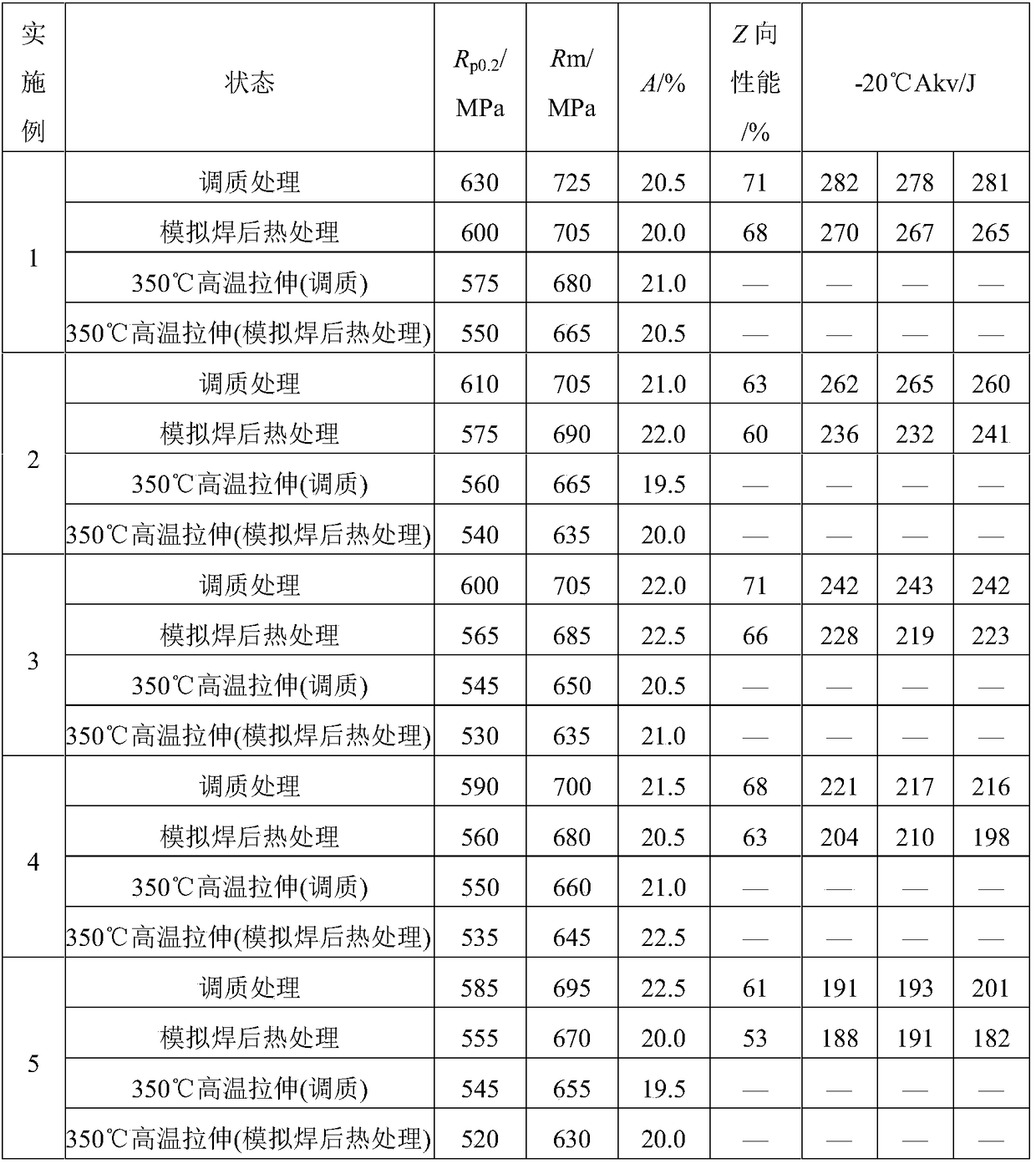

Steel for nuclear power pressure-bearing equipment and manufacturing method thereof

ActiveCN103160732AGood intensity levelLittle decrease in strengthChemical compositionNon-metallic inclusions

The invention discloses steel used for nuclear power pressure-bearing equipment and a manufacturing method thereof. The steel comprises the following chemical components by weight: 0.12%-0.18% of C; 0.15%-0.35% of Si; 1.20%-1.65% of Mn; less than or equal to 0.015% of P; less than or equal to 0.010% of S, 0.50%-0.85% of Ni; less than or equal to 0.15% of Cr; 0.020%-0.050% of Al; less than or equal to 0.02% of V; less than or equal to 0.02% of Ti, and the balance Fe and unavoidable impurities. At the same time, non-metallic inclusions in the steel are controlled, and A, B, C and D impurities are guaranteed less than or equal to grade 1.5. The manufacturing method mainly includes steel smelting, rolling, as well as quenching and tempering treatment. Through further optimization of the chemical components, a heat treatment process, and reduction of gas and non-metallic inclusions in steel, the method enables the mechanical properties of a steel plate to be maintained at a high level under a heat treatment state, a simulated post-weld heat treatment state, and a 200DEG C high temperature state, so that the steel plate completely meets the technical index requirements. Meanwhile, the 0DEG C impact absorption energy is still maintained at a high level, and good matching of steel plate strength and toughness is reflected, so that the steel provided in the invention is completely suitable for nuclear power pressure-bearing equipment.

Owner:ANGANG STEEL CO LTD

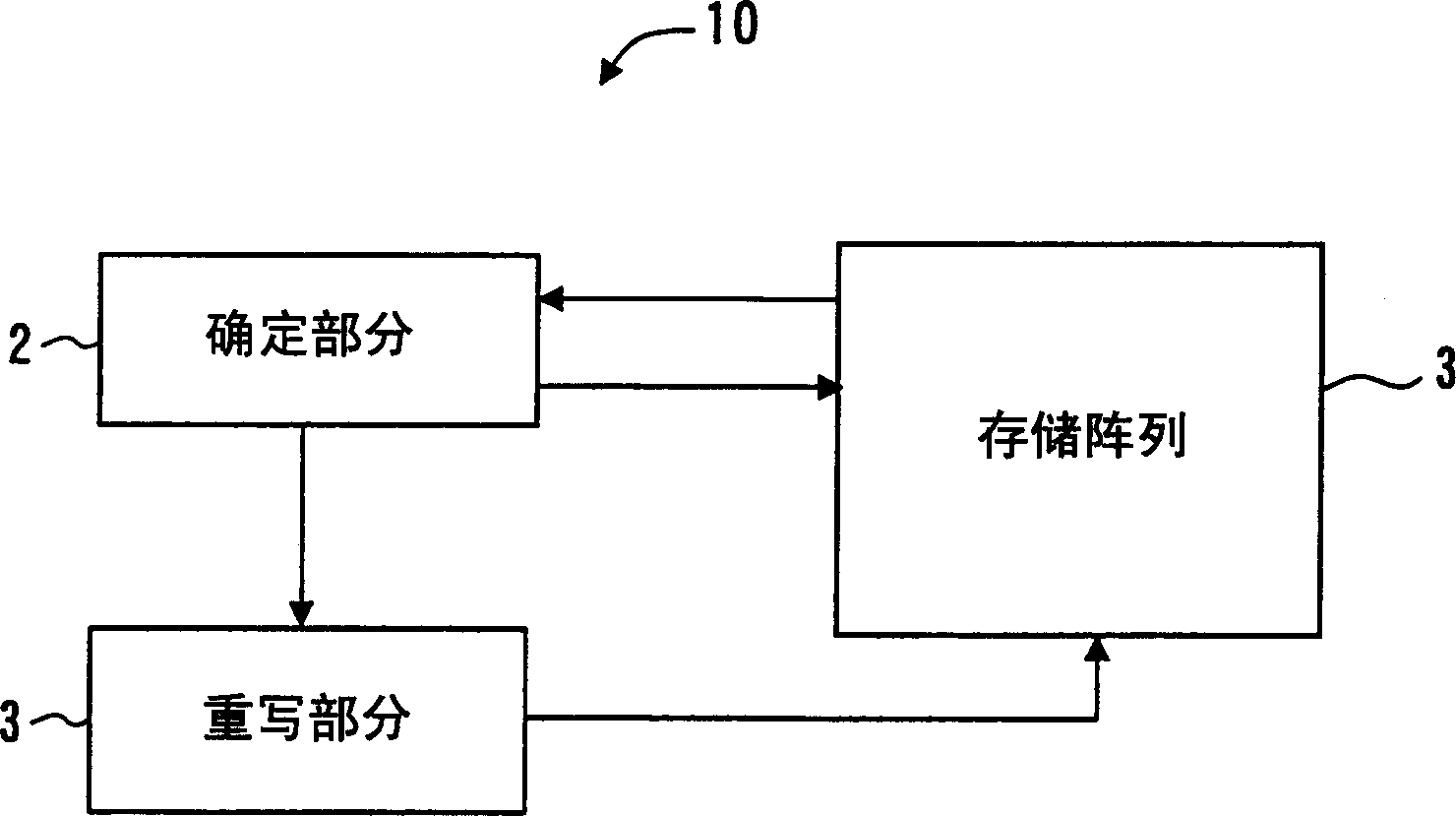

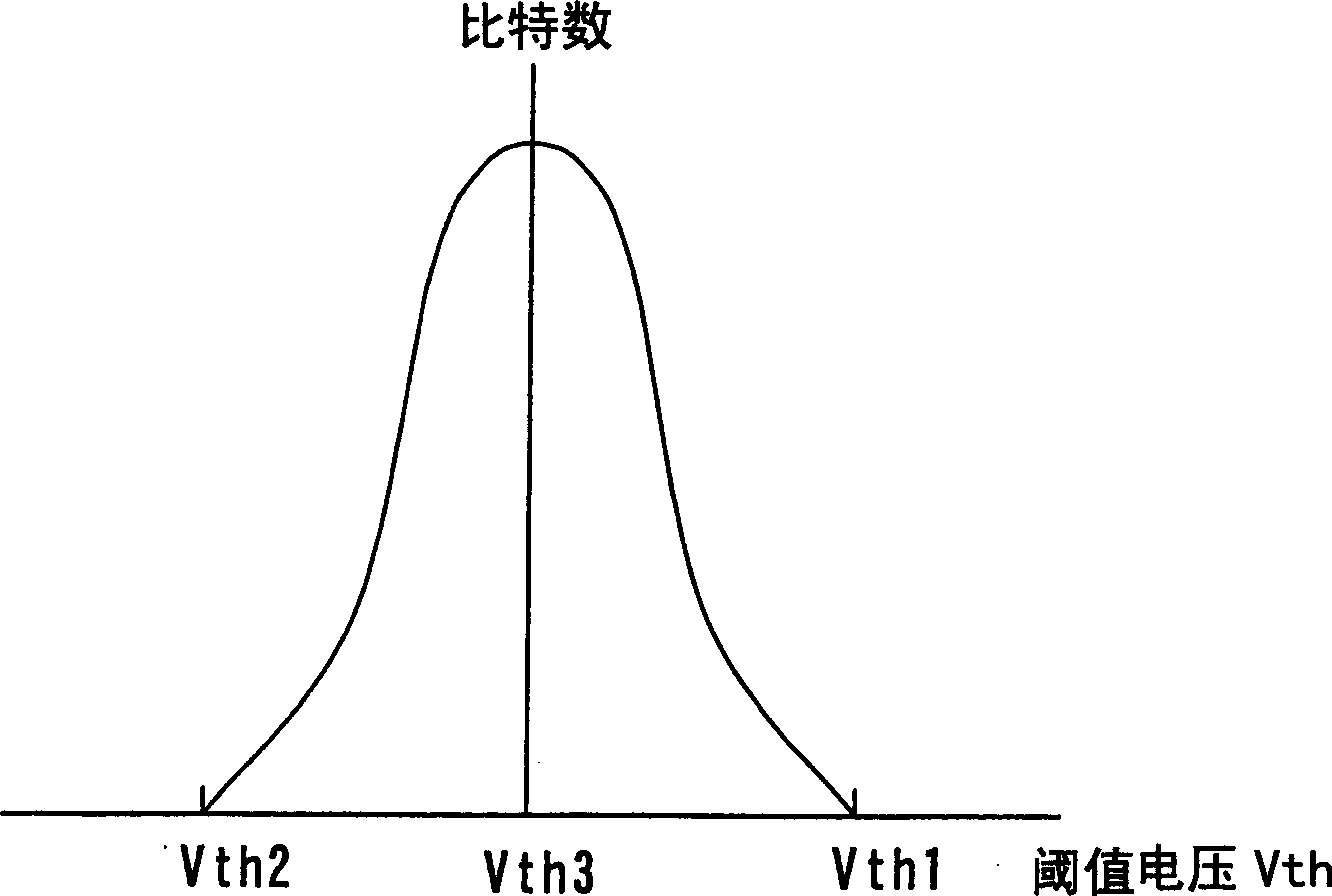

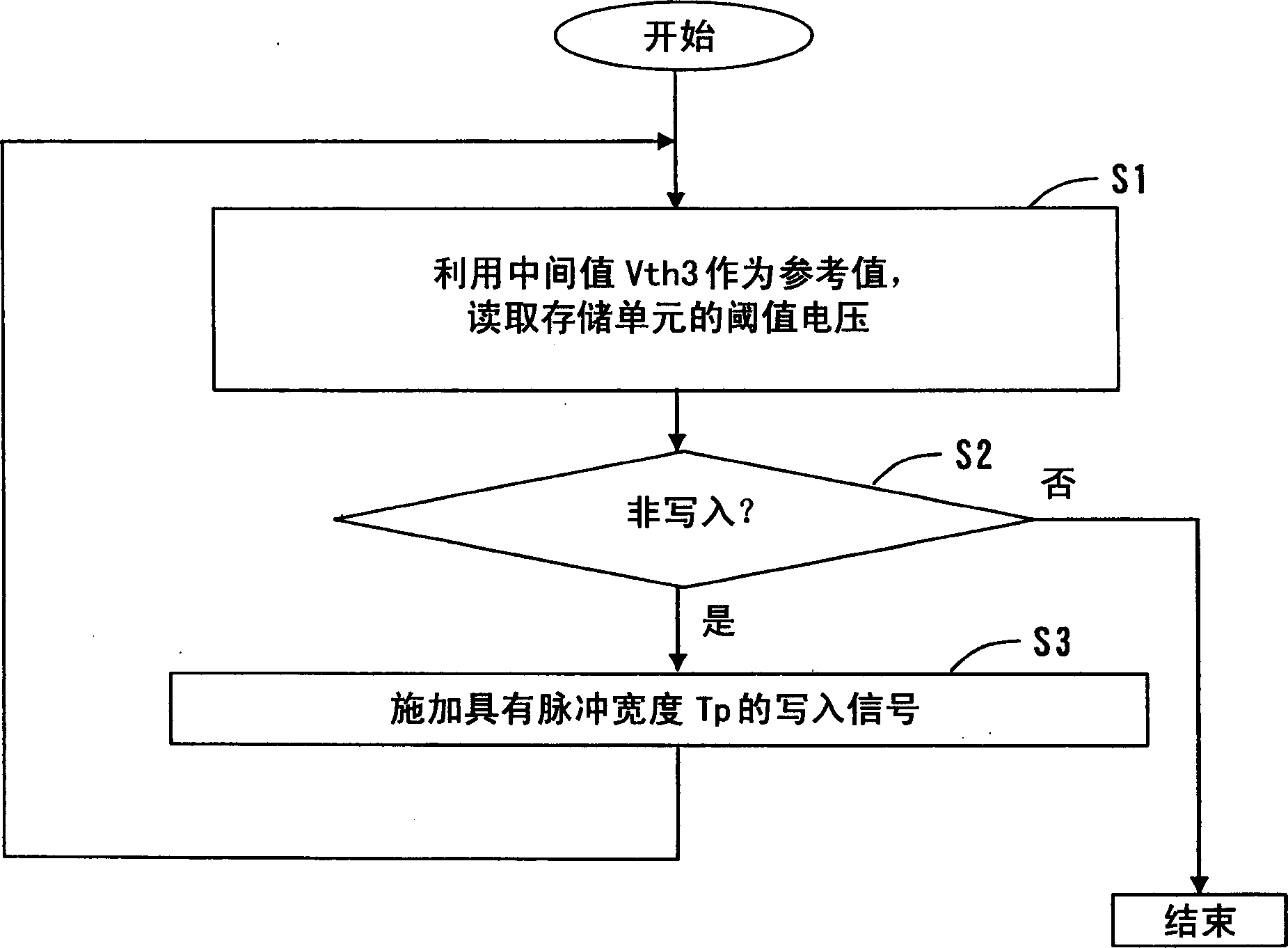

Non-volatile semiconductor memory device and rewriting method

InactiveCN1492446ASave operating timeGood retention propertiesRead-only memoriesDigital storageValue setVoltage range

A non-volatile semiconductor memory device is provided, which comprises a memory array comprising memory cells, in which each memory cell is capable of storing data values depending on the voltages thereof, the data values include a first data value corresponding to a first voltage range and a second data value corresponding to a second voltage range, and the first data is written in a memory cell of the memory cells, a determination section for determining whether a voltage value of the memory cell is higher or lower than a reference value set between a maximum value and a minimum value of the first voltage range, and a rewrite section for rewriting the first data into the memory cell based on a determination result of the determination section so that a margin between the first voltage range and the second voltage range in the memory cell is enlarged.

Owner:SHARP KK

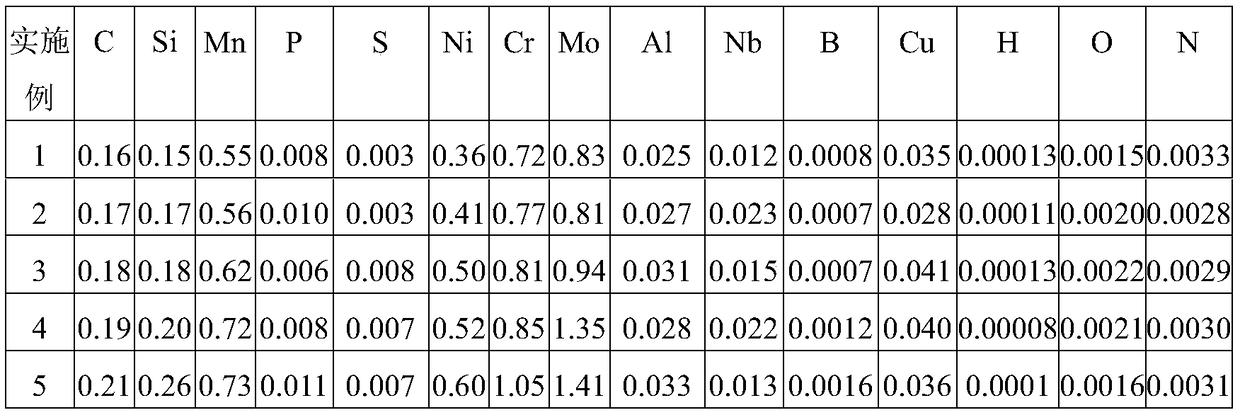

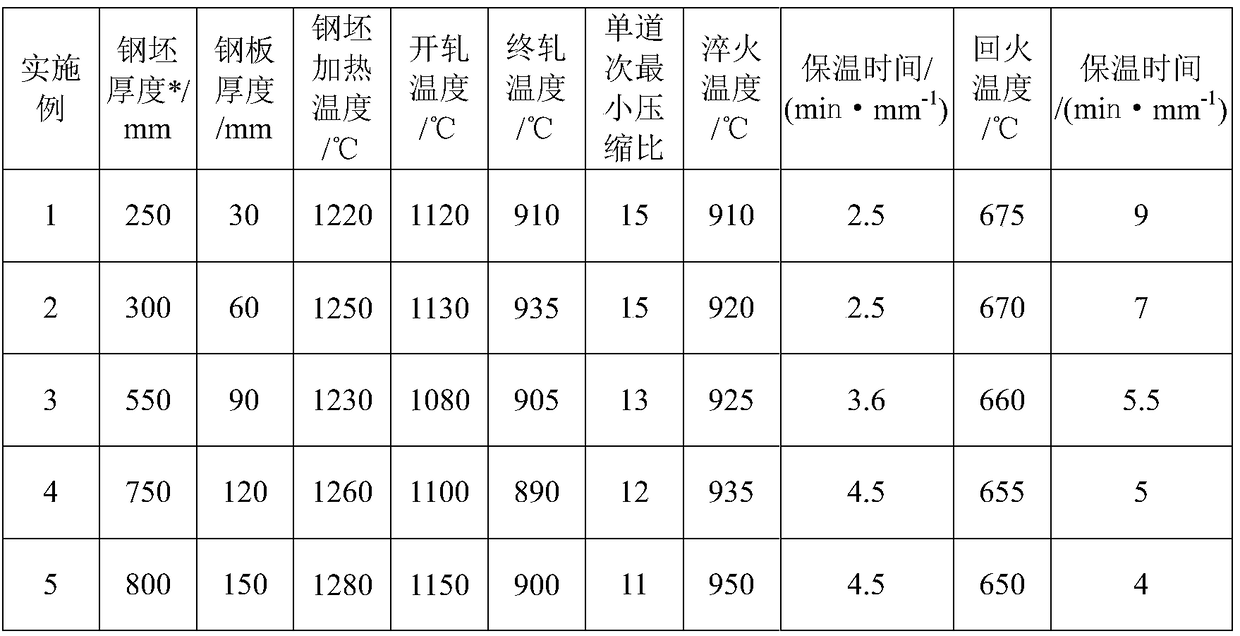

Steel for pressure bearing boundary part of steam generator in nuclear power plant and manufacturing method of steel

The invention discloses steel for a pressure bearing boundary part of a steam generator in a nuclear power plant and a manufacturing method of the steel. The steel comprises 0.15% to 0.22% of C, 0.10%to 0.30% of Si, 0.55% to 0.75% of Mn, less than or equal to 0.015% of P, less than or equal to 0.010% of S, 0.30% to 0.60% of Ni, 0.70% to 1.10% of Cr, 0.80% to 1.50% of Mo, 0.020% to 0.040% of Al, 0.010% to 0.030% of Nb, 0.0005% to 0.002% of B, less than or equal to 0.05% of Cu and the balance of Fe and unavoidable impurities. A converter-continuous casting process is adopted when the thicknessof a steel plate is less than 80mm, wherein the heating temperature is 1180-1250 DEG C, the rolling starting temperature is greater than or equal to 1100 DEG C, and the rolling finishing temperature is greater than or equal to 900 DEG C; an electric furnace-die casting process is adopted when the thickness of the steel plate is greater than or equal to 80mm, wherein the heating temperature is greater than or equal to 1200 DEG C, the rolling starting temperature is greater than or equal to 1050 DEG C, and the rolling finishing temperature is greater than or equal to 850 DEG C; quenching and tempering treatment are performed on the steel plate after rolling; and the produced steel plate of 30-150mm has good high temperature performance and strong strength-toughness matching.

Owner:ANGANG STEEL CO LTD

Rolling method of pipeline steel and stainless steel composite plate

InactiveCN104550234AGuaranteed normal formationGuaranteed mechanical performance indexTemperature control deviceMetal rolling arrangementsComposite plateHigh pressure

The invention discloses a rolling method of pipeline steel and a stainless steel composite plate. The rolling method comprises the step of a heating step, a rolling step, a cold control step, a straightening step and a stack cooling step. According to the rolling method, the rolling process is adjusted and researched, the low-temperature long heat preservation and heating process is adopted, a high-temperature low-speed high-pressure pressing process is adopted at the roughing rolling stage, the uniformity of the tissue of the steel plate before the cold control is guaranteed by controlling the thickness of an intermediate blank and controlling the finish rolling starting temperature, final rolling temperature, the pressing rate in the step before the final rolling and the like at the finish rolling stage, the particle size is relatively small, and the formation of the final steel plate needle-shaped ferritic structure is guaranteed by adopting a given cooling speed and controlling the start cooling temperature and the return red temperature by virtue of the cooling control process, so that the indexes of mechanical properties of the steel plate can be guaranteed.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

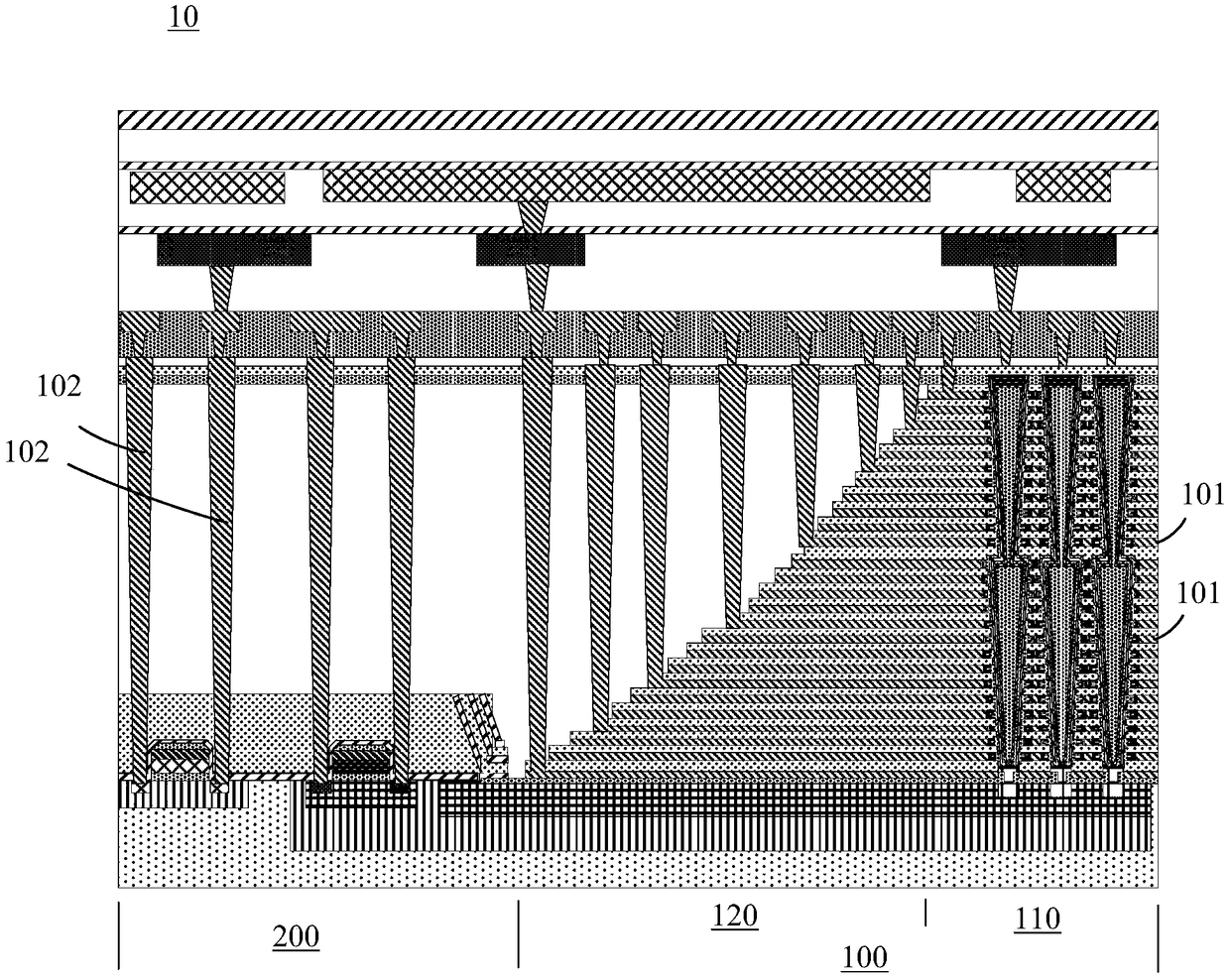

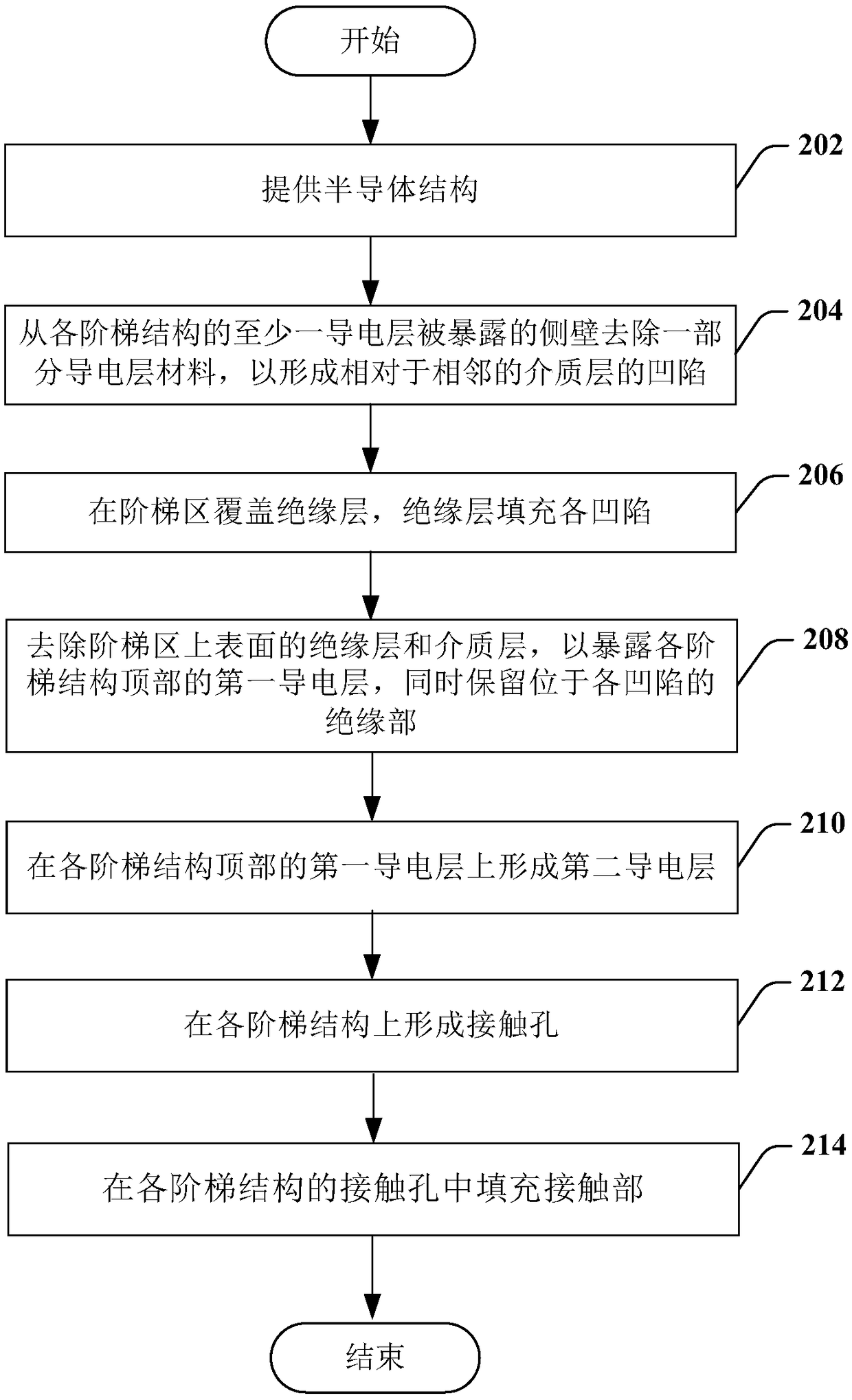

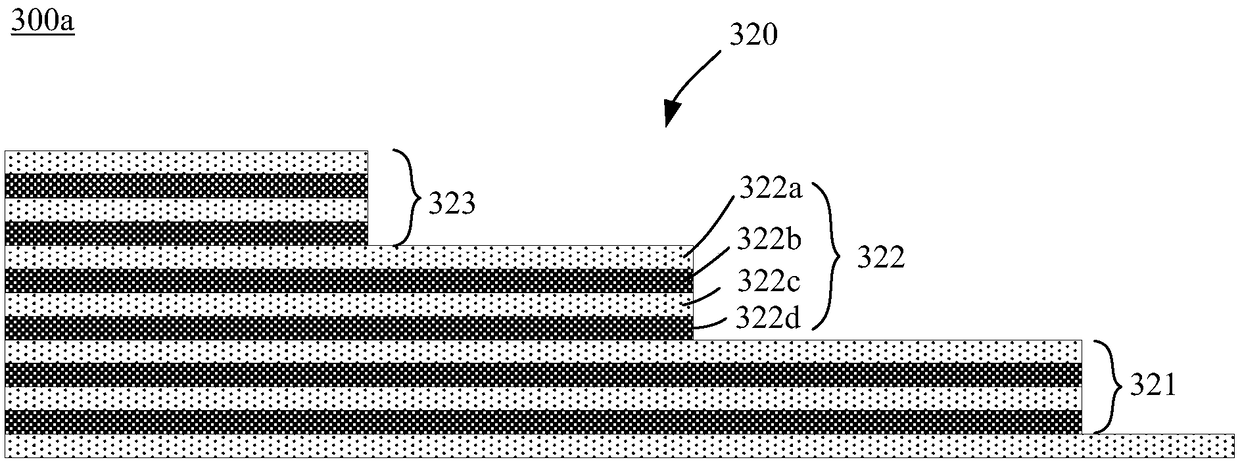

Three-dimensional storage device and method for forming contact hole in step region

PendingCN108899322AReduce the probability of etch punch-throughLarge marginSolid-state devicesSemiconductor devicesEtchingInsulation layer

The invention provides a method for forming a contact hole in a step region of a three-dimensional storage device. The method comprises the following steps of providing a semiconductor structure, wherein the semiconductor structure has a step region, the step region has a plurality of step structures, and each step structure comprises at least one medium layer and at least one conducting layer inalternate stacking from top to bottom; removing a part of conducting layer material from the exposed side wall of at least one conducting layer of each step structure so as to form recessed parts opposite to the adjacent medium layers; covering an insulation layer in the step region; filling each recessed part by the insulation layer; removing the medium layer and the insulation layer on the uppersurface of the step region so as to expose the first conducting layer on the top of each step structure; meanwhile, remaining the insulation layer positioned at each recessed part; forming a second conducting layer on the first conducting layer on the top of each step layer; forming the contact hole on each step structure. The thickness of the conducting layer on the step region is increased, sothat greater allowance can be provided for the etching of the contact hole, so that the contact hole etching penetration probability is reduced.

Owner:YANGTZE MEMORY TECH CO LTD

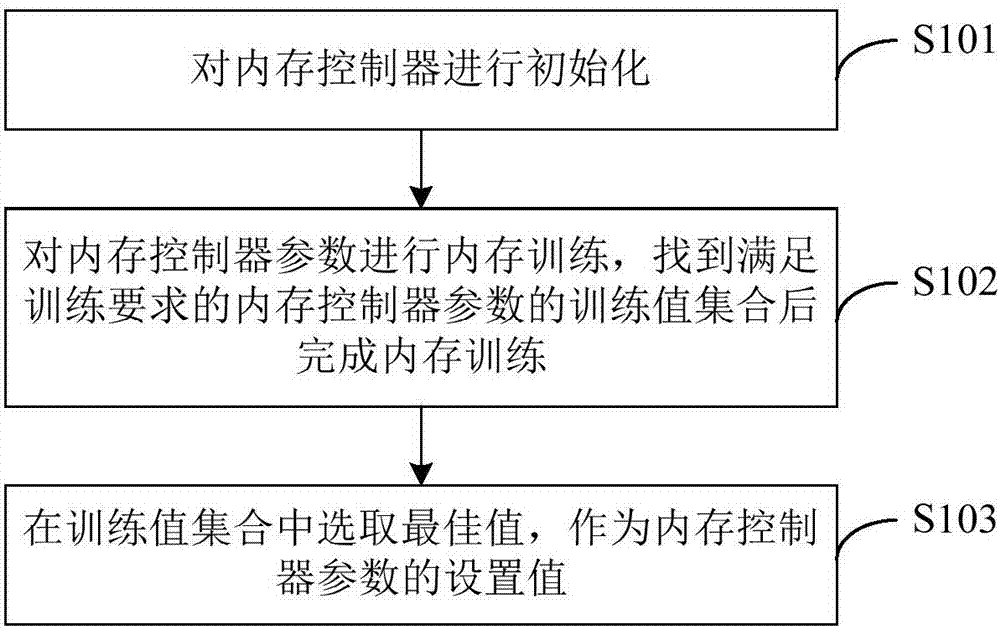

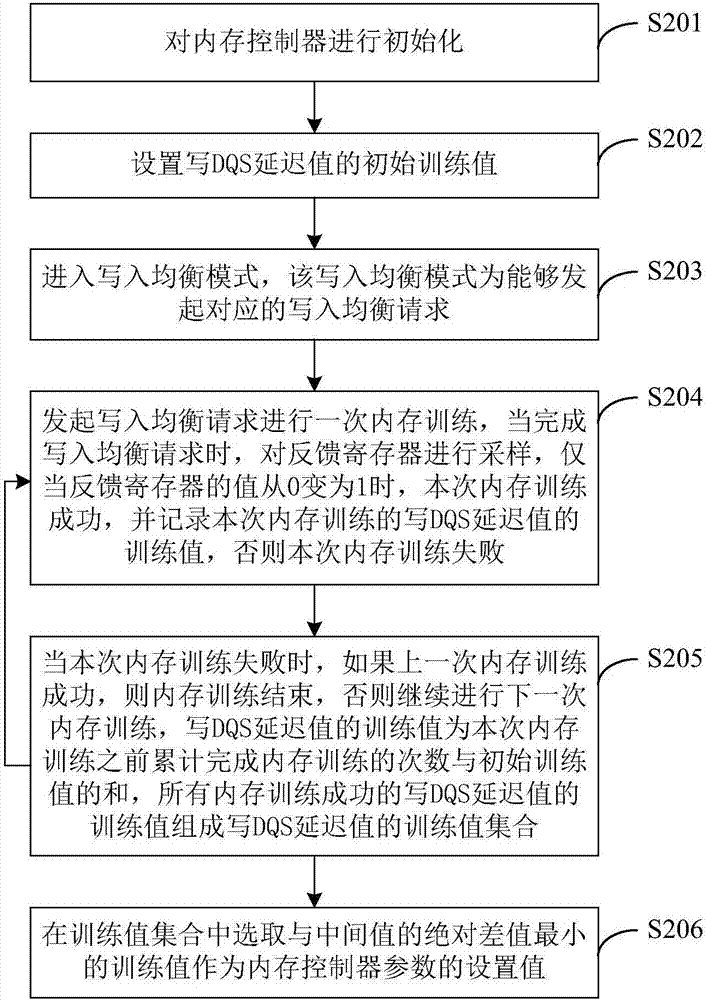

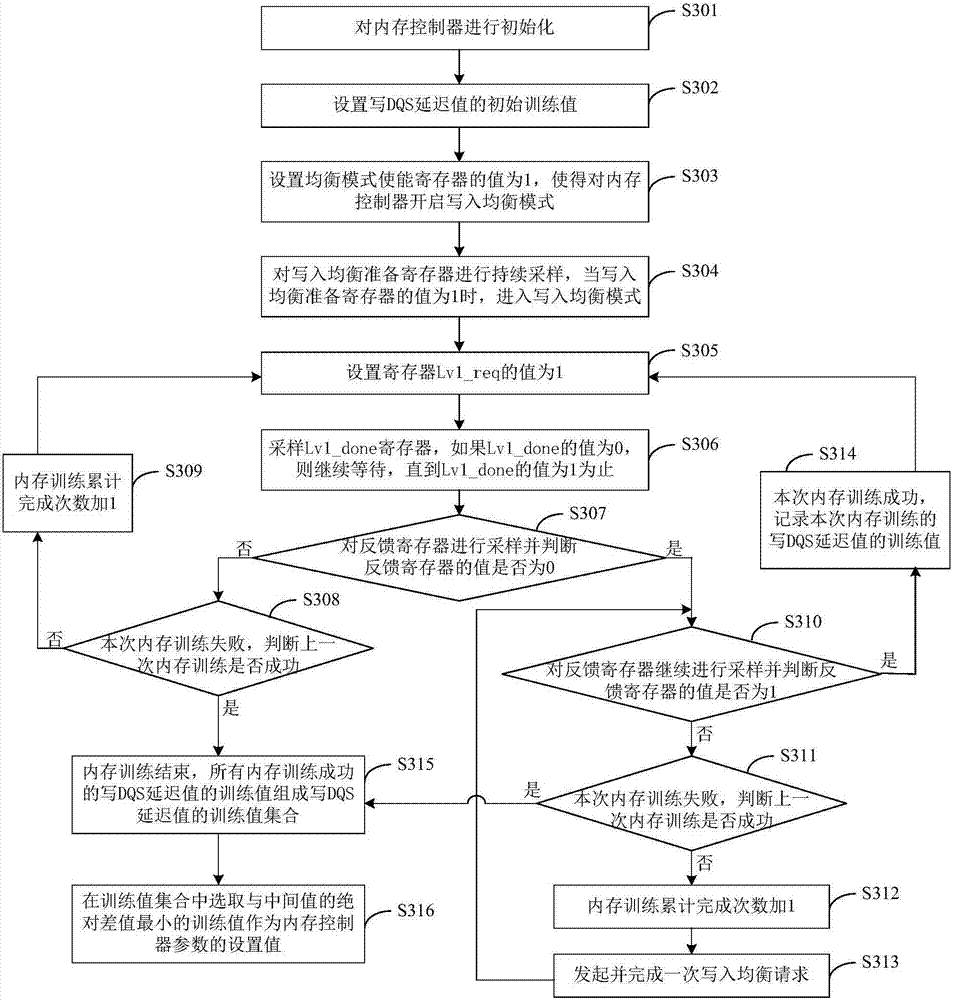

Memory training method and device

ActiveCN107393578ALarge marginMeet memory compatibilityDigital storageElectric digital data processingValue setSimulation

The invention is applied to the technical field of a chip, provides a memory training method and a memory training device and aims to solve the problem in the prior art that an over-measure of a training value which satisfies a training requirement and is obtained through memory training is small and cannot meet the demand of batch production. The method comprises the steps of initializing a memory controller; carrying out memory training on a memory controller parameter, and completing the memory training after finding out a training value set, which satisfies the training requirement, of the memory controller parameter; selecting an optimum value from the training value set as a set value of the memory controller parameter. Through the technical scheme, the training value set, which satisfies the training requirement, of the memory controller parameter is found, and one optimum value is selected from the training value set as the set value of the memory controller parameter, thereby guaranteeing the maximum over-measure of the memory controller parameter so as to satisfy the demand of memory compatibility of different brands, and realizing batch production.

Owner:CHINA GREATWALL TECH GRP CO LTD

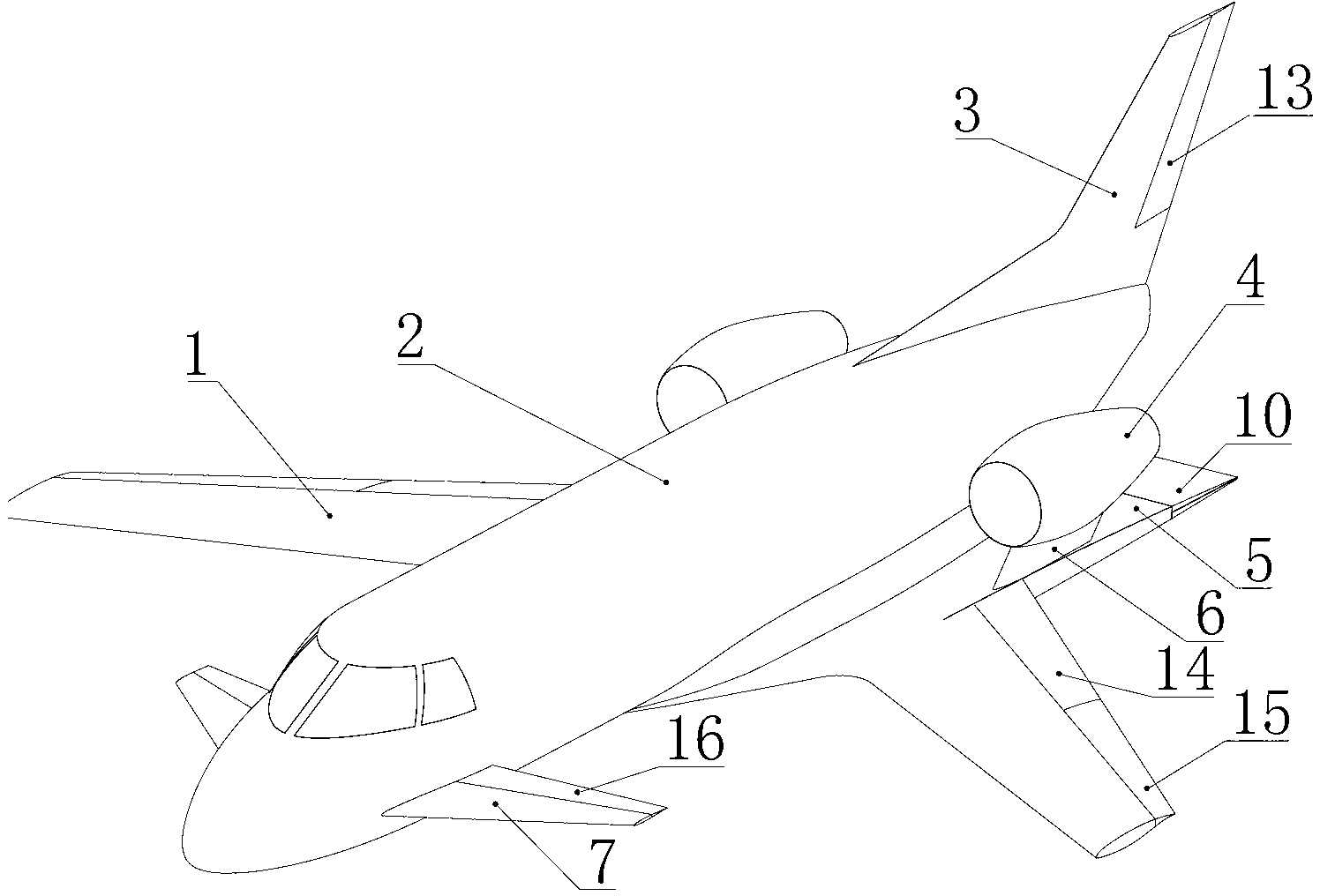

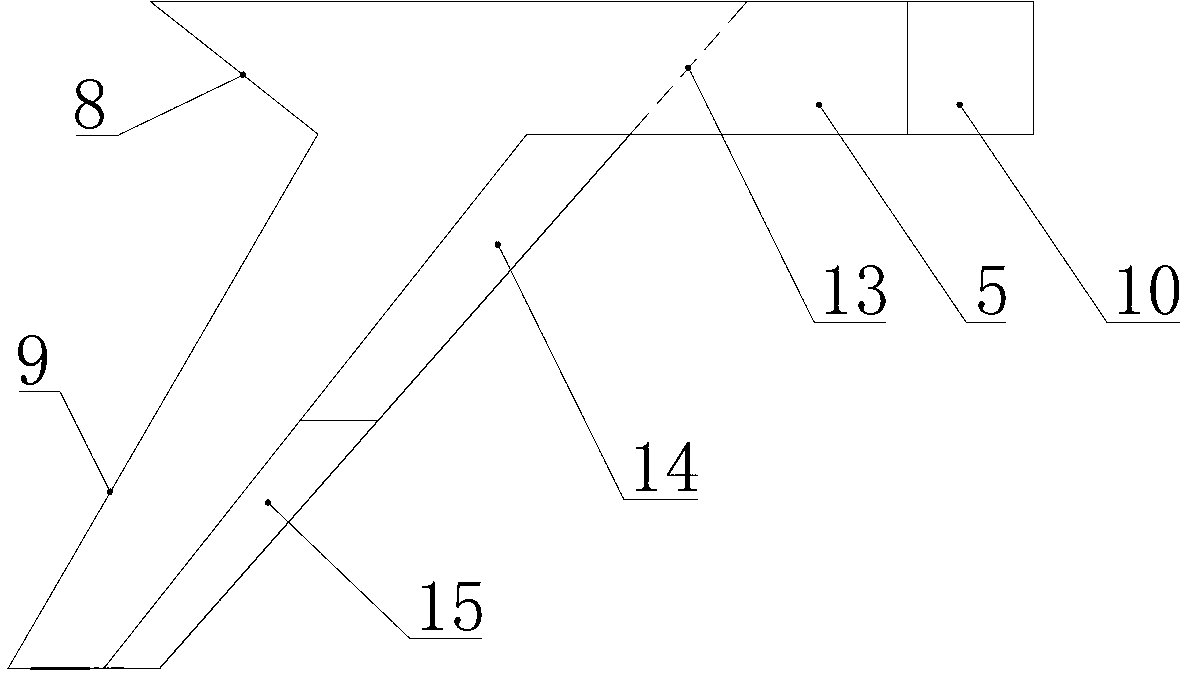

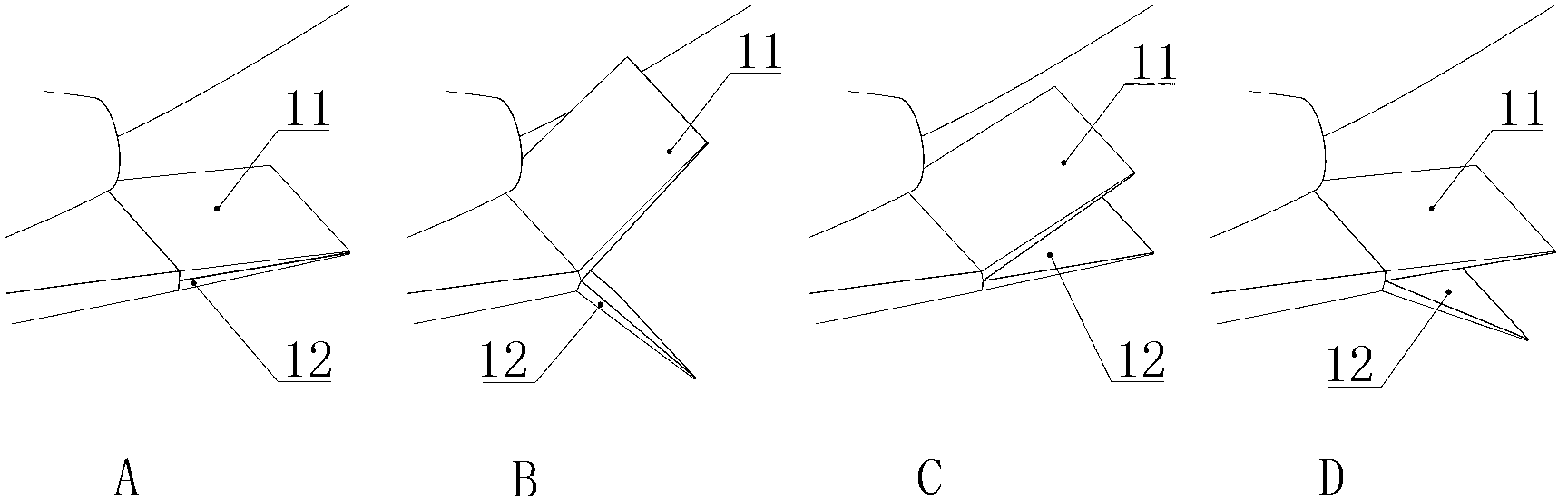

Corporate aircraft engine upper placement and front swept wing duck type layout

InactiveCN103231795AReduce stallGuaranteed control efficiencyHeat reducing structuresJet aeroplaneAviation

The invention provides a corporate aircraft engine upper placement and front swept wing duck type layout, which belongs to the aviation field, and relates to a high lift drag ratio airplane total layout scheme. The airplane comprises a fuselage, duck wings, wings, a vertical fin, an engine and a rear body edge strip; the wing leading edge inner segment sweeps back; the wing leading edge outer segment sweeps forward, and the engine is supported on an upper surface of a rear body edge strip between a wing trailing edge and an edge strip rudder by an engine, and in the top view projection, an engine axis crosses the corner of the wing leading edge inner segment and the wing leading edge outer segment, and an elevator is arranged at the wing trailing edge, and an inner side elevating auxiliary wing is arranged at the inner side of the wing trailing edge inner side, and an outside elevating auxiliary wing is arranged at the outer side of the wing trailing edge; an edge strip rudder is arranged at the rear edge of the rear body edge strip, and a rudder is arranged at the rear edge of the vertical fin. The wing trailing edge inner segment is connected with a rear body edge strip; the edge strip rudder at the rear body edge strip trailing edge is in cracking type, and is composed of an upper rudder surface and a lower rudder surface, and the shapes of the fuselage and the wing are in smooth transition. The invention has the advantages of high rising and landing lift coefficient and high trim lift drag ratio, light structure weight, long endurance and long voyage.

Owner:AVIC CHENGDU AIRCRAFT DESIGN & RES INST

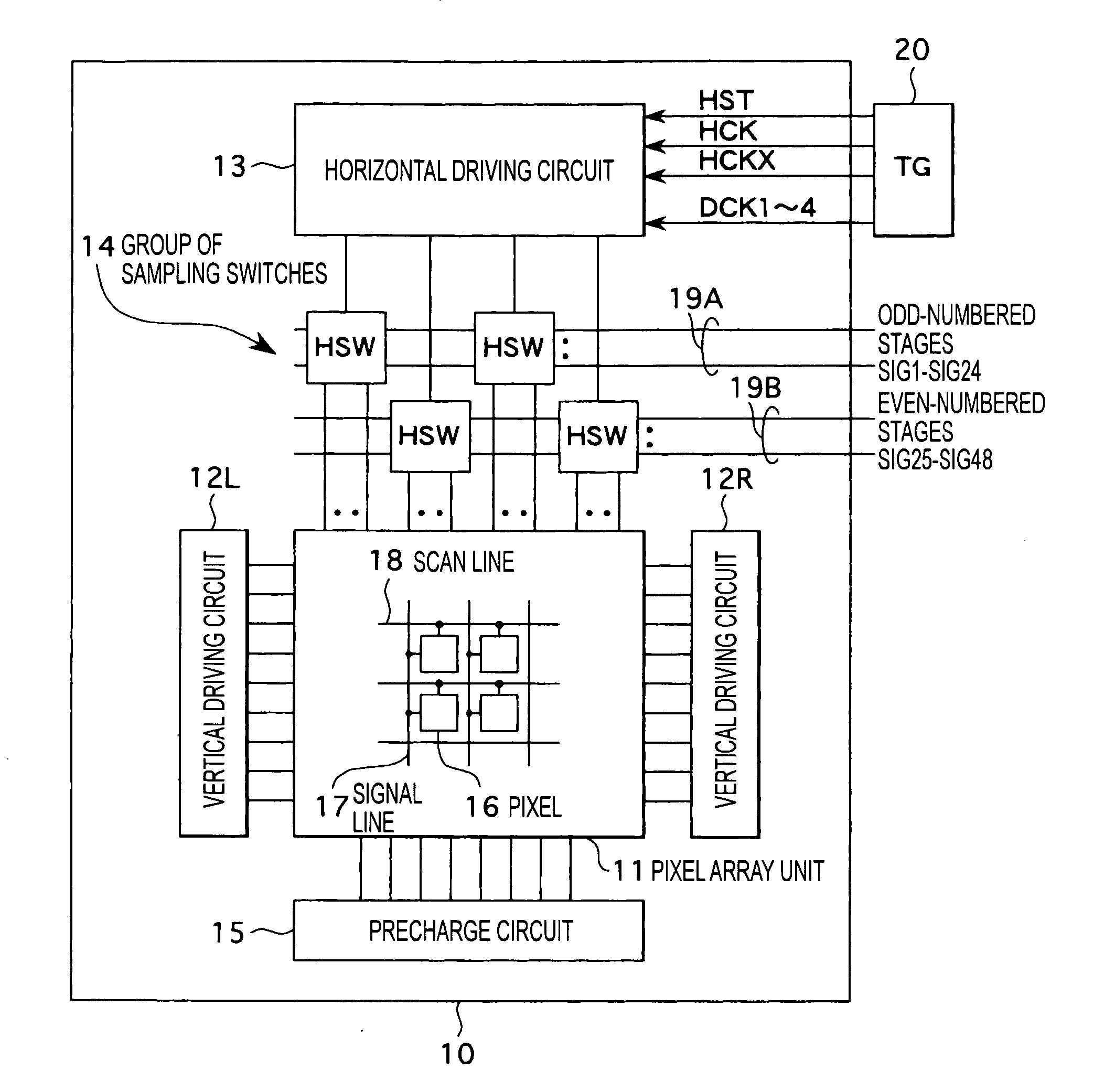

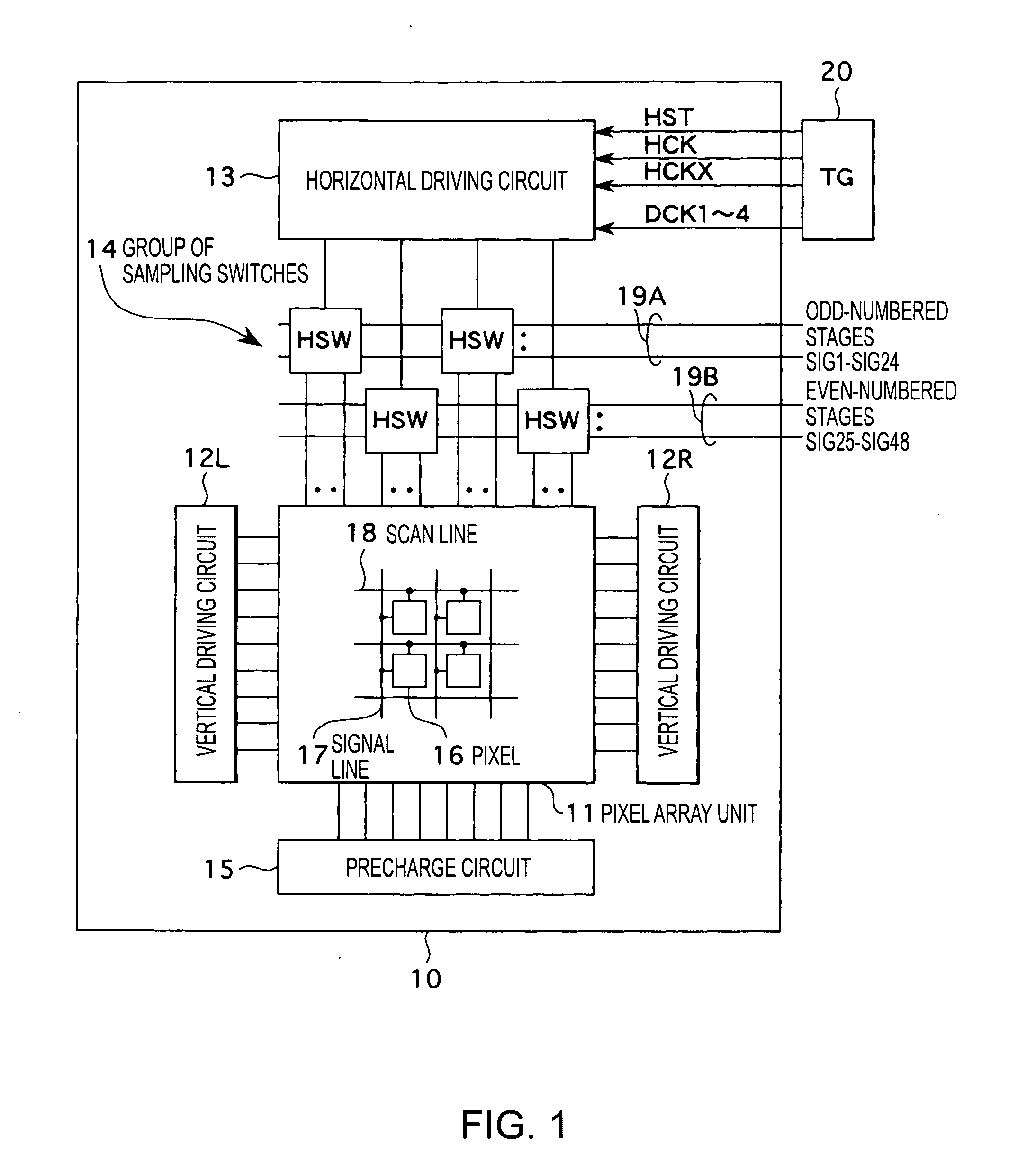

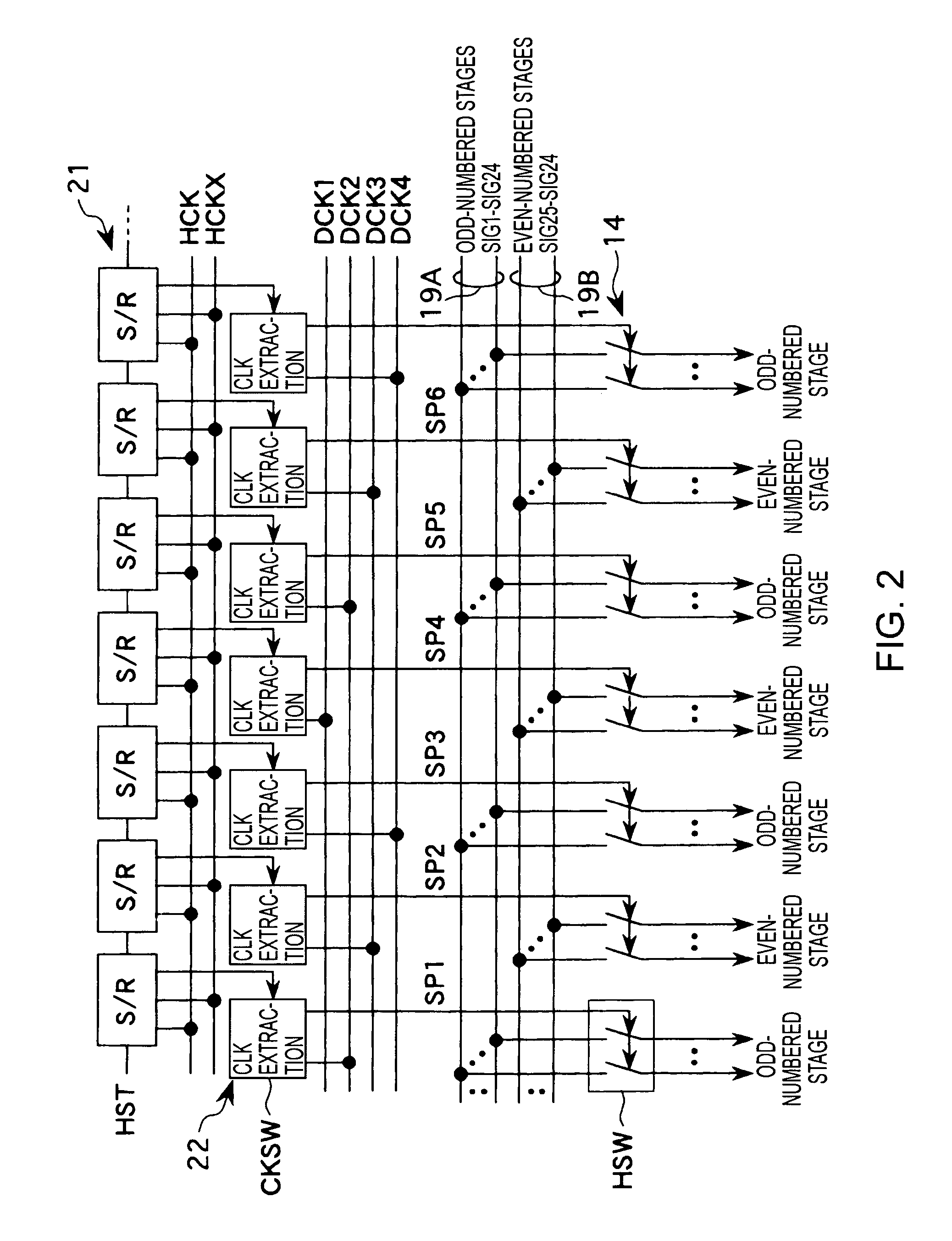

Display device and drive method thereof

InactiveUS20060232543A1Improve image qualityLarge marginStatic indicating devicesNon-linear opticsRoundingScan line

A display apparatus and a method for driving the display apparatus that are capable of suppressing image quality degradation resulting from delay in sampling pulses or from waveform rounding thereof and image quality degradation caused by coupling between the signal line and the common line and that between the signal line and the scan line even when the simultaneous sampling number is increased. The start pulse HST has a pulse width that includes a plurality of pulse widths of the clock pulses HCK and HCKX, for example, two pulse widths. The clock pulses DCK have four phases. Large margins α1 and α2 in the phase relationship between each of the clock pulses DCK1 to DCK4 and each of transfer pulses used for extracting the clock pulses DCK1 to DCK4 are assured. As a result, even if delay or waveform rounding occurs in the clock pulses DCK1 to DCK4, sampling pulses SP1 to SP6 with a constant pulse width equal to that of each of the clock pulses DCK1 to DCK4 can be generated without being affected by the delay or waveform rounding.

Owner:SONY CORP

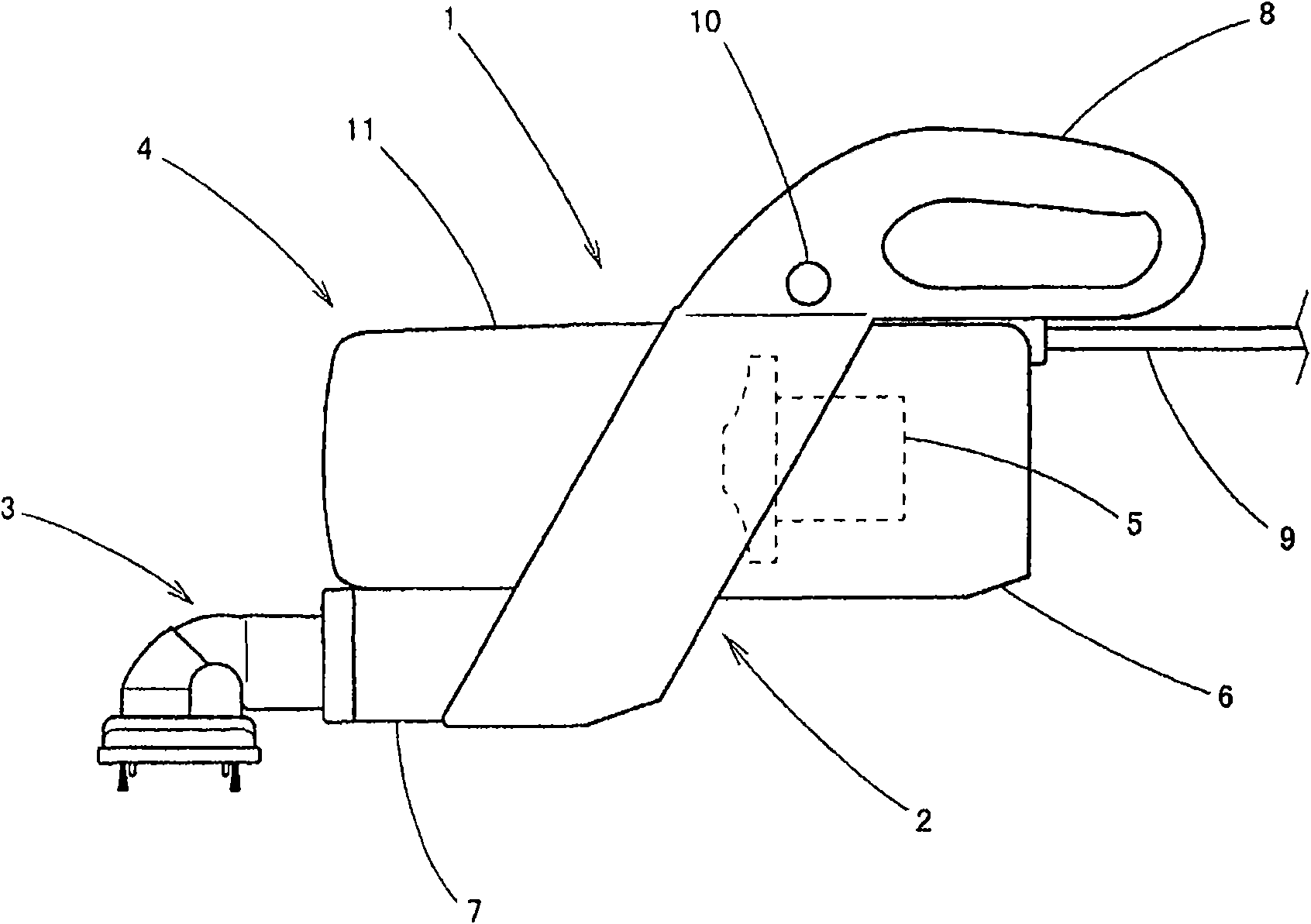

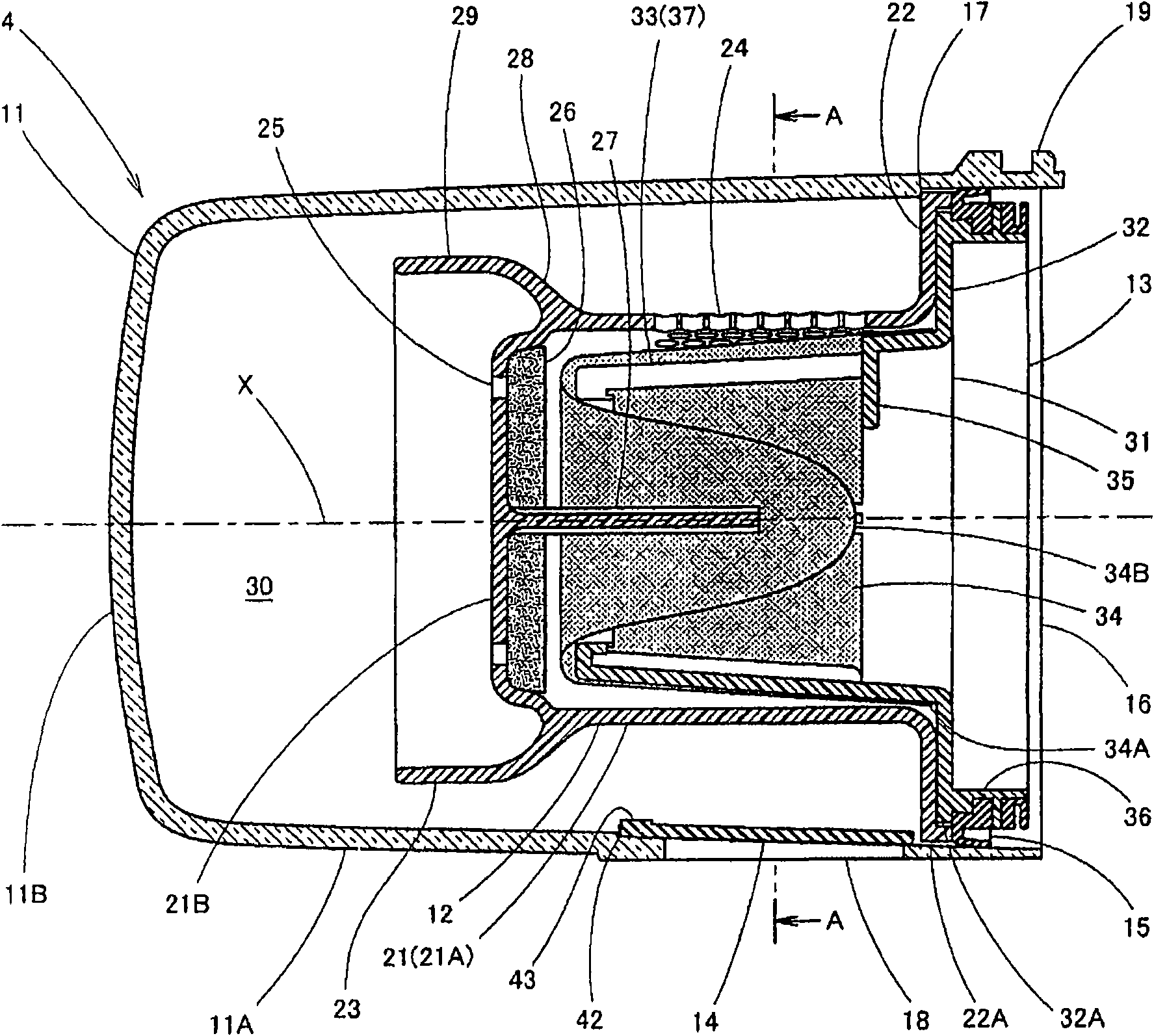

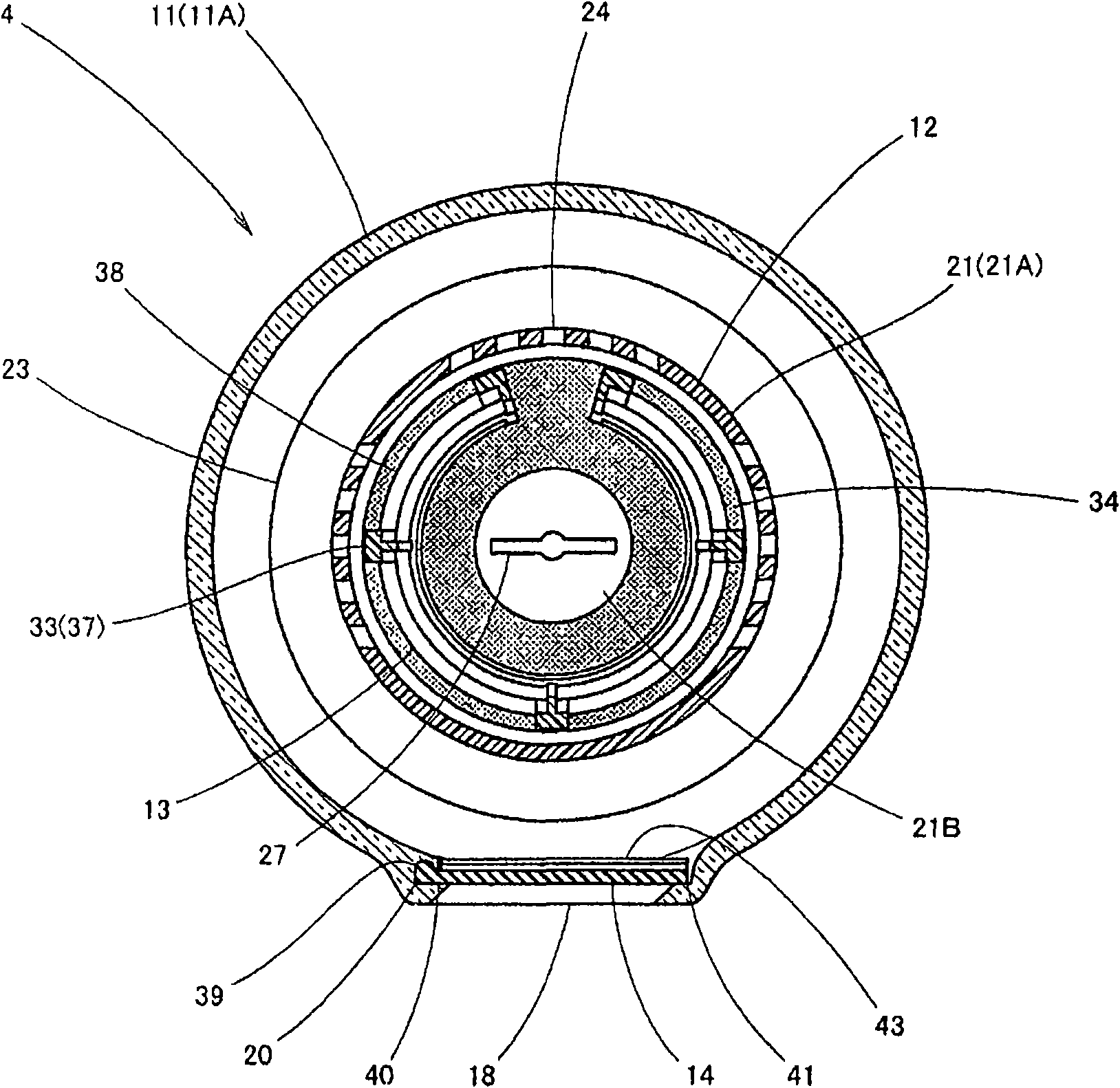

Whirlwind dusting machine

InactiveCN101584566AImprove handlingReduce the likelihood of fallingSuction filtersEngineeringWhirlwind

The invention provides a whirlwind dusting machine capable of easily demounting a tubular body to easily abandon dust. The tubular body (12) with a dust collection container (11) is installed with free dismounting relative to the dust collection container (11) and is provided with small holes (24), (25) playing the role of a primary filter and a secondary filter body (13) is installed at the downriver side of the tubular body with free dismounting and is provided with a baggy secondary filter (34) so that a dust collection member (4) is installed with free dismounting relative to the dusting machine body (2) internally provided with an electronic ventilating blower (5); moreover, a protuberance (27) in projecting manner extended to the side of the second filter (34) is installed at the central part of the tubular body (12), so the tubular body (12) can be held easily by grasping the protuberance (27) when the tubular body (12) is dismounted relative to the dust collection container (11); thereof, the possibility that the protuberance (27) drops off can be reduced.

Owner:TWINBIRD CORP

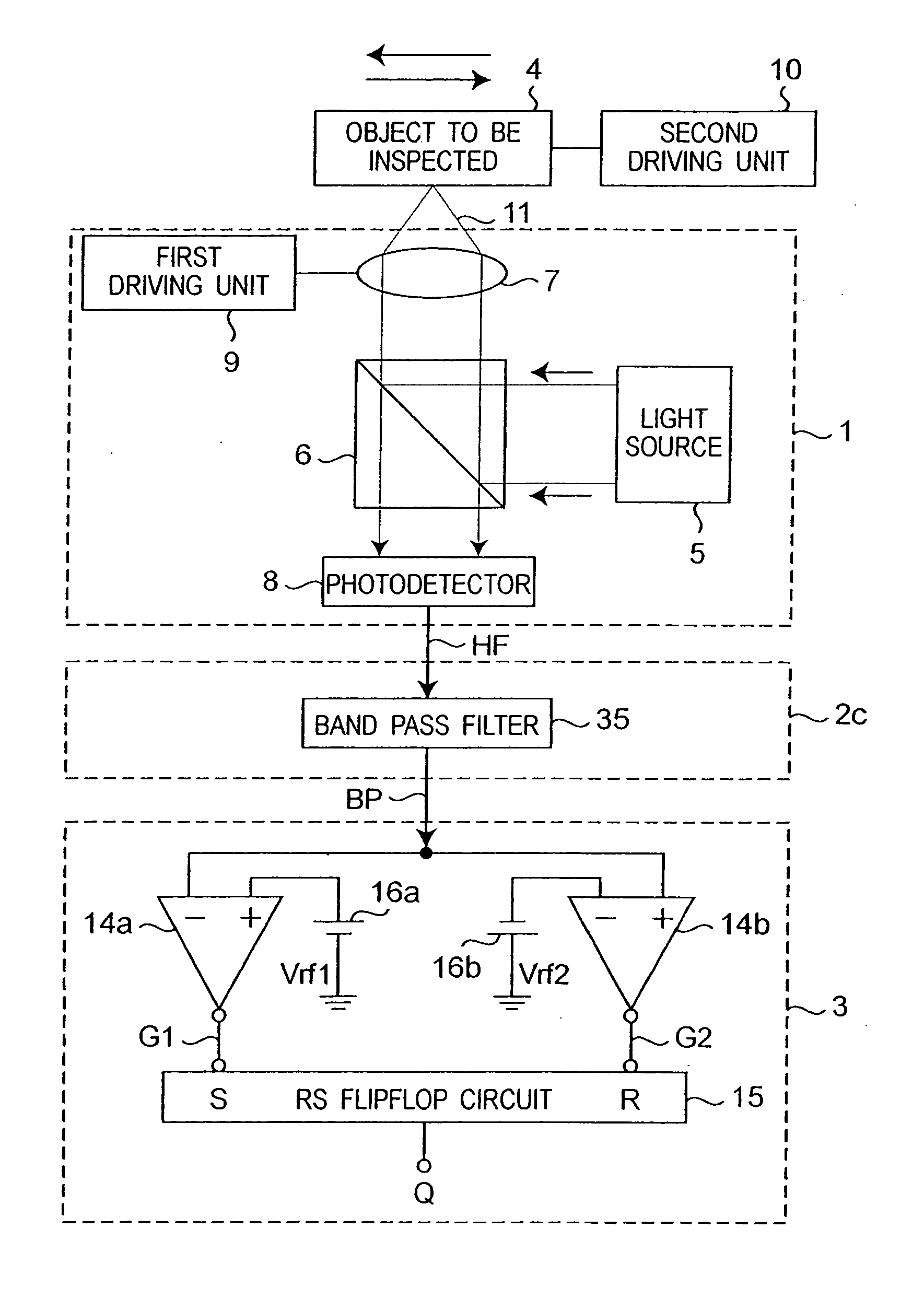

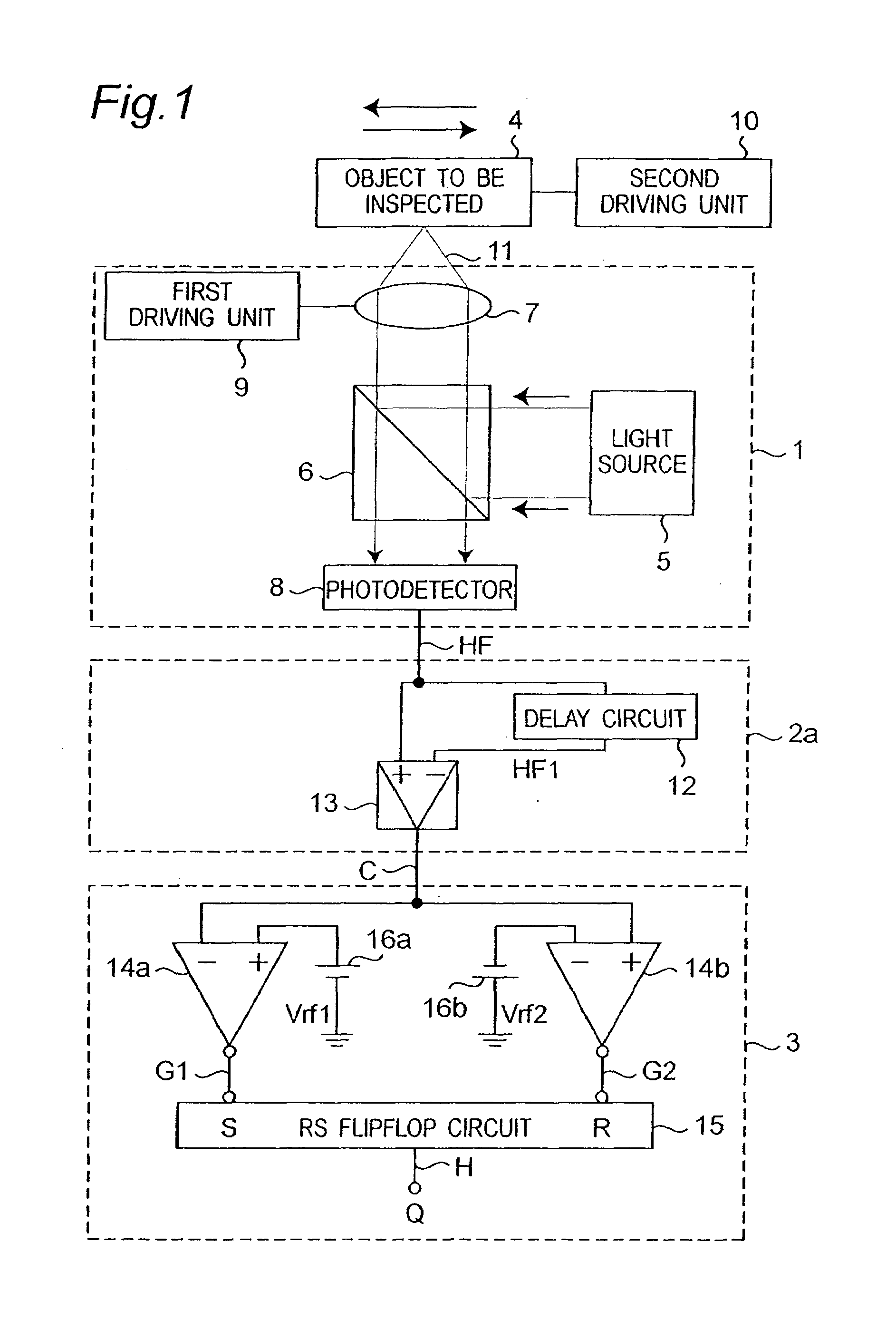

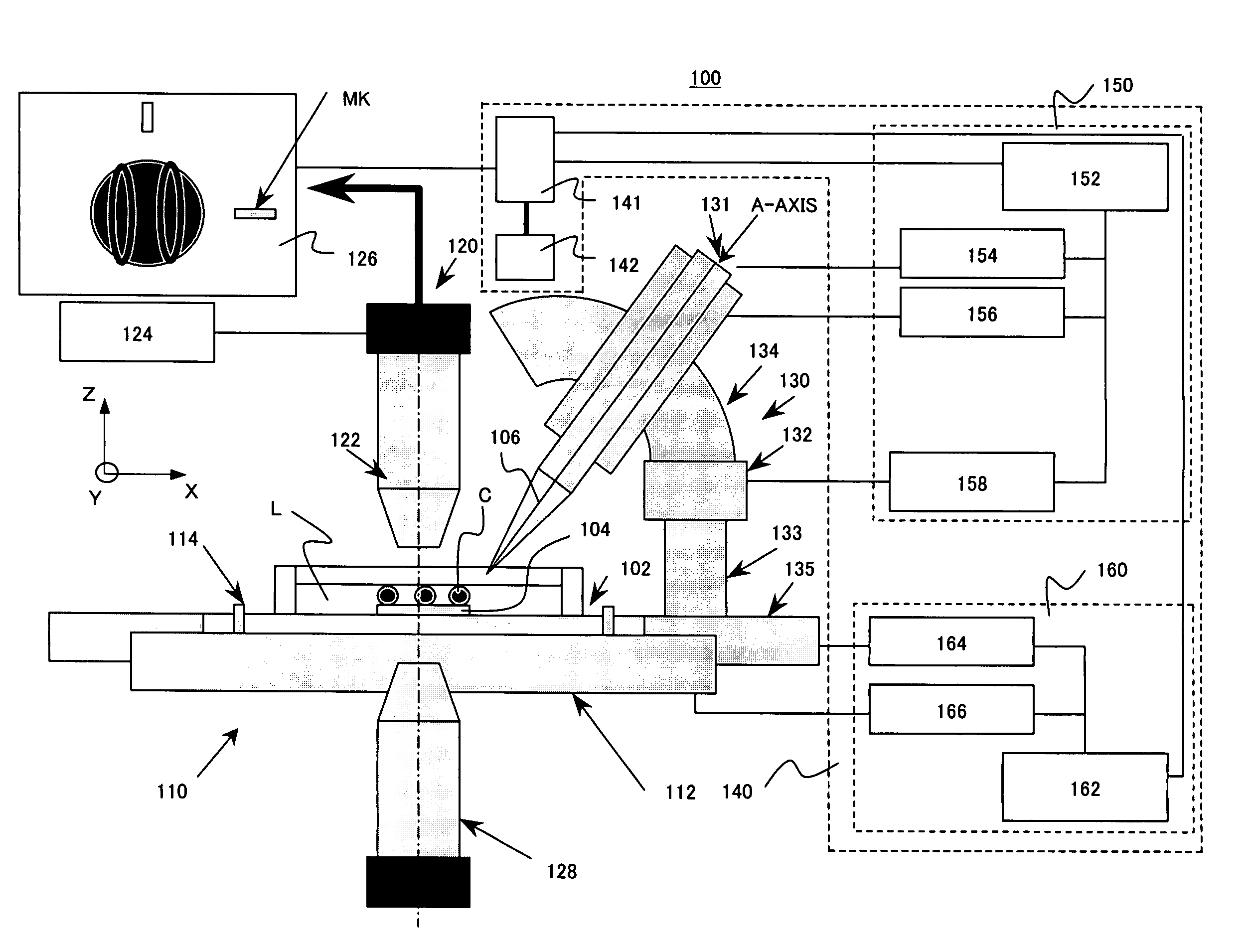

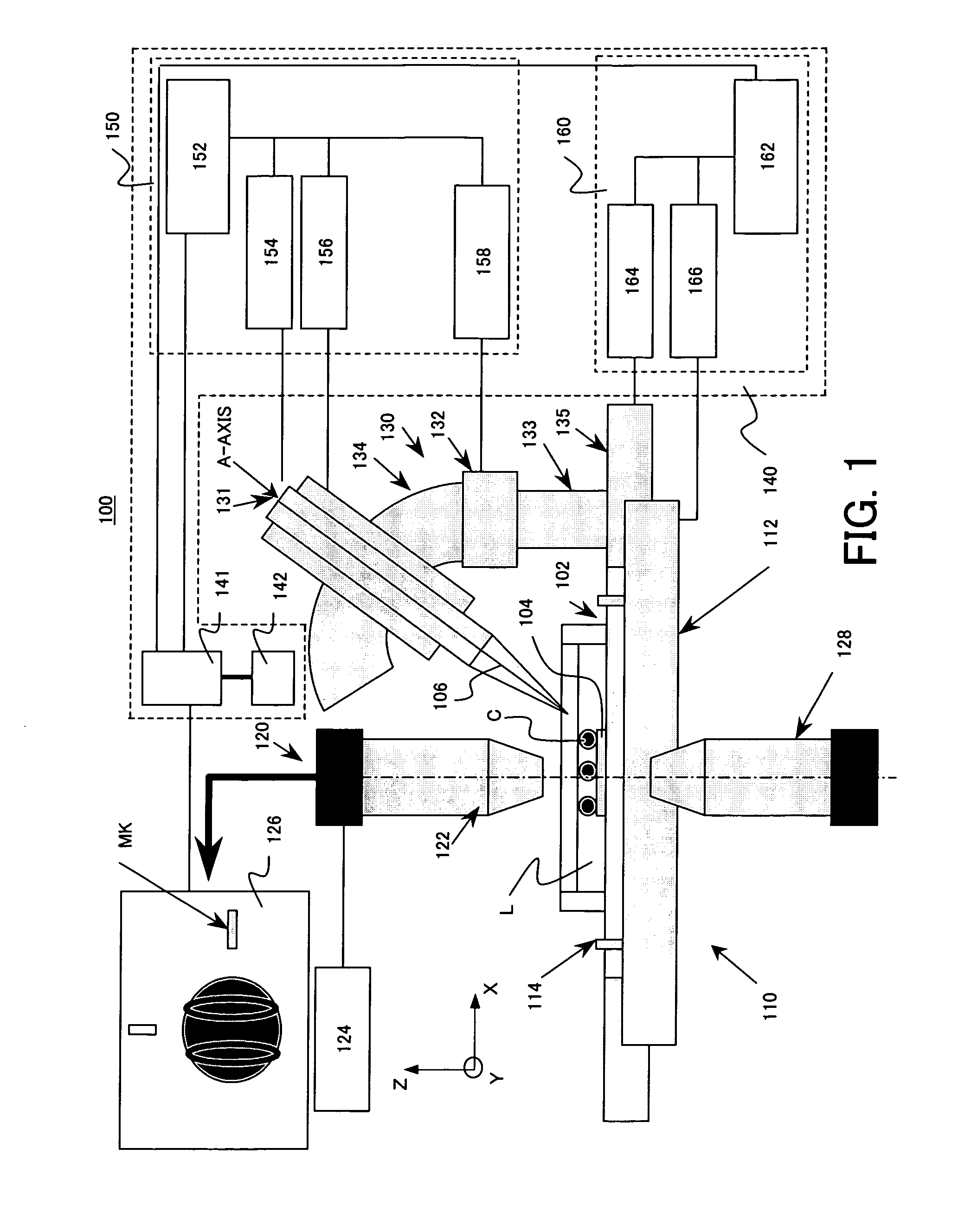

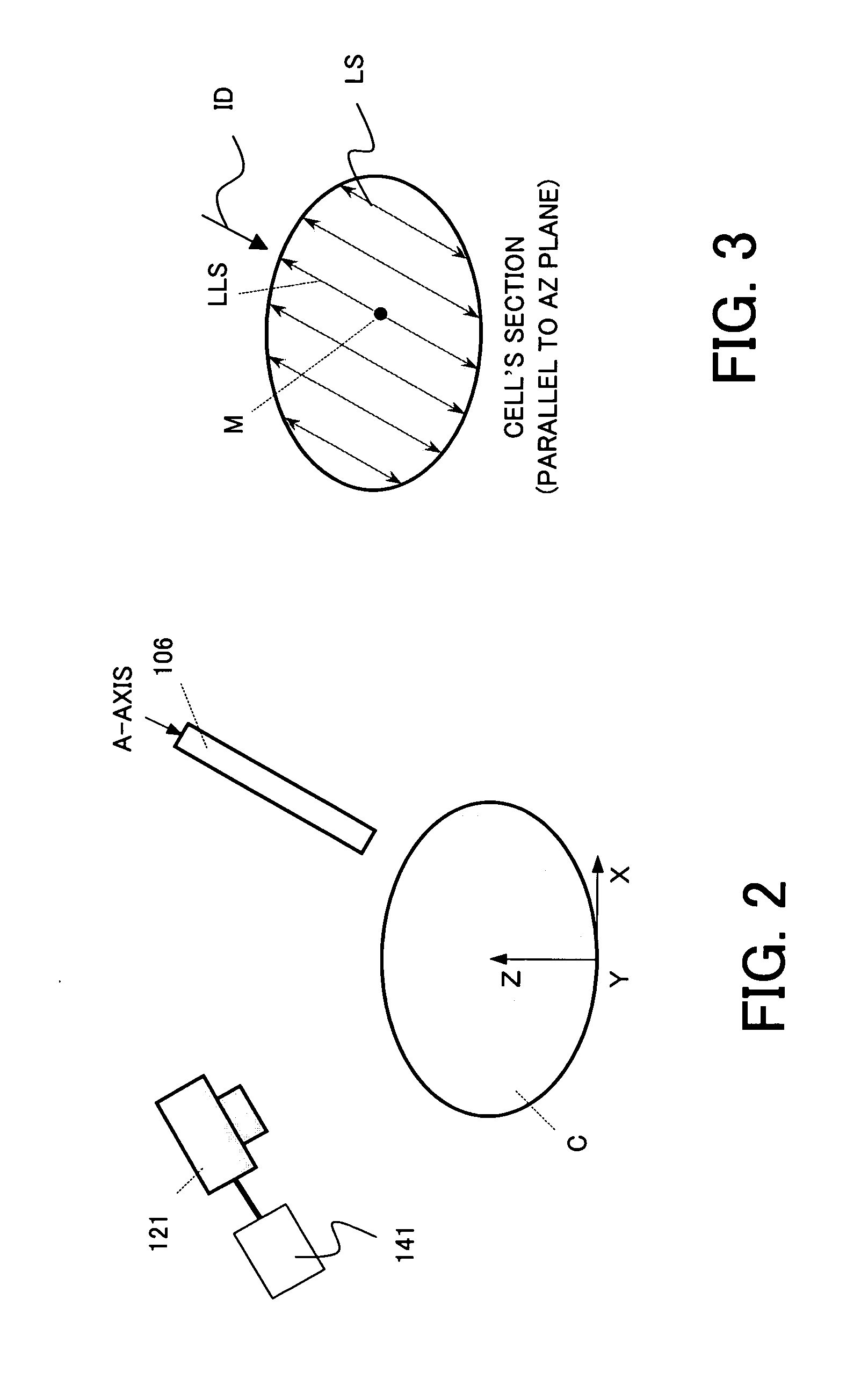

Method and apparatus for detecting foreign body on object surface, and optical disk apparatus

InactiveUS7239588B2Large marginImprove accuracyRecord information storageCarrier monitoringLight spotDelayed time

Owner:PANASONIC CORP

Injection apparatus and method

InactiveUS20070149984A1Secure marginImprove throughputSurgeryIntravenous devicesSurgeryBiomedical engineering

An injection apparatus that inserts an injection needle into a target region in a minute object, and injects a predetermined material into the target region from the injection needle includes a positioning controller that determines, as an insertion direction, a direction that provides the longest length in the target region among plural directions in each of which the injection needle can be inserted into the minute object, and a moving unit that moves the injection needle along the insertion direction.

Owner:FUJITSU LTD

Patterned vertically aligned liquid crystal display

InactiveUS7061562B2Large marginRepairing high pixel defectsNon-linear opticsLiquid-crystal displayEngineering

In a vertically aligned mode LCD, a gate line and a storage line are formed on a substrate in parallel, and a storage electrode and a cover pattern are formed as branches of the storage line. The storage electrode is overlapped with an aperture of a common electrode formed on an upper substrate. The cover pattern is located between a pixel electrode and a data line to prevent a light leakage. Accordingly, an alignment error margin of the upper substrate and the lower substrate is increased, an aperture ratio is enhanced, and repairing the high pixel defect is possible. Further, the light leakage caused by a voltage of the data line is prevented.

Owner:SAMSUNG DISPLAY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com