Steel for nuclear power pressure-bearing equipment and manufacturing method thereof

A technology for pressure-bearing equipment and a manufacturing method, which is applied in the field of steel for nuclear power-bearing equipment and its manufacturing, can solve the problems of low high temperature resistance, insufficient tensile strength to meet index requirements, and reduced strength of steel plates, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The steel for nuclear power pressure-bearing equipment in this embodiment, the molten steel is smelted in a converter, refined outside the furnace (LF, VD), cast into a continuous casting slab, and the finished steel plate is rolled with a specification of 20mm. Its composition, rolling and heat treatment process, and mechanical properties are shown in Tables 1, 2, and 3, respectively.

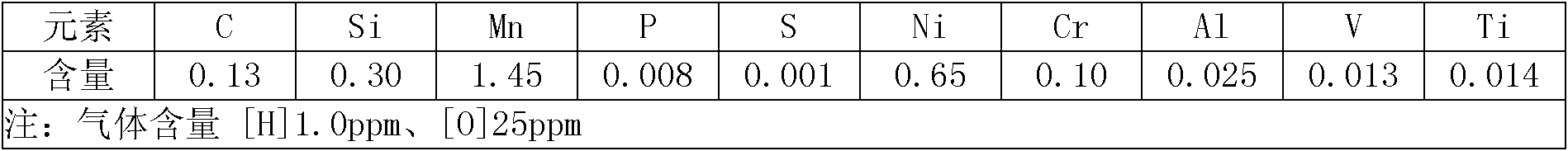

[0035] Table 1 Chemical Composition (%)

[0036]

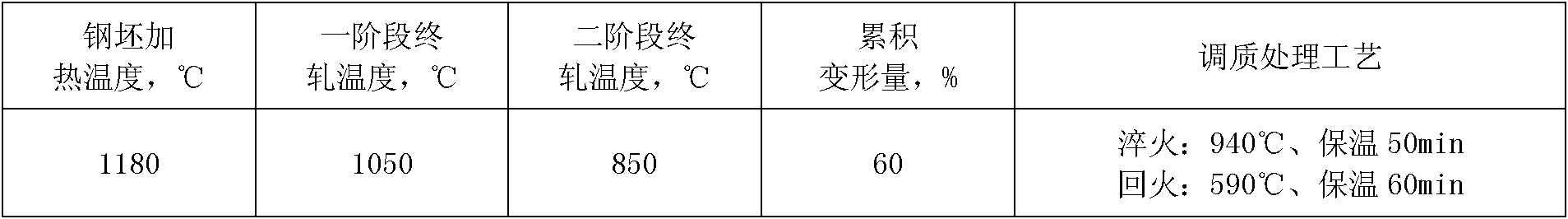

[0037] Table 2 Rolling and heat treatment process

[0038]

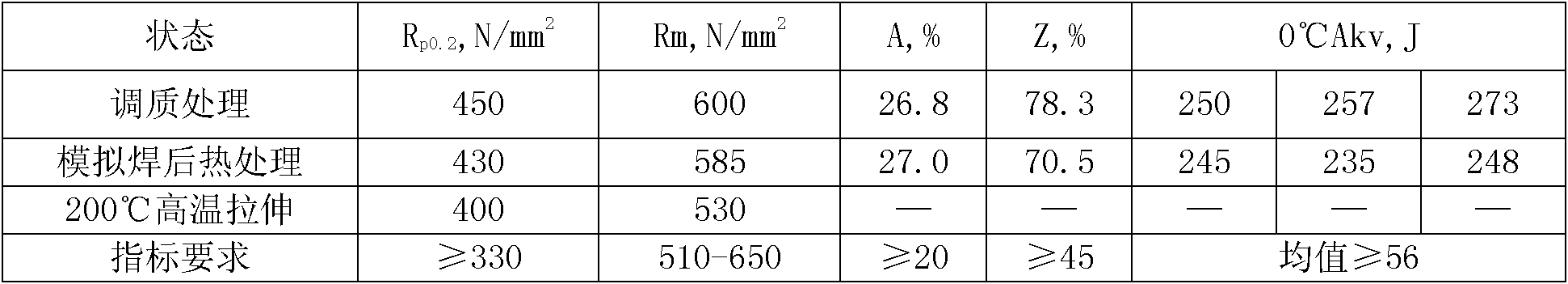

[0039] Table 3 mechanical properties results

[0040]

[0041] At the same time, non-metallic inclusions in steel are inspected: Class A 0.5, Class B 0.5, Class C 0.5, Class D 1.0.

[0042] Through the test of the mechanical properties of the 20mm plates in different states after heat treatment, the results all meet the requirements of the indicators, and have a certain margin, which fully meets the requirements of nuclear power pressure equipment materials.

Embodiment 2

[0044] The steel for nuclear power pressure-bearing equipment in this embodiment, the molten steel is smelted in a converter, refined outside the furnace (LF, VD), cast into a continuous casting slab, and the finished steel plate has a specification of 40 mm. Its composition, rolling and heat treatment process, and mechanical properties are shown in Tables 4, 5, and 6, respectively.

[0045] Table 4 Chemical Composition (%)

[0046]

[0047] Table 5 Rolling and heat treatment process

[0048]

[0049] Table 6 mechanical properties results

[0050]

[0051] At the same time, non-metallic inclusions in steel are inspected: Class A 0.5, Class B 1.0, Class C 0.5, Class D 1.0.

[0052] Through the test of the mechanical properties of the 40mm plate in different states after heat treatment, the results all meet the requirements of the indicators, and have a certain margin, which fully meets the requirements of nuclear power pressure equipment materials.

Embodiment 3

[0054] The steel for nuclear power pressure-bearing equipment in this embodiment, the molten steel is smelted in a converter, refined outside the furnace (LF, VD), cast into a continuous casting slab, and the finished steel plate is rolled with a specification of 60 mm. Its composition, rolling and heat treatment process, and mechanical properties are shown in Tables 7, 8, and 9, respectively.

[0055] Table 7 Chemical Composition (%)

[0056]

[0057] Table 8 Rolling and heat treatment process

[0058]

[0059] Table 9 mechanical properties results

[0060]

[0061] At the same time, non-metallic inclusions in steel are inspected: Class A 0.5, Class B 1.5, Class C 0.5, Class D 1.0.

[0062] Through the test of the mechanical properties of the 60mm plate in different states after heat treatment, the results all meet the requirements of the indicators, and have a certain margin, which fully meets the requirements of nuclear power pressure equipment materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| impact absorption energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com