A kind of steel for nuclear power pressure-bearing equipment and its manufacturing method

A technology for pressure equipment and nuclear power, which is applied in the field of steel used for nuclear power pressure equipment and its manufacturing, can solve problems such as low high temperature resistance, inability to meet the construction of key nuclear power equipment, and inability to meet index requirements for tensile strength. amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The steel for nuclear power pressure-bearing equipment in this embodiment, the molten steel is smelted in a converter, refined outside the furnace (LF, VD), cast into a continuous casting slab, and the finished steel plate is rolled with a specification of 20mm. Its composition, rolling and heat treatment process, and mechanical properties are shown in Tables 1, 2, and 3, respectively.

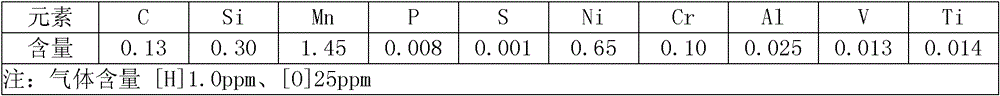

[0035] Table 1 Chemical Composition (%)

[0036]

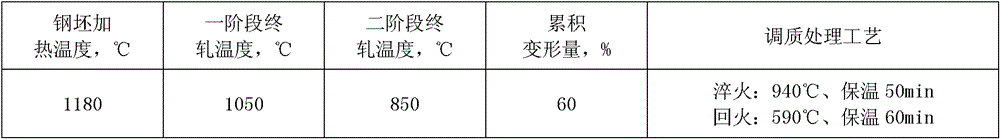

[0037] Table 2 Rolling and heat treatment process

[0038]

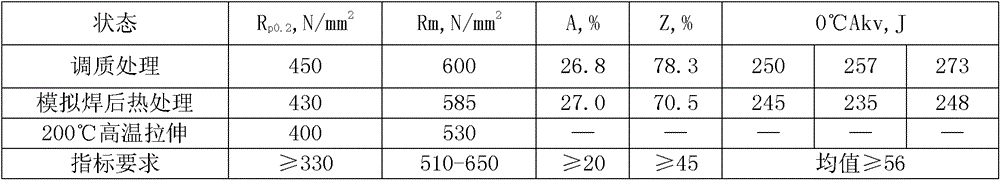

[0039] Table 3 mechanical properties results

[0040]

[0041] At the same time, non-metallic inclusions in steel are inspected: Class A 0.5, Class B 0.5, Class C 0.5, Class D 1.0.

[0042] Through the test of the mechanical properties of the 20mm plates in different states after heat treatment, the results all meet the requirements of the indicators, and have a certain margin, which fully meets the requirements of nuclear power pressure equipment materials.

Embodiment 2

[0044] The steel for nuclear power pressure-bearing equipment in this embodiment, the molten steel is smelted in a converter, refined outside the furnace (LF, VD), cast into a continuous casting slab, and the finished steel plate has a specification of 40mm. Its composition, rolling and heat treatment process, and mechanical properties are shown in Tables 4, 5, and 6, respectively.

[0045] Table 4 Chemical Composition (%)

[0046]

[0047] Table 5 Rolling and heat treatment process

[0048]

[0049] Table 6 mechanical properties results

[0050]

[0051] At the same time, non-metallic inclusions in steel are inspected: Class A 0.5, Class B 1.0, Class C 0.5, Class D 1.0.

[0052] Through the test of the mechanical properties of the 40mm plate in different states after heat treatment, the results all meet the requirements of the indicators, and have a certain margin, which fully meets the requirements of nuclear power pressure equipment materials.

Embodiment 3

[0054] The steel for nuclear power pressure-bearing equipment in this embodiment, the molten steel is smelted in a converter, refined outside the furnace (LF, VD), cast into a continuous casting slab, and the finished steel plate is rolled with a specification of 60mm. Its composition, rolling and heat treatment process, and mechanical properties are shown in Tables 7, 8, and 9, respectively.

[0055] Table 7 Chemical Composition (%)

[0056]

[0057] Table 8 Rolling and heat treatment process

[0058]

[0059] Table 9 mechanical properties results

[0060]

[0061] At the same time, non-metallic inclusions in steel are inspected: Class A 0.5, Class B 1.5, Class C 0.5, Class D 1.0.

[0062] Through the test of the mechanical properties of the 60mm plate in different states after heat treatment, the results all meet the requirements of the indicators, and have a certain margin, which fully meets the requirements of nuclear power pressure equipment materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| impact absorption energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com