Steel for high strength and high toughness nuclear power voltage stabilizer and manufacturing method of steel

A high-strength, high-toughness, voltage-stabilizer technology, applied in the field of high-strength and high-toughness nuclear power voltage stabilizer steel and its manufacturing field, can solve the problems of low yield, long production cycle, and low yield, so as to reduce production costs and improve yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

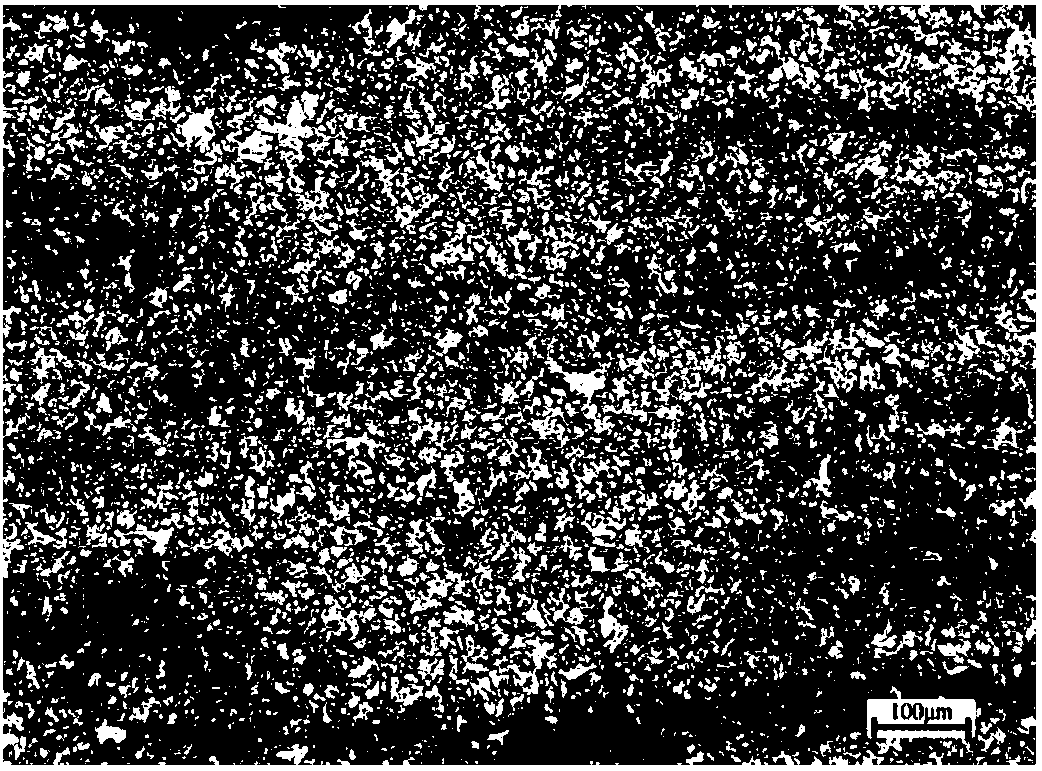

Image

Examples

Embodiment Construction

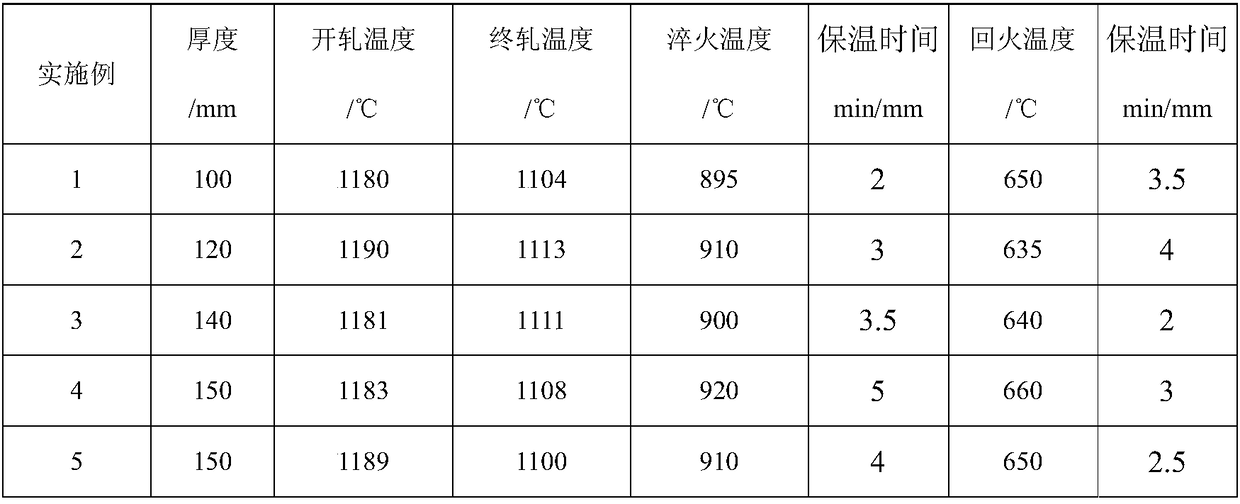

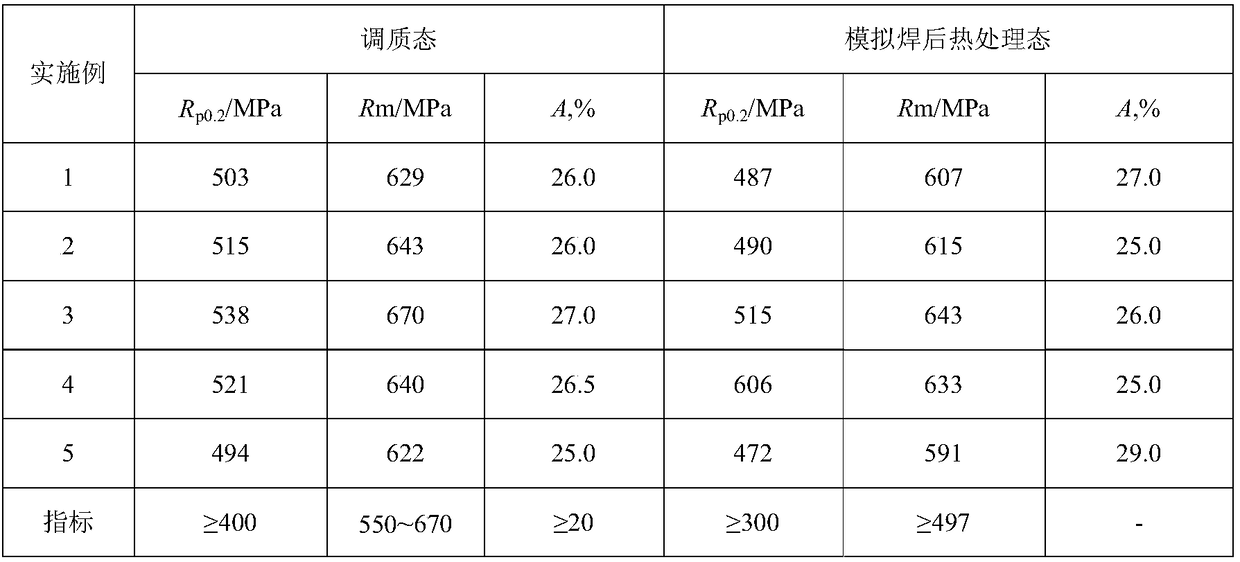

[0033] Below by embodiment the present invention will be further described.

[0034] In the embodiment of the present invention, according to the component ratio of the technical solution, pretreatment of molten iron - electric furnace smelting - LF furnace refining - VD vacuum treatment - electric furnace die casting - rolling - heat treatment,

[0035] Deep desulfurization treatment of molten iron is adopted, smelted in electric furnace, the temperature reaches 1610±10°C to tap steel, and then refined in LF refining furnace, the temperature reaches 1640±10°C to feed Fe-Ca wire 2m / t, and then VD vacuum treatment is carried out, the vacuum degree is ≤67Pa , the vacuum holding time is ≥20min, when the temperature reaches 1600±10℃, the steel is tapped for electric furnace die casting, and the pouring temperature is 1570±10℃;

[0036] The steel ingot heating temperature is 1250℃~1350℃, and the holding time is more than 2 hours to start the billet; the intermediate billet rolling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com