Steel for support and hanger of third-generation pressurized water reactor nuclear power plant and manufacturing method thereof

A technology for a pressurized water reactor nuclear power plant and a manufacturing method is applied in the field of steel manufacturing for nuclear power equipment, and can solve the problems of a complex three-stage heating system and low tensile strength of steel plates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

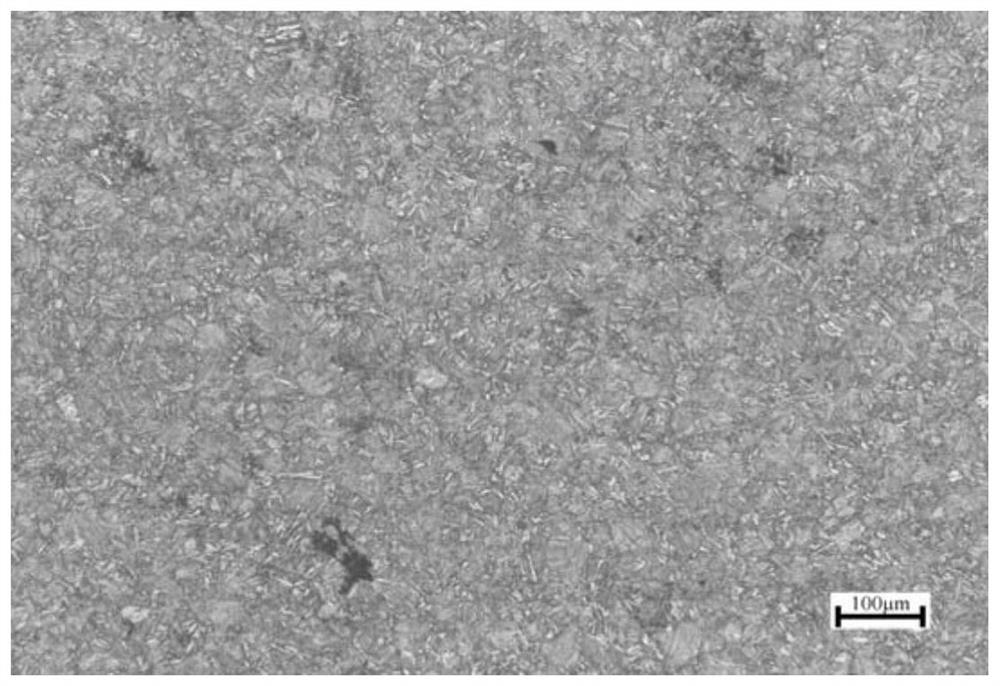

[0037] The following examples are used to specifically illustrate the contents of the present invention, and these examples are only general descriptions of the contents of the present invention, and do not limit the contents of the present invention.

[0038] Table 1 is the smelting chemical composition of the steel of the example; Table 2 is the steelmaking and continuous casting data; Table 3 is the rolling and heat treatment process of the steel of the example; Table 4 is the mechanical properties of the steel plate of the example.

[0039] The production method of steel in this embodiment is to use low-P and low-S molten iron as raw material. The molten steel is smelted in a converter, refined outside the LF+VD furnace, and cast into continuous casting slabs. The heat treatment process is a temperature of 605±10°C, a holding time of 10h, and a heating and cooling rate of ≤55°C / h above 425°C.

[0040] Table 1 embodiment steel smelting chemical composition (%)

[0041] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| impact absorption energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com