Cable protection sleeve and cable assembly

A technology for cable assemblies and protective sleeves, applied in the field of cable protective sleeves and cable assemblies, which can solve the problems of poor waterproof and sealing effects of sheaths, and achieve the effects of improving waterproof effects, reducing assembly difficulty, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

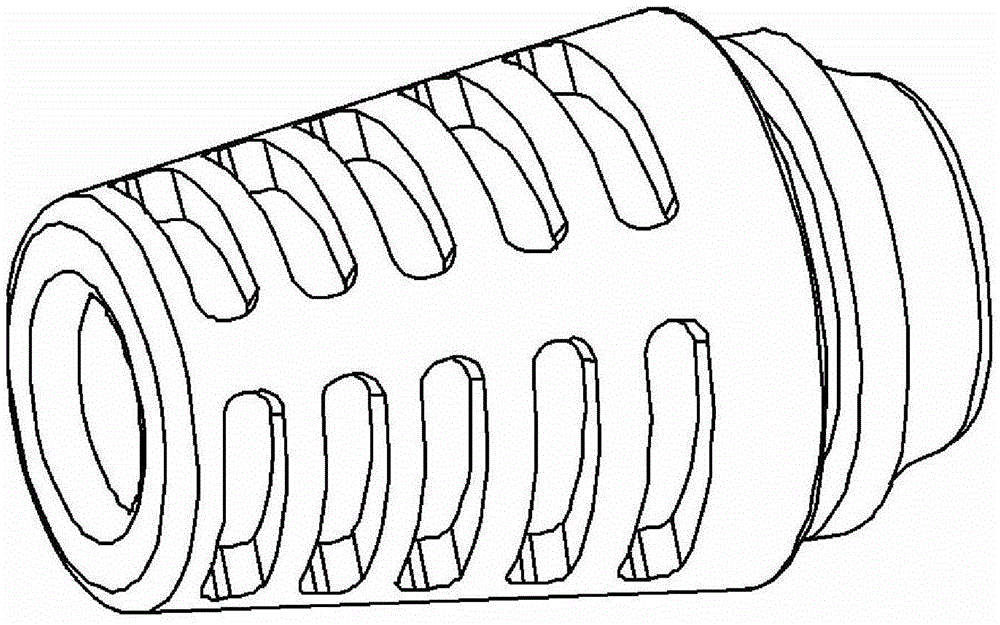

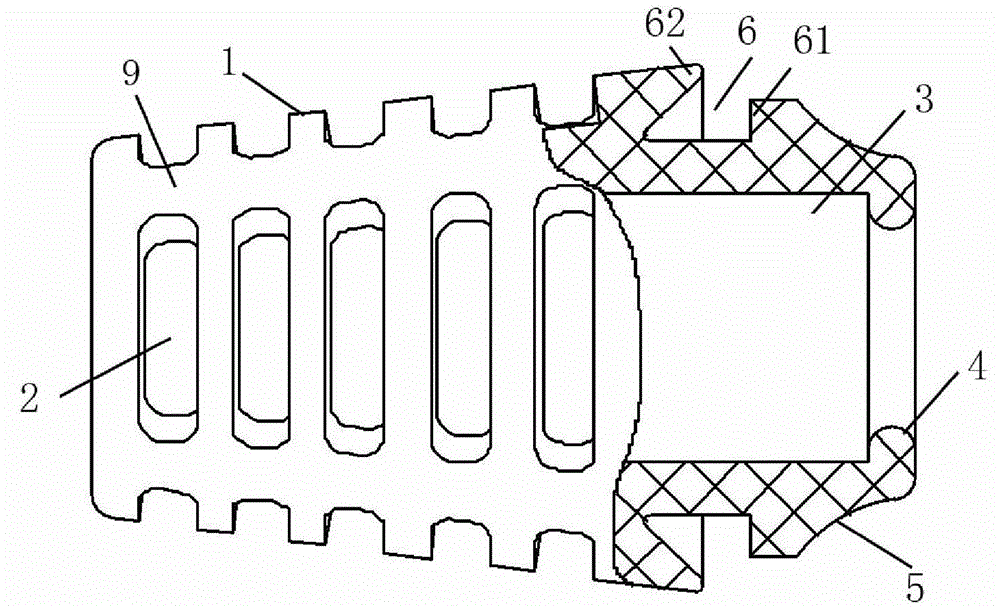

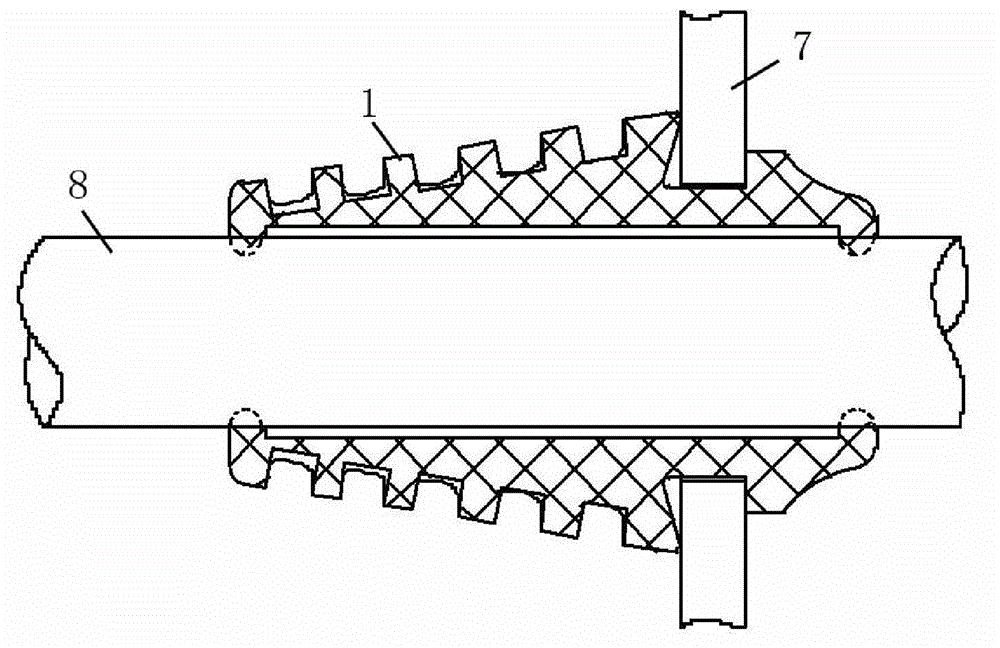

[0022] Embodiment 1 of the cable assembly of the present invention: it includes a cable and a cable protective sheath covering the cable, wherein the structure of the cable protective sheath is as follows Figure 1-3 As shown, it includes a threading sleeve body 1 extending forward and backward. The threading sleeve body is made of elastic material. The center of the threading sleeve body is provided with a central threading hole 3 extending forward and backward for the cable 8 to be worn. The diameter of the central threading hole is unchanged and basically equal to the diameter of the cable, the outer circumference of the threading sleeve 1 is provided with a ring groove 6 near the front end, and the ring groove 6 is used to snap fit with the hole of the outlet hole and fix the sleeve on the On the fixed plate 7 where the outlet hole is located, among the front and rear sides of the ring groove 6, the front side groove wall 61 is a vertical wall structure perpendicular to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com