Steel for pressure bearing boundary part of steam generator in nuclear power plant and manufacturing method of steel

A technology of steam generator and pressure-bearing boundary, which is applied in the field of steel metal materials and ferrous metal materials for nuclear power, and achieves the effect of excellent strength index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following examples are used to specifically illustrate the contents of the present invention, and these examples are only general descriptions of the contents of the present invention, and do not limit the contents of the present invention.

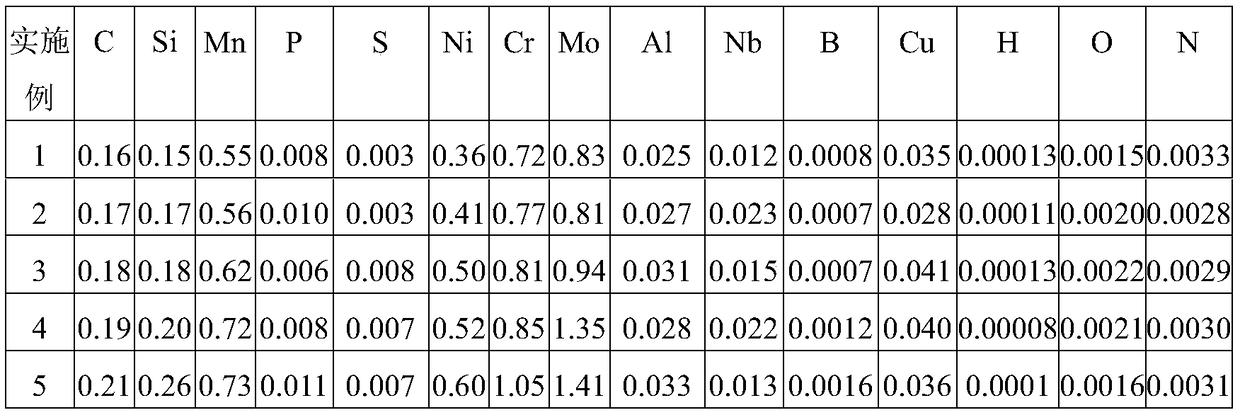

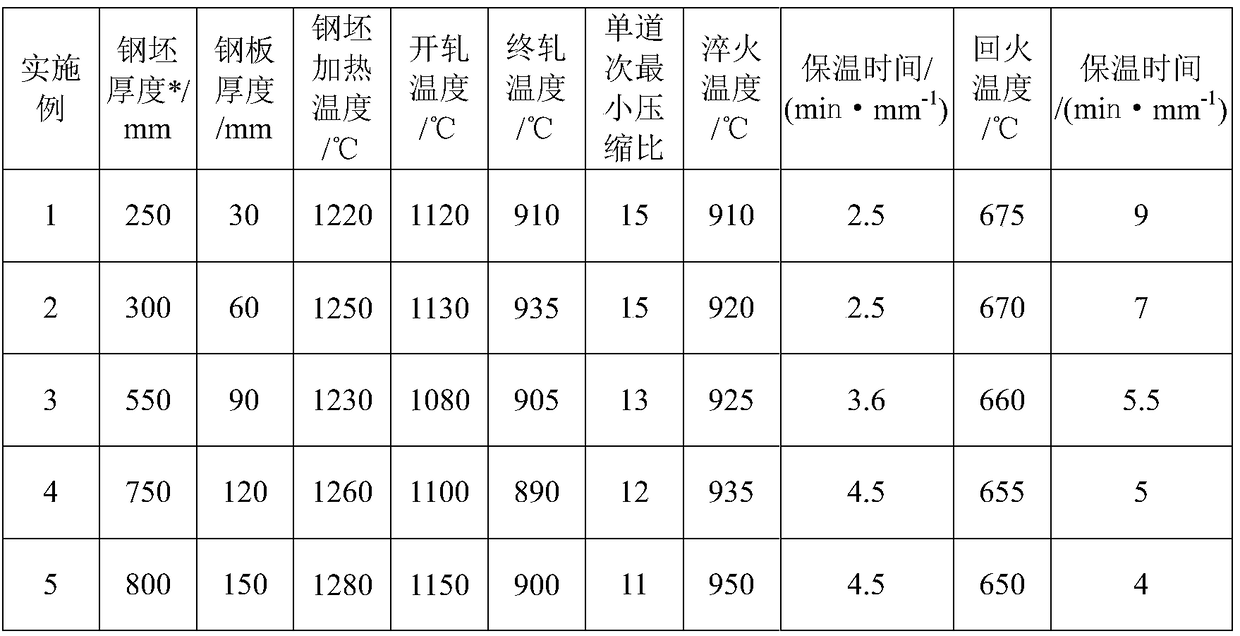

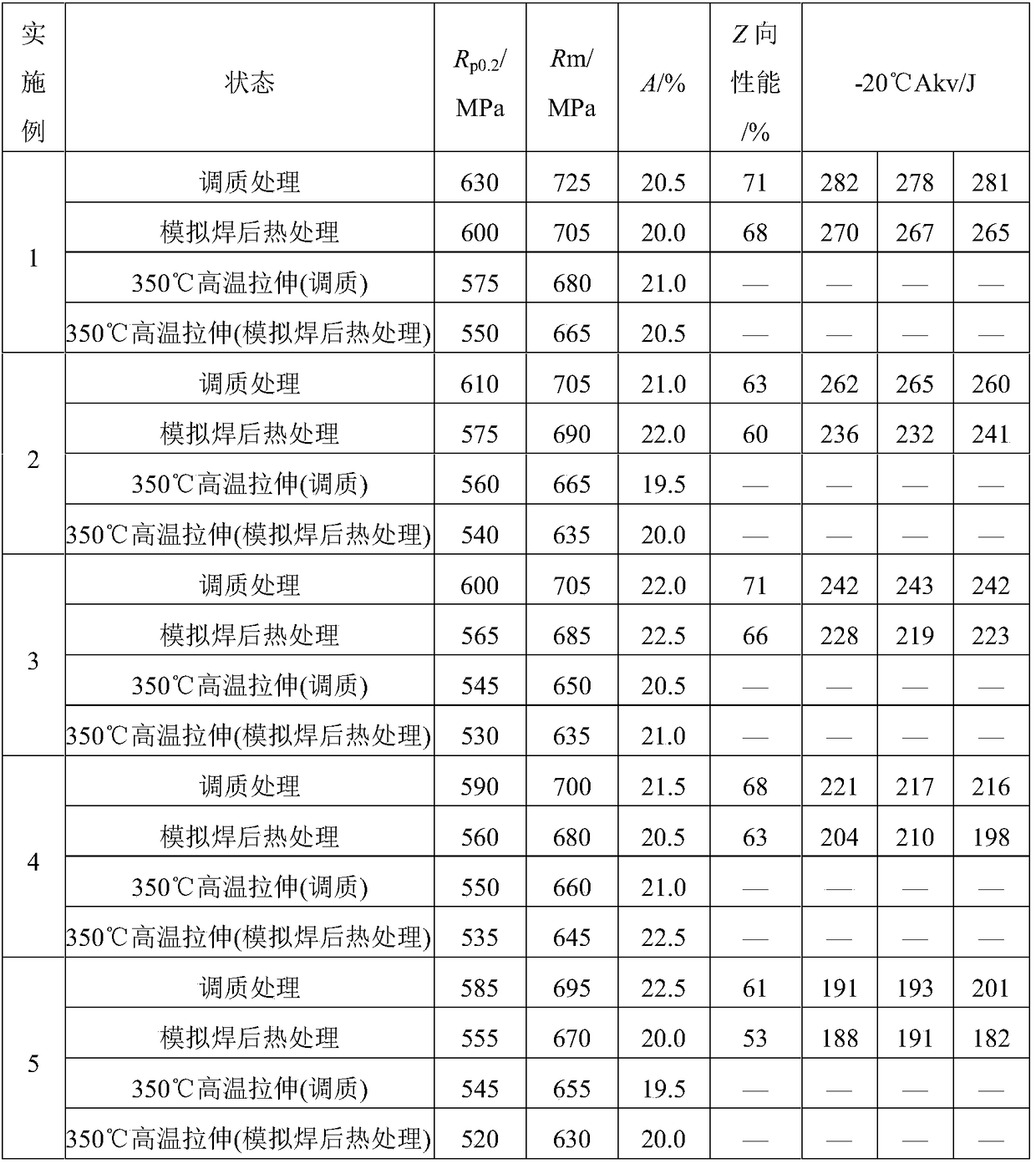

[0037] The chemical composition of steel smelting in each embodiment is shown in Table 1. The steel rolling process of each embodiment is shown in Table 2. After being rolled into steel plates, the simulated post-weld heat treatment system is as follows: holding temperature is 610°C, holding time is 13.5h, and the heating / cooling rate in the temperature range of 350-610°C is ≤55°C / h. The mechanical properties of the steels in each example are shown in Table 3.

[0038] Table 1 Example steel smelting chemical composition wt%

[0039]

[0040] Table 2 embodiment steel rolling and heat treatment process

[0041]

[0042] Note: Examples 1-2 are cast into continuous casting slabs after converter smelting; Examples 3-5 are c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com