Whirlwind dusting machine

A dust collector, cyclone technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

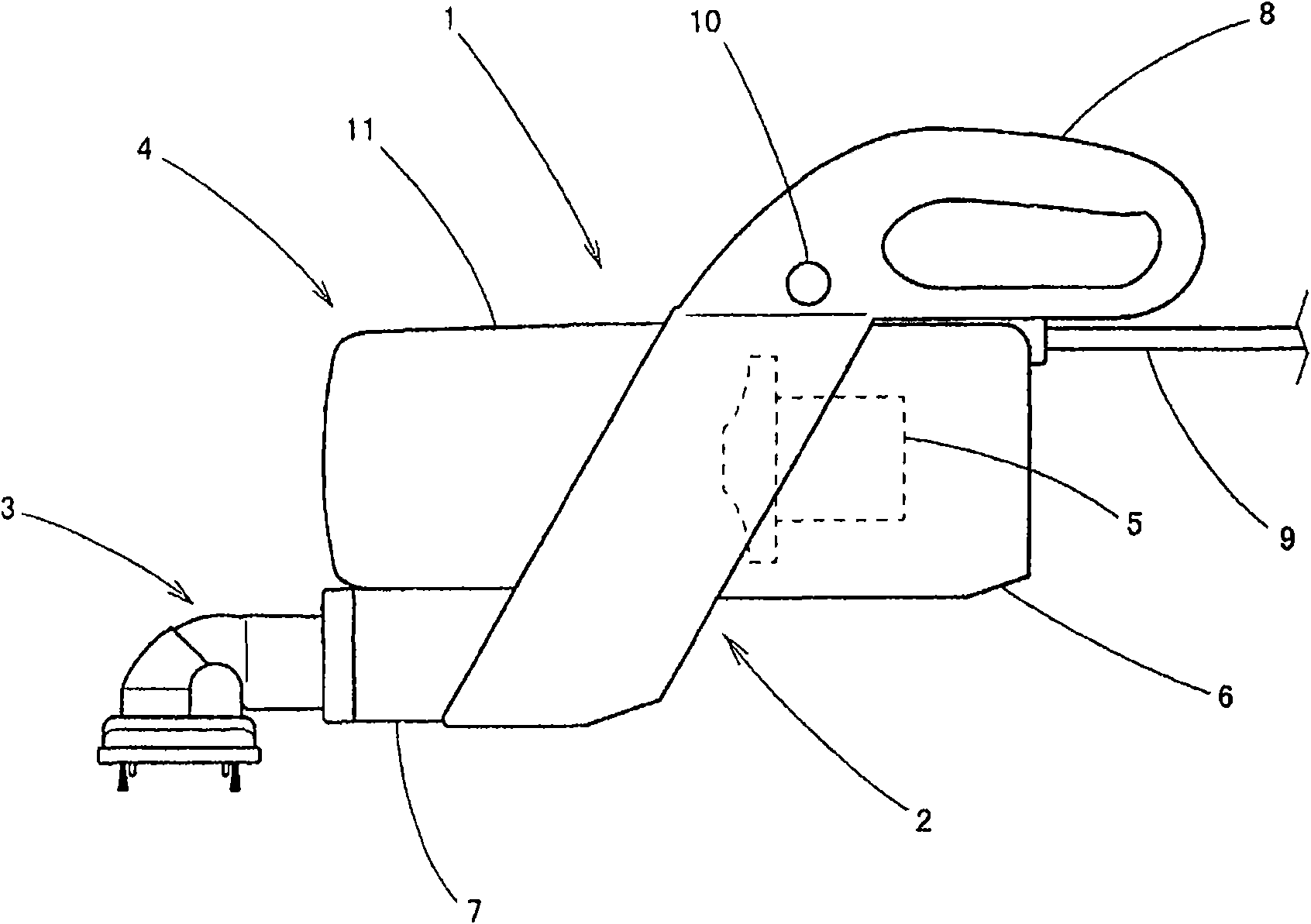

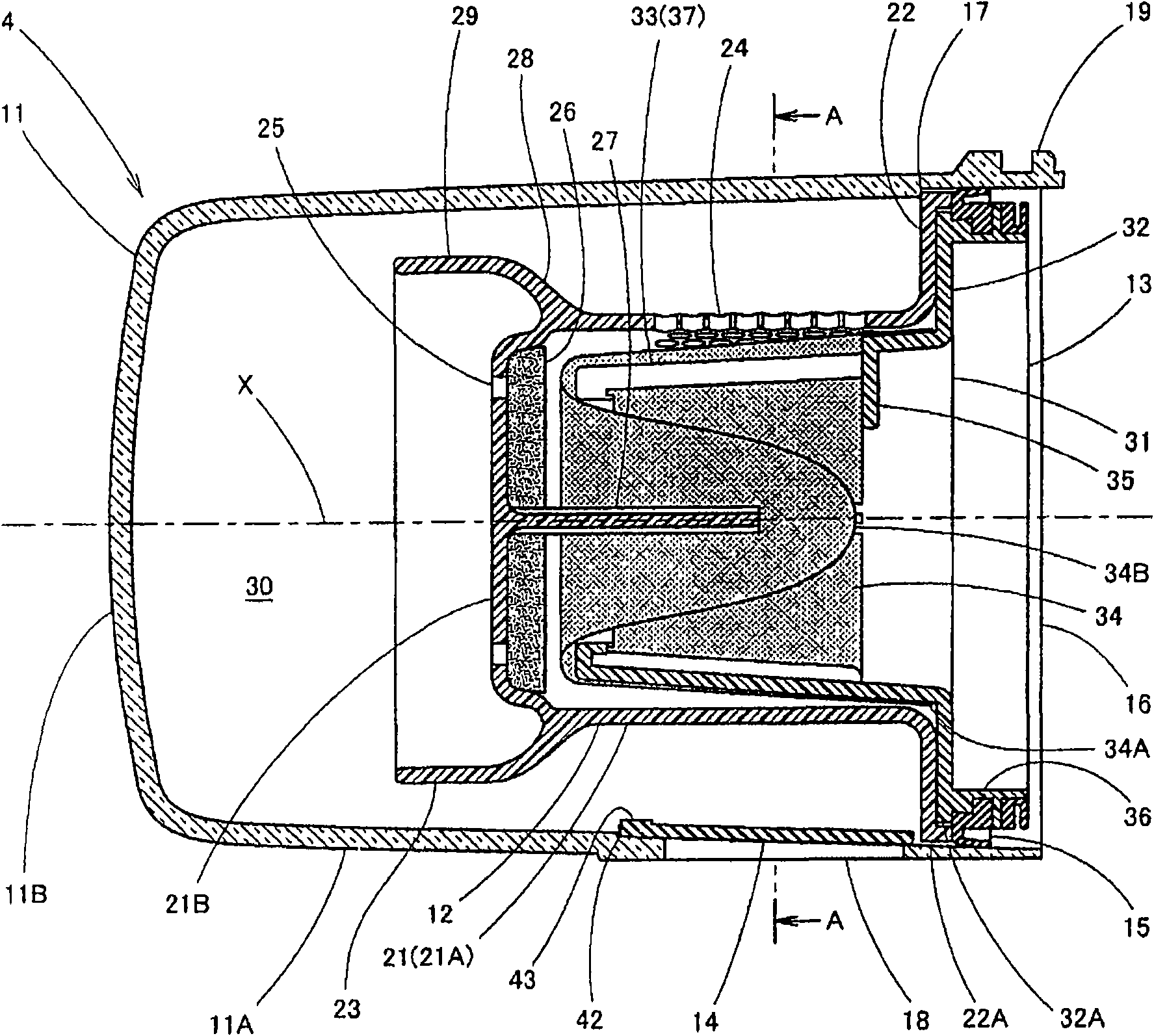

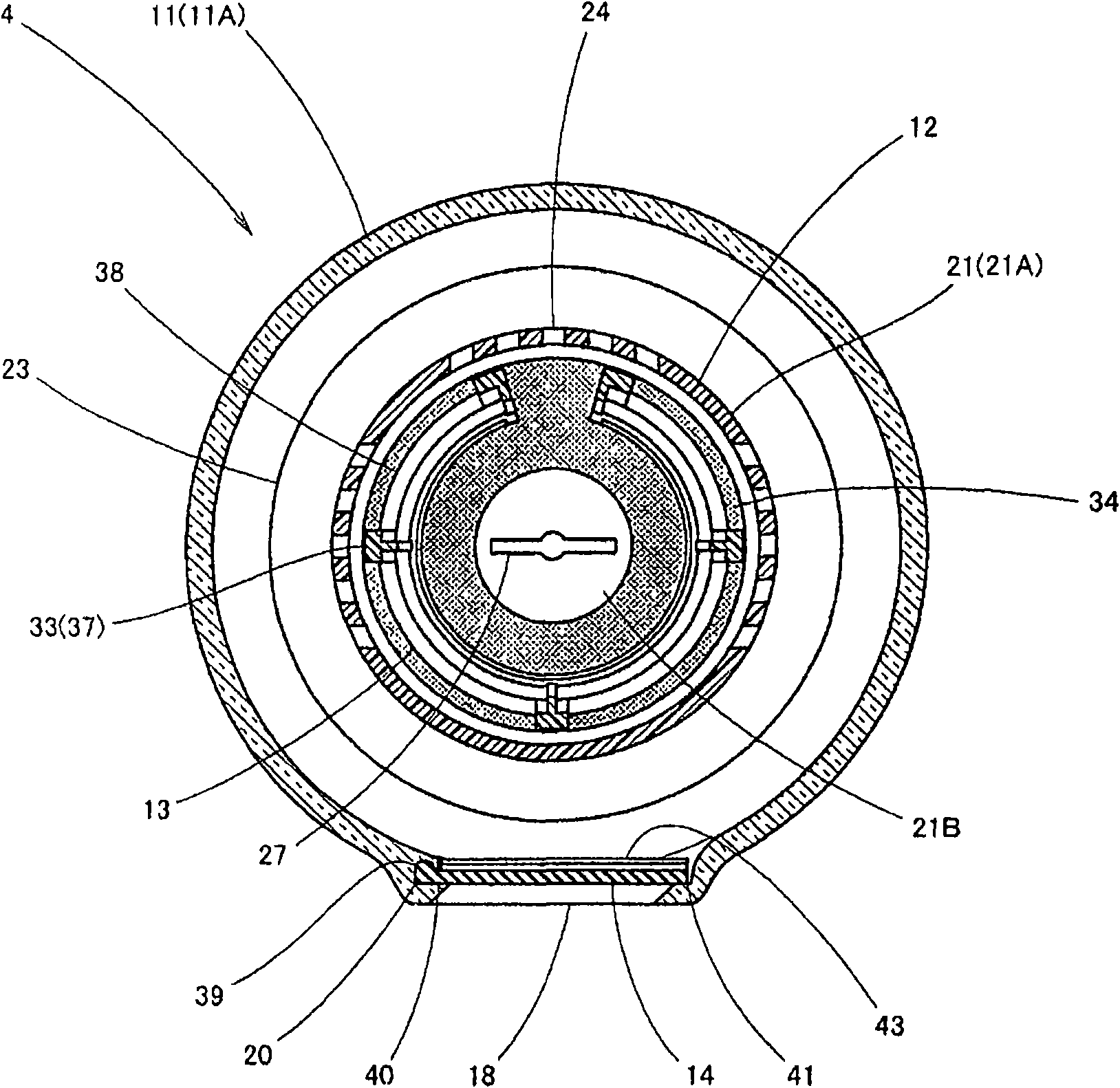

[0037] Below, according to Figure 1 to Figure 7 , to describe the embodiment of the present invention. 1 is a portable cyclone dust collector. This cyclone dust collector 1 is constituted by having a dust collector body 2 , a nozzle 3 detachably attached to the dust collector body 2 , and a dust collecting member 4 detachably attached to the dust collector body 2 .

[0038] The dust collector body 2 is constituted by having a main body 6 in which an electric blower 5 is built, a connecting portion 7 having a suction path not shown inside, a grip 8 and a power cord 9 . Moreover, the operation part 10 for attaching and detaching the said dust collection member 4, and the switch operation part which are not shown in figure are provided in the said grip part 8. As shown in FIG. Further, the nozzle 3 is detachably attached to one end of the suction path of the connection portion 7 .

[0039] The dust collecting member 4 is constituted by having a dust collecting container 11 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com