Precision investment casting method for magnesium alloy

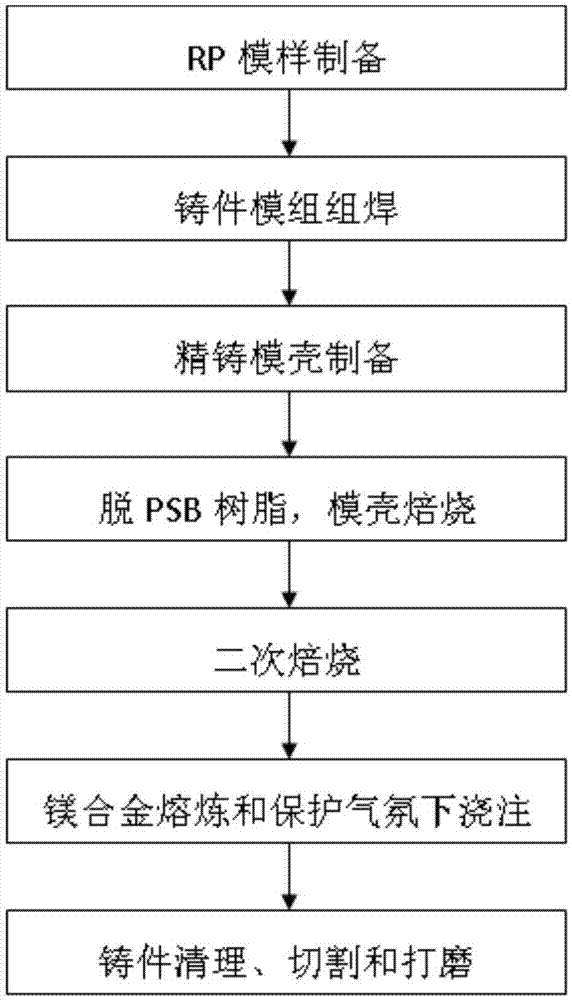

A technology of investment precision casting and magnesium alloy, which is applied in the direction of casting molding equipment, casting molds, and casting mold components. It can solve the problems of poor anti-oxidation measures, achieve oxidation prevention, ensure surface finish, and ensure dimensional accuracy and surface finish. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) 3D laser printing wax model.

[0021] Use commercial software to establish a 3D model of the casting in the computer, and use 3D selective laser printing rapid prototyping equipment to manufacture the RP shape of the casting. The RP pattern material is PSB powder (glass transition temperature is 70-98°C, decomposition temperature >300°C). Put the RP pattern into a water bath type wax melting insulation barrel for wax dipping treatment, and take it out after dipping for 3 minutes. After 3 minutes, carry out the second dip coating, and take it out after 2 minutes. The wax-soaked RP pattern is manually polished in water with No. 600 sandpaper, and then the RP pattern is degreased with washing powder or detergent, rinsed and dried. Subsequently, the casting gating system is assembled and welded according to the casting process.

[0022] (2) Shell making.

[0023] Choose ZrO 2 As the best surface sand material and coating powder. Wherein, the proportioning of the s...

Embodiment 2

[0033] (1) 3D laser printing wax model.

[0034] Use commercial software to establish a 3D model of the casting in the computer, and use 3D selective laser printing rapid prototyping equipment to manufacture the RP shape of the casting. The RP pattern material is PSB powder (glass transition temperature is 70-98°C, decomposition temperature >300°C). Put the RP pattern into the water-bath type wax melting insulation barrel for wax dipping treatment, and take it out after dipping for 2 minutes. After 3 minutes, carry out the second dip coating, and take it out after 1 minute. The wax-soaked RP pattern is manually polished in water with No. 600 sandpaper, and then the RP pattern is degreased with washing powder or detergent, rinsed and dried. Subsequently, the casting gating system is assembled and welded according to the casting process.

[0035] (2) Shell making.

[0036] Choose ZrO 2 As the optimal surface layer sand material and coating powder, the ratio of the surface l...

Embodiment 3

[0046] (1) 3D laser printing wax model.

[0047] Use commercial software to establish a 3D model of the casting in the computer, and use 3D selective laser printing rapid prototyping equipment to manufacture the RP shape of the casting. The RP pattern material is PSB powder (glass transition temperature is 70-98°C, decomposition temperature >300°C). Put the RP pattern into a water bath type wax melting insulation barrel for wax dipping treatment, and take it out after dipping for 3 minutes. After 3 minutes, carry out the second dip coating, and take it out after 2 minutes. The wax-soaked RP pattern is manually polished in water with No. 600 sandpaper, and then the RP pattern is degreased with washing powder or detergent, rinsed and dried. Subsequently, the casting gating system is assembled and welded according to the casting process.

[0048] (2) Shell making.

[0049] Choose ZrO 2 As the optimal surface layer sand material and coating powder, the ratio of the surface la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com