Composite material grid skin structure part die compression molding forming method

A compression molding and composite material technology, which is applied in the field of composite material molding, can solve the problems of increasing the production cycle of grid structural parts, difficulty in ensuring product quality, and increasing production costs, and achieve uniform skin thickness, small product deformation, and high molding efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

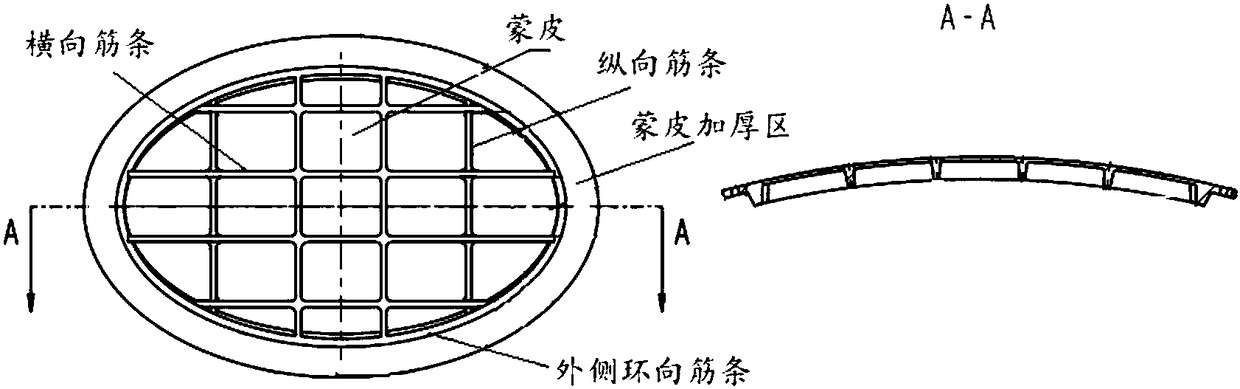

[0063] Such as figure 1 Shown, product name: operating cover

[0064] Dimensions: the length of the long axis is 510mm, the length of the short axis is 340mm, the cross section of the longitudinal and transverse ribs is trapezoidal, the size is 6mm×11mm×18mm, the size of the outer circumferential ribs is 8mm×13mm×18mm, the thickness of the skin thickening area is 8mm, Skin thickness 4mm.

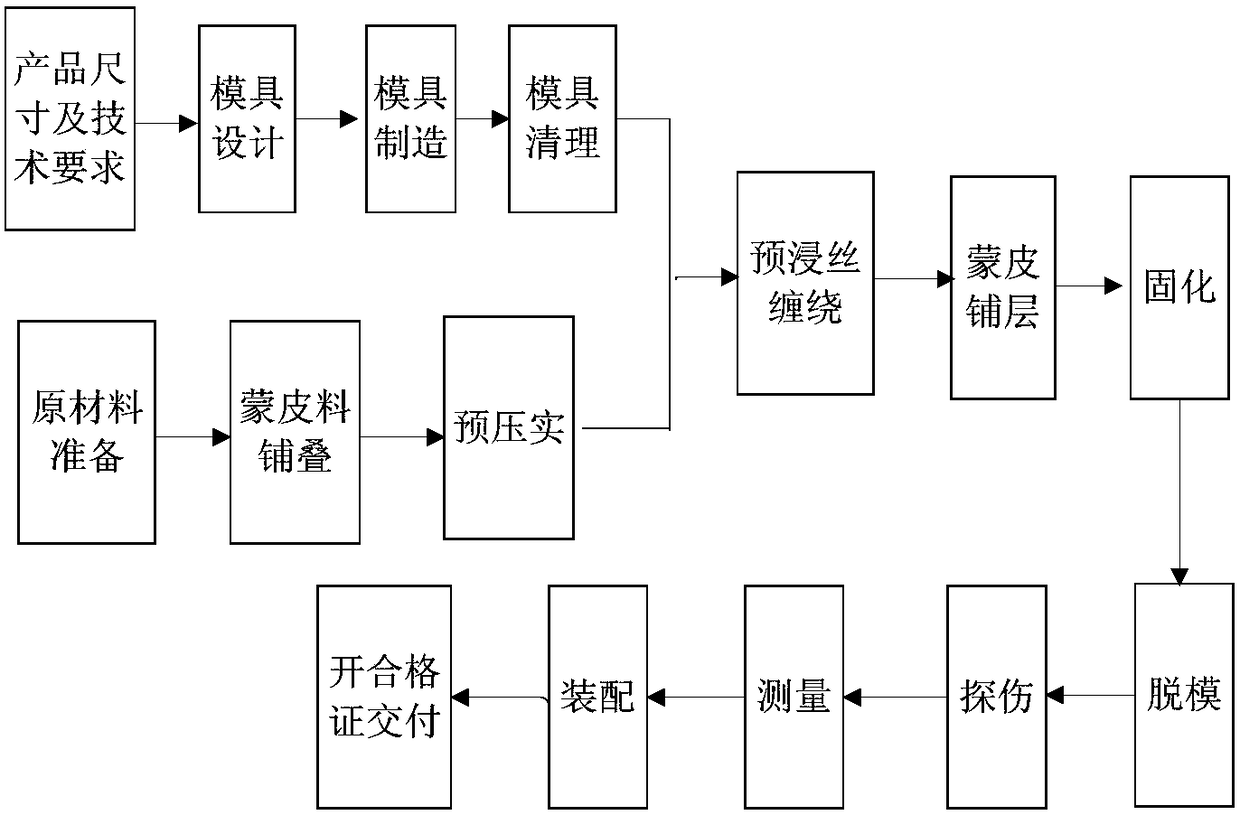

[0065] Such as figure 2 As shown, the method steps are:

[0066] (1) Manufacture and install forming molds;

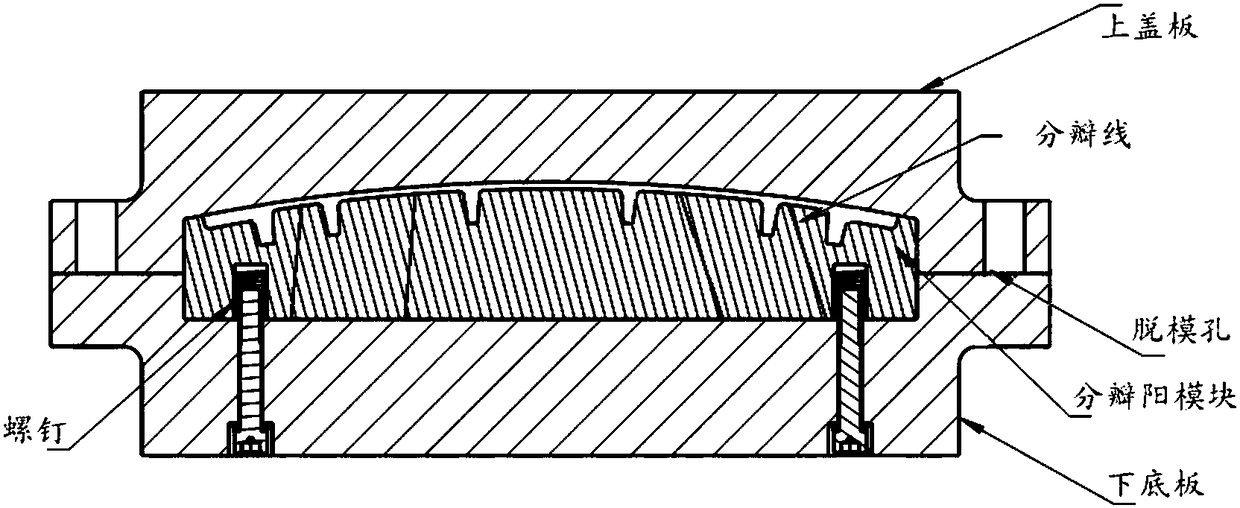

[0067] Such as image 3 As shown, the forming mold is first manufactured, and the forming mold includes the lower base plate, the split male module and the upper cover plate, wherein the lower base plate and the upper cover plate are steel molds, and the split male module is an aluminum mold; the split number of the split male module There are 5 petals, the split gap is 0.3mm, a draft angle of 6 degrees is left around the split male module (outer edge of the product), and the g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com