Patents

Literature

42results about How to "Meet the design index requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sigmoid function fitting hardware circuit based on Remez approximating algorithm

ActiveCN104484703ASatisfy consumptionIncrease the number ofPhysical realisationResource consumptionSigmoid function

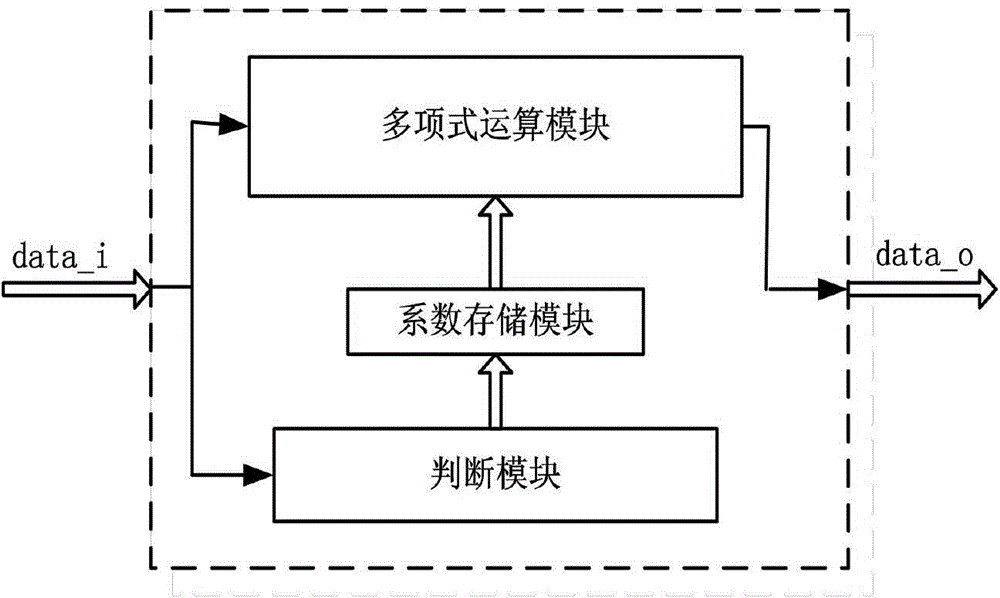

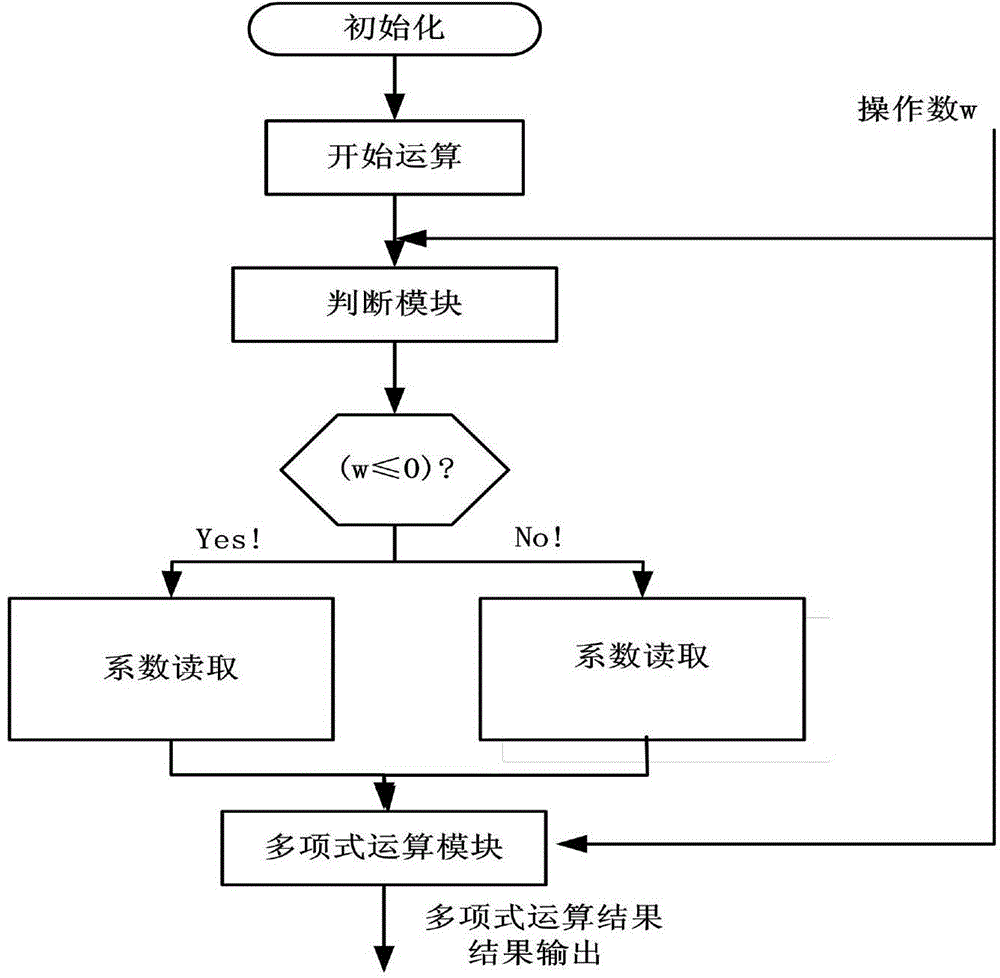

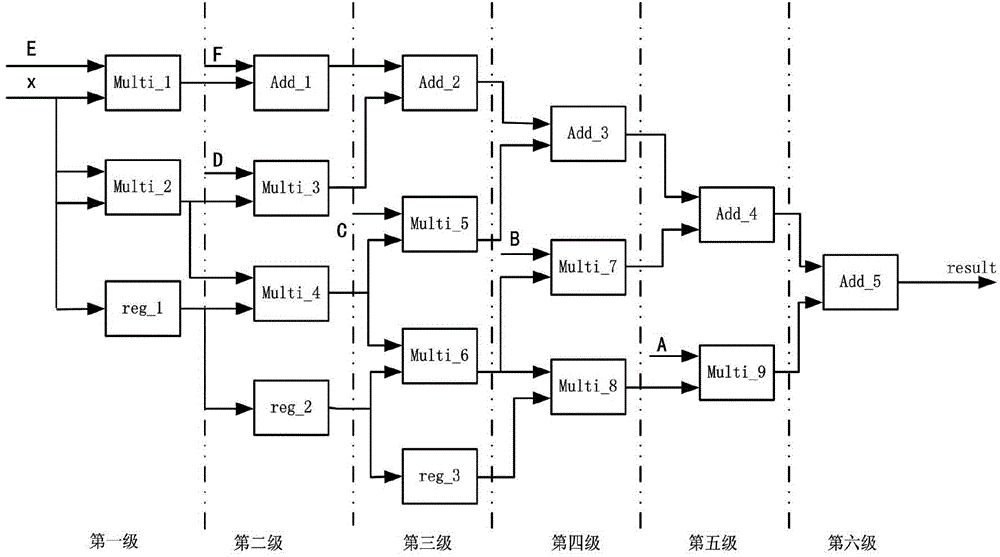

The invention discloses a sigmoid function fitting hardware circuit based on a Remez approximating algorithm. A sigmoid function fitting method is characterized by including the following steps that (1), the order of a fitting polynomial is determined; (2), a fitting interval of a sigmoid function is obtained; (3), a piecewise interval is obtained; (4), the fitting polynomial is obtained; (5), a coefficient storing module is designed; (6), a polynomial calculation module is designed; (7), a judgment module is designed; (8), the fitting hardware circuit is obtained; (9), a fitting execution interval where operands are located is judged; (10), a coefficient of the fitting polynomial is read; (11), fitting calculation is carried out in the polynomial calculation module. On the basis of reducing hardware resource consumption, the calculation accuracy is improved, the calculation speed is increased, and the flexibility of a calculation structure is promoted.

Owner:黄山市开发投资集团有限公司

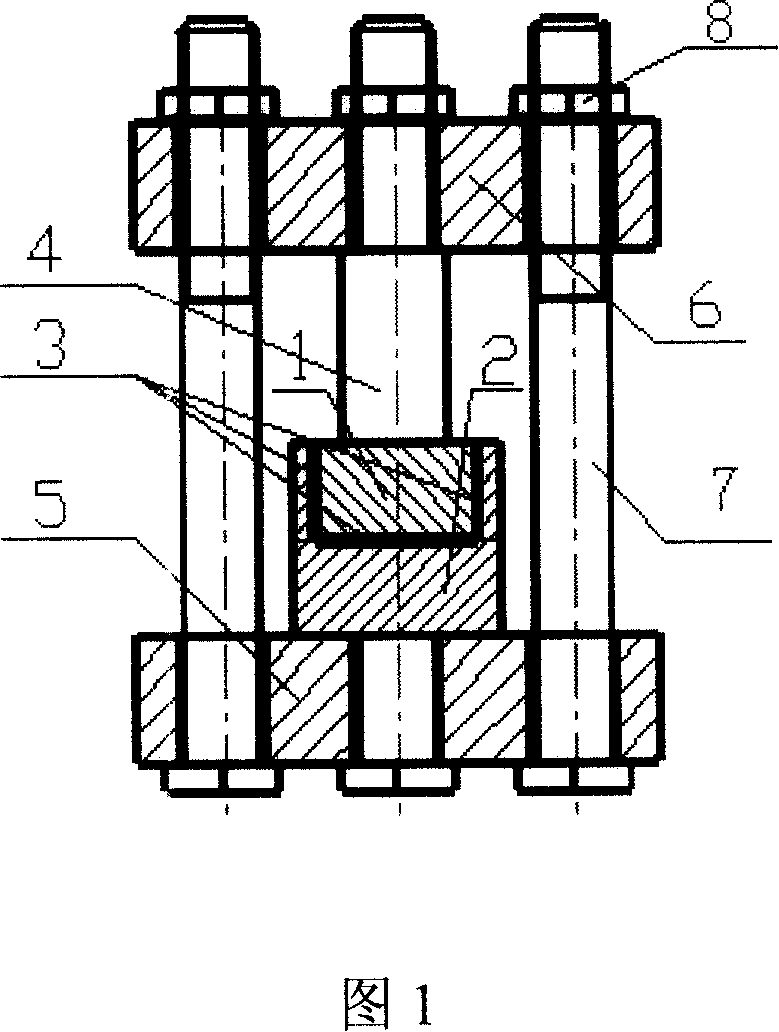

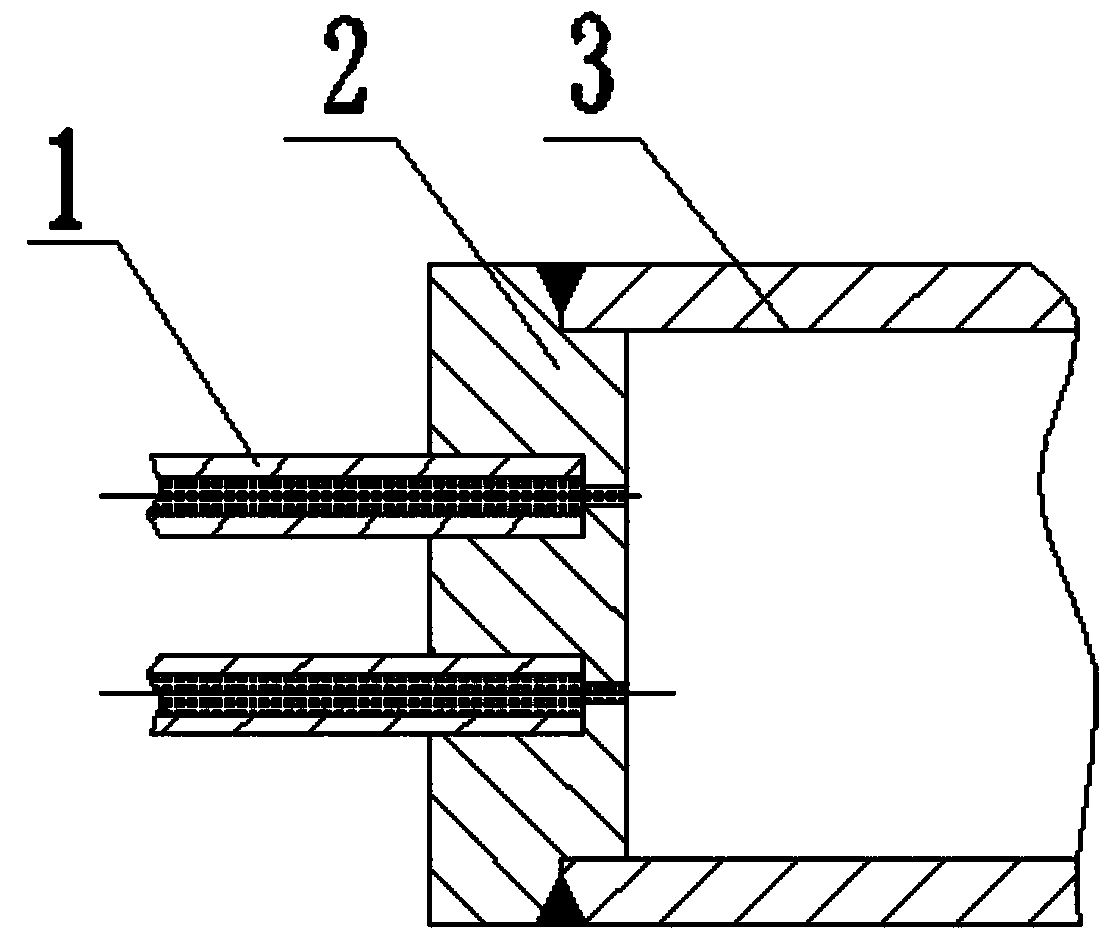

High temperature alloy complex groove structure panel and flange liquid phase diffusion connecting method

InactiveCN101148000AFirmly connectedImprove welding qualityWelding/cutting auxillary devicesAuxillary welding devicesTitanium alloyMaterials science

The liquid phase diffusion process for connecting high temperature titanium alloy panel in complicated channel structure and flange includes the following steps: 1. surface treatment of the panel and the flange before welding; 2. sot welding the interlayer material onto the surface of the panel or the flange; 3. fixing the welded parts with welding fixture; and 4. setting inside a vacuum furnace, heating to melt the interlayer material, maintaining the temperature for connection, maintaining at the diffusion temperature after solidification for certain time and cooling inside the furnace. The process realizes the effective connection between high temperature titanium alloy panel in complicated channel structure and flange.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH

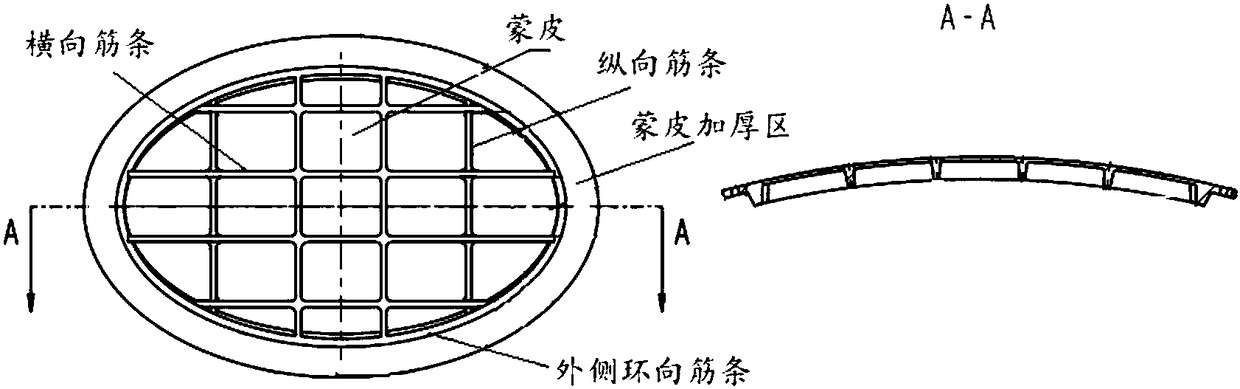

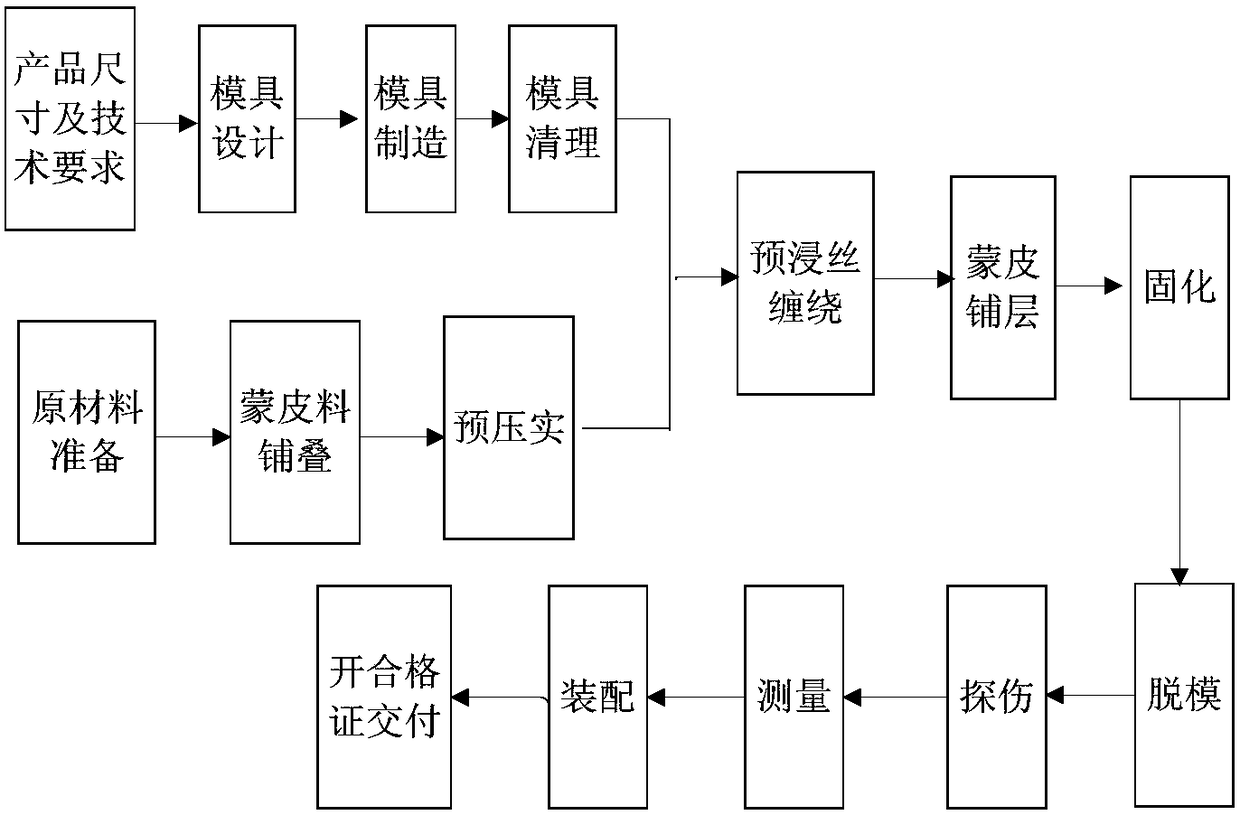

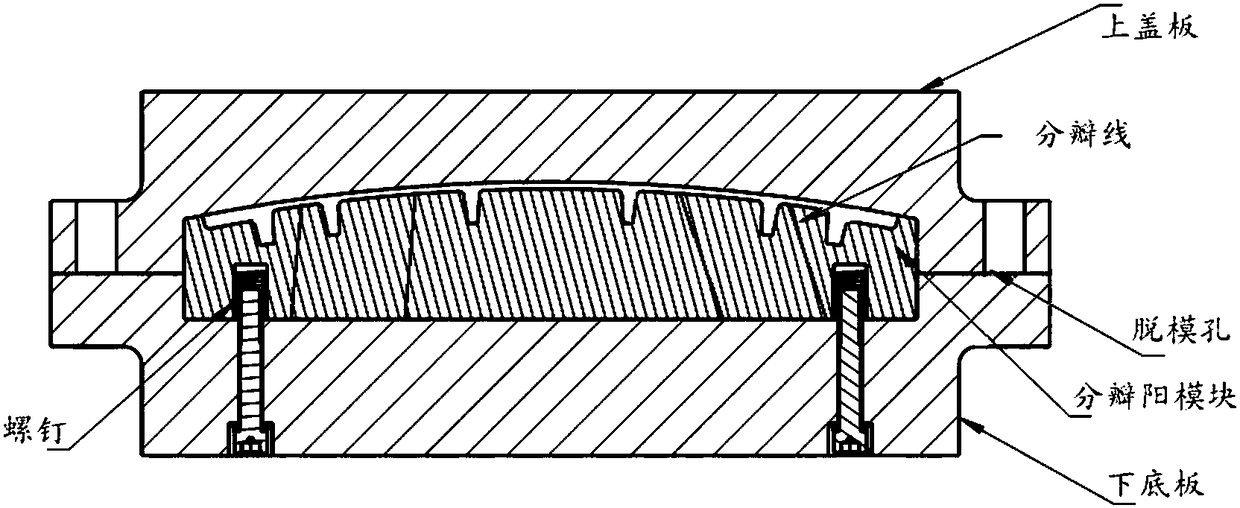

Composite material grid skin structure part die compression molding forming method

ActiveCN108407332AUniform thicknessGood internal and external qualityCompression moldingSkin structure

The invention relates to a composite material grid skin structure part die compression molding forming method, and belongs to the technical field of composite material forming. A set of control measures suitable for skin grid structure part die compression molding forming technology are found through reasonable rib winding and skin laying technological design, one-time integral forming of a composite material skin grid structure part is achieved, product deformation is small, the thickness is uniform, the operation efficiency is high, and rib winding and skin layer laying for the composite material skin grid structure part can be completed only through one day.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

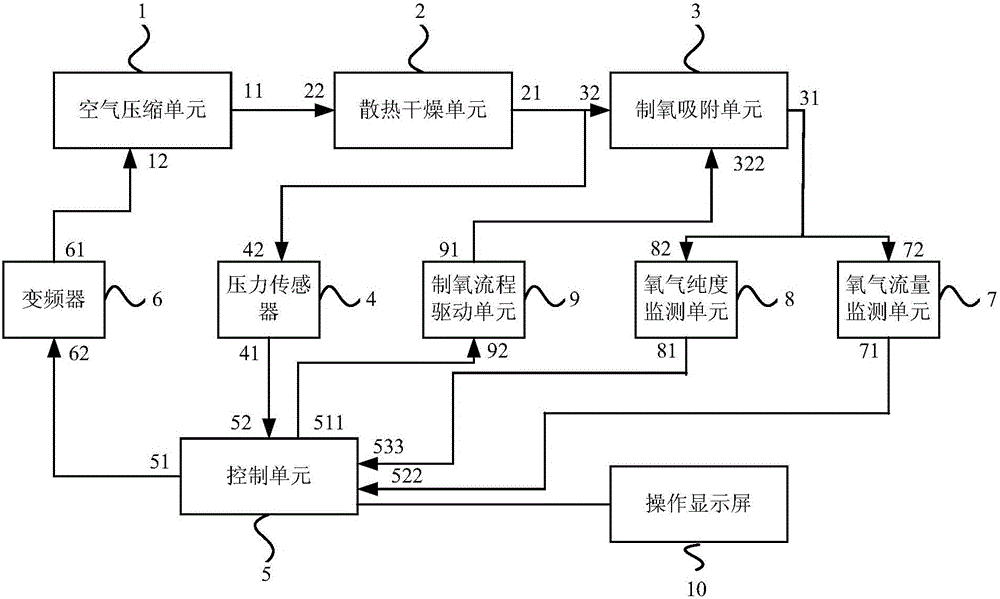

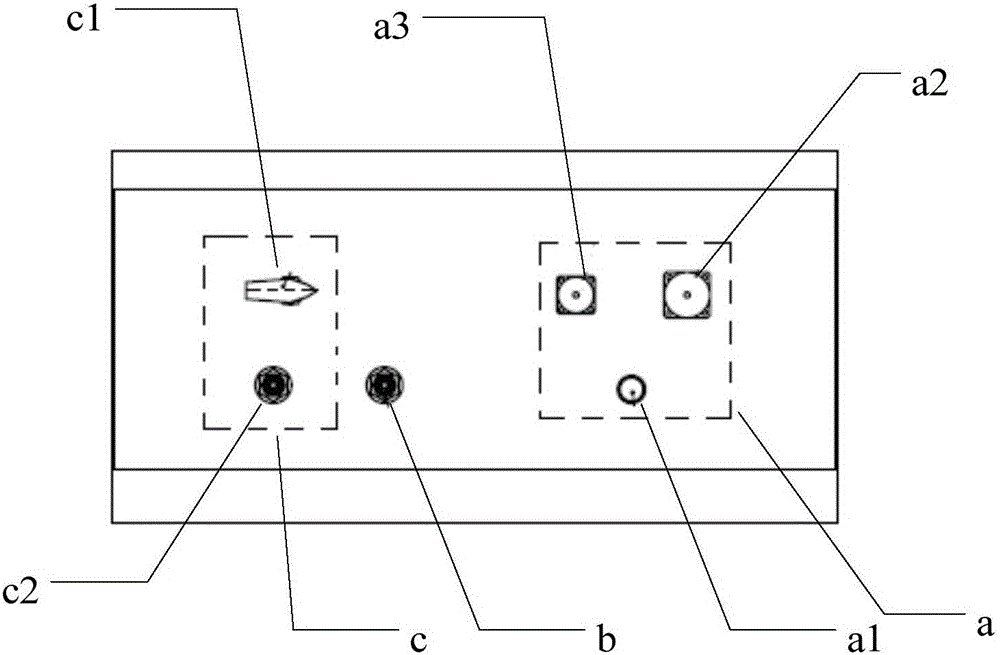

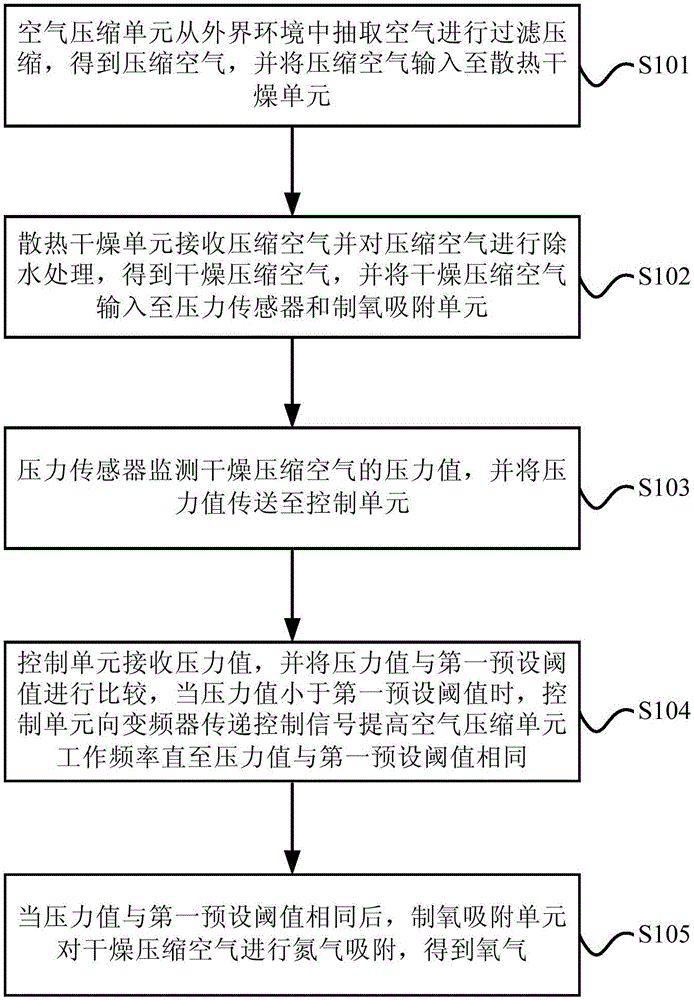

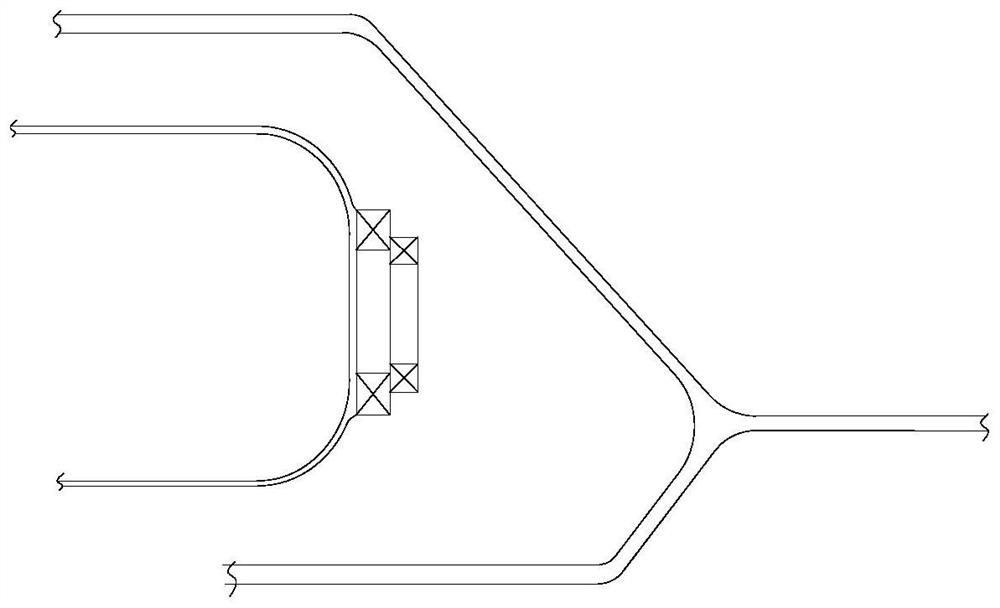

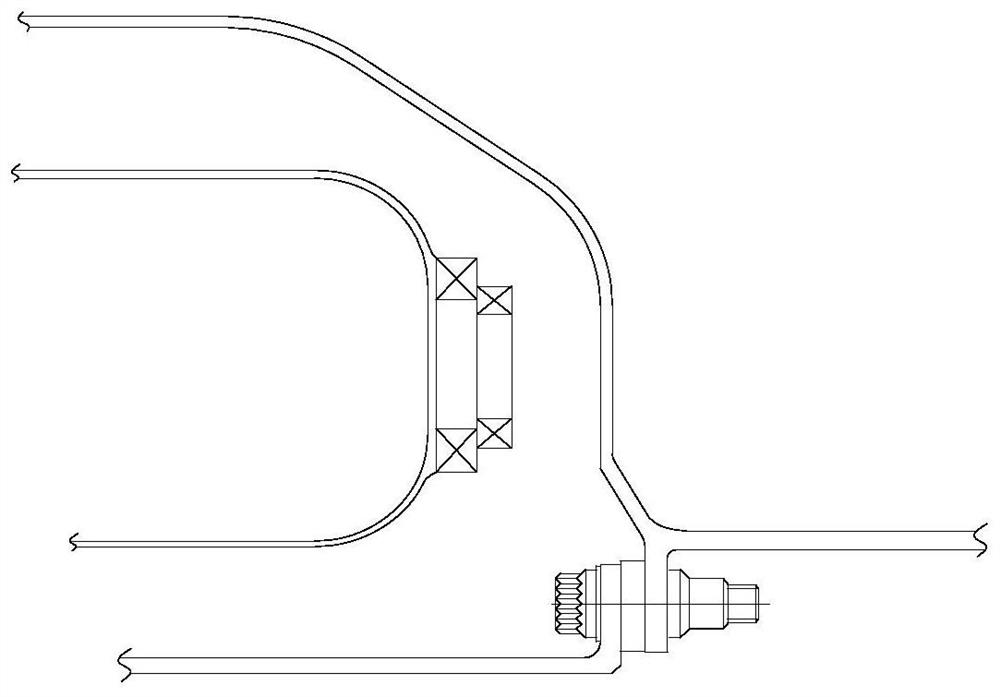

Variable frequency altitude self-adaption pressure swing adsorption oxygenator and oxygen generation method

ActiveCN105883723AMeet the design index requirementsSpecific gas purification/separationOxygen preparationFrequency changerAir compression

The invention provides a variable frequency altitude self-adaption pressure swing adsorption oxygenator and an oxygen generation method. The oxygenator comprises an air compression unit, a heat dissipating dry unit, an oxygen generation adsorption unit, a pressure sensor, a control unit and a frequency converter. A first output end of the air compression unit is connected with a first input end of the heat dissipating dry unit, and a first output end of the heat dissipating dry unit is connected with a first input end of the oxygen generation adsorption unit. An input end of the pressure sensor is connected with the first output end of the heat dissipating dry unit, and an output end of the pressure sensor is connected with a first input end of the control unit. An input end of the frequency converter is connected with a first output end of the control unit, and an output end of the frequency converter is connected with a first input end of the air compression unit. The control unit changes the power working frequency of the air compression unit through the frequency converter according to a control signal transmitted by the pressure sensor. The variable frequency altitude self-adaption pressure swing adsorption oxygenator and the oxygen generation method can meet the oxygen generation requirements in all areas where the air thickness degrees are different at different altitudes.

Owner:SANITARY EQUIP INST ACAD OF MILITARY MEDICAL SCI PLA

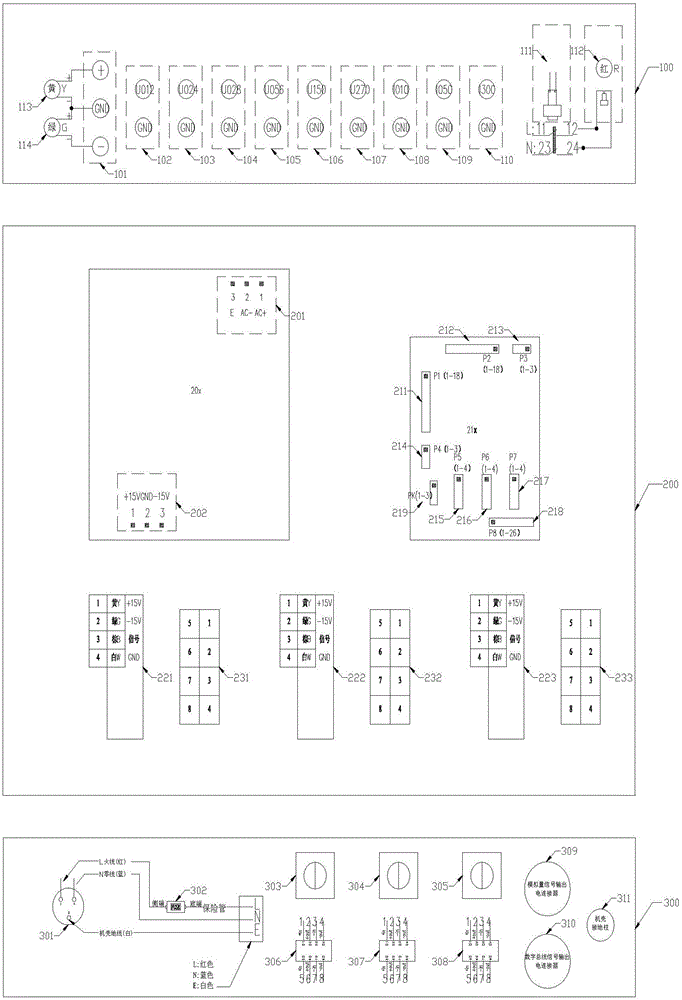

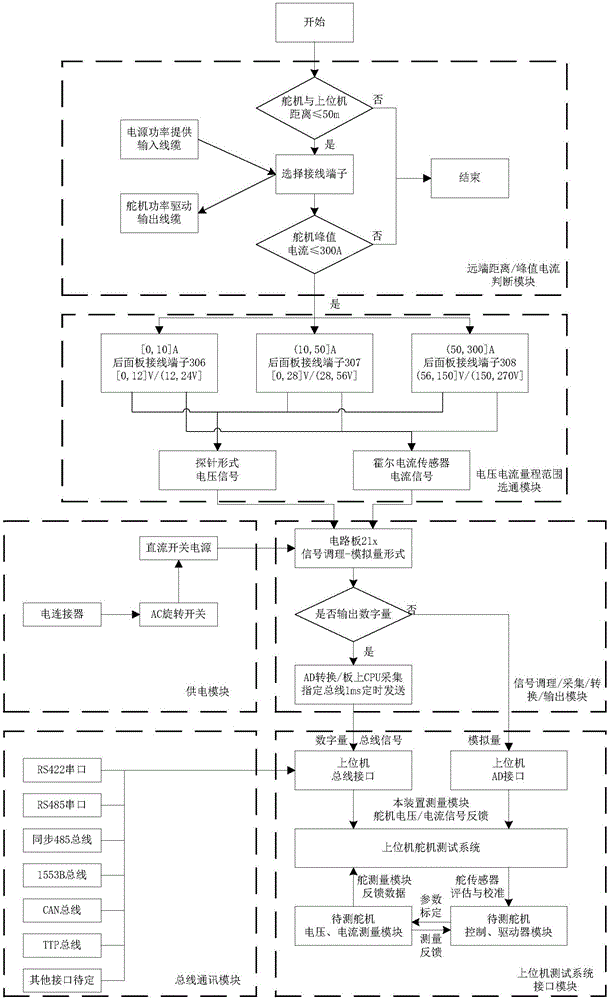

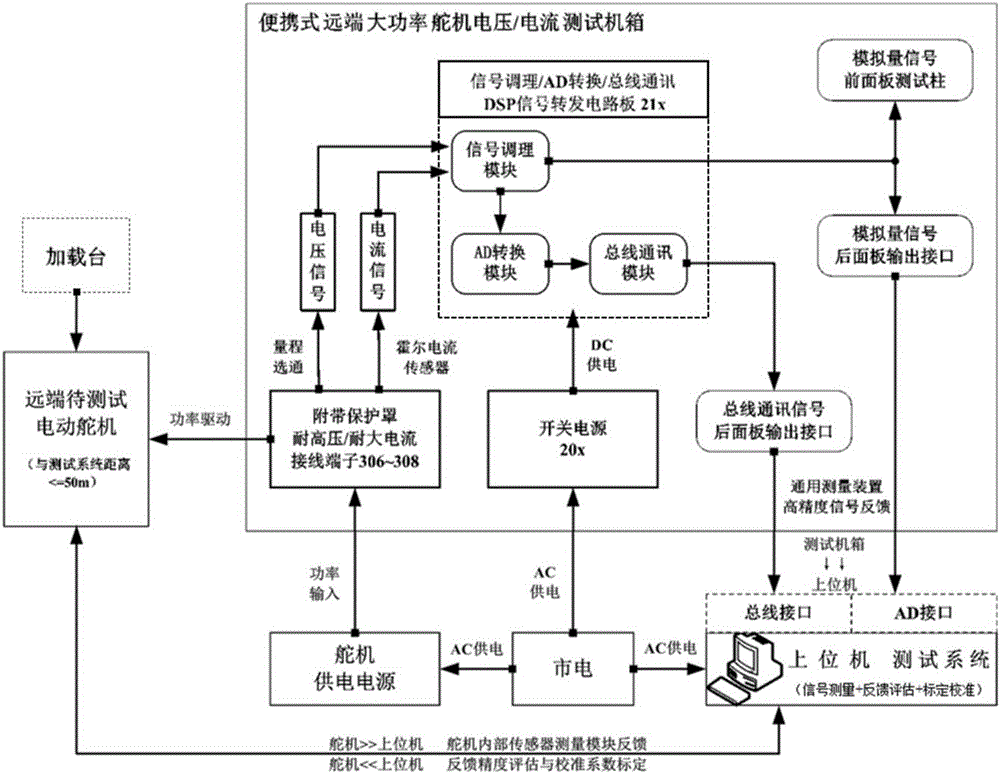

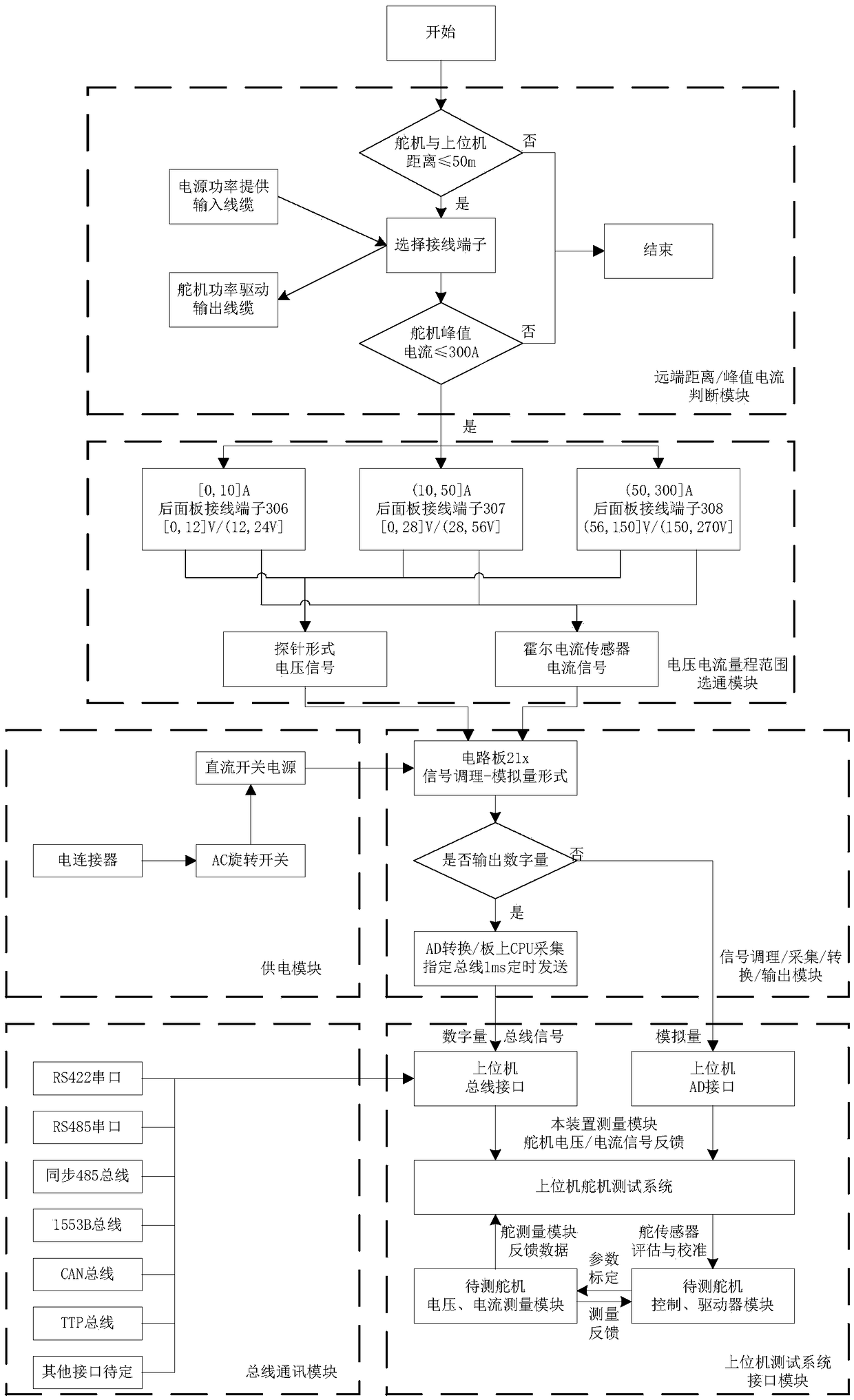

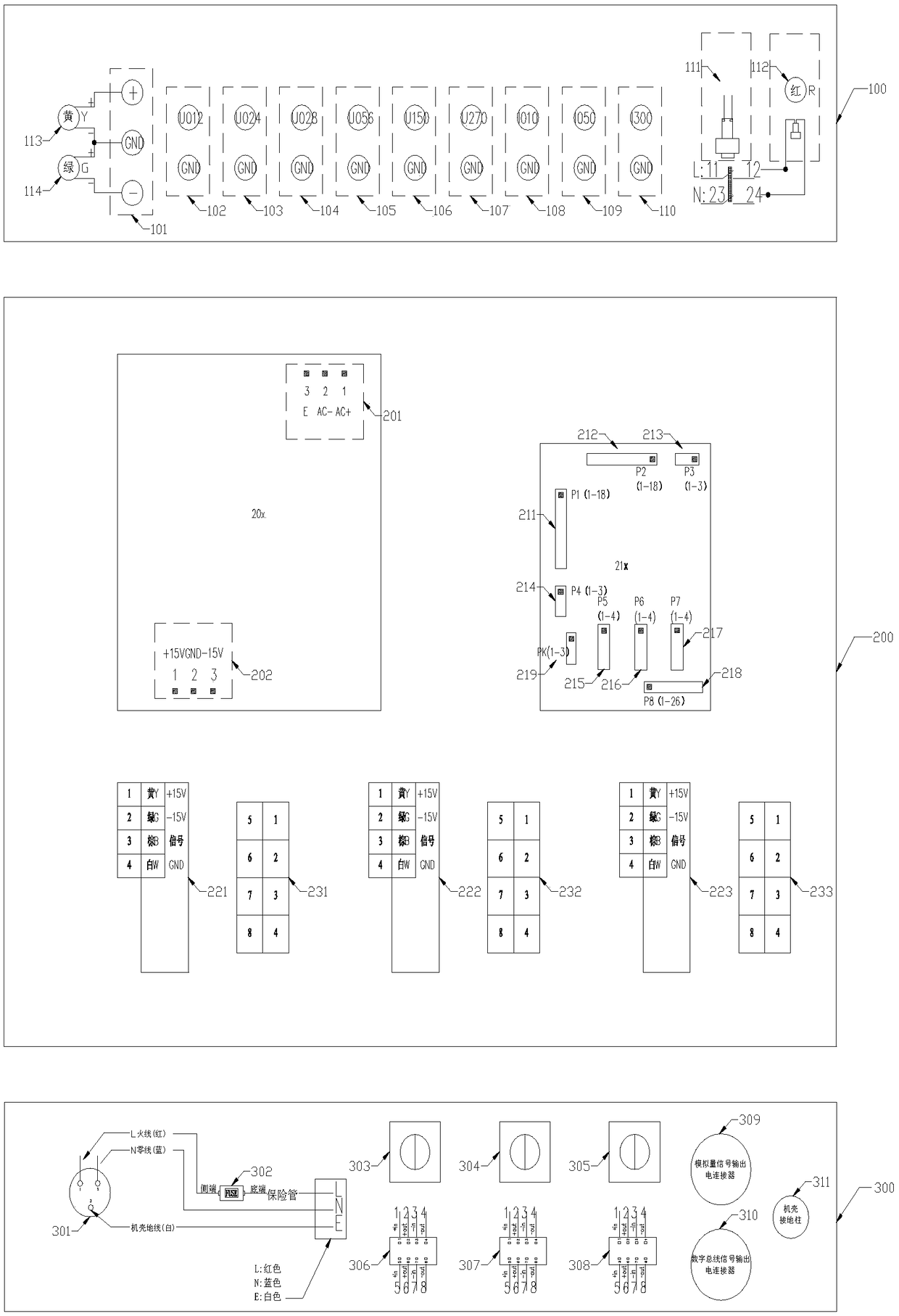

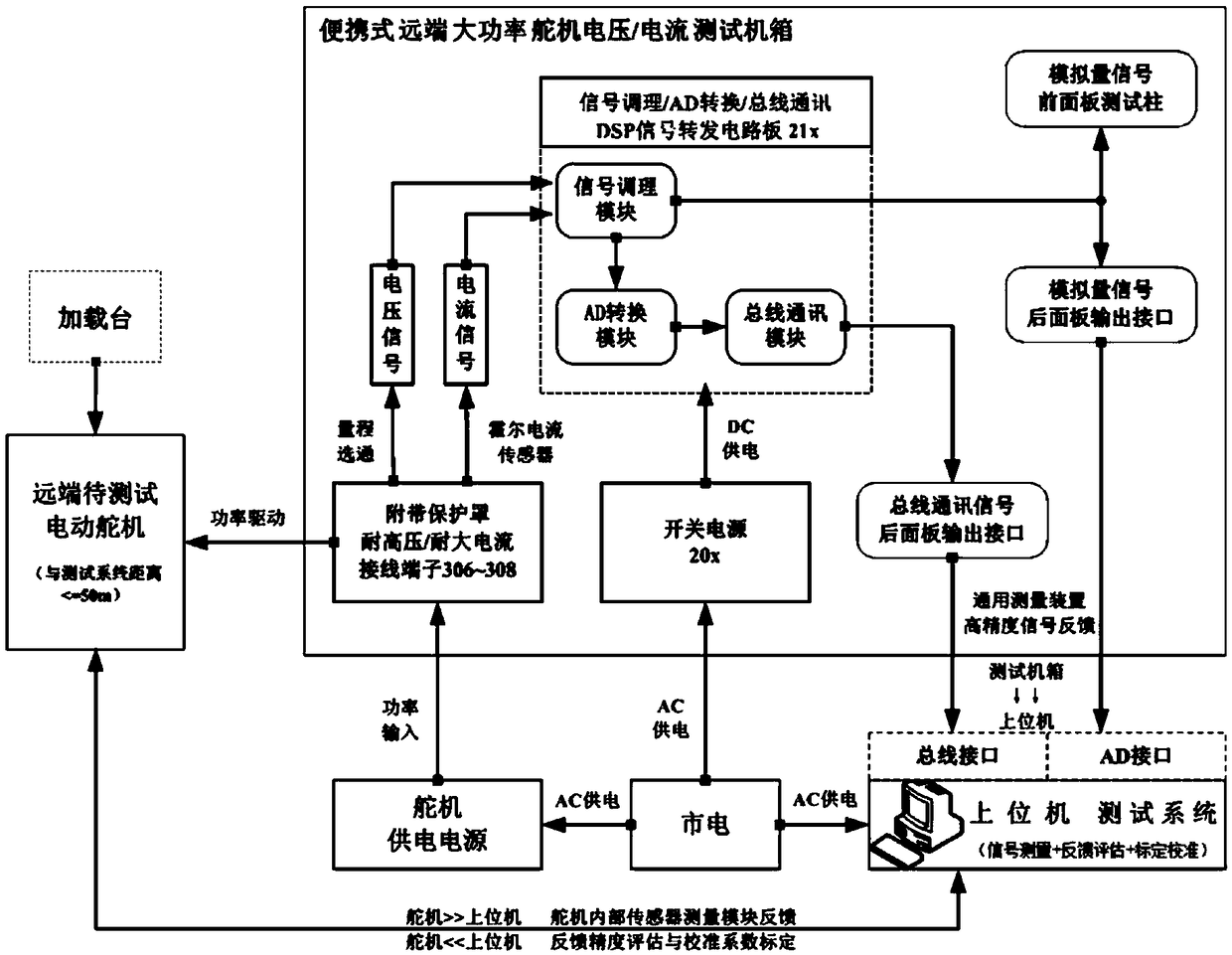

Universal portable remote high-power steering gear voltage and current measurement and calibration device

ActiveCN106249038AReduce volumeRich interfaceMeasurement using digital techniquesPeak valuePeak current

The invention relates to a universal portable remote high-power steering gear voltage and current measurement and calibration device, which comprises a power supply module, a bus communication module, a remote distance / peak current judgment module, a voltage and current range gating module, a signal conditioning / acquiring / converting / outputting module, and a principal computer test system interface module. The device has a small size and a complete range of interfaces, can be easily carried and used in all test sites, is suitable for measuring and calibrating the current and voltage of a remote to-be-tested steering gear with high peak current and rated voltage, is provided with a multi-gear measurement output range, is equipped with a variety of interface equipment, and is of high universality.

Owner:BEIJING MECHANICAL EQUIP INST

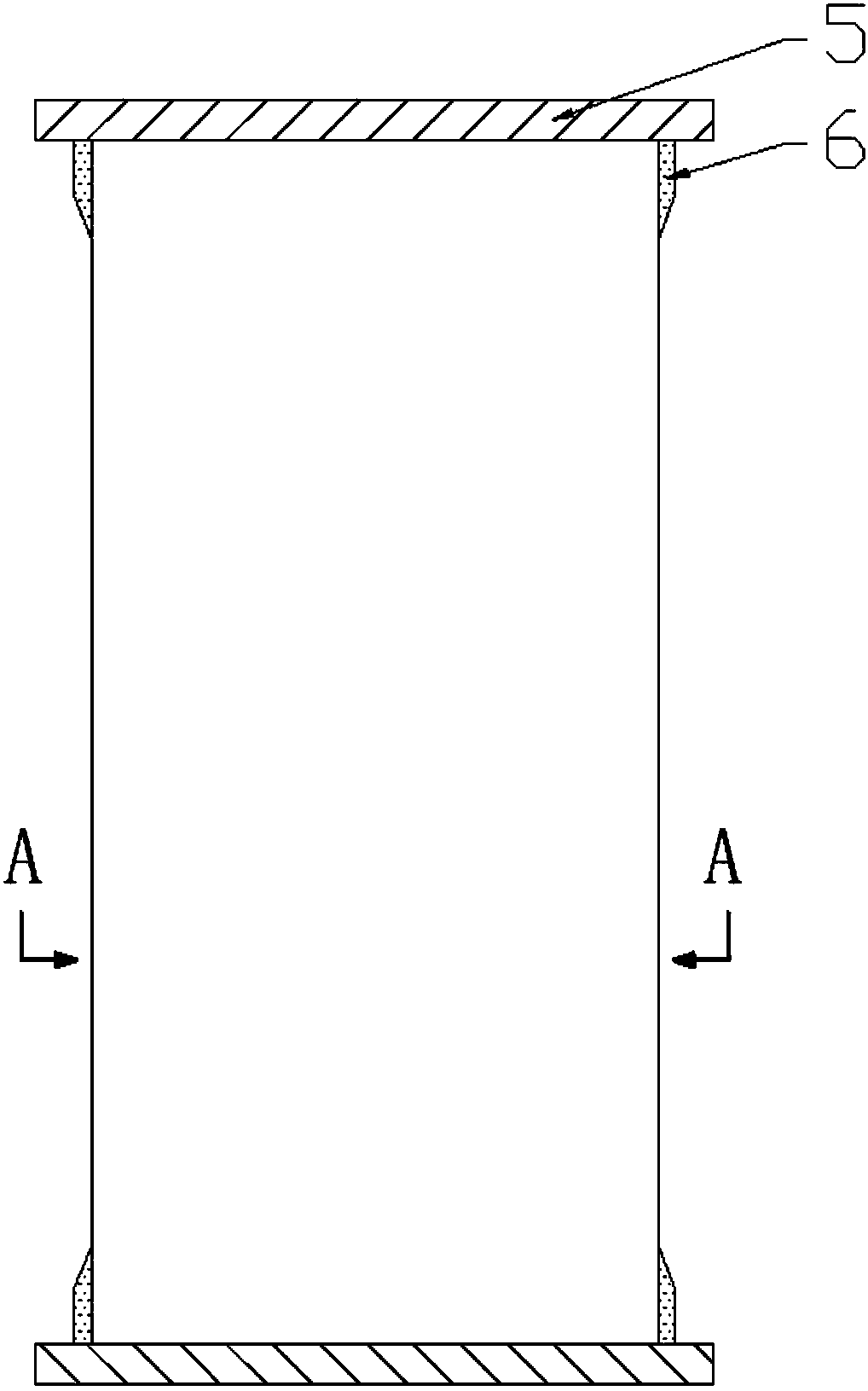

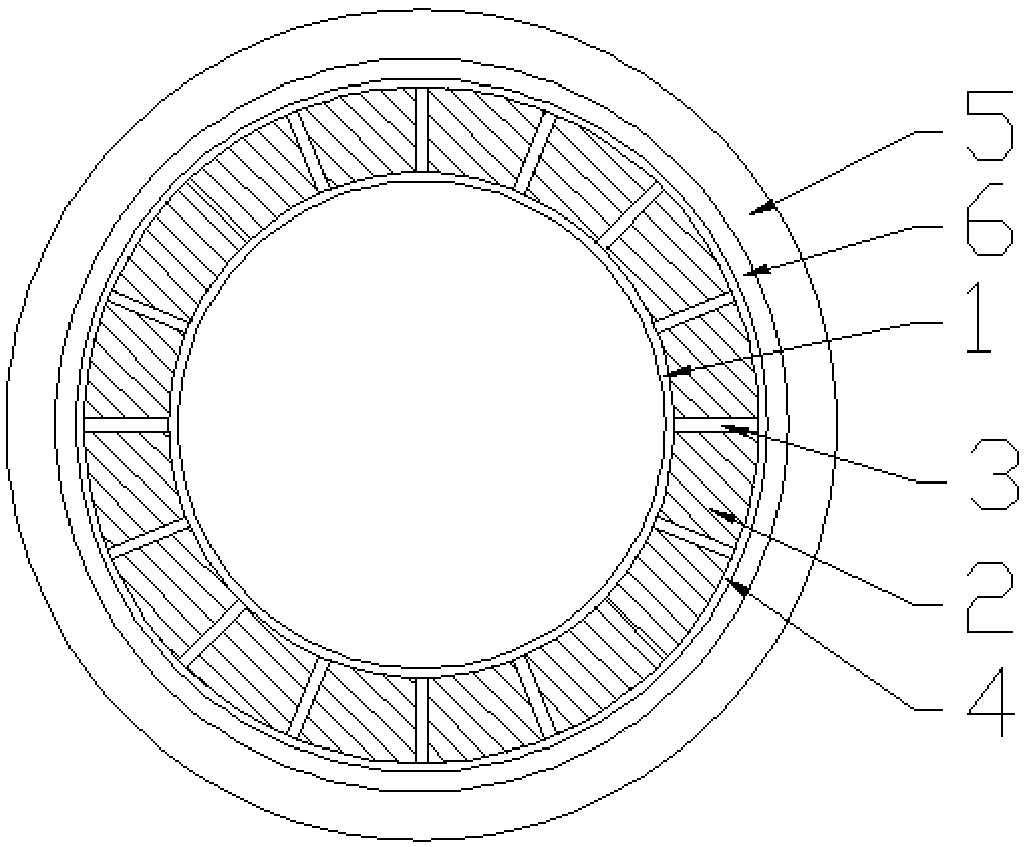

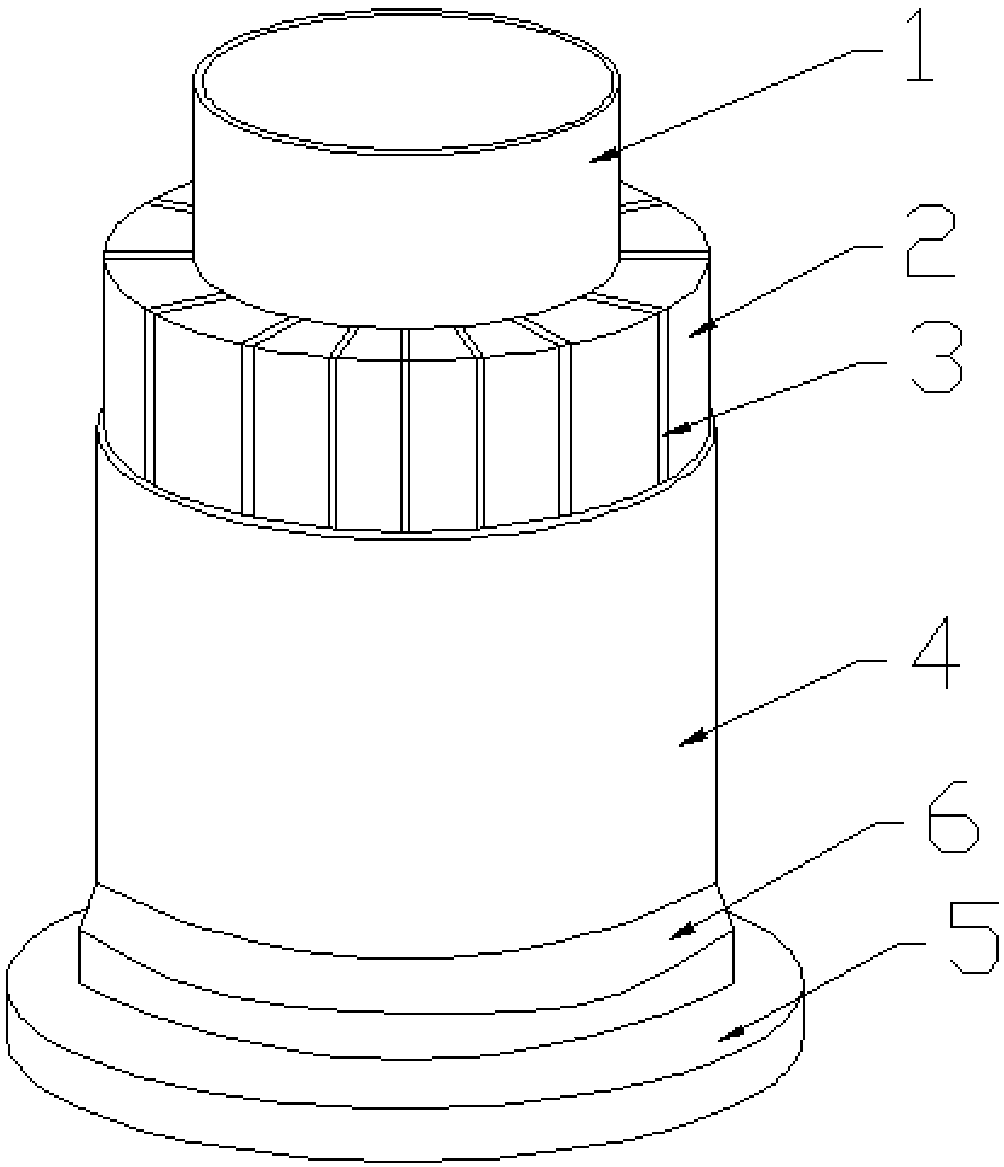

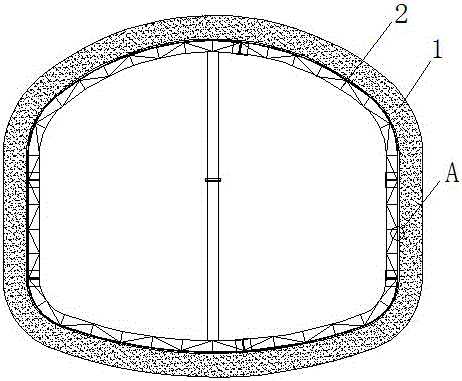

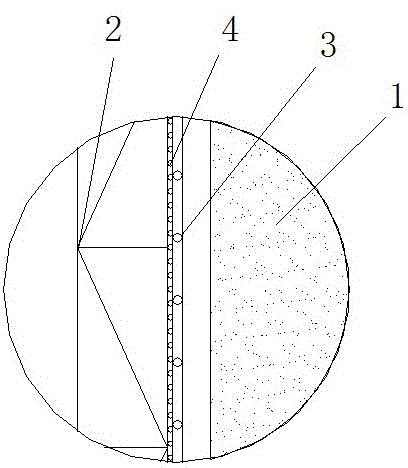

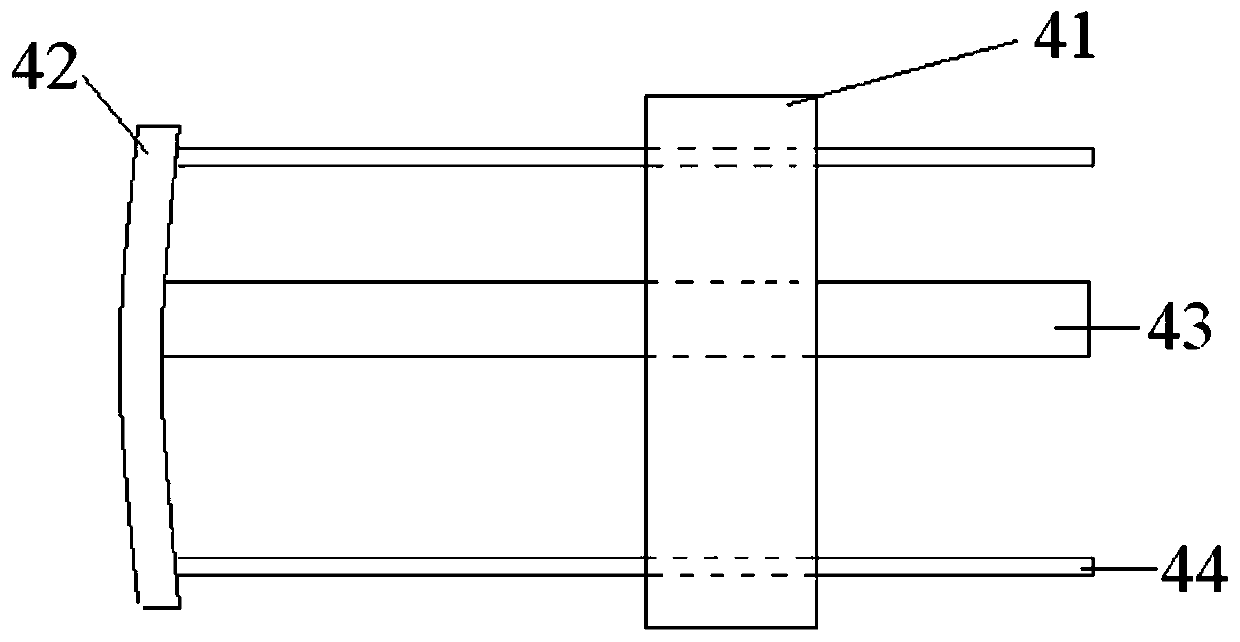

Lattice enhanced type composite material foam core sandwich supporting column and preparation method thereof

The invention discloses a lattice enhanced type composite material foam core sandwich supporting column and a preparation method thereof. A supporting column main body comprises a composite material inner skin and a composite material outer skin which are in cylindrical shapes, foam plate strips are arranged between the composite material inner skin and the composite material outer skin, compositematerial lattices are arranged between the foam plate strips, and the composite material lattices are distributed between the foam plate strips at equal intervals to connect the composite material inner skin with the composite material outer skin together. Supporting face connection flanges for being connected with a top structure or connected with another same supporting column are arranged at the two ends of the supporting column. End enhancing parts are arranged at the two ends of the outer skin of the supporting column. The lattice enhanced type composite material foam core sandwich supporting column can sharply improve the bearing efficiency under the precondition that the self weight of the structure is hardly increased, and meanwhile, the preparation method is low in cost and stable in property, and can prepare the lattice enhanced type composite material foam core sandwich supporting columns with large sizes.

Owner:ARMY ENG UNIV OF PLA

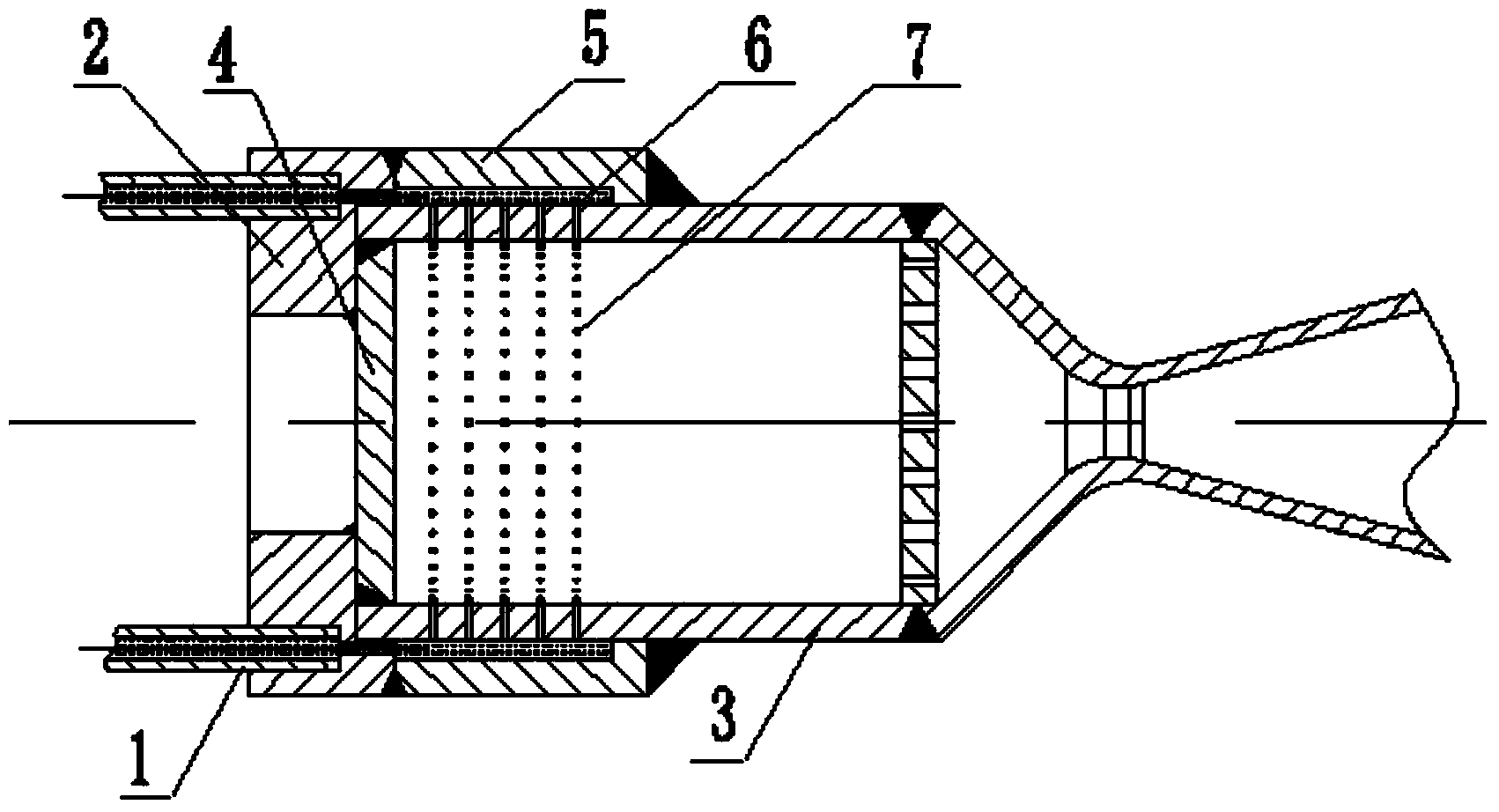

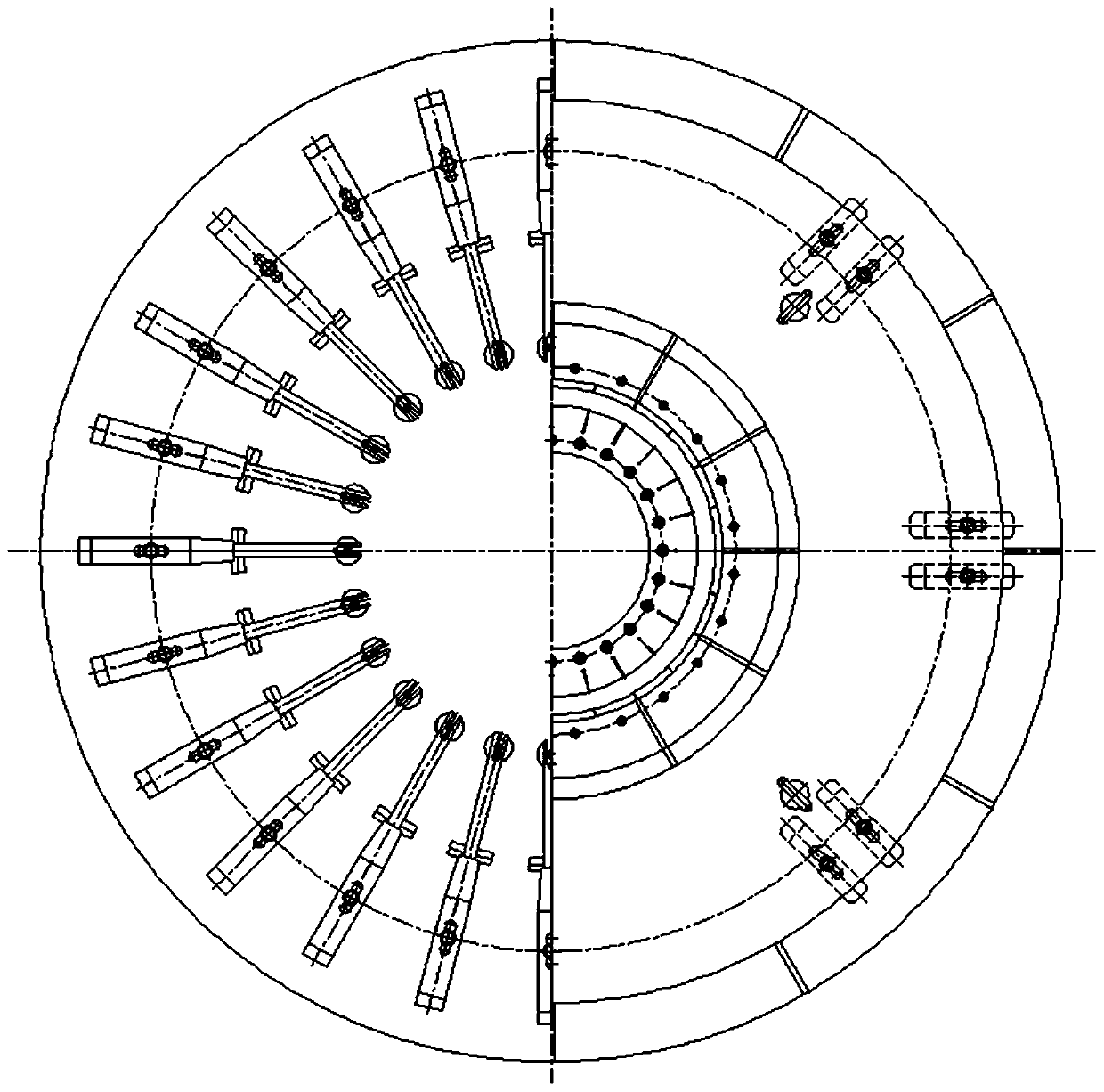

Thrust chamber injector of hydrazine type low-thrust single-unit engine

ActiveCN104265507AInjection easy to controlReduce pressure roughnessRocket engine plantsInjection pressureThrust chamber

A thrust chamber injector of a hydrazine type low-thrust single-unit engine adopts a radial injection mode and structurally comprises injection pipes, a thrust chamber and an injection disc, wherein the injection pipes are fixed to the injection disc and installed at the front end of the thrust chamber, a thrust chamber head baffle is arranged at the front end of the thrust chamber, the injection disc is of an end cover structure capable of enveloping the front section of the thrust chamber, the injection disc is in matched connection with the front section of the thrust chamber, the front section of the thrust chamber is sleeved with the injection disc, an annular injection cavity is arranged between the injection disc and the front section of the thrust chamber, more than one circle of injection micropores are evenly formed in the periphery of the barrel wall of the annular injection cavity corresponding to the front section of the thrust chamber, the injection pipes are circumferentially and evenly distributed and fixed to the injection disc, and spray nozzles of the injection pipes correspond to the annular injection cavity. A propellant is radially injected through the micropores, reasonable injection pressure drop can be provided under the condition that related propellant flows are ensured, and the thrust chamber injector is reasonable in structure and simple in manufacture, is easily retrofitted to be serialized, and can meet the power demand of the single-unit engine.

Owner:贵州航天朝阳科技有限责任公司

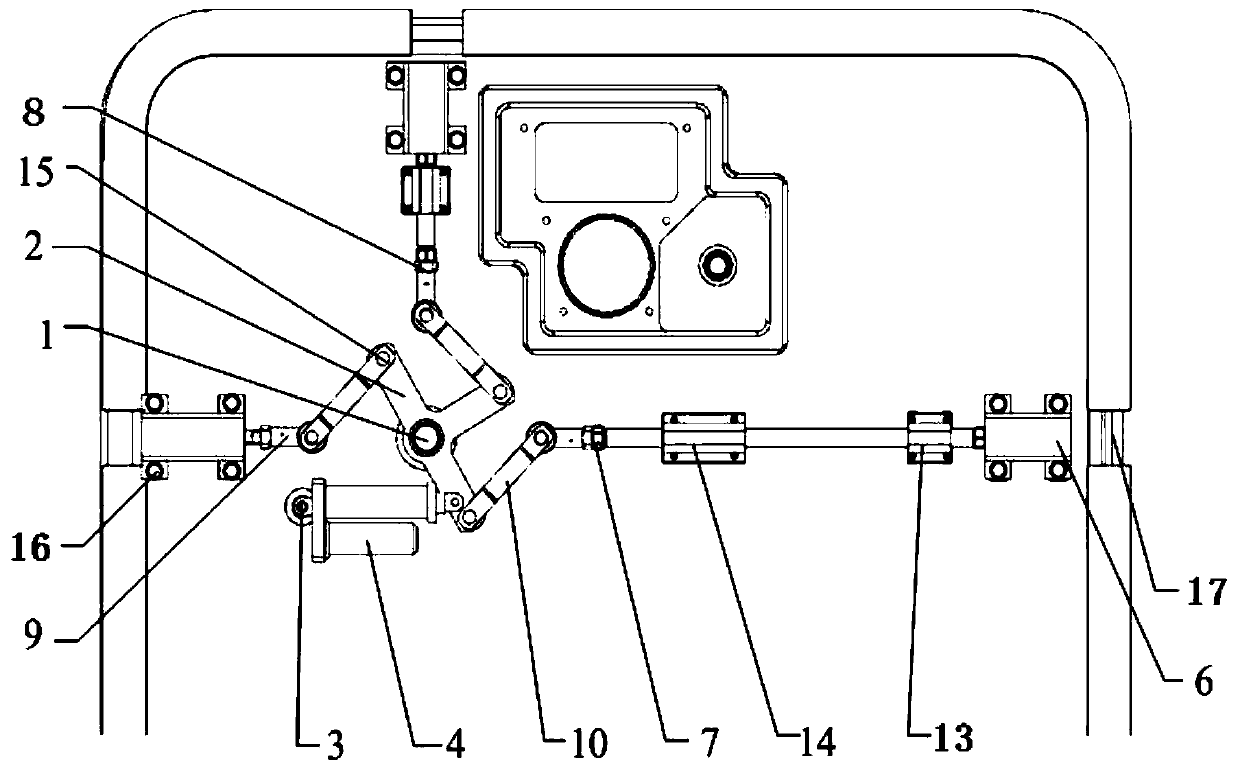

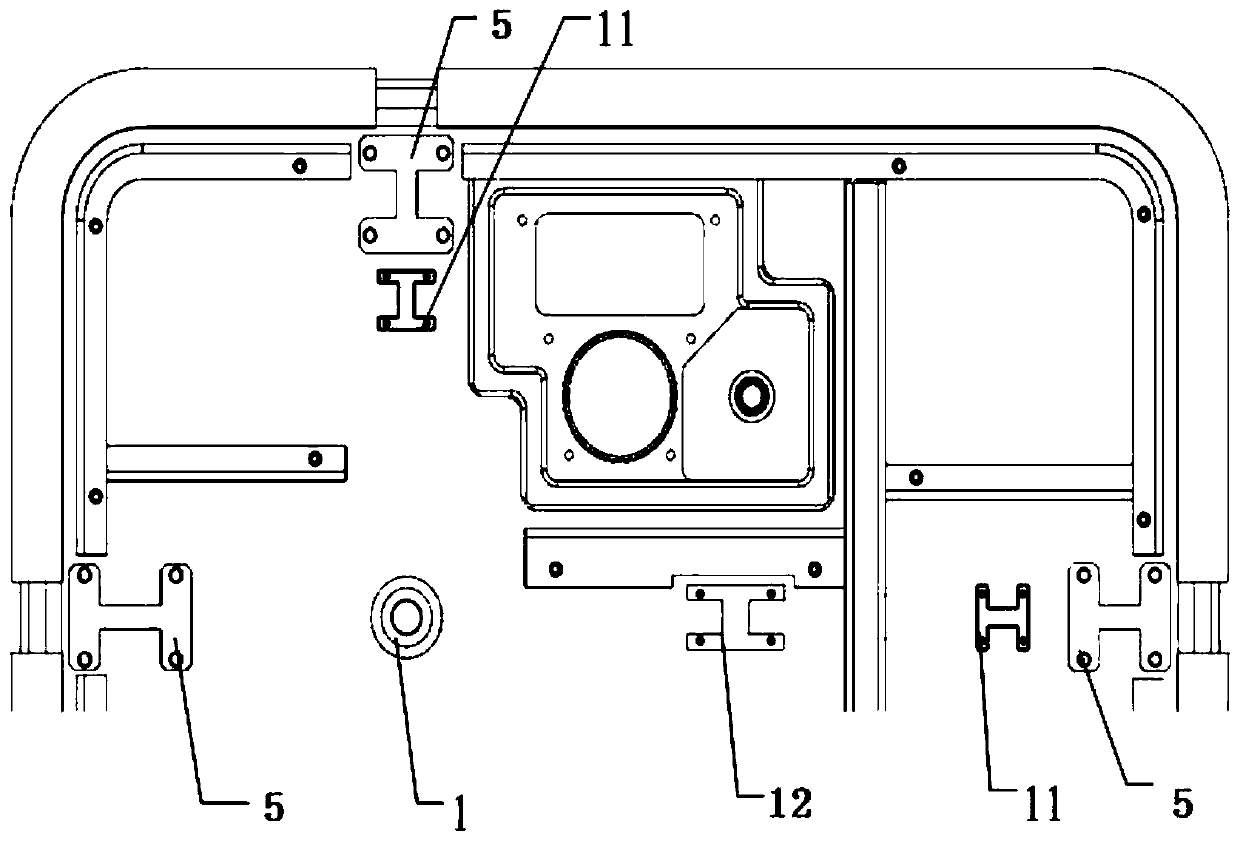

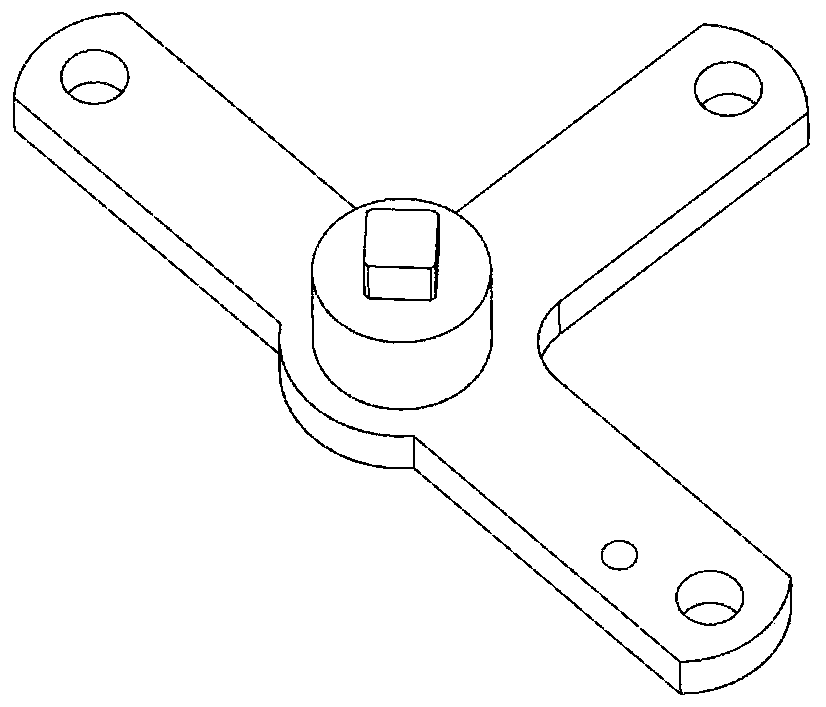

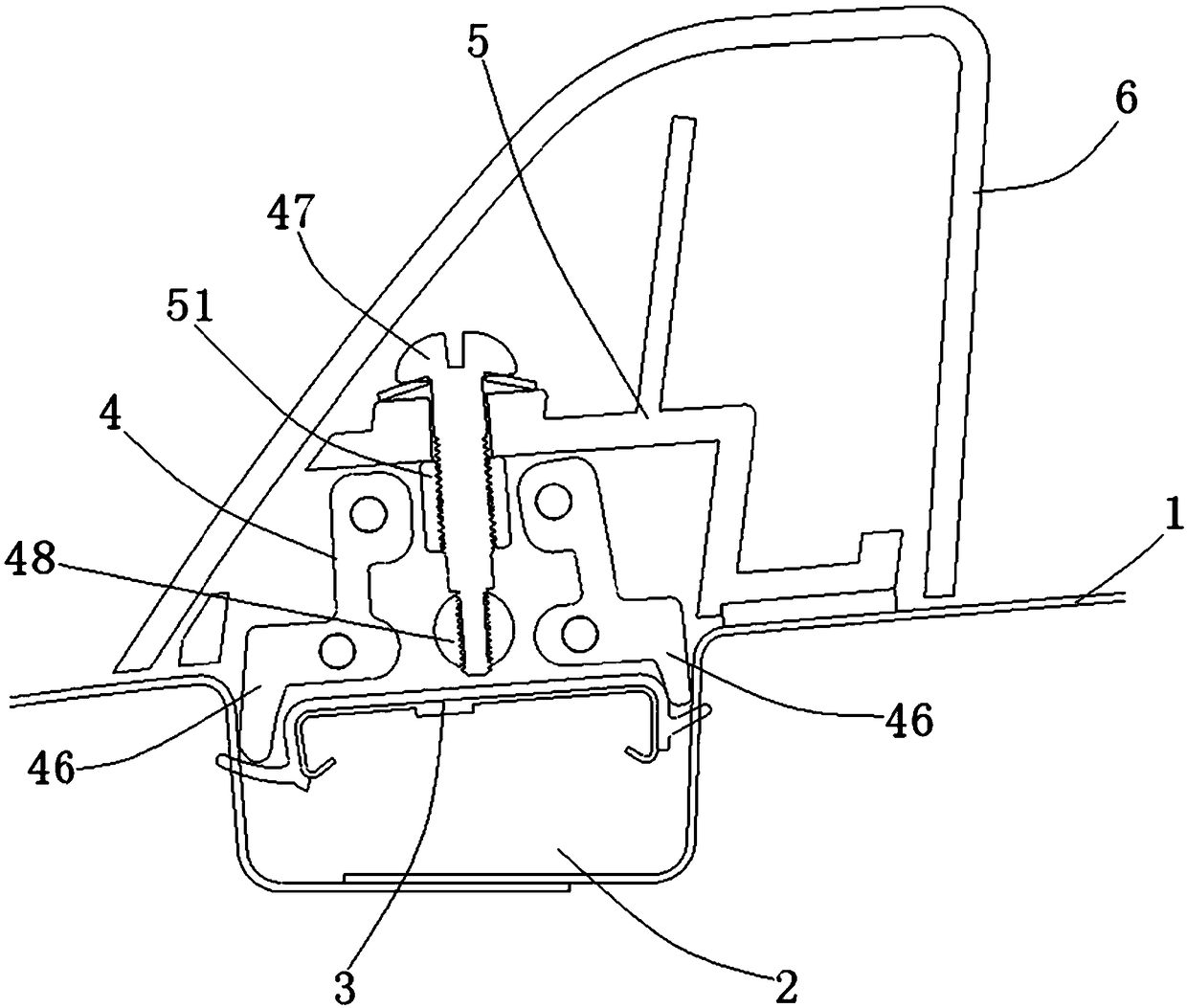

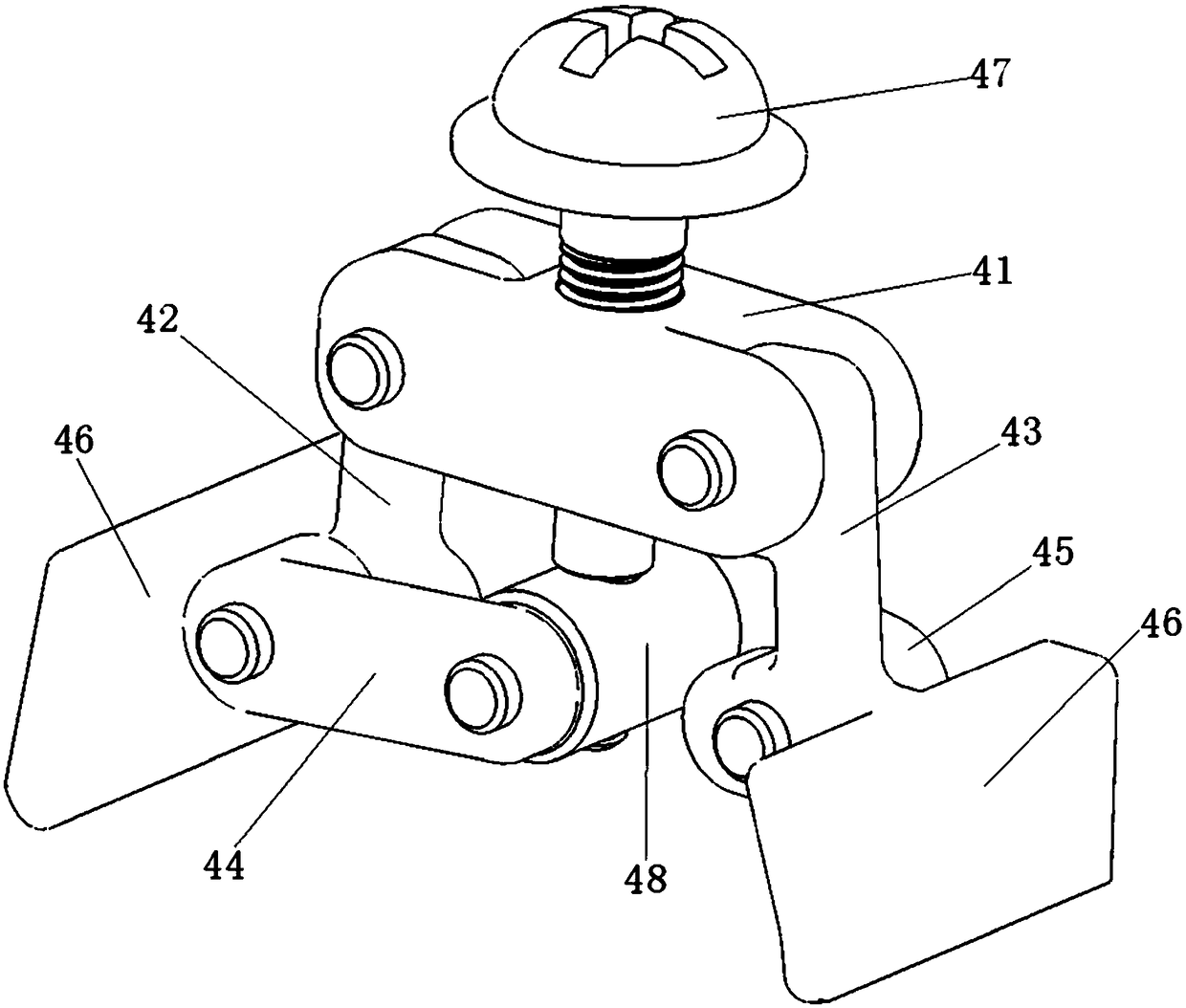

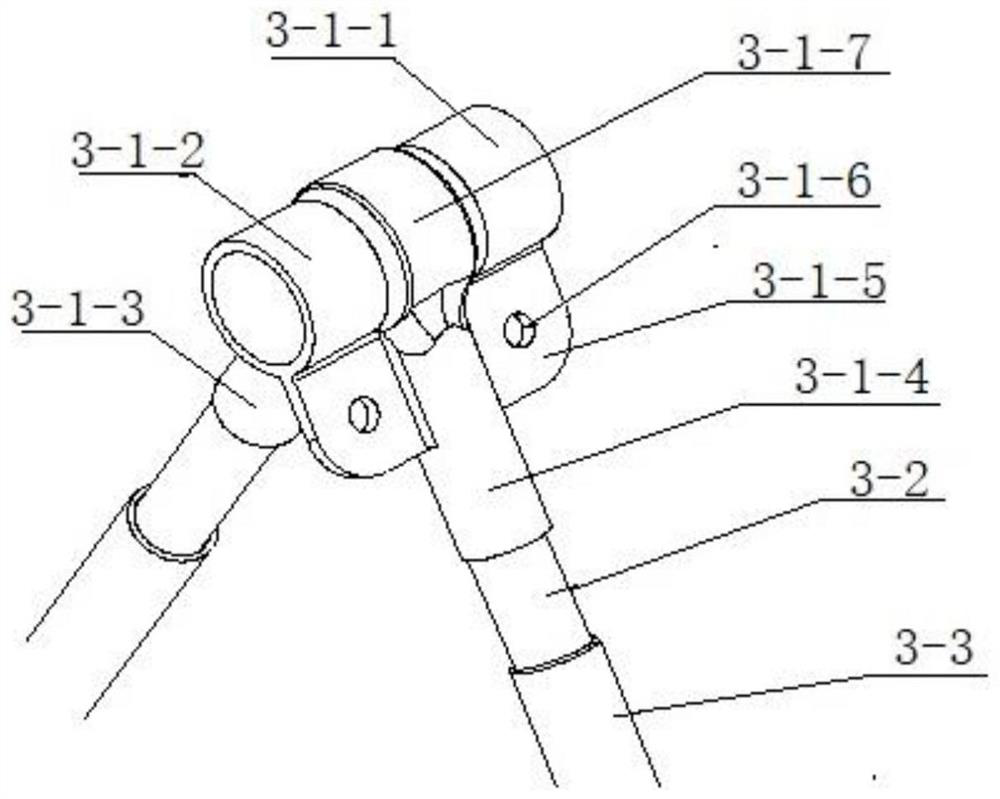

Multi-point automatic locking mechanism for armored vehicle window door

PendingCN109898942AExtended service lifeRealize automatic lockingConstruction fastening devicesDoor/window applicationsLocking mechanismEngineering

The invention belongs to the technical field of armored vehicles, and relates to a multi-point automatic locking mechanism suitable for an armored vehicle window door with the large size and high sealing requirement. The locking mechanism mainly includes a rotary arm, an electric cylinder, locking tongue guide seats, connecting rods and pull rods; and the locking mechanism is automatic, a power source is the electric cylinder, the rotary arm is driven to rotate around a rotary arm support during expansion and contraction of the electric cylinder, the three ends of the rotary arm are connectedwith the three connecting rods through the pull rods correspondingly, the connecting rods are connected with three locking tongues in a threaded mode along a linear bearing, the locking tongues extendand retract along the locking tongue guide seats under acting force of the connecting rods, the locking tongues and a window door frame are fitted and released, the locking and unlocking functions ofthe window door are realized. In case of failure of the electric cylinder, a pin shaft at the connection between the electric cylinder and the rotary arm can be loosened and released, and by rotatingthe rotary arm through tools, the manual locking and unlocking actions of the locking mechanism are realized.

Owner:BEIJING NORTH VEHICLE GROUP CORP

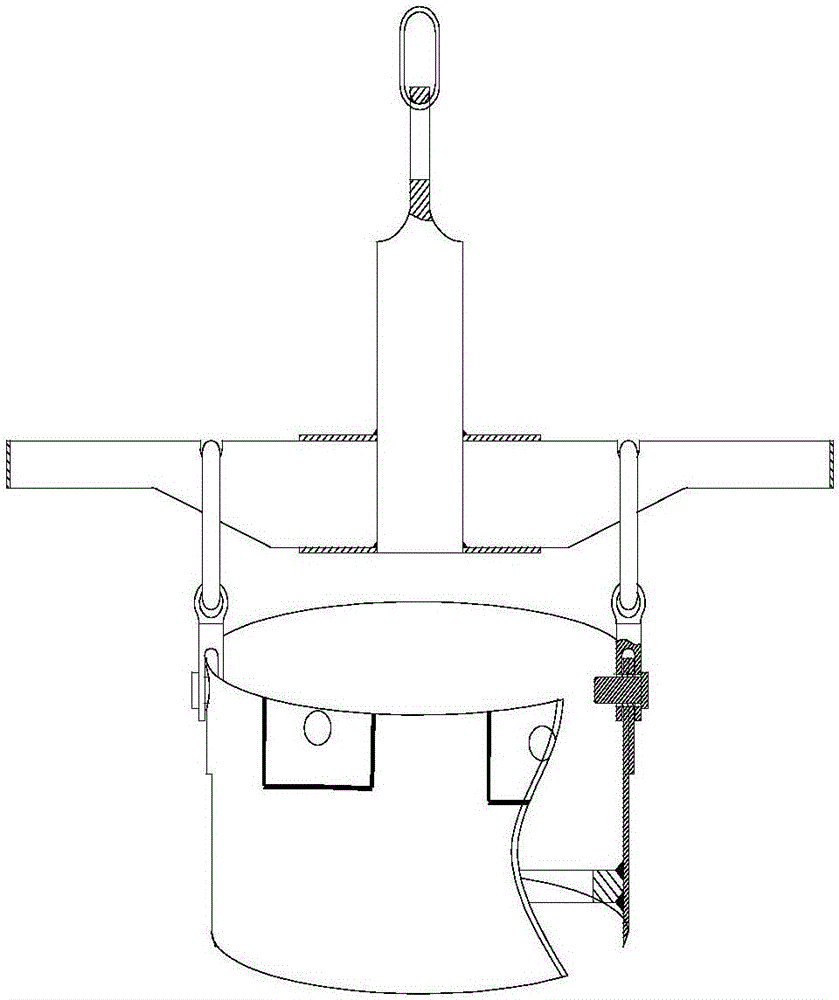

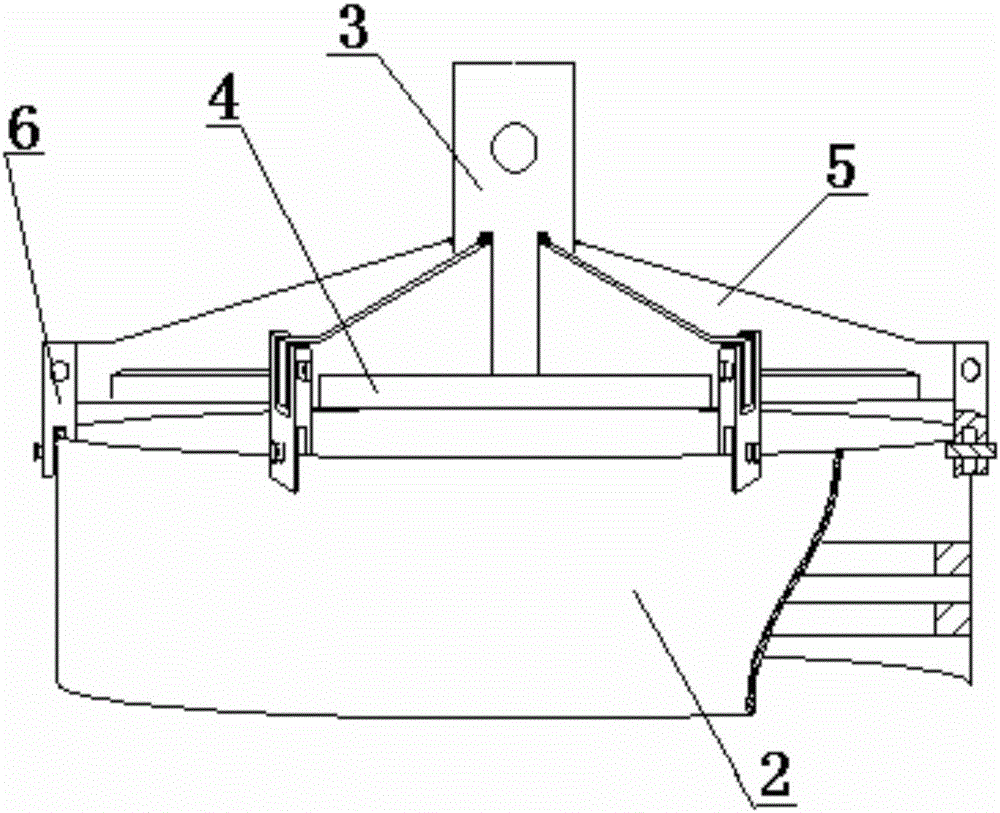

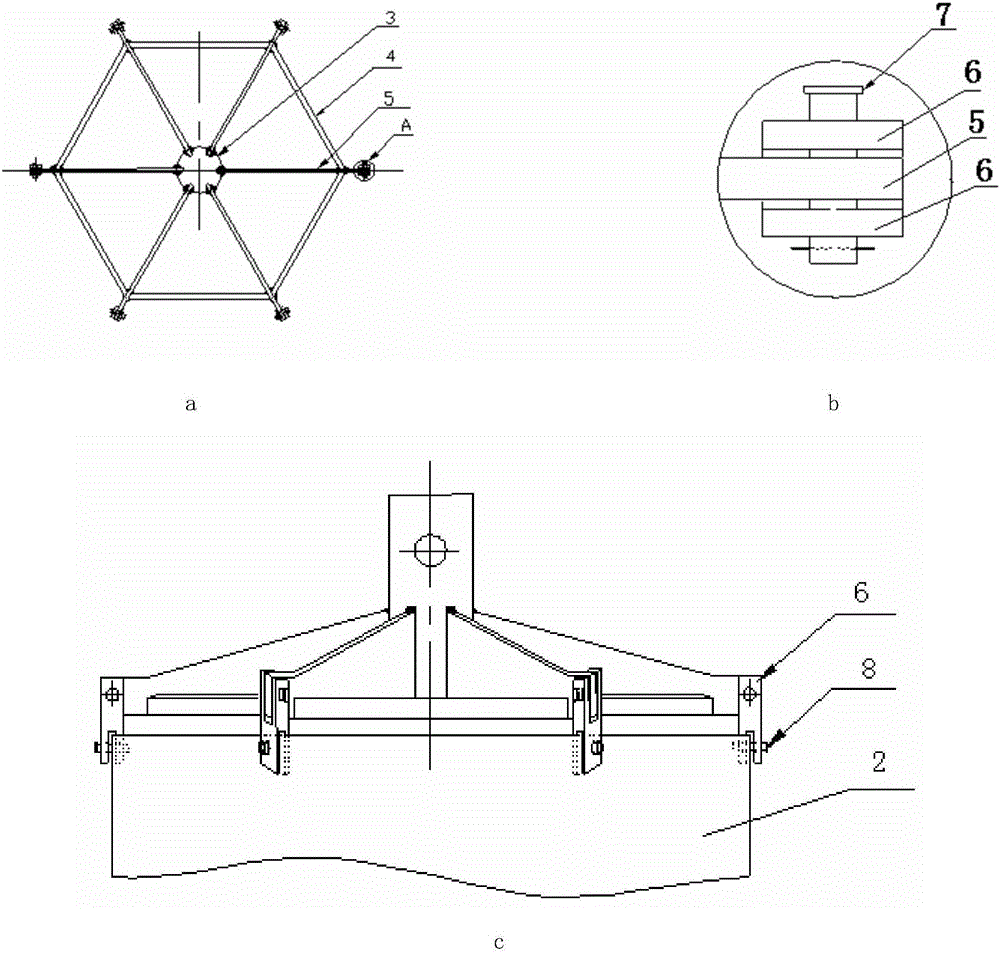

Tool for heat treatment of solid rocket engine shell

InactiveCN106755890AMeet the design index requirementsGuaranteed StrengthFurnace typesHeat treatment furnacesCantileverMechanical property

The invention provides a tool for the heat treatment of a solid rocket engine shell. A quenching lifting appliance and a technical lifting ring are used in a cooperation manner. One ends of six support plates in the quenching lifting appliance are all fixed to the circumferential surface of a vertical column, the other ends of the support plates are lifting arm ends, and the end head of each lifting arm end is separately provided with a lifting lug. A framework plate is separately fixed between the side surfaces of the lifting arm ends of every two adjacent support plates. In the invention, the perpendicular lifting heat treatment of a certain large solid rocket engine shell is realized, the heat treatment of the solid rocket engine shell is finished in a pit furnace of which the furnace opening diameter is 200mm larger than the diameter of the metal shell, and both the mechanical properties and the size of the engine shell meet design index requirements after heat treatment. Besides, after heat treatment, the tool is free of deformation and can be repeatedly used.

Owner:XIAN AEROSPACEMOTOR MACHINE FACTORY

Simple and quick geometric-constraint and weight-function calculation method suitable for use in complex aerodynamic shape of aircraft

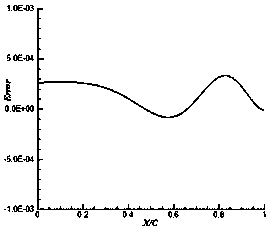

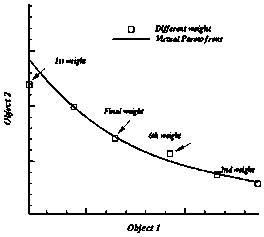

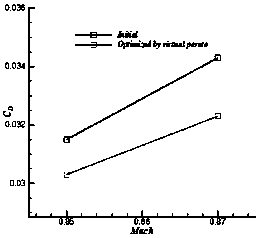

ActiveCN108197368AAvoid interpolationSimplify constraint computational difficultyGeometric CADSustainable transportationButt jointWeight coefficient

The invention discloses a simple and quick geometric-constraint and weight-function calculation method suitable for use in a complex aerodynamic shape of an aircraft. An entirely new evaluation methodof complex-aerodynamic-shape optimization design geometric-constraint and a method of weight-function selection of sensitivity-based multi-point optimization are adopted, geometric constraints of thickness, volume and the like of the any complex shape are accurately and conveniently calculated, and the calculation method is compatible with discrete surface multi-block-butt-joint-connection-grids,discrete surface unstructured-grids and the like; and weight-function selection can fully utilize valid information of existing weight-function data, and has weight coefficient selection instructiveness, and thus design potential of sensitivity-based optimization technology is fully exploited.

Owner:CALCULATION AERODYNAMICS INST CHINA AERODYNAMICS RES & DEV CENT

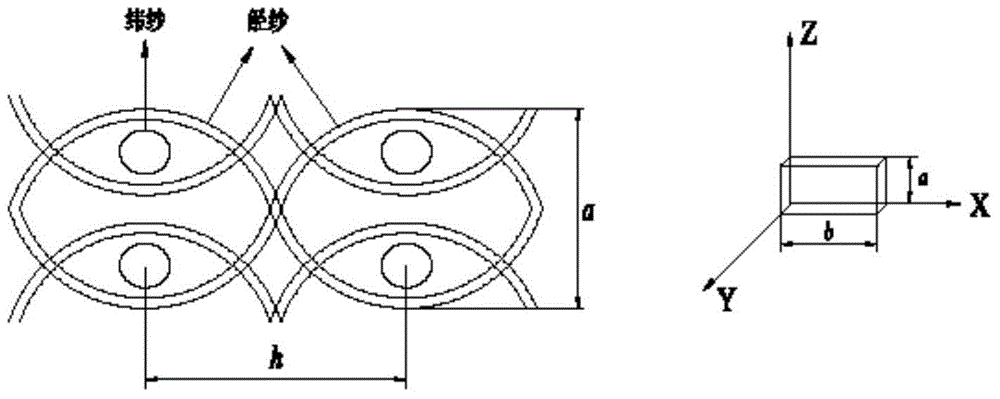

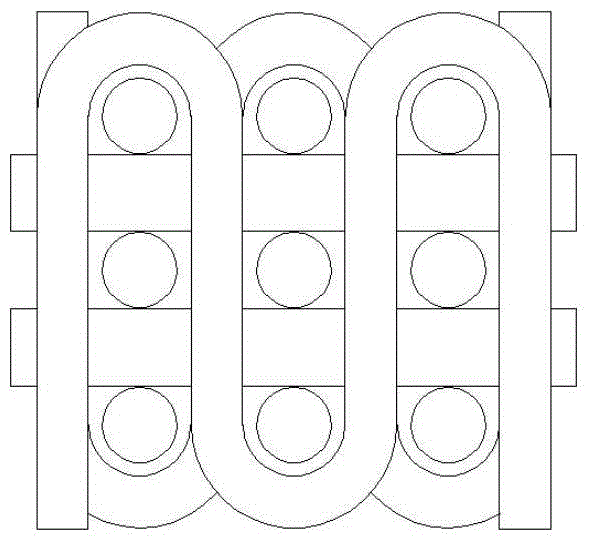

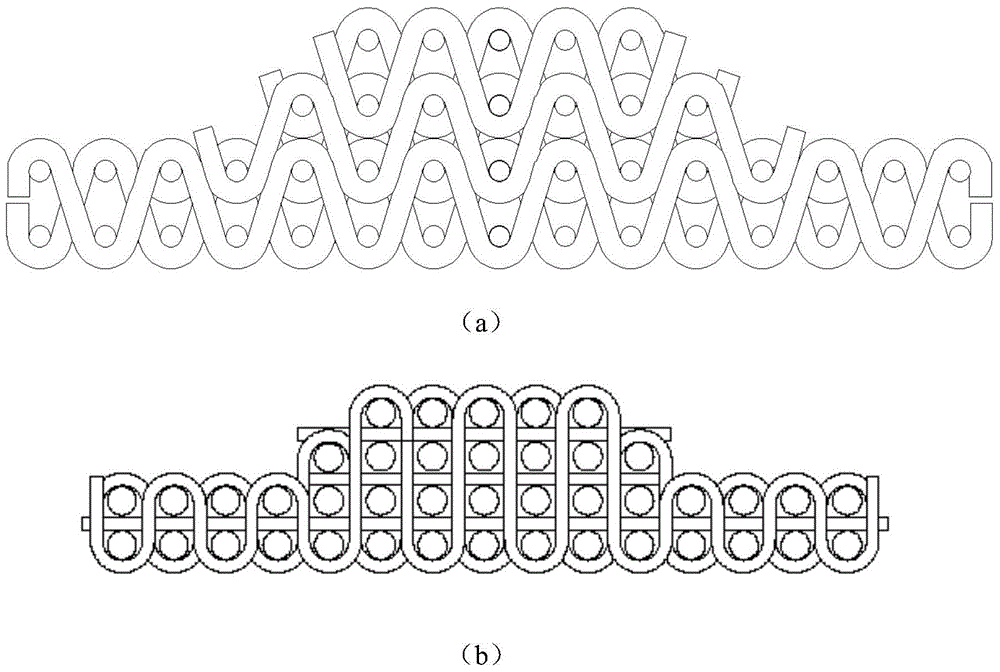

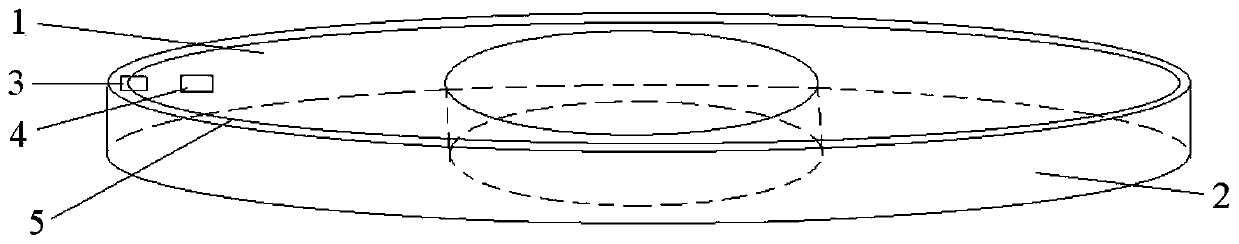

Tubular facesheet-linked fabric with ribs additionally arranged in circumferential/axial direction and preparation method thereof

ActiveCN104878507AImprove mechanical propertiesSolve the problem of two-way reinforcementWoven fabricsEngineeringVolume content

The invention discloses a tubular facesheet-linked fabric with ribs additionally arranged in the circumferential / axial direction and a preparation method thereof. The tubular facesheet-linked fabric with the ribs additionally arranged in the circumferential / axial direction comprises round tubes and rib layers in the circumferential / axial direction; the rib layers are integrally formed with the round tubes. The tubular facesheet-linked fabric with the ribs additionally arranged in the circumferential / axial direction and the preparation method of the tubular facesheet-linked fabric can achieve integrally rib adding in the circumferential direction and the axial direction at any position of the tubular facesheet-linked fabric, the rib dimensions and the fiber volume content can be designed, the structure is intact, and the rib layers in the circumferential / axial direction are well connected with the tubular facesheet-linked fabric, so the problem of integral bidirectional rib adding of the tubular facesheet-linked fabric is solved; in addition, as fibers in the thickness direction of the rib layers and the tubular facesheet-linked fabric are continuous, the connection effect is far superior to that of an original gluing or riveting mode; according to tests of the composite fabric, the performance of the fabric can totally meet the requirement of the design index and the fabric has a practical application value.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD

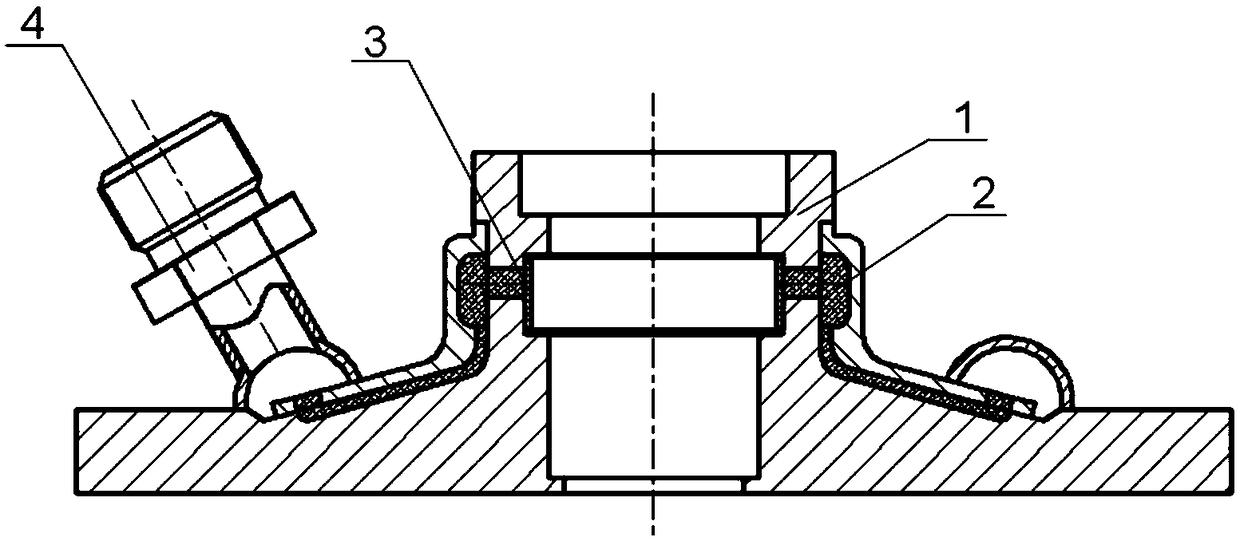

Luggage rack for roof

ActiveCN108928300AMeet individual needsMeet the needs of useSupplementary fittingsMechanical engineeringEngineering

The invention discloses a luggage rack for a roof. A luggage rack body is arranged above a roof moudling in a mounting groove and directly bonded with the roof; and moreover, a connecting structure isarranged and is in contact fit with the groove wall of the mounting groove while being connected with the luggage rack body; and therefore, the luggage rack body is firmly connected with the roof through the connecting structure. According to the luggage rack for the roof, connection and fixing can be realized without reserving a projection welding bolt on the roof and forming a hole in the roofmoudling; consumers can also additionally mount the luggage rack body by themselves in the later period, the operation is made convenient, and personalized demands of the consumers are met; in addition, the connection strength between the luggage rack body and the roof satisfies a design index requirement; and the length of a friction block can be flexibly designed according to a designed payloadweight of the luggage rack body so that the luggage rack body sufficiently meets the use demands of the consumers.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

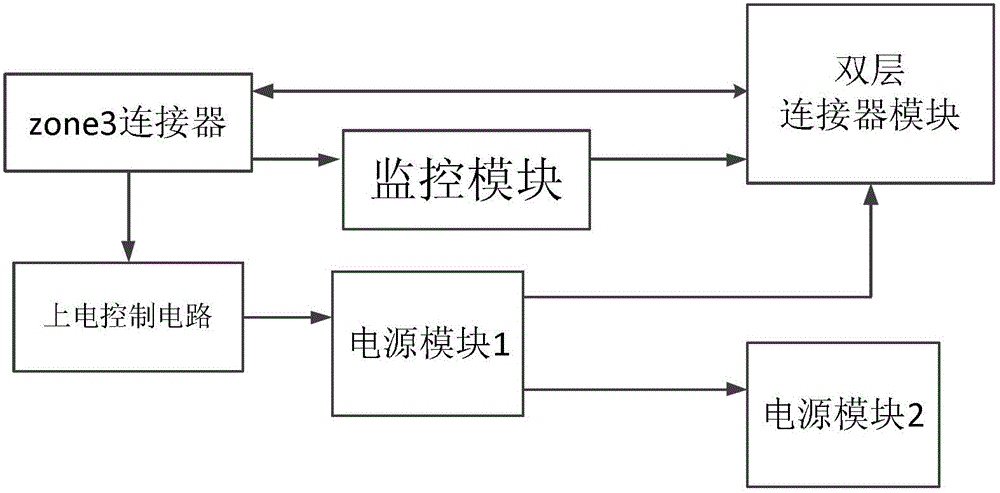

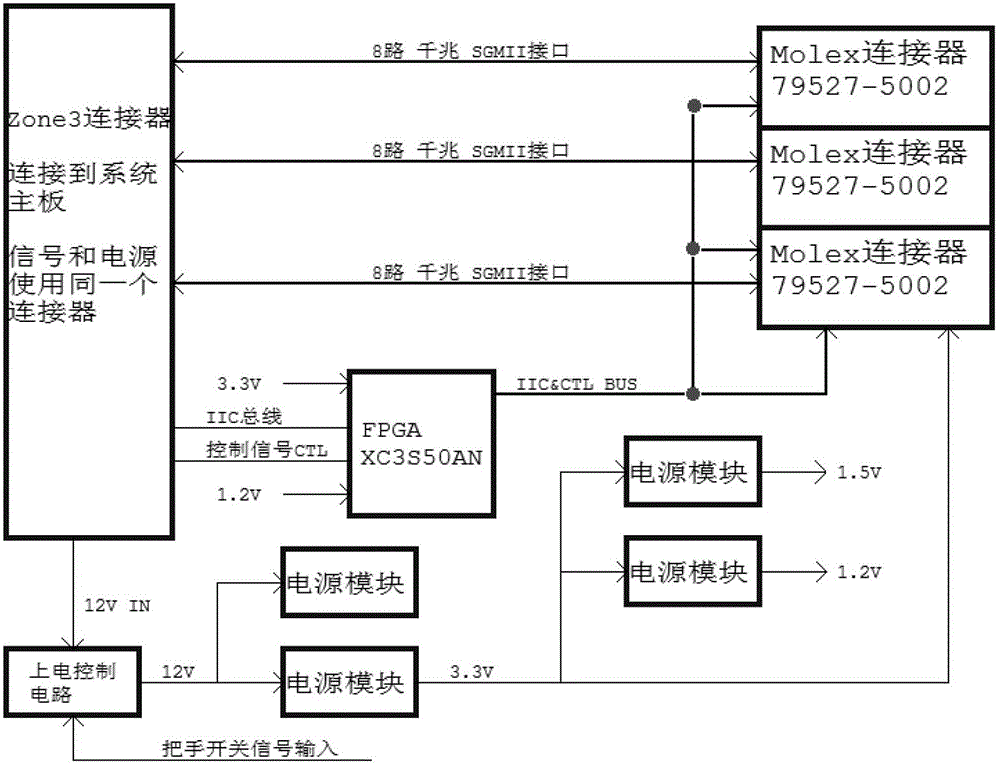

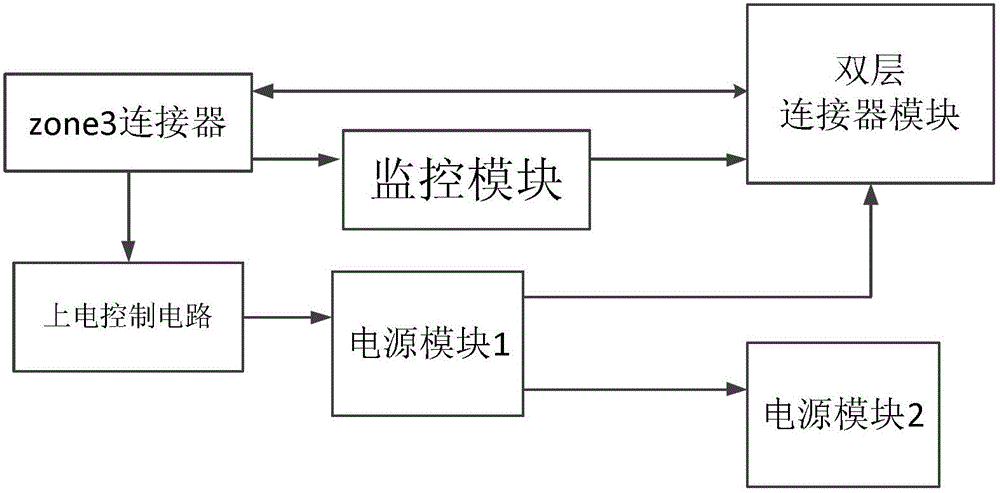

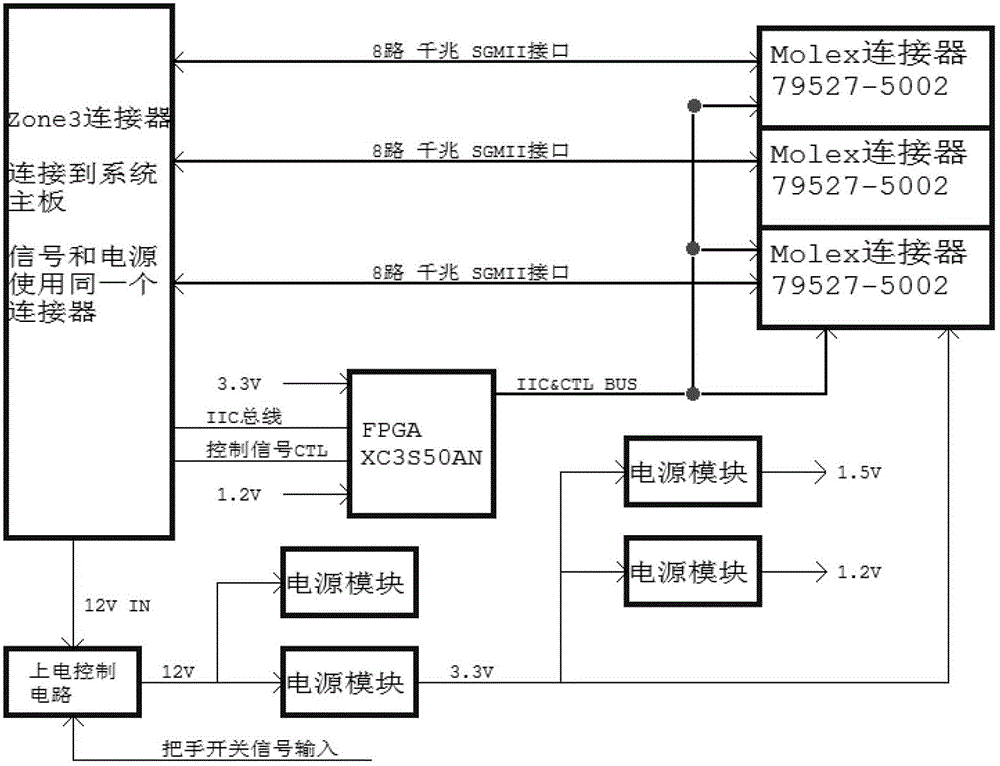

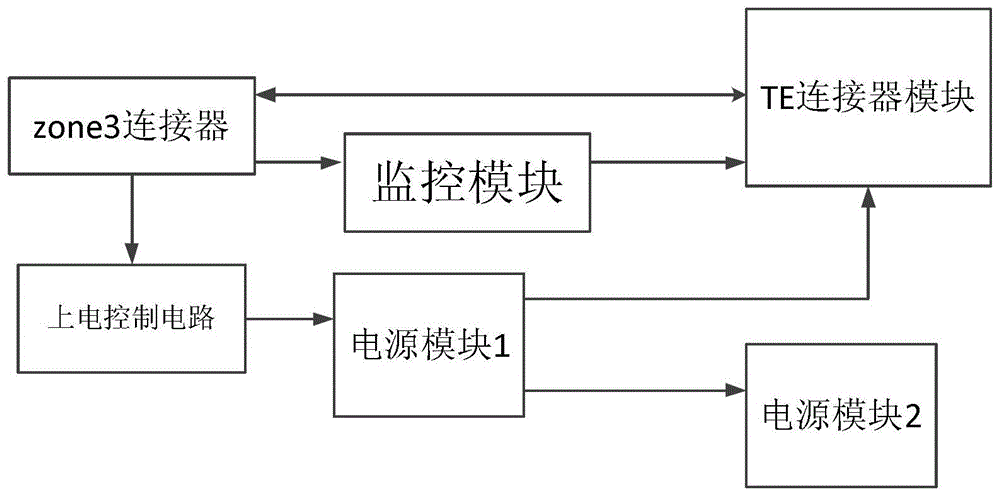

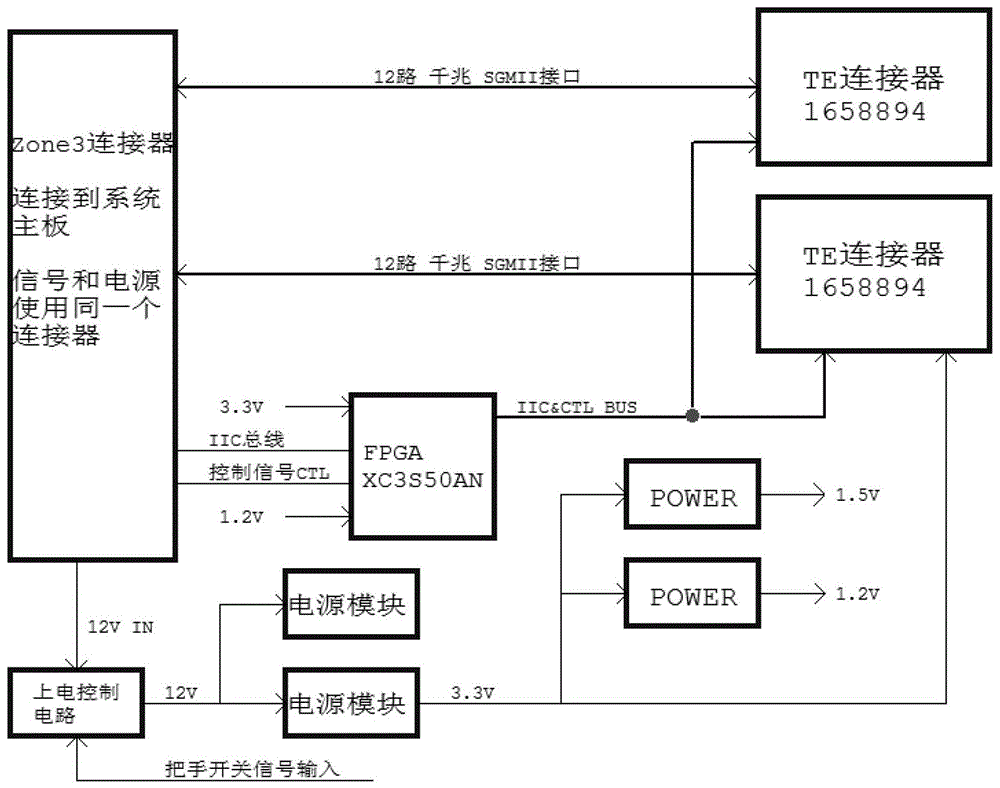

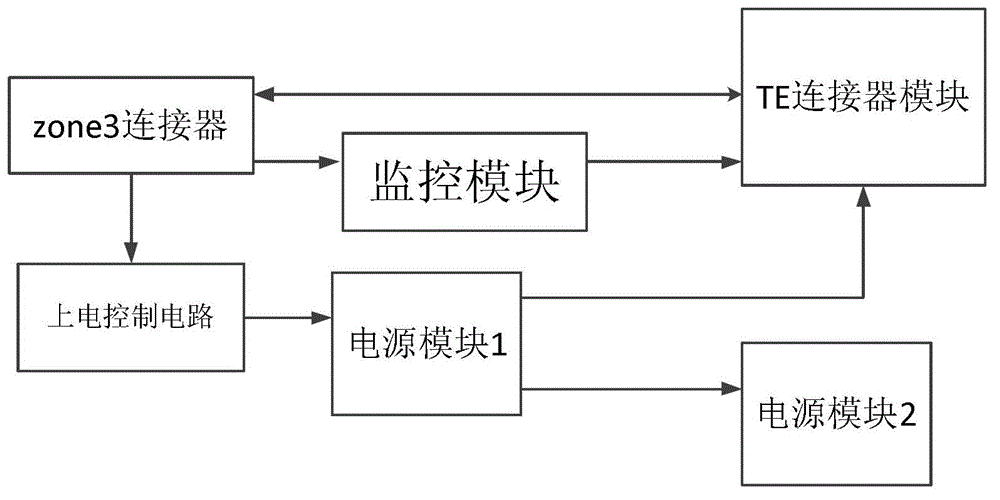

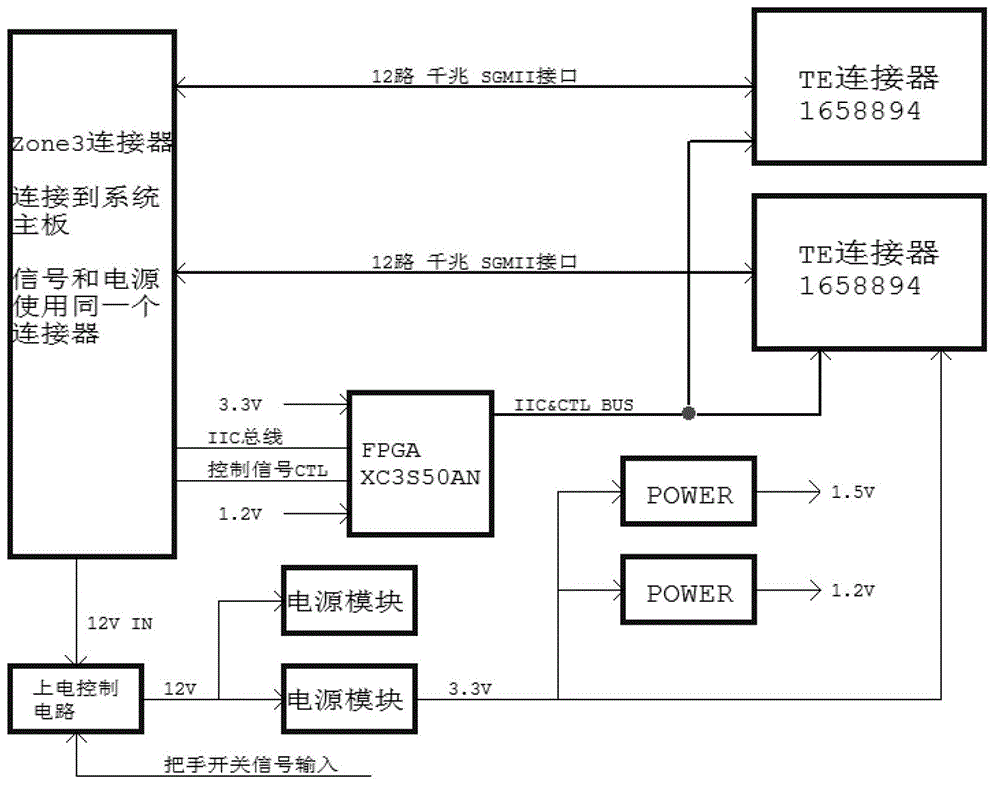

24 kilomega ethernet back plug-in card achieved by utilizing two-layer connector

ActiveCN103067179AMeet the design index requirementsPrevent incomingData switching detailsElectricityExpansion card

The invention provides a 24 kilomega Ethernet back plug-in card achieved by utilizing a 79527 to 5002 two-layer connector. The 24 kilomega Ethernet back plug-in card achieved by utilizing a two-layer connector is connected to a system mainboard and used as an expansion card of the system mainboard. The back plug-in card comprises a zone 3 connector, an upper electric control circuit, a monitoring module, a power source module 1, a power source module 2 and a two-way connector module. The zone 3 connector is communicated with the upper electric control circuit, the monitoring module and the two-way connector module. The monitoring module receives data of the zone 3 connector and is communicated with the two-way connector module. The upper electric control circuit sends power source signals to the power source module 1. The power source module 1 conducts depressurization operation on received voltage signals and then respectively transmits the voltage signals to the power source module 2 and the two-way connector module. The 24 kilomega Ethernet back plug-in card achieved by utilizing a 79527 to 5002 connector possesses enough space to hold a 24 kelomega socket and meets design objective requirements of the 24 kilomega Ethernet card with a framework of the ATC.

Owner:DAWNING INFORMATION IND BEIJING +1

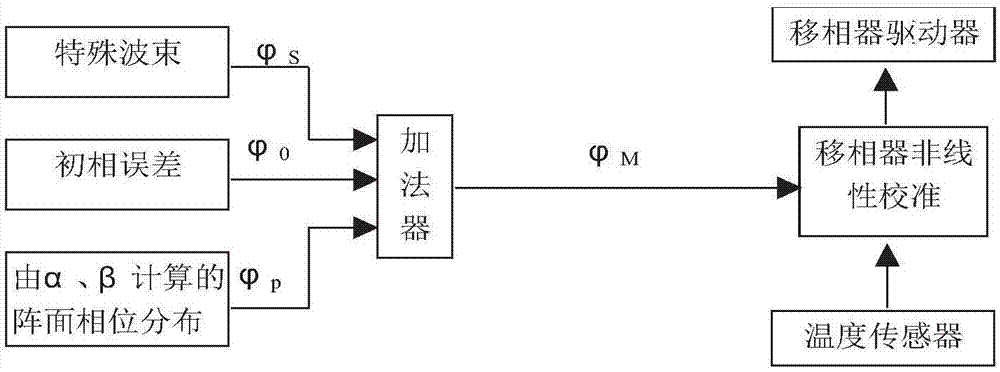

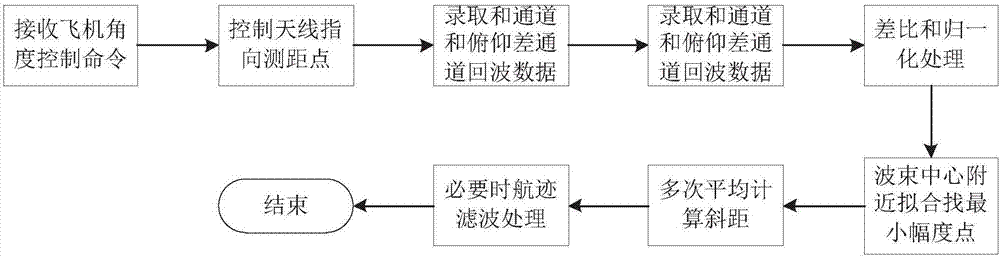

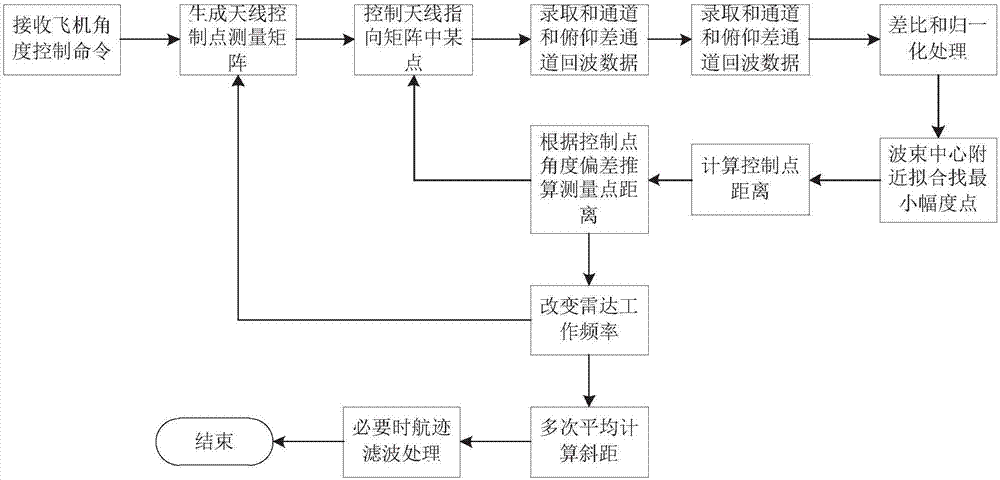

Air-to-ground slope distance measuring method applicable to phased array radar

InactiveCN107991668AReduce adverse effectsRandomize the errorRadio wave reradiation/reflectionRadarGranularity

The invention discloses an air-to-ground slope distance measuring method applicable to phased array radar. The method includes: according to the angle, given by a system, of to-be-measured points, controlling an antenna beam to pitch a certain small-angle area at the to-be-measured point and in the direction of the to-be-measured point to select multiple angle control points, and performing AGR (air-to-ground ranging) on each measuring point to obtain a slope distance value, wherein the interval between every two control points is larger than one beam granularity; hypothesizing that the groundof a small region is flat due to the fact angle detection is small according to the angle differences of the control points and the to-be-measured points, and using carrier height, antenna pointing information and space geometry relation to calculate the slope distance of the to-be-measured points according to the slope distance and angle differences of the control points; averaging slope distance data, obtained by approaching the different control points, of the to-be-measured points to obtain the slope distance values of the target to-be-measured points; using three different working frequency to average the measuring results. By the method, error randomization of multiple measuring is achieved, and slope distance measuring errors can be reduced.

Owner:CHINA ELECTRONICS TECH GRP CORP NO 14 RES INST

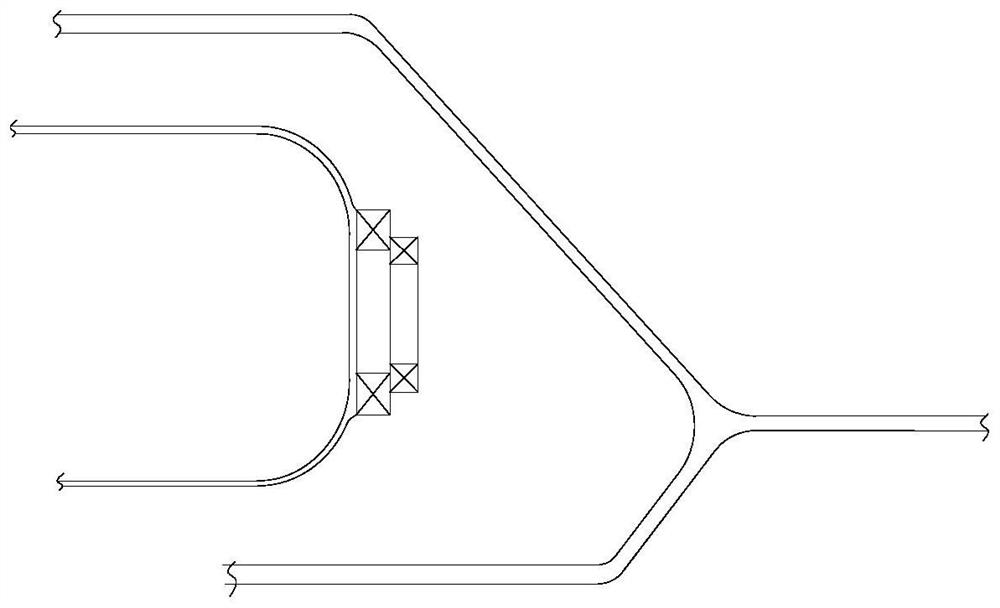

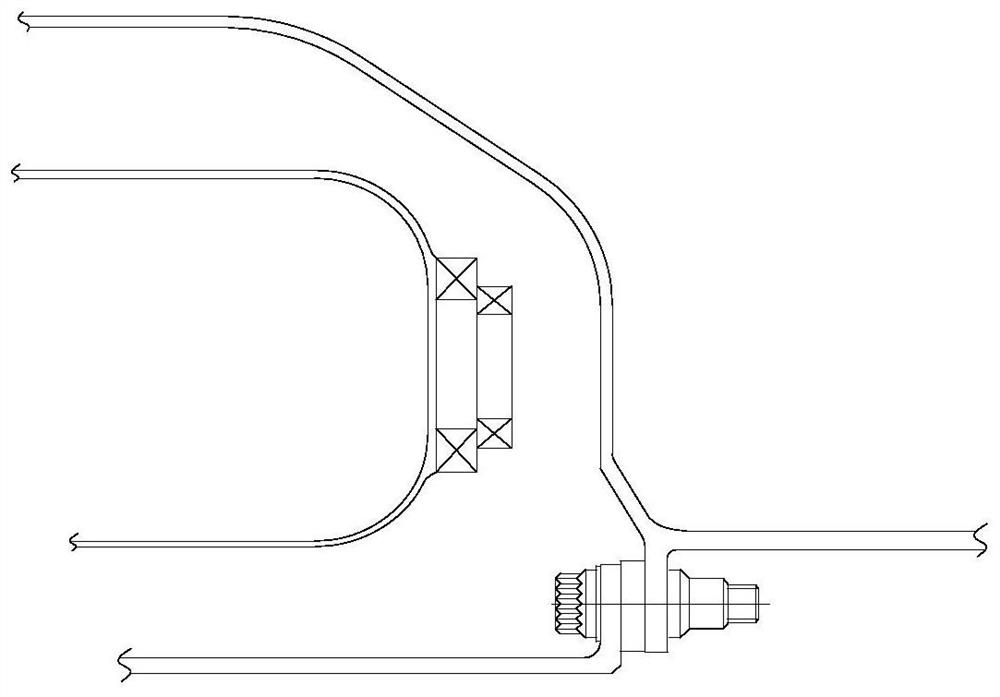

Control Method of Residuals in Machining Process of Cavity with Annular Gap

ActiveCN107138475BEasy to fillEasy to cleanParticle size analysisCleaning using toolsThrust chamberMegasonic cleaning

The invention provides a method for controlling excess materials during the processing of a cavity with an annular gap. Before processing the inner cavity mold, clean animal fat is used as the gap filler in the inner cavity, and the entrance of the annular gap is blocked with a spring steel sheet to form an opposite Protect large chips, fine chips and cutting fluid from entering the inner cavity of the product. After processing, heating treatment, hot steam blowing, ultrasonic cleaning and pressure flushing cleaning and cleaning processes are used to clean the lard in the annular gap of the inner cavity to ensure that the cleanliness of the inner cavity of the product meets the requirements. The invention effectively solves the technical problem of preventing and controlling excess objects during the processing of the needle bolt injector housing of the liquid rocket engine thrust chamber, avoids the impact of excess objects on product performance, and improves the reliability of the product.

Owner:XIAN SPACE ENGINE CO LTD

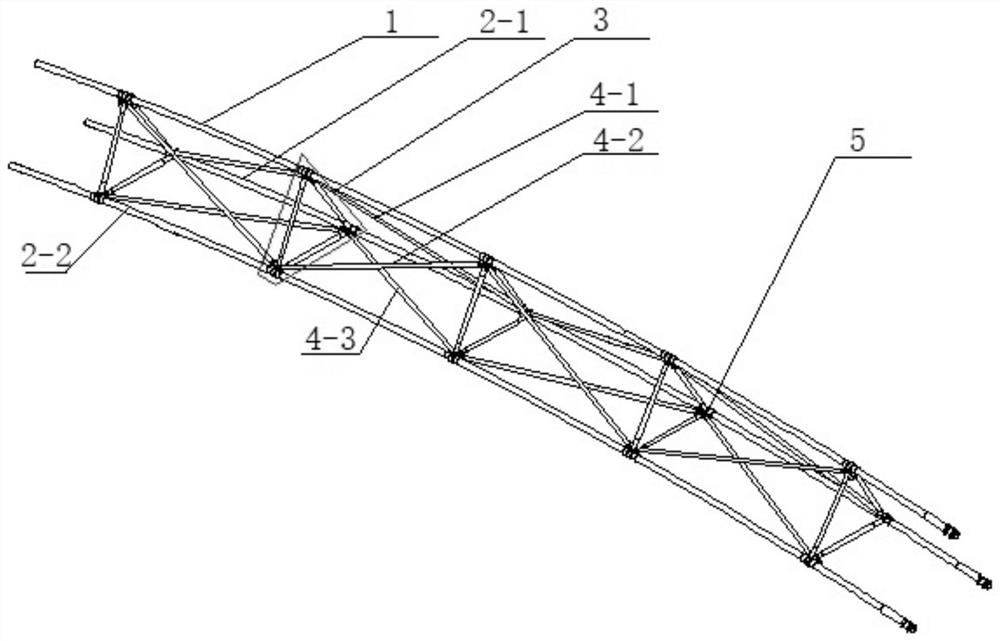

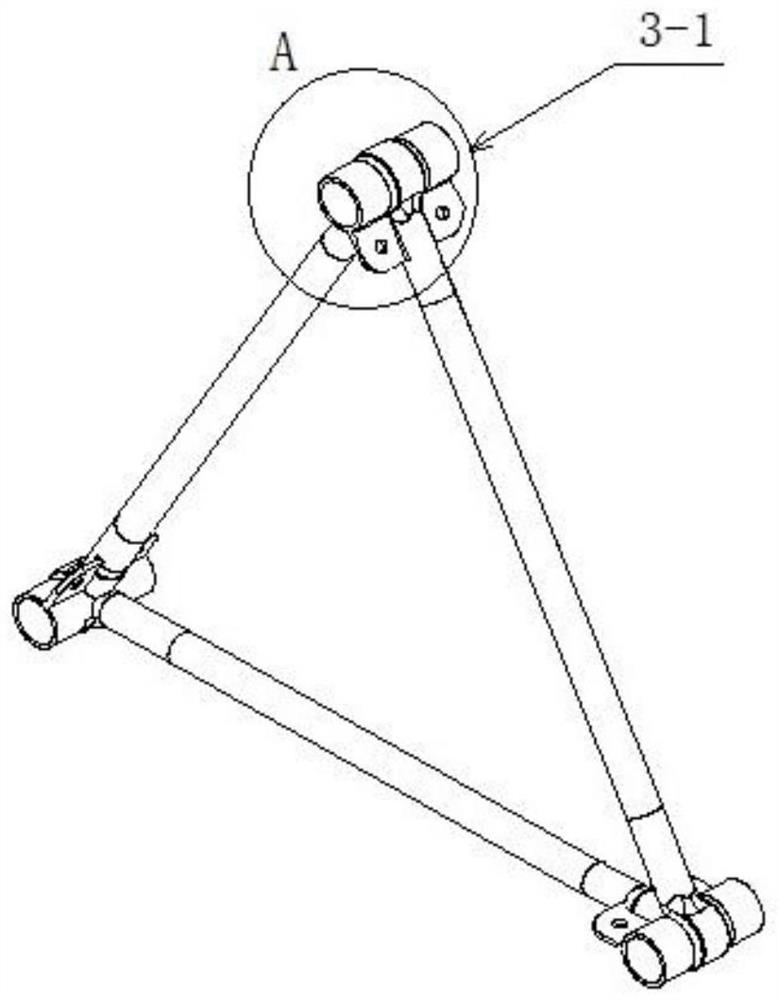

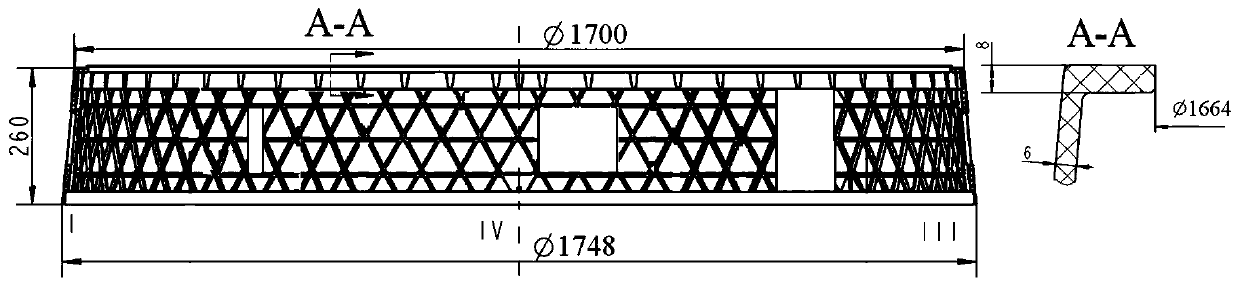

Triangular-section arc-shaped composite truss and preparation method thereof

ActiveCN112722232ALarge connection cross sectionImprove overall structural rigidityFuselage framesCosmonautic vehiclesCarbon fiber compositeDimensional precision

The invention discloses a triangular-section arc-shaped composite truss which is of an arc-shaped three-dimensional structure formed by connecting an outer chord member, a first inner chord member and a second inner chord member which are parallel to one another through a triangular-section web member assembly. A first outer diagonal web member, a second outer diagonal web member and an inner diagonal web member are diagonally arranged on the outer chord member, the first inner chord member and the second inner chord member between the adjacent triangular section web member assemblies respectively and are fixedly connected with the four-way joint, and each member is made of a carbon fiber composite material; the invention further discloses a preparation method of the triangular-section arc-shaped composite material truss. The large-radian composite material truss structure with the curvature is formed by connecting the web member assemblies with the triangular sections, the size precision is high, the loading performance is good, the truss structure achieves ultra-light weight, and modular connection of large composite material pipe trusses is achieved; the self-heating mold is adopted for preparation, curing equipment does not need to enter or exit, the quality stability of the arc rod piece is improved, and the size precision is high.

Owner:XIAN KANGBEN MATERIAL

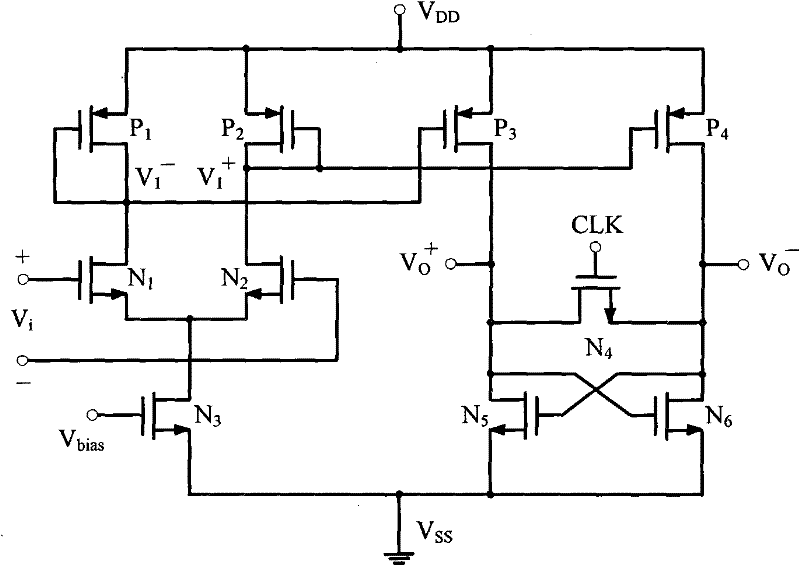

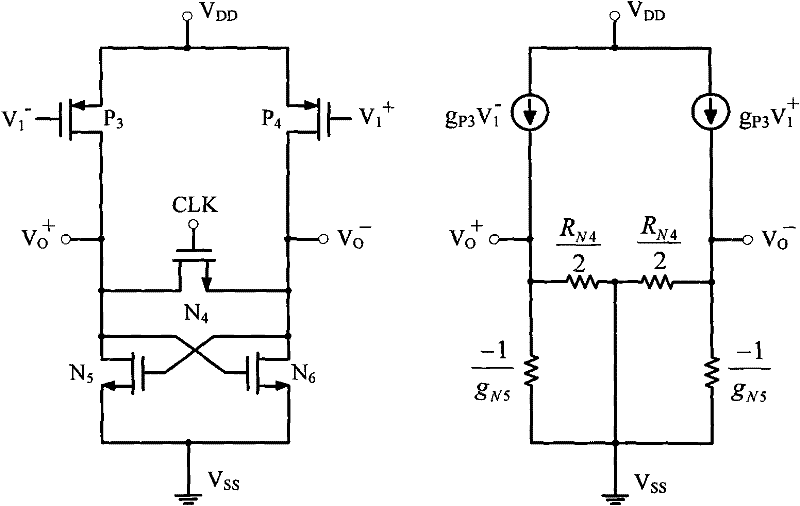

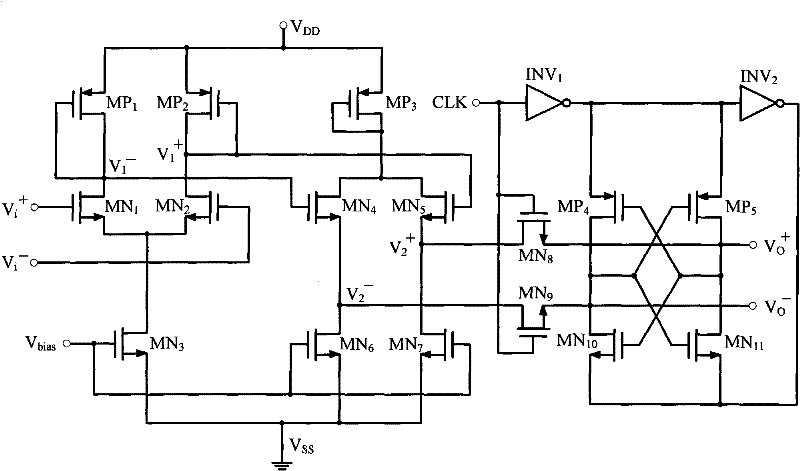

High speed comparator

ActiveCN101841315BWork fasterQuick responseAnalogue/digital conversionElectric signal transmission systemsAudio power amplifierLow speed

The invention relates to a high speed comparator, which comprises a preamplifier unit, an emitter follower unit and a latch unit. In the circuit of the invention, one emitter follower unit is arranged between the preamplifier unit and the latch unit of the traditional comparator to play a buffer role so that the input voltage needed by the latch unit can reach in a short time and the work speed of the comparator is improved. The circuit of the invention has the advantages of high speed and stable transmission delay, effectively overcomes the defects of the low speed and unstable transmission delay of the traditional comparator and can be extensively applied to the A / D conversion field of high speed and high precision.

Owner:CHONGQING GIGACHIP TECH CO LTD

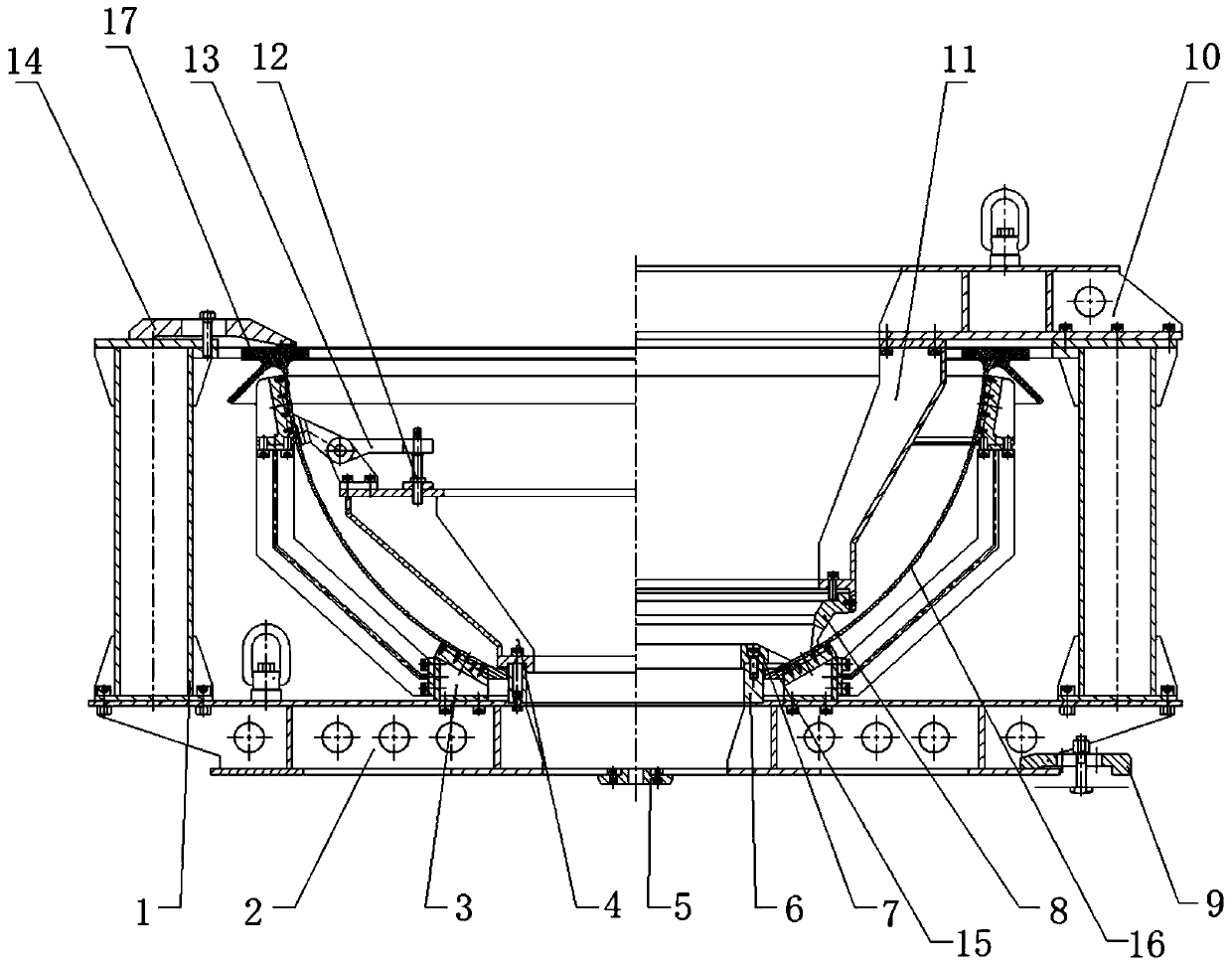

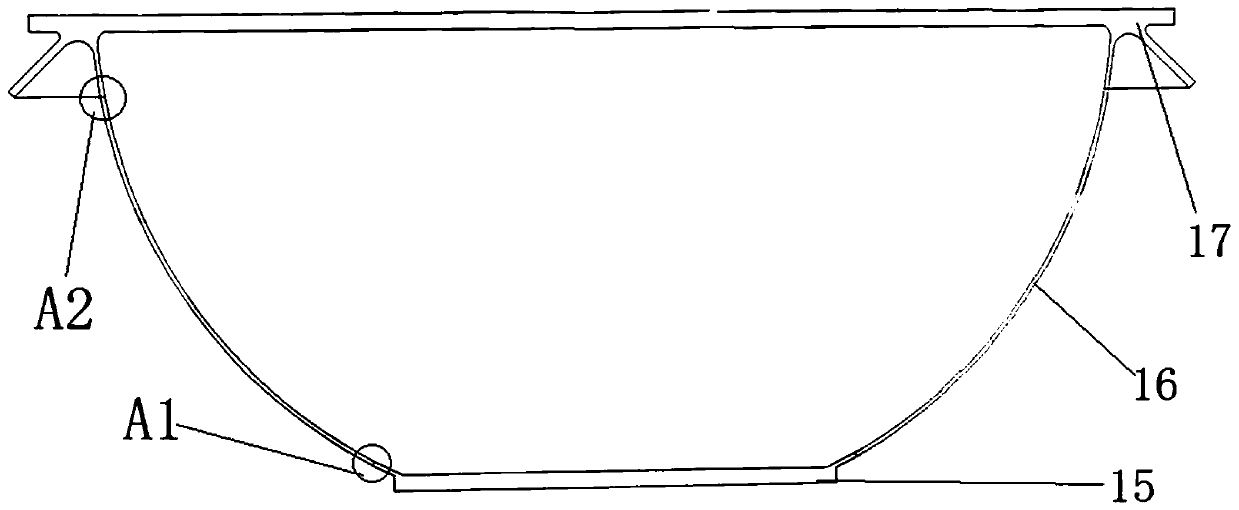

Spherical top cover assembly tailor-welding method and device

PendingCN110977110ATailored welding realizationMeet the design index requirementsWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringTop cap

The invention provides a spherical top cover assembly tailor-welding method and device. The tailor-welding method comprises the four steps. The tailor-welding device comprises a base, a positioning base, an annular body, an upper presser structure, an internal supporting structure, an outer supporting structure capable of positioning the outer wall of a spherical top cover, a press plate assemblycapable of tightly pressing the upper end face of a connection flange, and a first press ring capable of positioning a tunnel connection flange. The spherical top cover assembly tailor-welding methodand device solves the technical problems that because the structure of the spherical top cover is specific, the assembly and welding difficulty between parts is high, and welding methods in the priorart are not suitable for assembly welding.

Owner:TIANJIN AEROSPACE CHANGZHENG ROCKET MFGCO

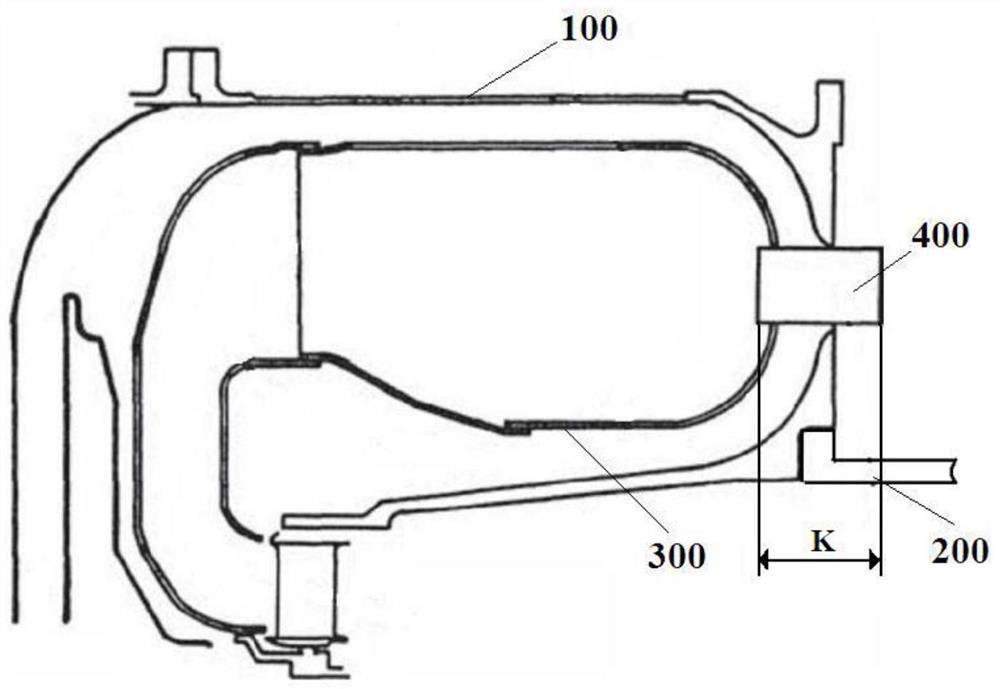

Backflow combustion chamber casing head structure, manufacturing method thereof and engine combustion chamber

ActiveCN113154456ANo deformationAvoid scratchesContinuous combustion chamberCombustion chamberTurbine

The invention discloses a backflow combustion chamber casing head structure, a manufacturing method thereof and an engine combustion chamber. The backflow combustion chamber casing head structure adopts an annular base structure and comprises arch-shaped bearing beams and nozzle parts which are alternately arranged along the circumferential direction of the annular base structure, and the arch-shaped bearing beams and the nozzle parts are in smooth transition connection by adopting arc surfaces. The arch-shaped bearing beams are of a base body structure with the cross sections in an arch shape, and the radial size of the arch-shaped bearing beams is gradually reduced in the direction from a combustion chamber case to a turbine case. Each nozzle part comprises a nozzle mounting surface and a connecting surface, each nozzle mounting surface is positioned between every two adjacent arch-shaped bearing beams and is parallel to the head part of a flame tube, each connecting surface is positioned at the bottom end of each nozzle mounting surface and is vertical to each nozzle mounting surface, and the nozzle mounting surfaces are in smooth transition connection with the connecting surfaces. The backflow combustion chamber casing head structure forms a similar frame type structure, does not deform when being subjected to load action, always ensures concentricity of a rotor and a stator of an engine, and avoids the problems of scraping, abrasion, vibration and the like of the rotor.

Owner:AECC HUNAN AVIATION POWERPLANT RES INST

Method for construction of sprayed steel fiber reinforced concrete in sandy surrounding rock

InactiveCN106223984AGuaranteed compactnessReduce rebound rateUnderground chambersTunnel liningSteel frameRebar

The invention relates to a method for construction of sprayed steel fiber reinforced concrete in sandy surrounding rock. The method comprises the steps of arranging a pre-support advanced grouting ductile on an excavation face, conducting hand excavation of tunnel sandy soil, assembling tunnel grid steel frames, arranging main reinforcing meshes according to design requirements between the grid steel frames along the outer arcs of the steel frames, arranging auxiliary steel meshes on the inner sides of the main reinforcing meshes, and spraying steel fiber reinforced concrete. By additionally arranging a layer of auxiliary steel mesh piece on the inner side of each main reinforcing mesh, effective bonding between sprayed steel fiber reinforced concrete and sandy surrounding rock is guaranteed, the rebound rate of sprayed steel fiber reinforced concrete is reduced to be about 10%, and raw materials are saved; meanwhile, wind pressure is adjusted and controlled reasonably, the compactness of sprayed steel fiber reinforced concrete is ensured, engineering construction quality is guaranteed, the requirement for design indexes of tunnel first lining engineering is met, and construction efficiency is improved.

Owner:CHINA 22MCC GROUP CORP

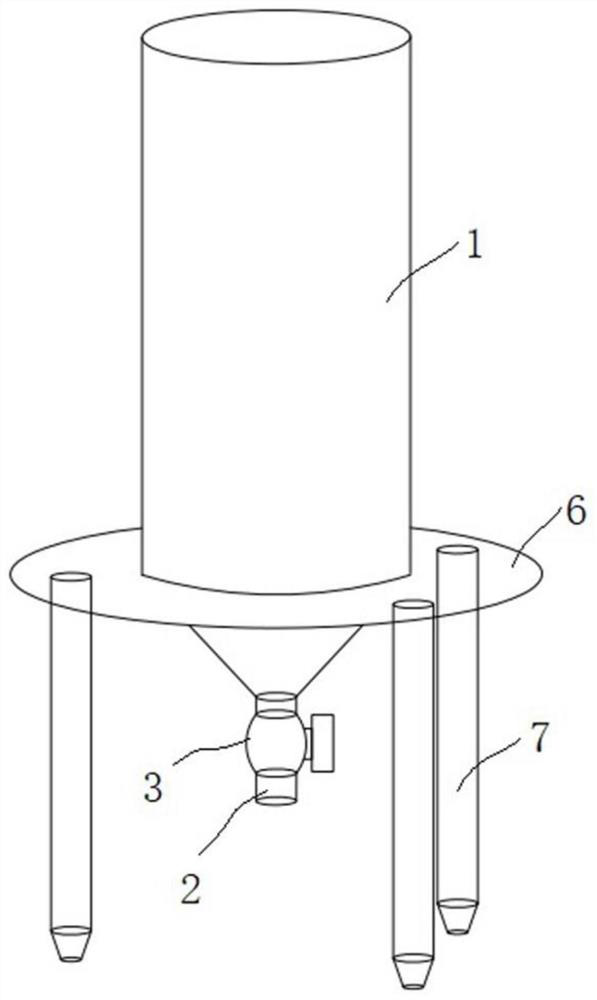

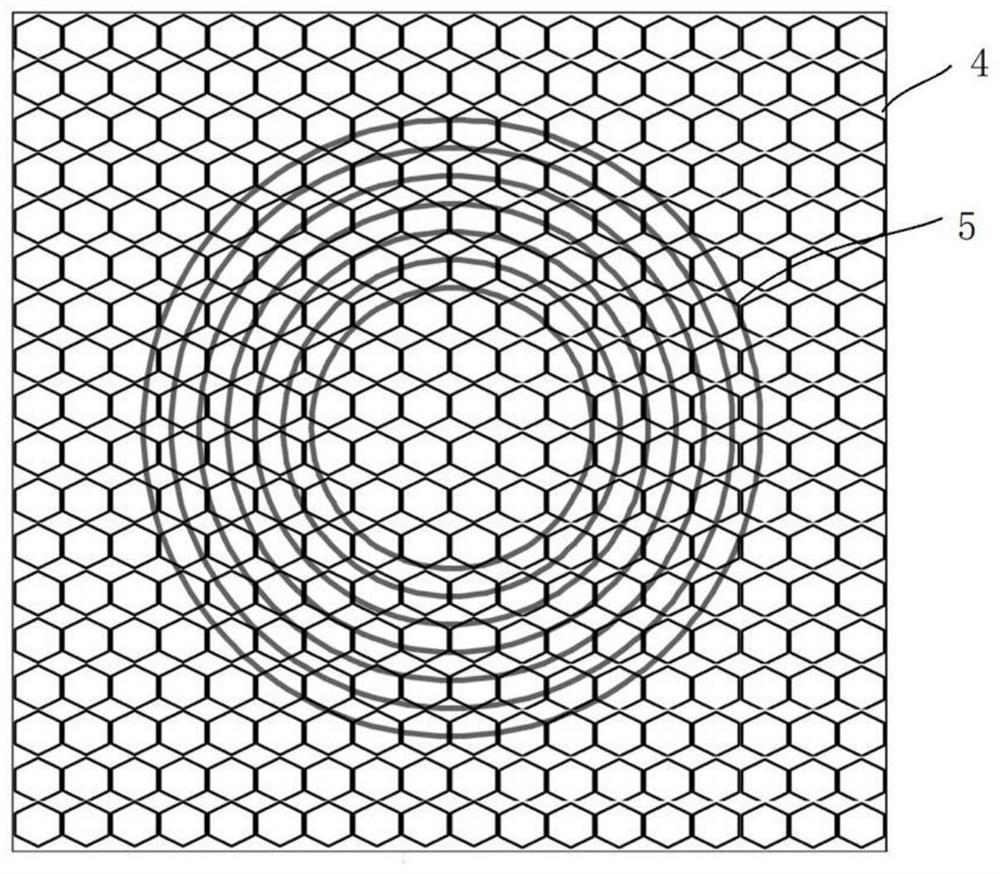

Detection device and detection method for detecting drainage coefficient of drainage asphalt pavement

ActiveCN112240862AMeet the design index requirementsThermometers using physical/chemical changesPermeability/surface area analysisAsphalt pavementWater resource management

The invention relates to a detection device for detecting a drainage coefficient of a drainage asphalt pavement. The detection device comprises a liquid storage container, the interior of the liquid storage container is hollow to form a cavity used for storing liquid, a liquid discharging channel communicated with the cavity is formed in the bottom of the liquid storage container, and a liquid outlet of the liquid discharging channel is vertically downward; a test net which is arranged below the liquid outlet of the liquid storage container and can be attached to a tested drainage asphalt pavement; the test net is provided with vertical drain holes which are uniformly distributed, and a plurality of temperature sensing concentric circles which take the center of the projection of the liquid outlet of the liquid discharge channel in the vertical direction as the center of a circle and are formed by coating a temperature sensing color-changing coating. When the detection device is used for detecting the drainage coefficient of the drainage asphalt pavement, the drainage coefficient of the drainage asphalt pavement can be vividly judged and tested, and the detection range can meet thedesign index requirements of the drainage asphalt pavement. The invention also relates to a method for detecting the drainage coefficient of the drainage asphalt pavement.

Owner:GUANGDONG GUANYUE HIGHWAY & BRIDGE

A 24 Gigabit Ethernet Rear Card Using Double Layer Connectors

ActiveCN103067179BMeet the design index requirementsPrevent incomingData switching detailsElectricityExpansion card

The invention provides a 24 kilomega Ethernet back plug-in card achieved by utilizing a 79527 to 5002 two-layer connector. The 24 kilomega Ethernet back plug-in card achieved by utilizing a two-layer connector is connected to a system mainboard and used as an expansion card of the system mainboard. The back plug-in card comprises a zone 3 connector, an upper electric control circuit, a monitoring module, a power source module 1, a power source module 2 and a two-way connector module. The zone 3 connector is communicated with the upper electric control circuit, the monitoring module and the two-way connector module. The monitoring module receives data of the zone 3 connector and is communicated with the two-way connector module. The upper electric control circuit sends power source signals to the power source module 1. The power source module 1 conducts depressurization operation on received voltage signals and then respectively transmits the voltage signals to the power source module 2 and the two-way connector module. The 24 kilomega Ethernet back plug-in card achieved by utilizing a 79527 to 5002 connector possesses enough space to hold a 24 kelomega socket and meets design objective requirements of the 24 kilomega Ethernet card with a framework of the ATC.

Owner:DAWNING INFORMATION IND BEIJING +1

A 24 Gigabit Ethernet rear card realized by connector

Owner:DAWNING INFORMATION IND BEIJING +1

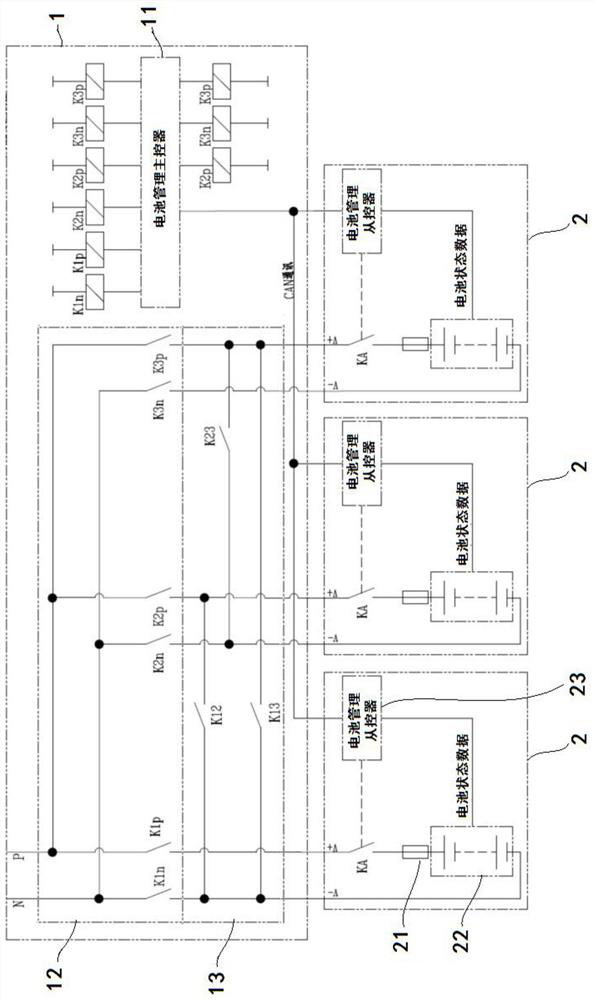

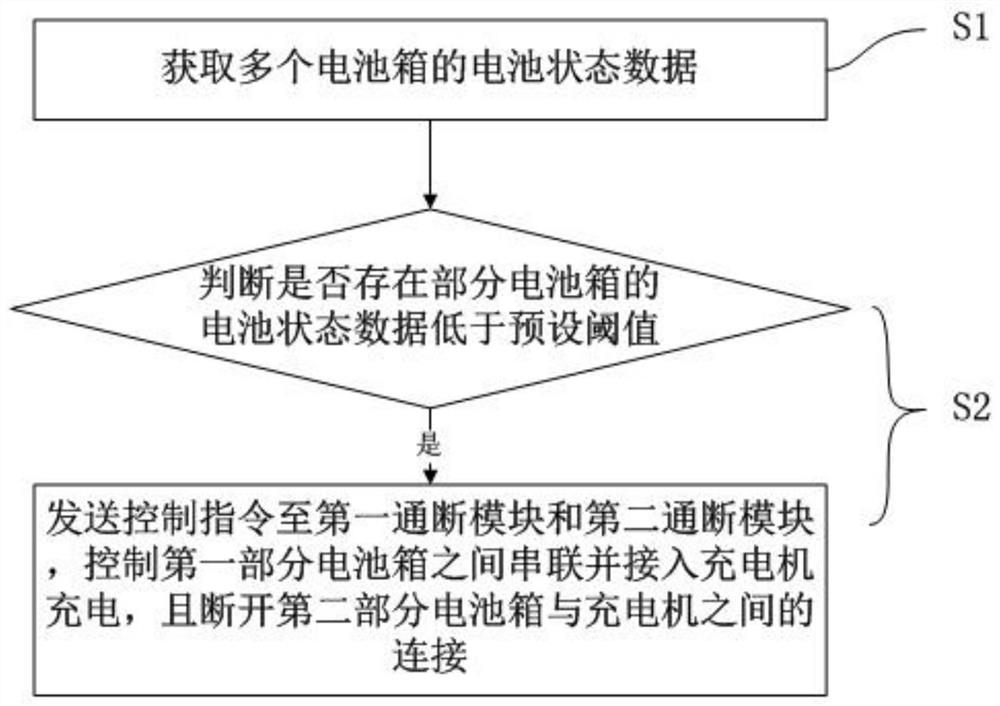

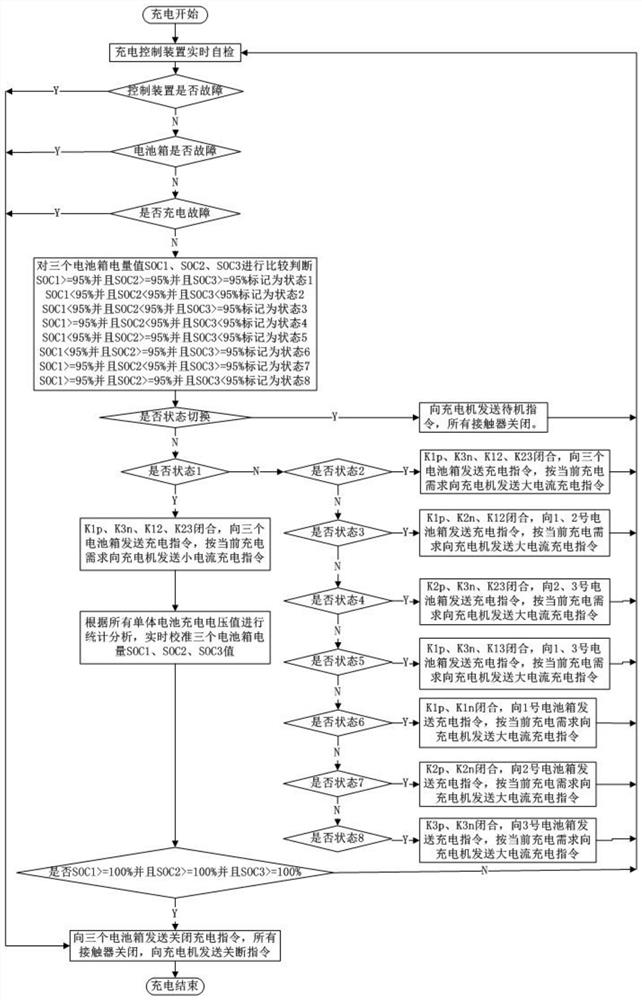

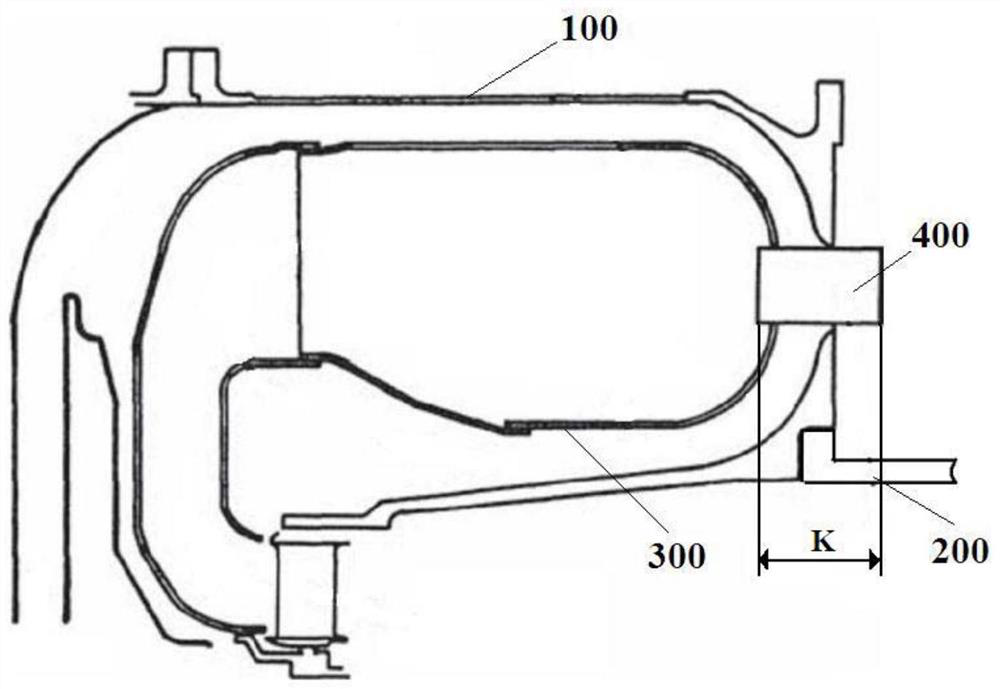

Electric vehicle battery box charging control device, system and method and electric vehicle

ActiveCN112793464AShort charging timeConvenient charging operationElectric devicesVehicular energy storageElectric-vehicle batteryElectrical battery

The invention discloses an electric vehicle battery box charging control device, system and method and an electric vehicle. The device is characterized in that a first end of a first on-off module is connected with a charger, a second end of the first on-off module is connected with a plurality of battery boxes, and the first on-off module is used for controlling connection or disconnection between the battery boxes and the charger; a second on-off module is connected with the plurality of battery boxes and is used for controlling two battery boxes to be connected in series or disconnected; a battery management master controller is connected with the first on-off module, the second on-off module and the plurality of battery boxes and is used for acquiring battery state data of the plurality of battery boxes and judging whether the battery state data of part of the battery boxes are lower than a preset threshold value or not, if yes, the first part of the battery boxes are controlled to be connected in series and connected into the charger for charging, and the connection between the second part of the battery boxes and the charger is disconnected. According to the invention, the problems of low equalization efficiency and long charging time existing in series charging of a plurality of battery boxes can be solved.

Owner:AEROSPACE HEAVY IND

Backflow combustor case head structure and manufacturing method thereof and engine combustor

ActiveCN113154456BNo deformationGuaranteed operational safetyContinuous combustion chamberCombustion chamberTurbine

The invention discloses a casing head structure of a backflow combustion chamber, a manufacturing method thereof, and an engine combustion chamber. The casing head structure of the backflow combustion chamber adopts an annular base structure, including bow bearings arranged alternately along the circumferential direction of the ring base structure. The force beam and the nozzle part, the arc-shaped force-bearing beam and the nozzle part are connected by a smooth transition of the arc surface; the arch-shaped force-bearing beam adopts a bow-shaped base structure in cross section, and the radial dimension of the bow-shaped force-bearing beam is from the combustion chamber casing to the turbine casing The direction gradually decreases; the nozzle part includes a nozzle installation surface between two adjacent bow-shaped load-bearing beams and parallel to the head of the flame tube, a connecting surface at the bottom of the nozzle installation surface and perpendicular to the nozzle installation surface, and the nozzle The installation surface and the connection surface are smoothly transitioned and connected. The casing head structure of the recirculation combustion chamber of the present invention is similar to a frame structure, and does not deform when subjected to a load, and always ensures that the engine rotates and the stator is concentric, avoiding problems such as rotor scraping and vibration.

Owner:AECC HUNAN AVIATION POWERPLANT RES INST

24 kilomega ethernet back plug-in card achieved by utilizing connector

ActiveCN103067178APrevent incomingReduce occupancyData switching detailsExpansion cardTerminal equipment

The invention provides a 24 kilomega Ethernet back plug-in card achieved by utilizing a 1658894 connector. The 24 kilomega Ethernet back plug-in card achieved by utilizing the connector is connected to a system mainboard and used as an expansion card of the system mainboard. The back plug-in card comprises a zone 3 connector, an upper electric control circuit, a monitoring module, a power source module 1, a power source module 2 and a Terminal Equipment (TE) connector module. The zone 3 connector is communicated with the upper electric control circuit, the monitoring module and the TE connector module. The upper electric control circuit sends power source signals to the power source module 1, the power source module 1 conducts depressurization operation on received voltage signals and then transmits the voltage signals to the power source module 2 and the TE connector module. The 24 kilomega Ethernet back plug-in card achieved by utilizing a 1658894 connector possesses enough space to hold a 24 kelomega socket and meets design objective requirements of the 24 kilomega Ethernet card with a framework of the ATC.

Owner:DAWNING INFORMATION IND BEIJING +1

A universal portable remote high-power servo voltage and current measurement and calibration device

ActiveCN106249038BReduce volumeRich interfaceMeasurement using digital techniquesPower flowCurrent range

The invention relates to a universal portable remote high-power steering gear voltage and current measurement and calibration device, which comprises a power supply module, a bus communication module, a remote distance / peak current judgment module, a voltage and current range gating module, a signal conditioning / acquiring / converting / outputting module, and a principal computer test system interface module. The device has a small size and a complete range of interfaces, can be easily carried and used in all test sites, is suitable for measuring and calibrating the current and voltage of a remote to-be-tested steering gear with high peak current and rated voltage, is provided with a multi-gear measurement output range, is equipped with a variety of interface equipment, and is of high universality.

Owner:BEIJING MECHANICAL EQUIP INST

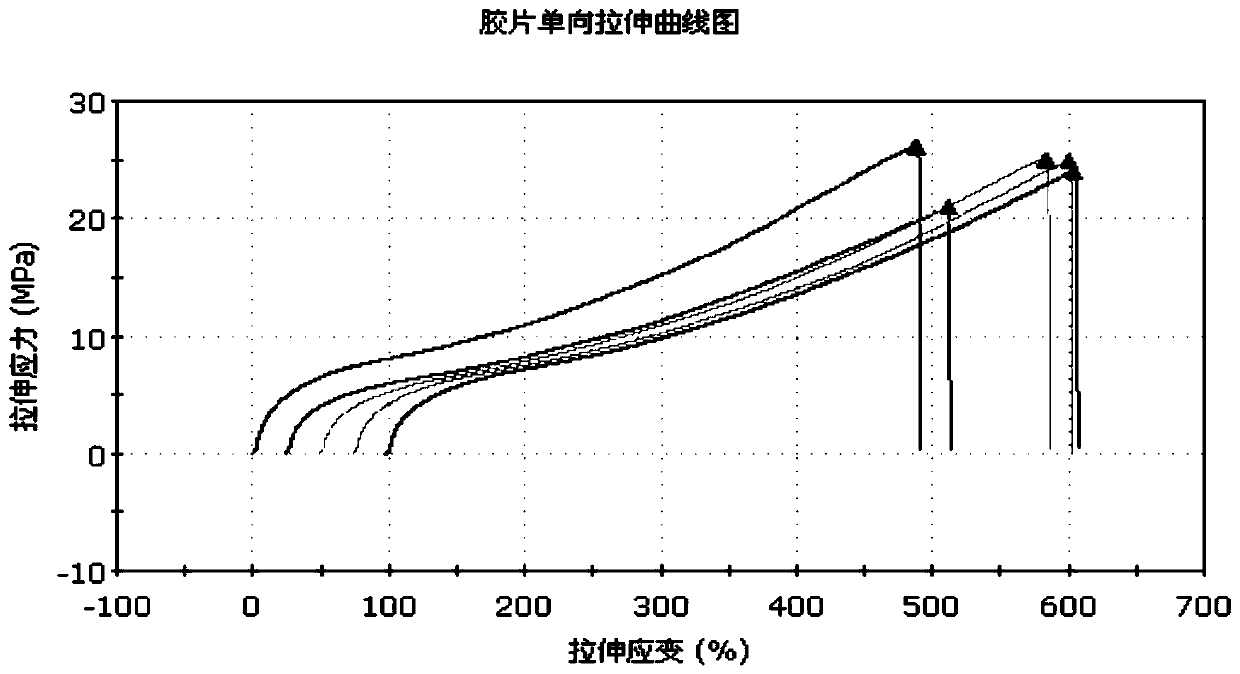

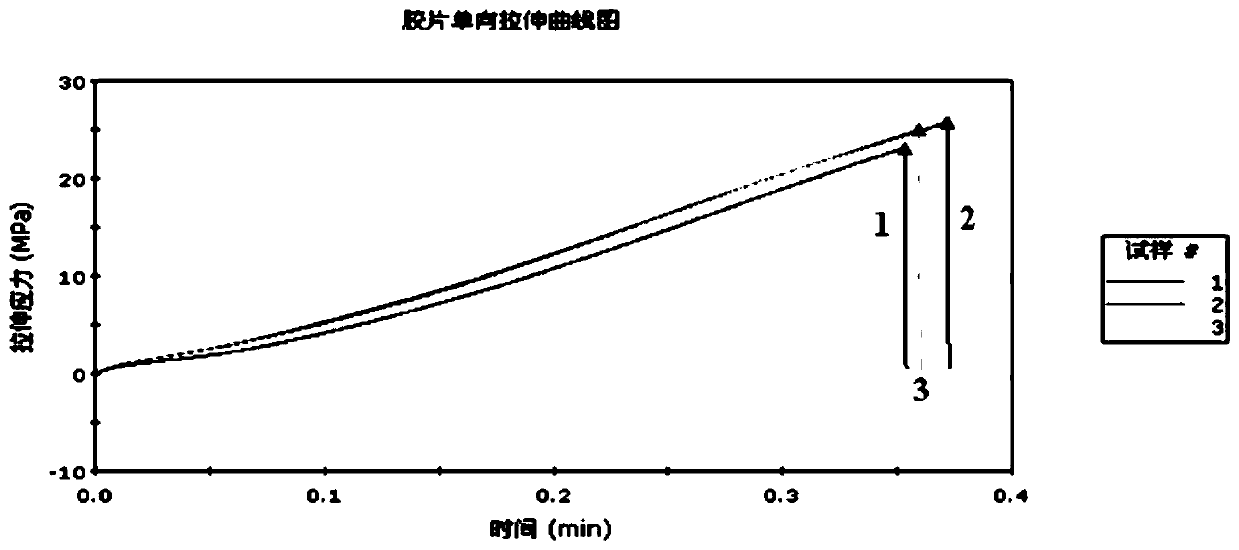

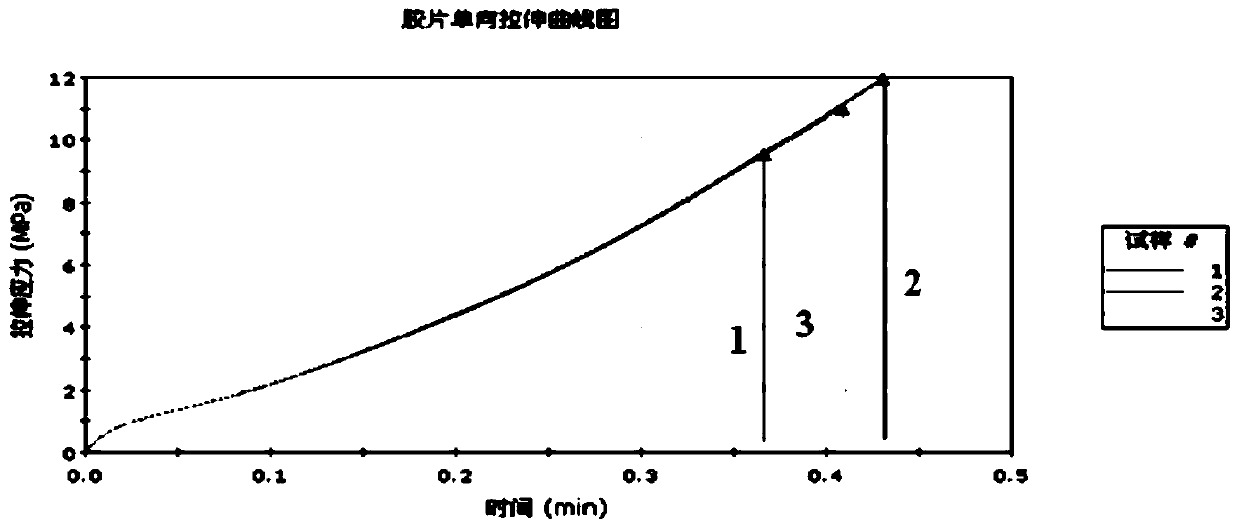

Low-temperature-resistant and ablation-resistant butadiene rubber vulcanized thermal insulation material, and preparation method and application thereof

ActiveCN111117008AExcellent low temperature mechanical propertiesGood ablation performanceRocket engine plantsThermal insulationPolymer chemistry

The invention relates to a low-temperature-resistant and ablation-resistant butadiene rubber vulcanized thermal insulation material, and a preparation method and an application thereof. A novel low-temperature-resistant base material is adopted, novel high-temperature-resistant and ablation-resistant resin is selected, a vulcanizing agent, a vulcanization accelerator and other preferable components are combined, the ratio of the optimal components is given, and an ablation-resistant technique is combined to vulcanize and mold a thermal insulation material, so the obtained material has very excellent low-temperature mechanical properties and excellent ablation performance, can meet new requirements of an engine on the thermal insulation material, meets the requirements of the thermal insulation material on excellent mechanical properties and ablation resistance of materials at different temperatures, and can meet the requirements of the engine on comprehensive properties such as the mechanical properties, the bonding performance, the ablation resistance and the erosion resistance of an interlayer material at the same time.

Owner:HUBEI INST OF AEROSPACE CHEMOTECH

Composite cabin orthopedic tooling and orthopedic method

The invention relates to a tool and method for correcting the shape of a composite cabin section and belongs to the technical field of composite component curing deformation. In the method, the shape of the composite cabin section is corrected by using the tool at set temperature so as to reduce the problems that the deformation of a composite component causes product scrap, or too-concentrated stress on the following processing and assembly and the like.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

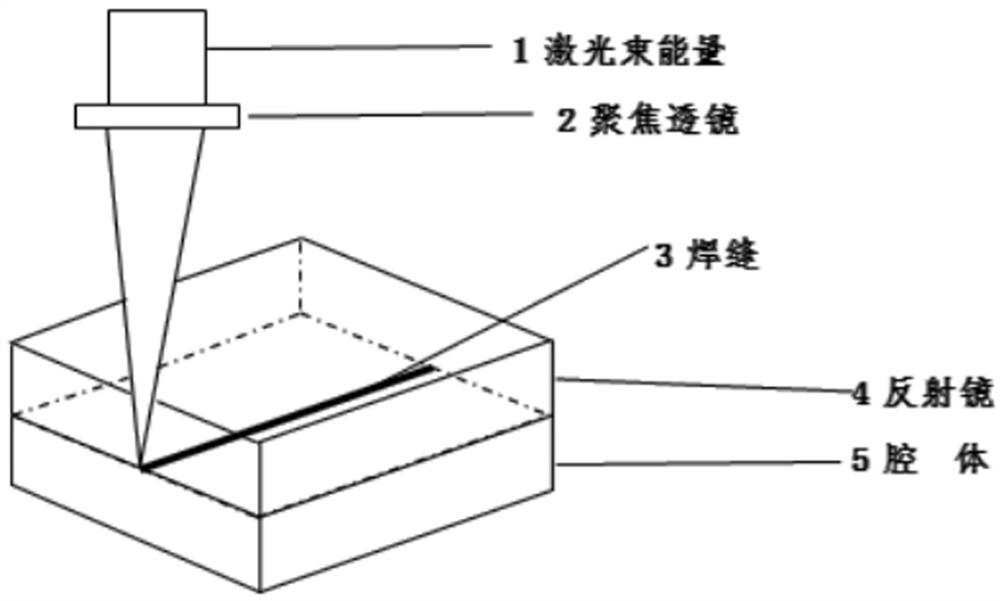

Assembly method of ultrafast laser reflector for miniature laser gyroscope

ActiveCN114289872AStable jobGuaranteed not to be brokenOrganic detergent compounding agentsSurface-active detergent compositionsResonant cavityGyroscope

The invention discloses an assembling method of an ultrafast laser reflecting mirror for a miniature laser gyroscope, and belongs to the technical field of laser gyroscope reflecting mirror assembly.The assembling method comprises the following steps that 1, a laser gyroscope cavity and a reflecting mirror are cleaned through a cleaning agent, and then an optical adjusting tool is fixed; and (2) transferring the laser gyroscope cavity and the reflector which are fixed in the step (1) to a welding area of a laser welding machine, and carrying out laser welding. The assembling method is based on the laser micro-welding technology, in the welding process of the laser gyroscope reflector and the resonant cavity, the quality of a coating layer of the reflector is well protected, the whole welding process is short in time and easy to operate, batch production can be achieved, and the production efficiency can be greatly improved; and through an impact test, the resonant cavity subjected to laser micro-welding passes a 10000 g unprotected impact test, and the performance of the resonant cavity is tested to meet the design index requirement after impact.

Owner:XIAN SINO HUAXIN MEASUREMENT & CONTROL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com