Low-temperature-resistant and ablation-resistant butadiene rubber vulcanized thermal insulation material, and preparation method and application thereof

A technology of butadiene rubber and thermal insulation materials, which is applied in the direction of mechanical equipment, jet propulsion devices, rocket engine devices, etc., can solve the problems of low glass transition temperature, achieve low glass transition temperature, excessive smoothness, and improve ablation resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] The preparation method of the low-temperature-resistant and ablation-resistant butadiene rubber vulcanized heat insulating material of the present invention, the specific steps are:

[0049] The first step is to add butadiene rubber, reinforcing agent, high temperature resistant resin, tackifying resin, flame retardant, plasticizer, anti-aging agent RD, metal oxide to the double-roller internal mixer in proportion in sequence at room temperature . Stearic acid is practiced until it is evenly mixed;

[0050] In the second step, add a vulcanizing agent and a vulcanization accelerator in proportion to the double-roll mill for mixing, and then perform mixing after 7-8 times of thinning, and finally the thinning is uniformly produced;

[0051] In the third step, the product obtained in step (2) is vulcanized and molded in a flat vulcanizer at 150-160°C.

Embodiment

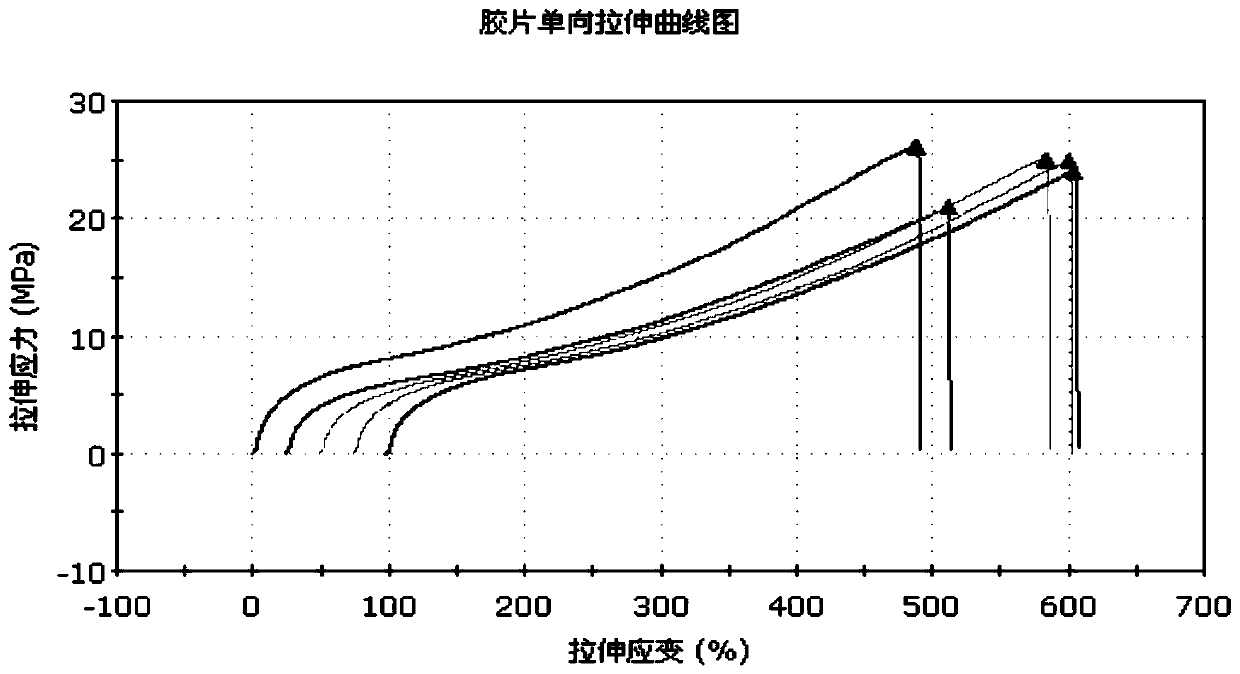

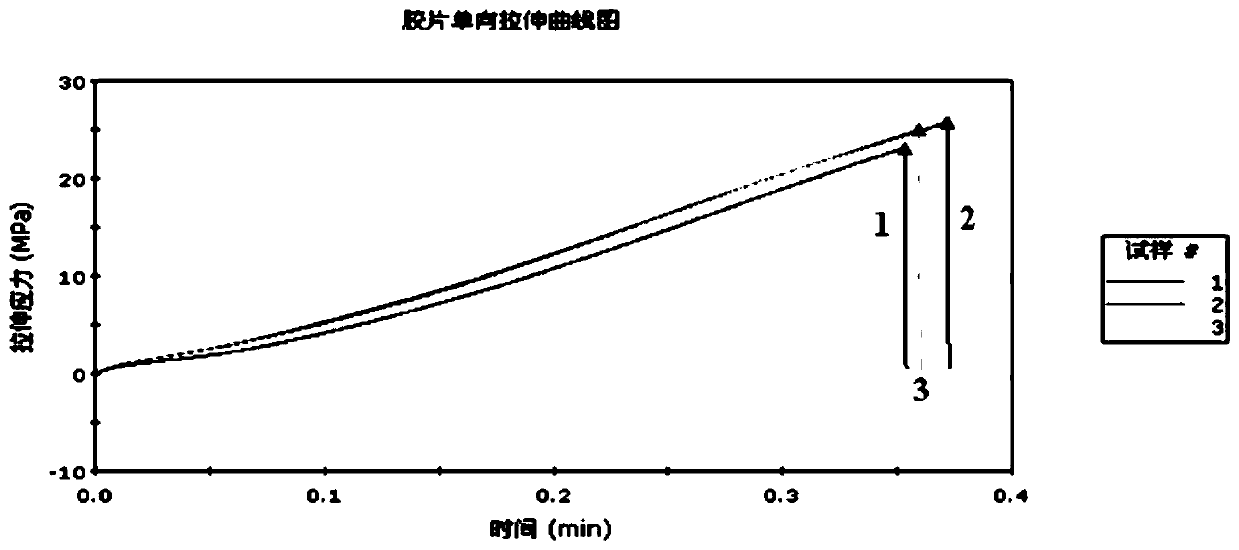

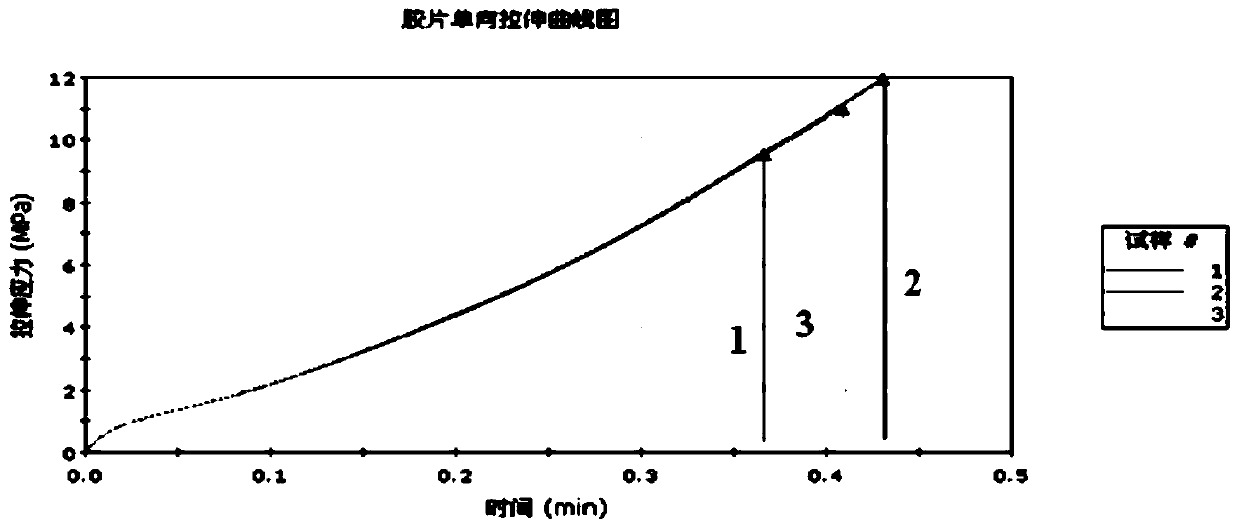

[0053] In the following various examples, the described line ablation and mass ablation rates are all measured according to the provisions of the National Military Standard "GJB323A-96 Ablation Test Method for Ablation Materials". 2mm, ablation distance 10mm, oxygen pressure 0.4MPa, acetylene pressure 0.1MPa, oxygen flow 0.6m 3 / h, acetylene flow rate 0.68m 3 / h, ablation time of 20 seconds) simulated ablation conditions; tensile strength and elongation at break were in accordance with "Q / G197-2008 Solid Rocket Motor Combustion Chamber Thermal Insulation Layer, Lining Material Tensile Strength, Elongation at Break The standard for the determination of elongation stipulates the mechanical properties of thermal insulation materials at 20°C and the pulling speed of 100mm / min. Test the bonding strength of the insulation material at 20°C and a pulling speed of 20mm / min. The glass transition temperature is tested according to the standard "Q / G325-2016 Method for Determination of G...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com