Low temperature resistant h-shaped steel and its production method

A production method and low temperature resistance technology, applied in the manufacture of converters, etc., can solve the problems of low temperature resistance performance, achieve the effect of improving low temperature resistance performance, improving product qualification rate, and stable production in large quantities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

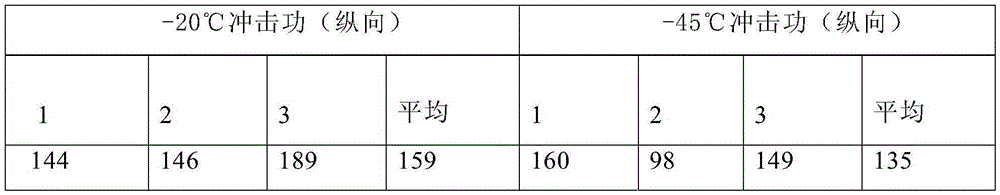

Embodiment 1

[0034] According to the mass percentage, the composition of H-shaped steel is: C: 0.06%, Si: 0.29%, Mn: 1.47%, P: 0.011%, S≤0.003%, Nb: 0.030%, Ti: 0.022%, Al t : 0.021%, the rest is iron and unavoidable impurities.

[0035] The production method of the H-shaped steel with above-mentioned composition comprises the following steps:

[0036] 1) Pre-desulfurization: transport the molten iron to the desulfurization station, and the sulfur content in the molten iron after desulfurization is 0.015wt%.

[0037] 2) Converter smelting: 43t of molten iron and 7t of scrap steel are added to the converter as raw materials. After smelting is completed, 2kg·t is pre-pressed at the bottom of the ladle before tapping. -1 The amount of steel is added to the fully pre-fused synthetic slag, and the components of the fully pre-fused slag are SiO by mass percentage 2 : 1.86%, CaO: 52.10%, Al 2 o 3 : 44.69%, TFe: 1.35%; silicon-manganese alloying is carried out when 1 / 4 of the steel is tapped, ...

Embodiment 2

[0045] The composition of H-shaped steel according to mass percentage is: C: 0.07%, Si: 0.35%, Mn: 1.53%, P: 0.014%, S: 0.006%, Nb: 0.029%, Ti: 0.025%, Al t : 0.018%, the rest is iron and unavoidable impurities.

[0046] The production method of the H-shaped steel with above-mentioned composition comprises the following steps:

[0047] 1) Pre-desulfurization: Transport the molten iron to the desulfurization station. After desulfurization, the sulfur content in the molten iron is 0.012wt%.

[0048] 2) Converter smelting: 45t of molten iron and 7t of scrap steel are added to the converter as raw materials. After the smelting is completed, 2kg·t is pre-pressed at the bottom of the ladle before tapping. -1 The amount of steel is added to the fully pre-fused synthetic slag, and the components of the fully pre-fused slag are SiO by mass percentage 2 : 1.86%, CaO: 52.10%, Al 2 o 3 : 44.69%, TFe: 1.35%; silicon-manganese alloying is carried out when 1 / 4 of the steel is tapped, and a...

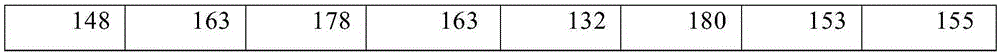

Embodiment 3

[0057] The composition of H-shaped steel according to mass percentage is: C: 0.09%, Si: 0.38%, Mn: 1.55%, P: 0.011%, S: 0.005%, Nb: 0.029%, Ti: 0.021%, Al t : 0.019%, the rest is iron and unavoidable impurities.

[0058] The production method of the H-shaped steel with above-mentioned composition comprises the following steps:

[0059] 1) Pre-desulfurization: transport the molten iron to the desulfurization station, and the sulfur content in the molten iron after desulfurization is 0.015wt%.

[0060] 2) Converter smelting: 45t of molten iron and 7t of scrap steel are added to the converter as raw materials. After smelting, 2kg·t is used before tapping. -1 Add fully pre-melted synthetic slag to the amount of steel, carry out silicon-manganese alloying when 1 / 4 of the steel is tapped, and add deoxidizer Al-Mn-Fe alloy according to the amount of steel of 3.5kg / t; Niobium and aluminum composite microalloying, making Nb: 0.028% in molten steel, Al t : 0.005%. The composition of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com