A method of micro-deformation strengthening martensitic stainless steel

A martensitic stainless steel, micro-deformation technology, applied in the field of metal materials, to achieve the upper limit of high service strength, the improvement of low temperature yield strength, and the improvement of low temperature mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for micro-deformation strengthening of martensitic stainless steel, the method comprising the following steps:

[0029] 1) Place the brand S04 martensitic stainless steel in a liquid nitrogen circulation environment at a temperature of -190°C, and keep it warm for 60 minutes to make it sufficiently low temperature;

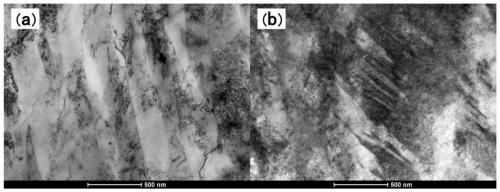

[0030] 2) After the martensitic stainless steel samples are subjected to sufficient low temperature, perform a low temperature tensile test on some of the samples to obtain the low temperature tensile test data as parameters of the original mechanical properties before strengthening, and record the low temperature yield strength data of the material σ 0.2 ; Observe the initial microstructure of martensitic stainless steel by transmission electron microscope;

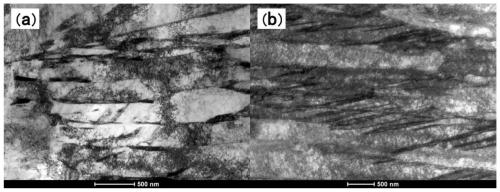

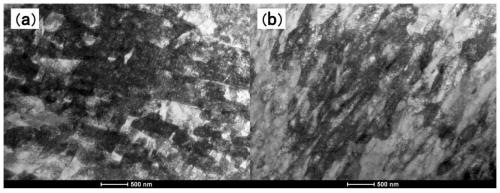

[0031] 3) Perform repeated stretching under a fixed high load on another part of the martensitic stainless steel sample after sufficiently low temperature, and obtain a micro-deformed and st...

Embodiment 2

[0038] A method for micro-deformation strengthening of martensitic stainless steel, the method comprising the following steps:

[0039] 1) Place the brand S08 martensitic stainless steel in a liquid nitrogen circulation environment with a temperature of -180°C, and keep it warm for 65 minutes to make it sufficiently low temperature;

[0040] 2) After the martensitic stainless steel samples are subjected to sufficient low temperature, perform a low temperature tensile test on some of the samples to obtain the low temperature tensile test data as parameters of the original mechanical properties before strengthening, and record the low temperature yield strength data of the material σ 0.2 ; Observe the initial microstructure of martensitic stainless steel by transmission electron microscope;

[0041] 3) Perform repeated stretching under a fixed high load on another part of the martensitic stainless steel sample after sufficiently low temperature, and obtain a micro-deformed and ...

Embodiment 3

[0048] A method for micro-deformation strengthening of martensitic stainless steel, the method comprising the following steps:

[0049] 1) Place the brand S04 martensitic stainless steel in a liquid nitrogen circulation environment with a temperature of -196°C, and keep it warm for 5 minutes to make it sufficiently low temperature;

[0050] 2) After the martensitic stainless steel samples are subjected to sufficient low temperature, perform a low temperature tensile test on some of the samples to obtain the low temperature tensile test data as parameters of the original mechanical properties before strengthening, and record the low temperature yield strength data of the material σ 0.2 ; Observe the initial microstructure of martensitic stainless steel by transmission electron microscope;

[0051] 3) Perform repeated stretching under a fixed high load on another part of the martensitic stainless steel sample after sufficiently low temperature, and obtain a micro-deformed and s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com