Patents

Literature

56results about How to "Improve service stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Server cluster system and load balancing implementation method thereof

ActiveCN104283948AImprove service stabilityGuarantee the best electionTransmissionCluster systemsComputer science

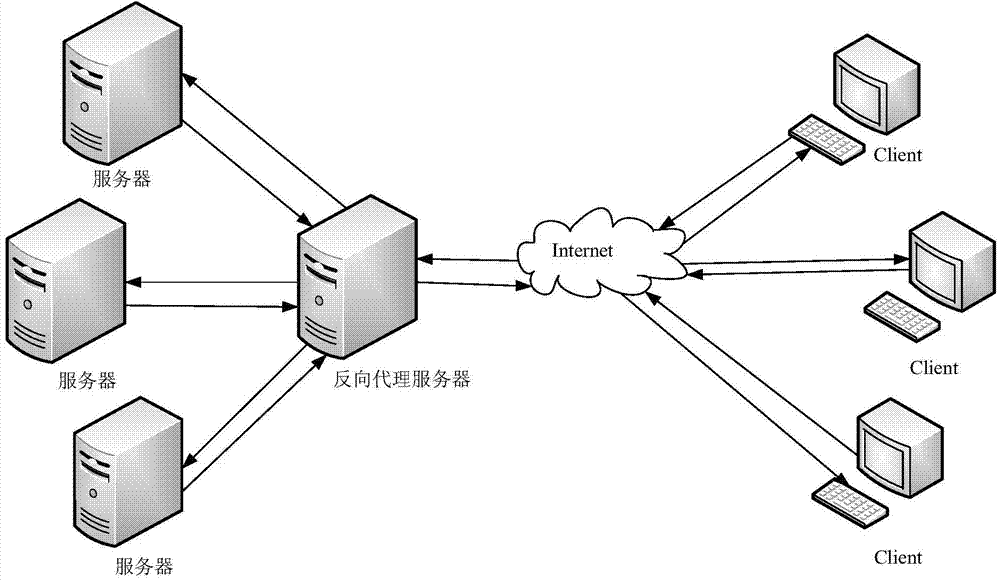

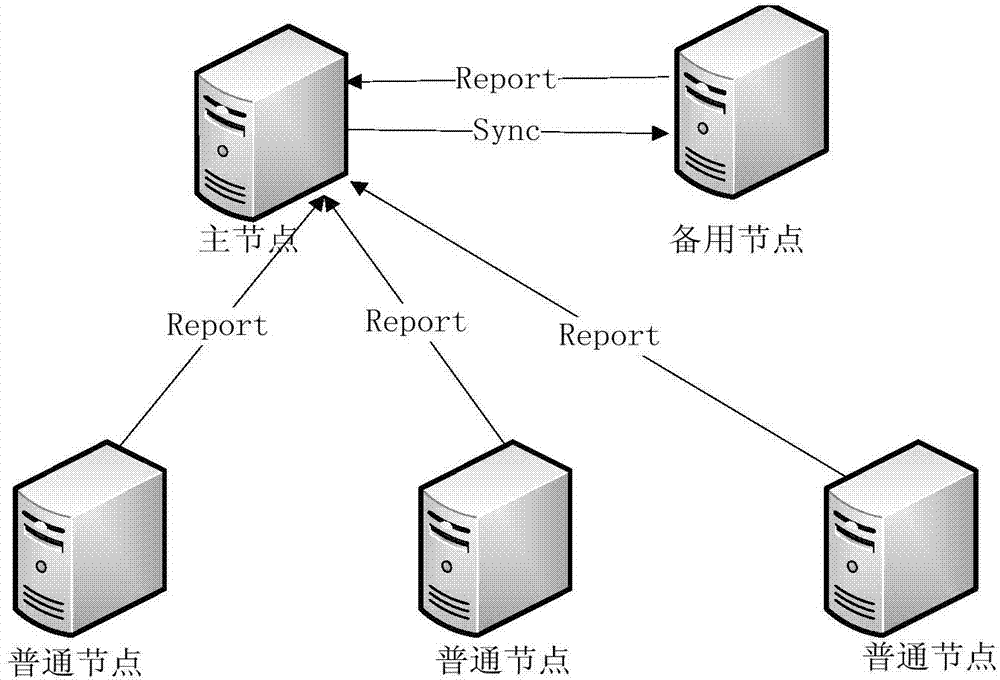

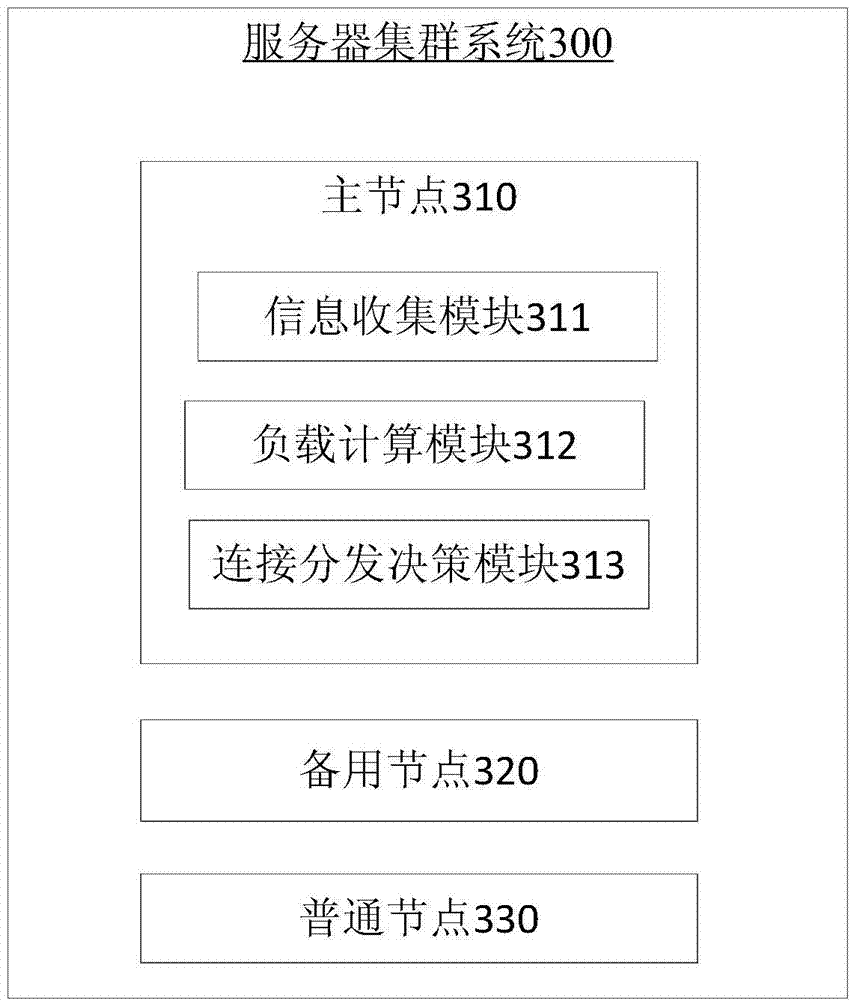

The invention provides a server cluster system and a load balancing implementation method of the server cluster system. The system comprises a main node, a standby node and common nodes. The main node comprises an information collecting module, a load calculating module and a connecting and distribution deciding module. The standby node is used for reporting the information of the standby node to the main node, and synchronizes with the information of the main node, and the common nodes are screened, so that the selected common node is adopted as a new standby node after the common node becomes the main node. The common nodes are used for reporting the information of the common nodes to the main node, and when one common node becomes the standby node, standby node switching is carried out. Through the server cluster system and the load balancing implementation method, the server cluster system with the main node and the standby node of a mesh network is adopted, the structure of the main node and the standby node is utilized for achieving connection and distribution, the function of sharing connection is achieved, and the problems that connection and distribution delay, and connection is unstable and unreliable can be solved.

Owner:NEUSOFT CORP

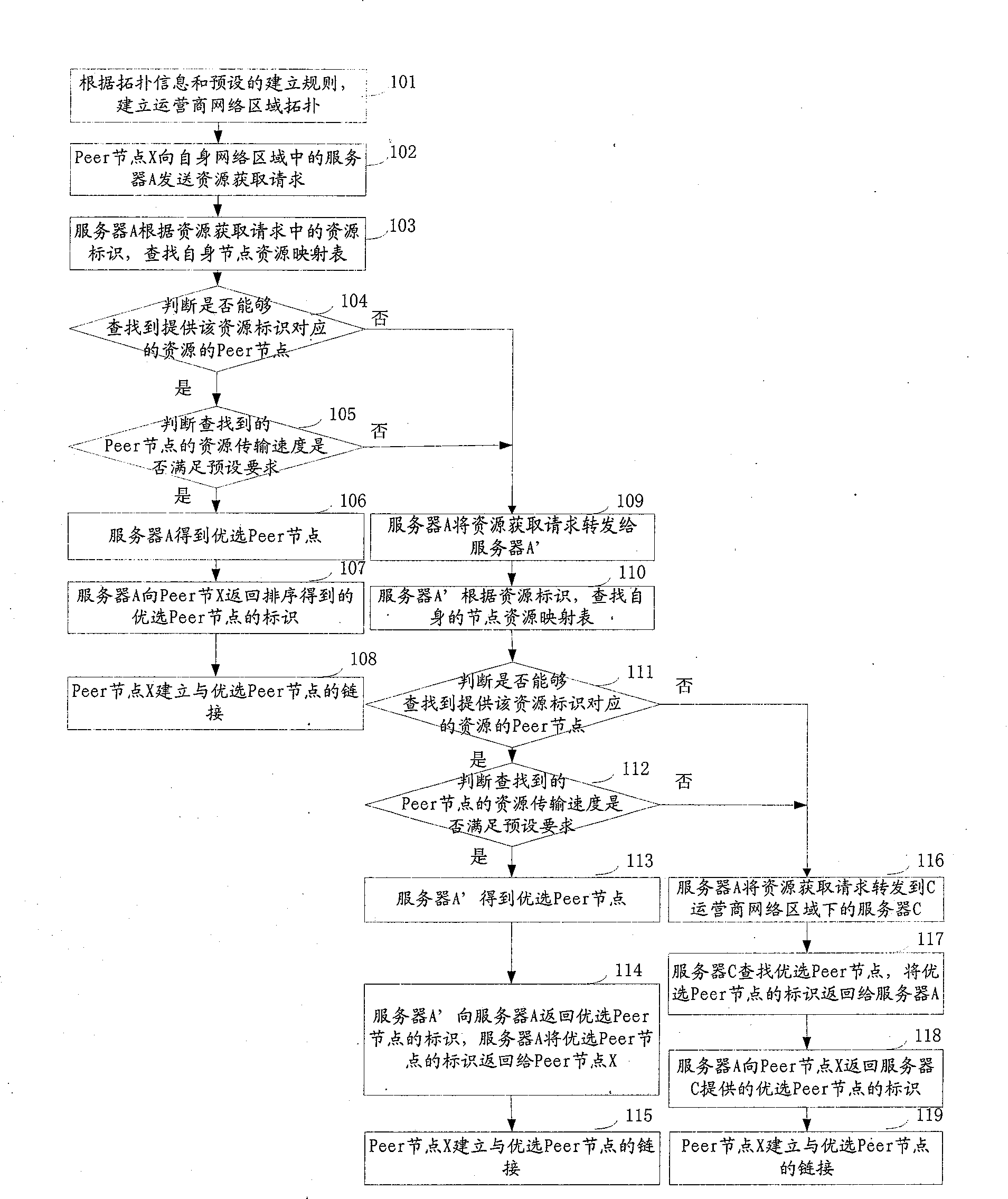

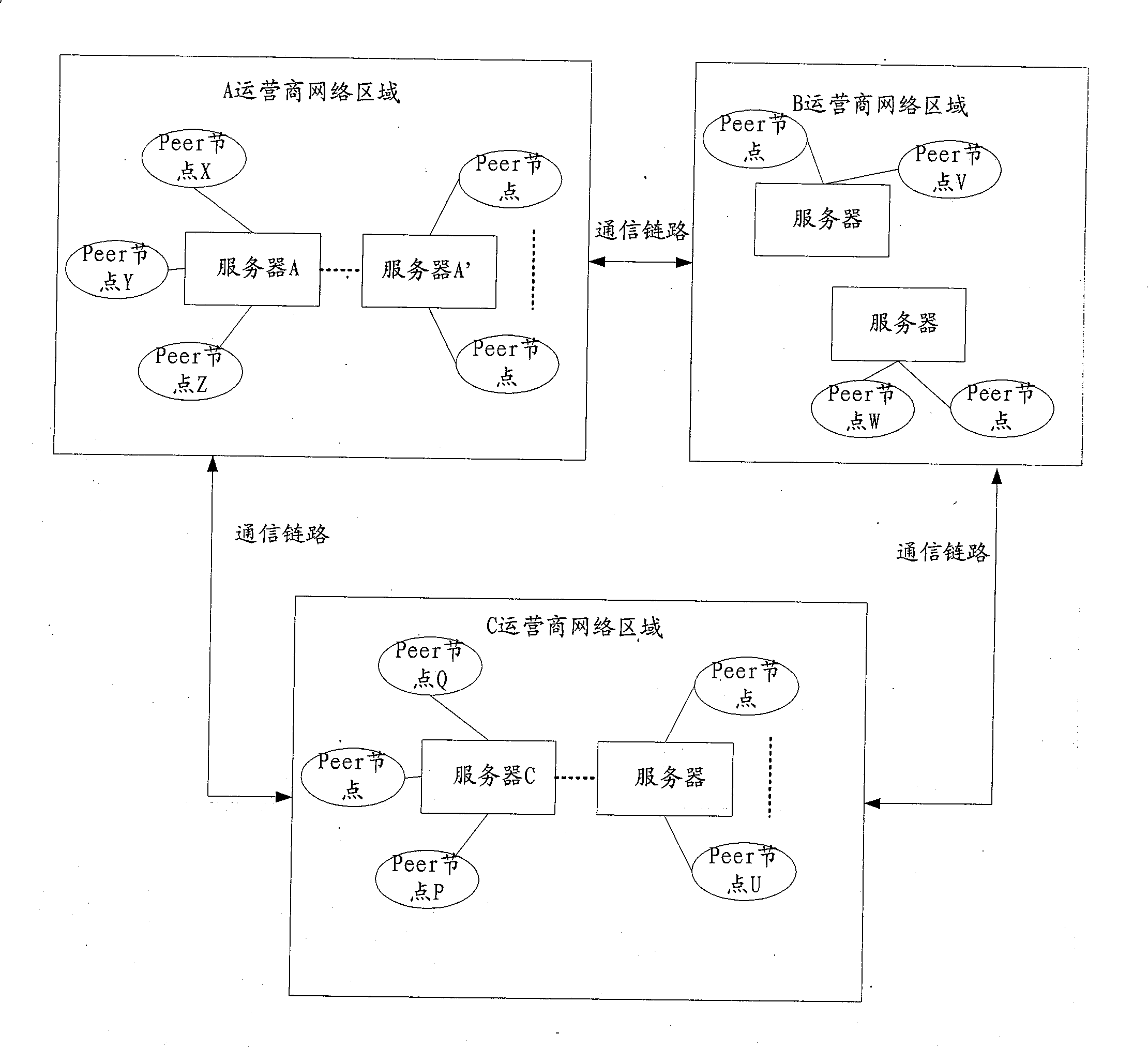

Method, system and equipment for network data transmission

ActiveCN101459614ASpeed up serviceImprove service stabilityData switching networksOperational costsNetwork link

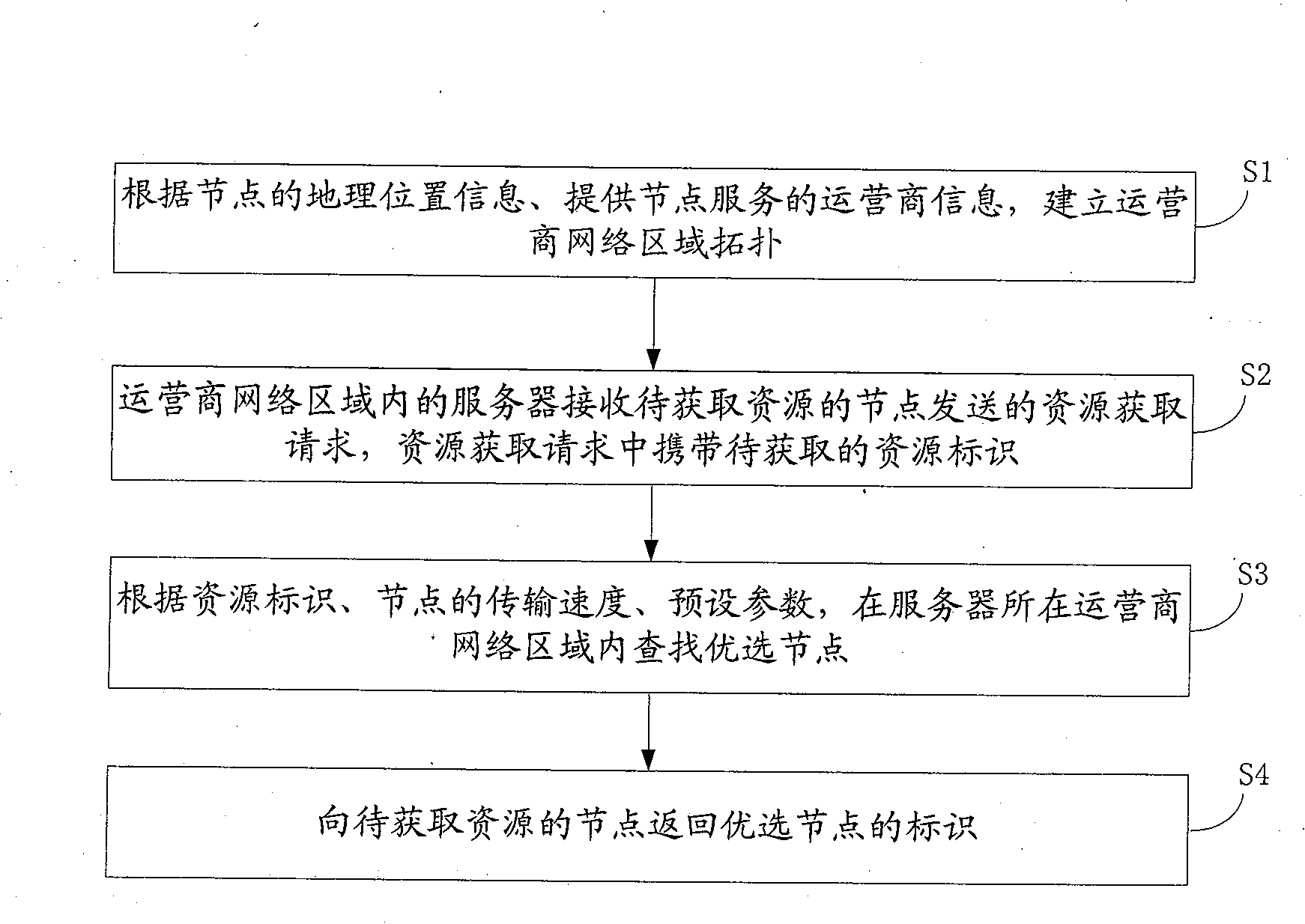

The invention discloses a method, a system and a device of network data transmission, which belong to the communication field, wherein the method comprises establishing operation business network interval topology according to geographical position information of nodes and operation business information providing node service, receiving resource obtaining request transmitted by nodes of resources which need to be obtained by a server in an operation business network region, wherein marks of resources which need to be obtained are carried in the resource obtaining request, presetting parameters according to resource marks and transmission speeds of nodes, searching for optimum nodes in the operation business network region where the server is arranged, and returning the marks of optimum nodes to the nodes of resources which need to be obtained. The invention improves network linking speed, accelerates service quality of network application, lowers service pressure of each operation business, assures basic service quality, and lowers operation cost.

Owner:TENCENT TECH (SHENZHEN) CO LTD

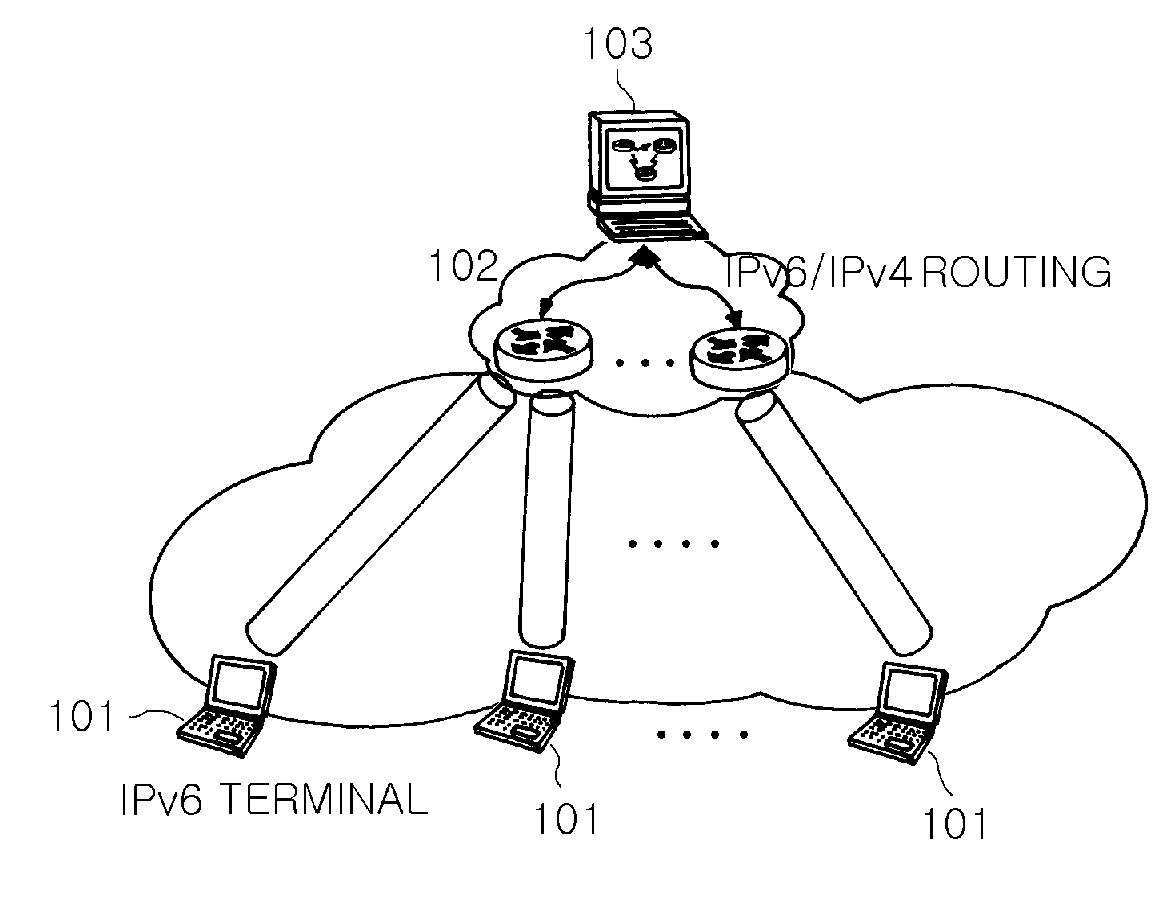

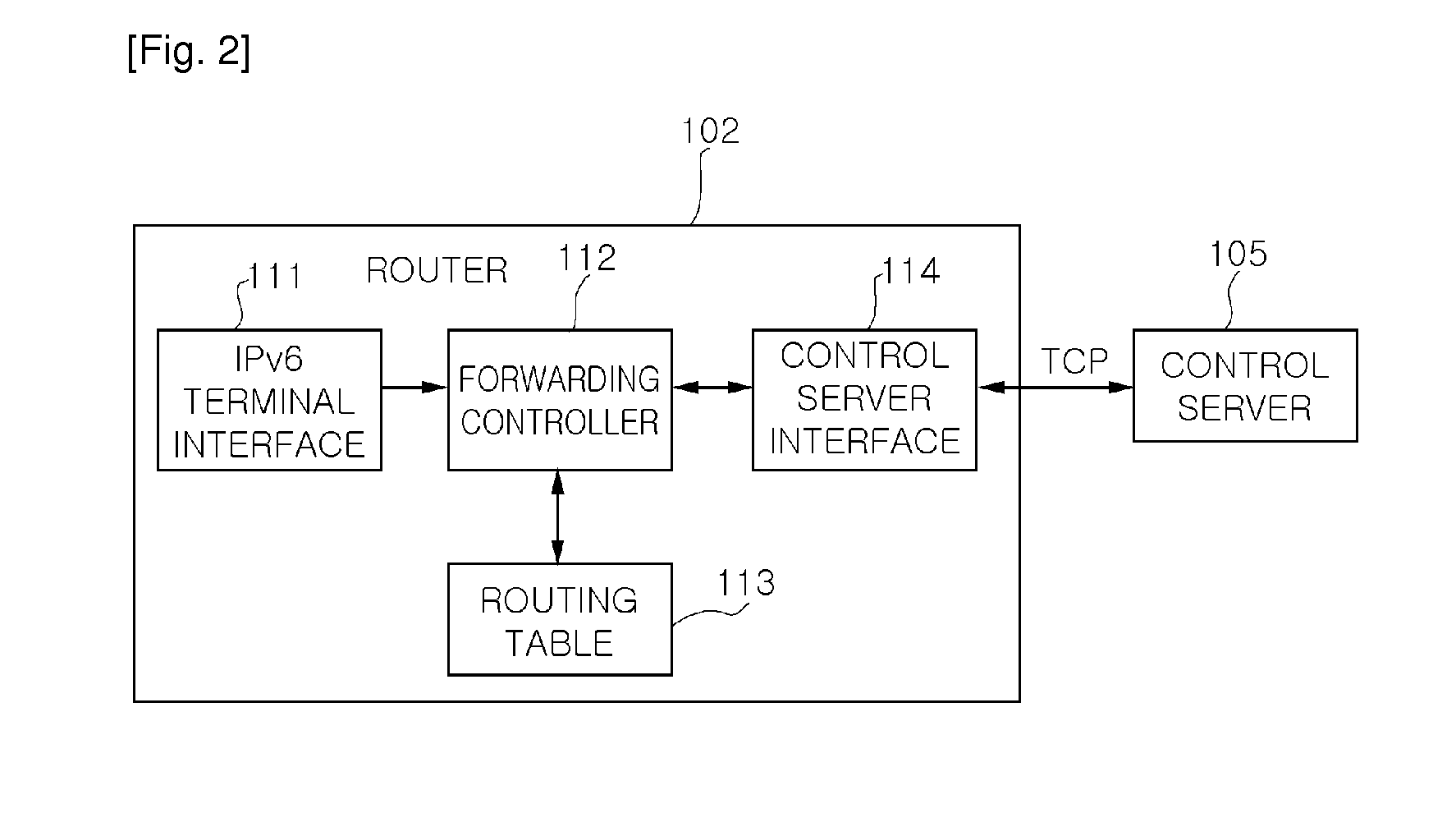

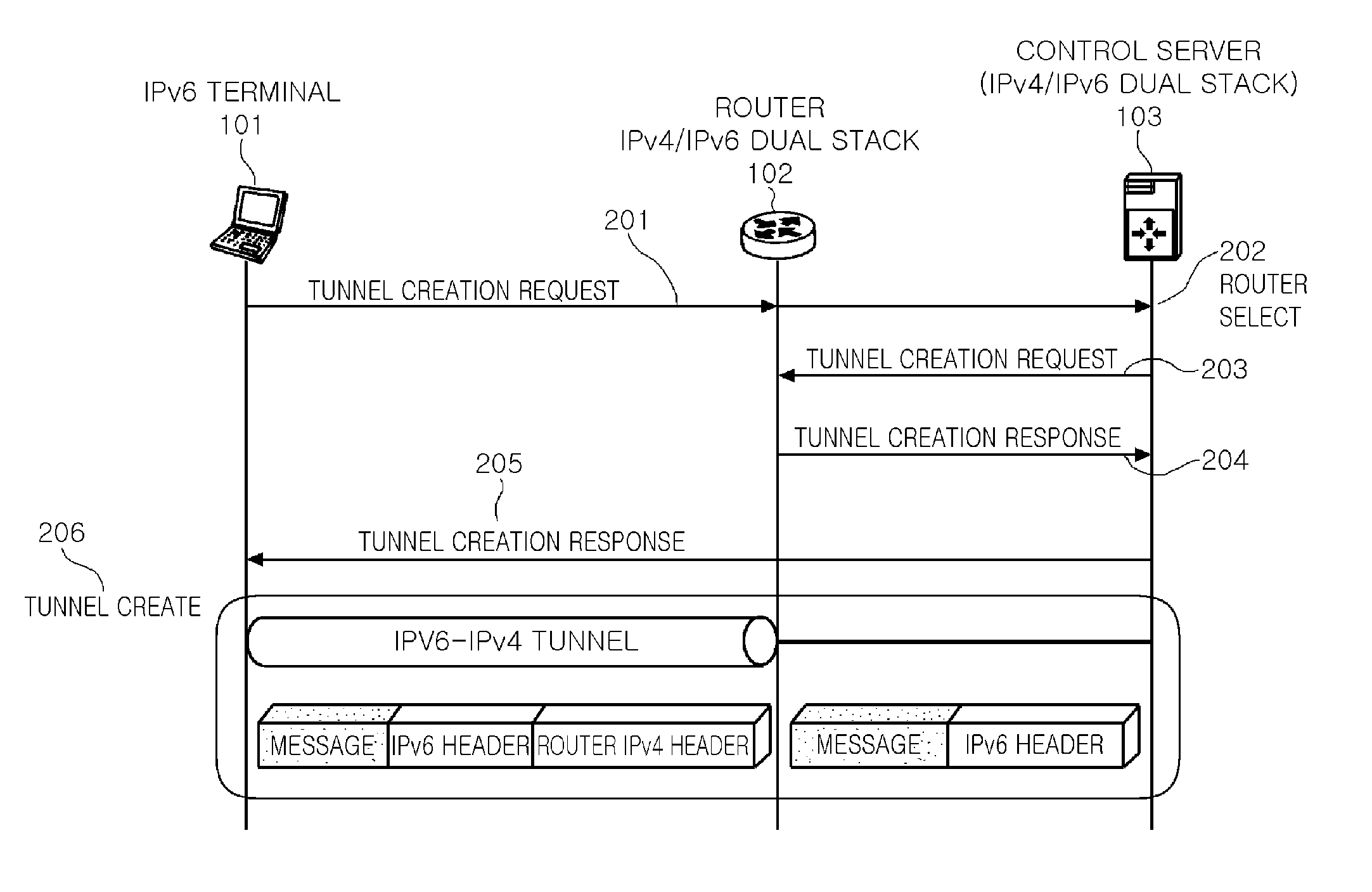

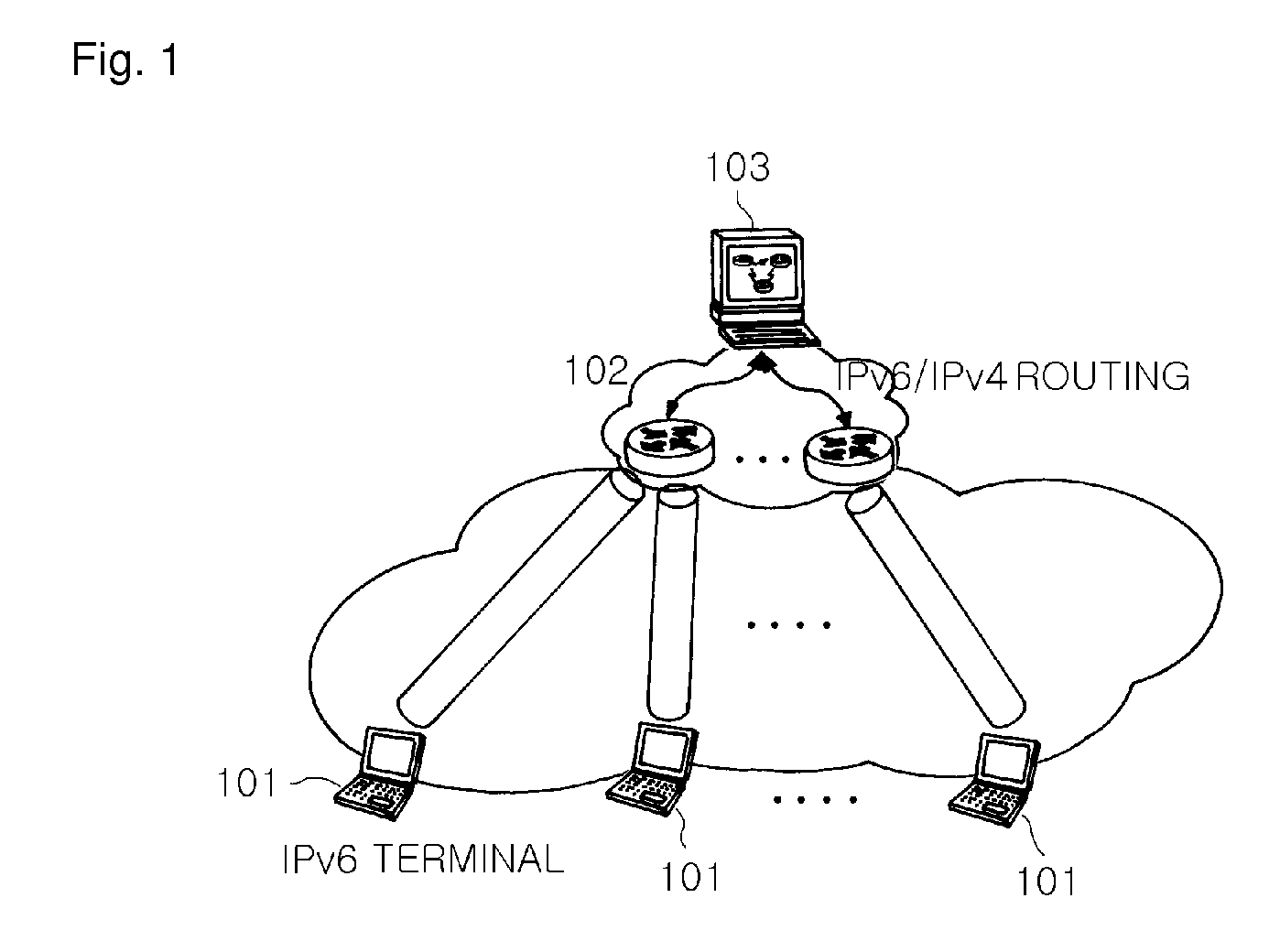

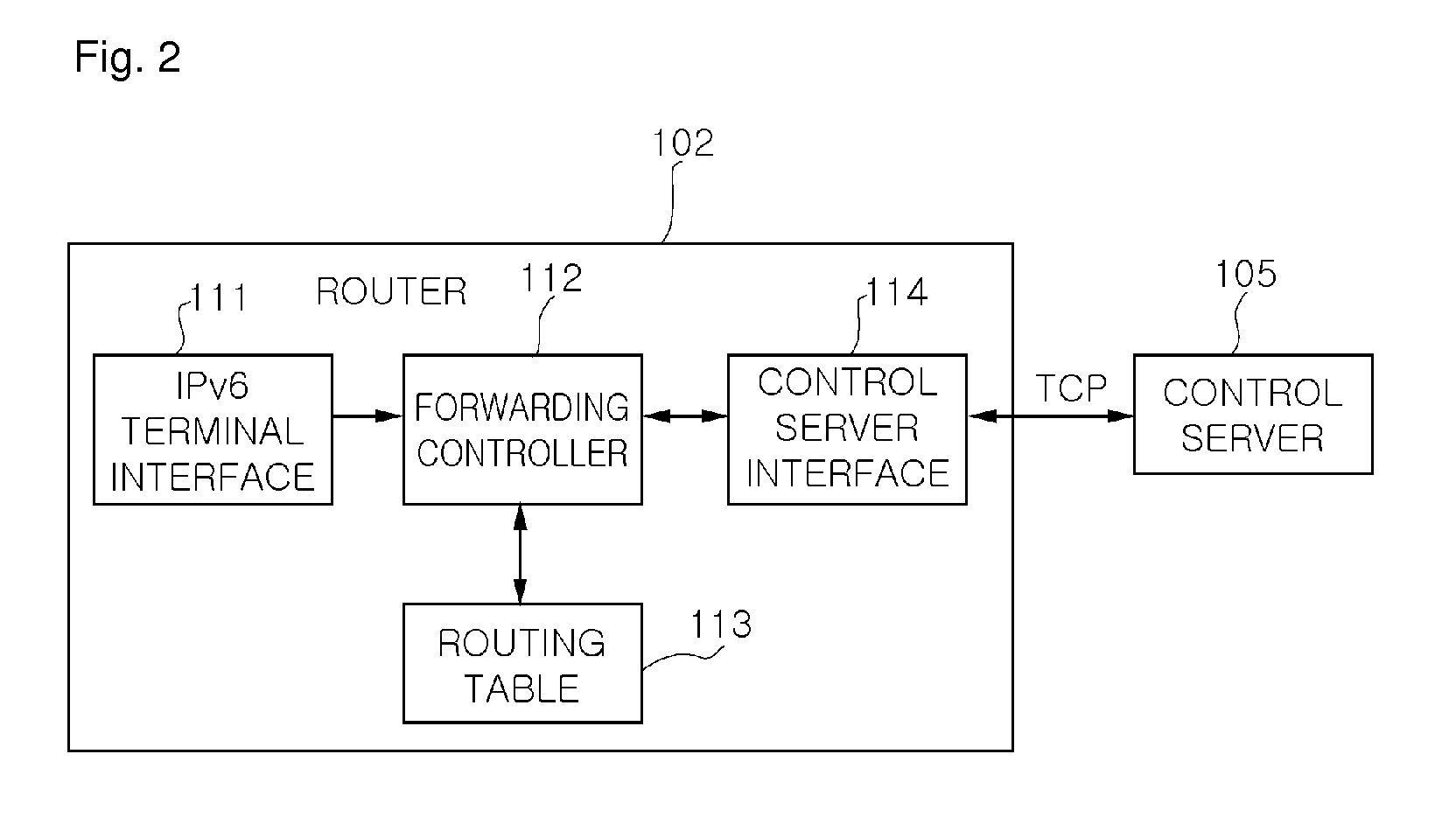

Ipv6 over ipv4 transition method and apparatus for improving performance of control server

InactiveUS20110013647A1Easy to manageImprove controlTime-division multiplexData switching by path configurationExtensibilityComputer terminal

The present invention relates to a method and apparatus for performing IPv6 over IPv4 transition to improve performance of a control server. When an edge router selected by the control server according to a tunnel creation request of an IPv6 terminal receives a tunnel creation request message from the control server, the edge router transmits a tunnel creation response message for the received tunnel creation request message to the IPv6 terminal through the control server, and the edge router performs IPv6 over IPv4 transition through a tunnel created by the IPv6 terminal that received the tunnel creation response message so as to improve the performance of the control server. Therefore, loads of the control server occurred because all terminals set control tunnels to the control server can be prevented, and service extensibility due to the increase in the number of subscribers can be guaranteed.

Owner:ELECTRONICS & TELECOMM RES INST

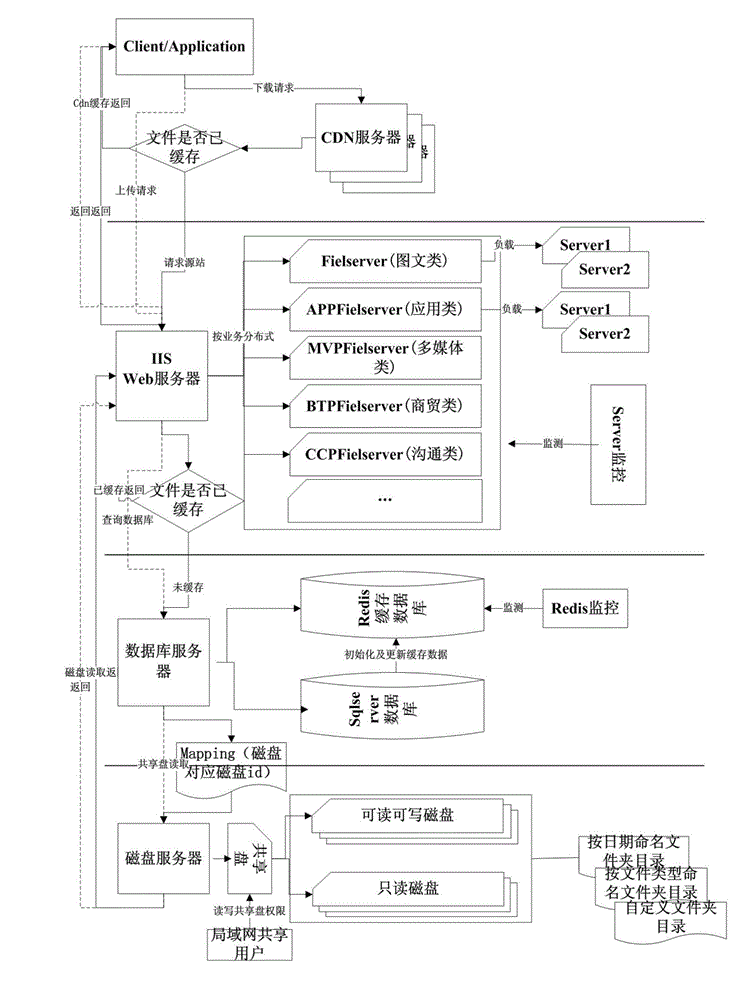

Method and system for uploading and downloading file

ActiveCN104601724AImprove download speedIncrease upload speedWeb data retrievalTransmissionFailure rateWeb service

The invention belongs to the field of file services, and specifically relates to method and system for uploading and downloading a file. The method and system are that a downloading request from a client is queried and downloaded by layers through a CDN server, an IIS Web server, a database server and a disk server; with the adoption of the server combined querying method, the file downloading speed is greatly raised; the client sends the uploading request to the IIS Web server, the database server and the disk server to quickly upload the specified file; in addition, discontinuous downloading and uploading are supported, namely, large files can be downloaded or uploaded by segmentation due to the influences such as network cause, and therefore, the failure rate of downloading and uploading of the large files can be greatly reduced.

Owner:BEIJING JINHER SOFTWARE

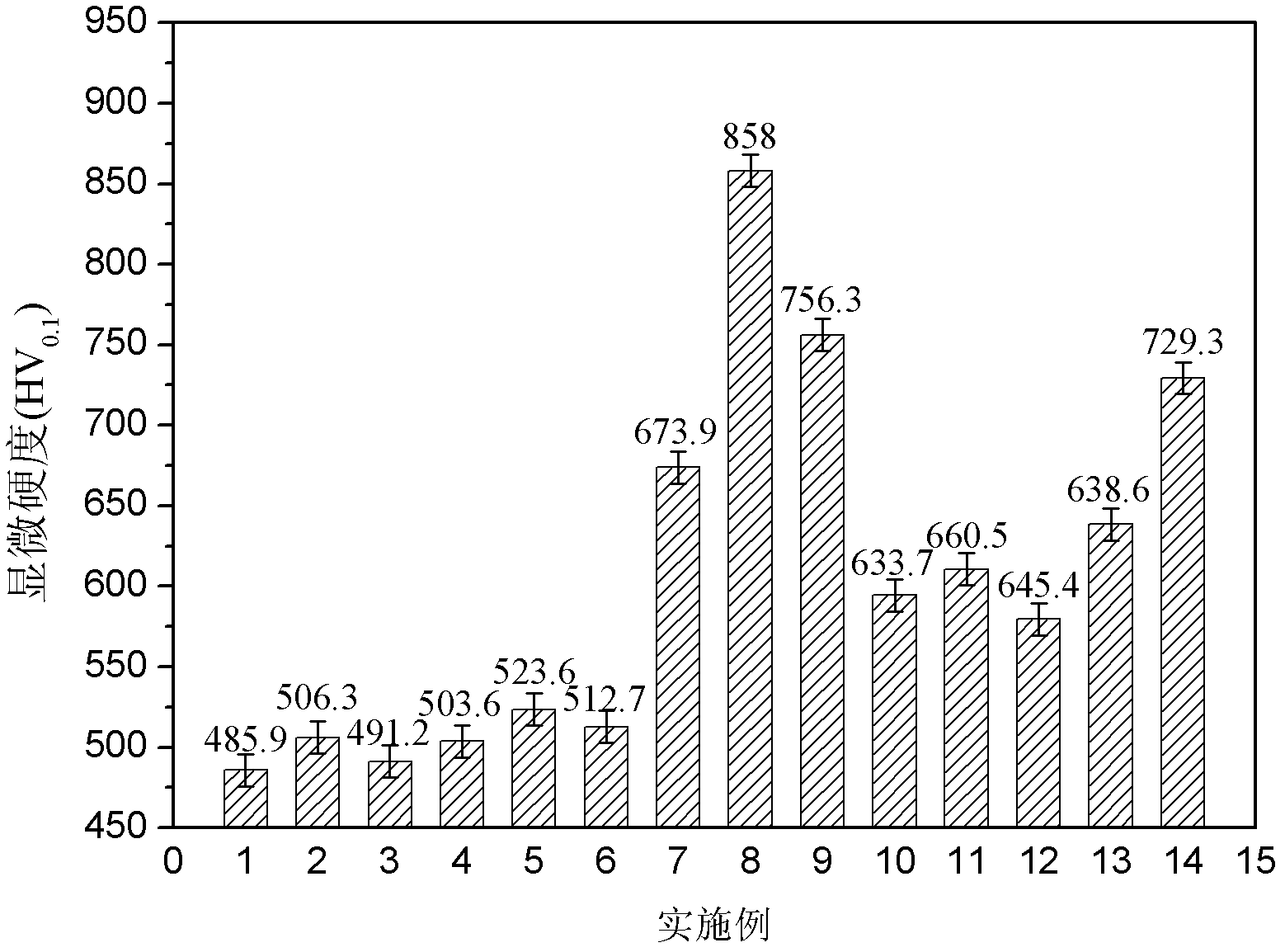

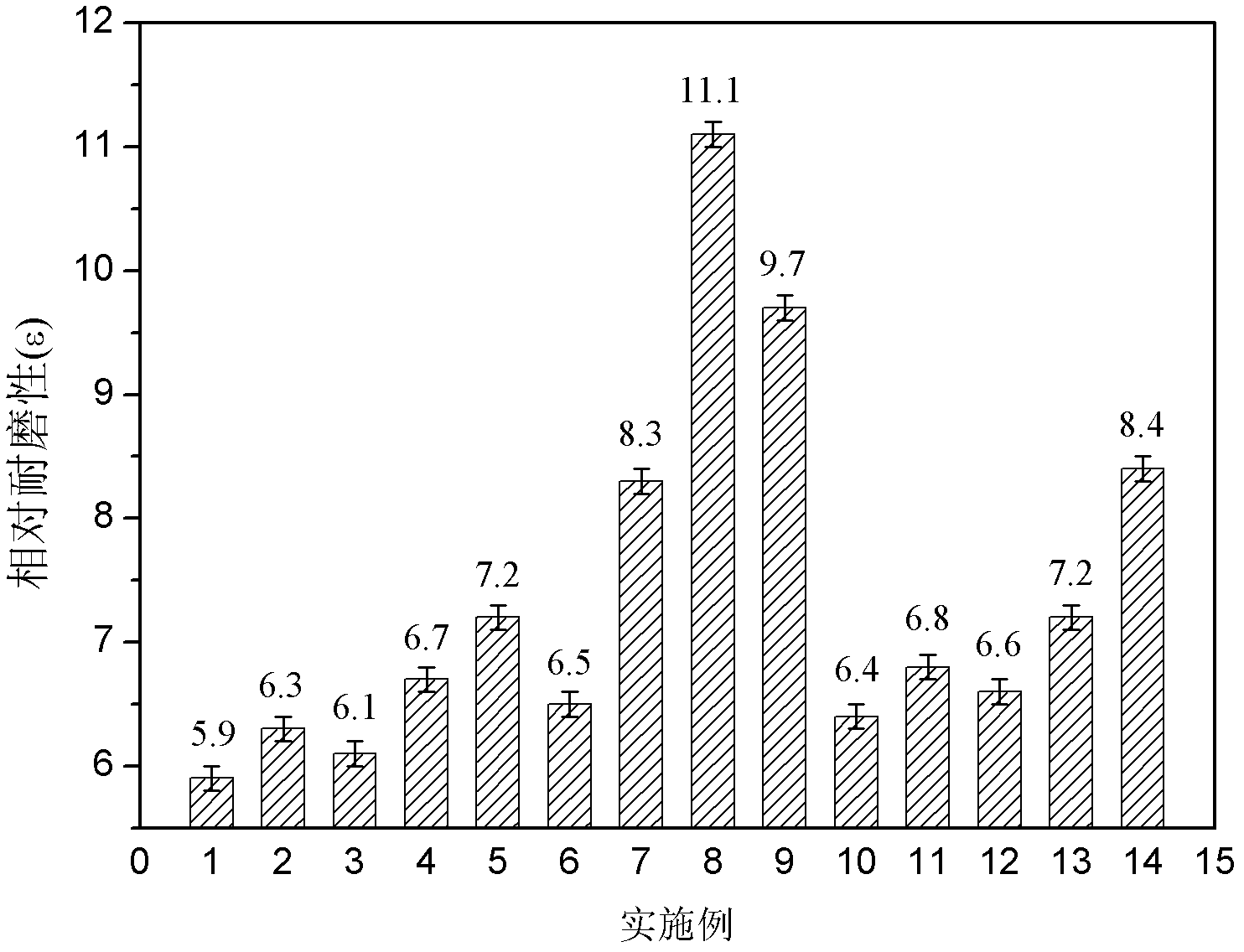

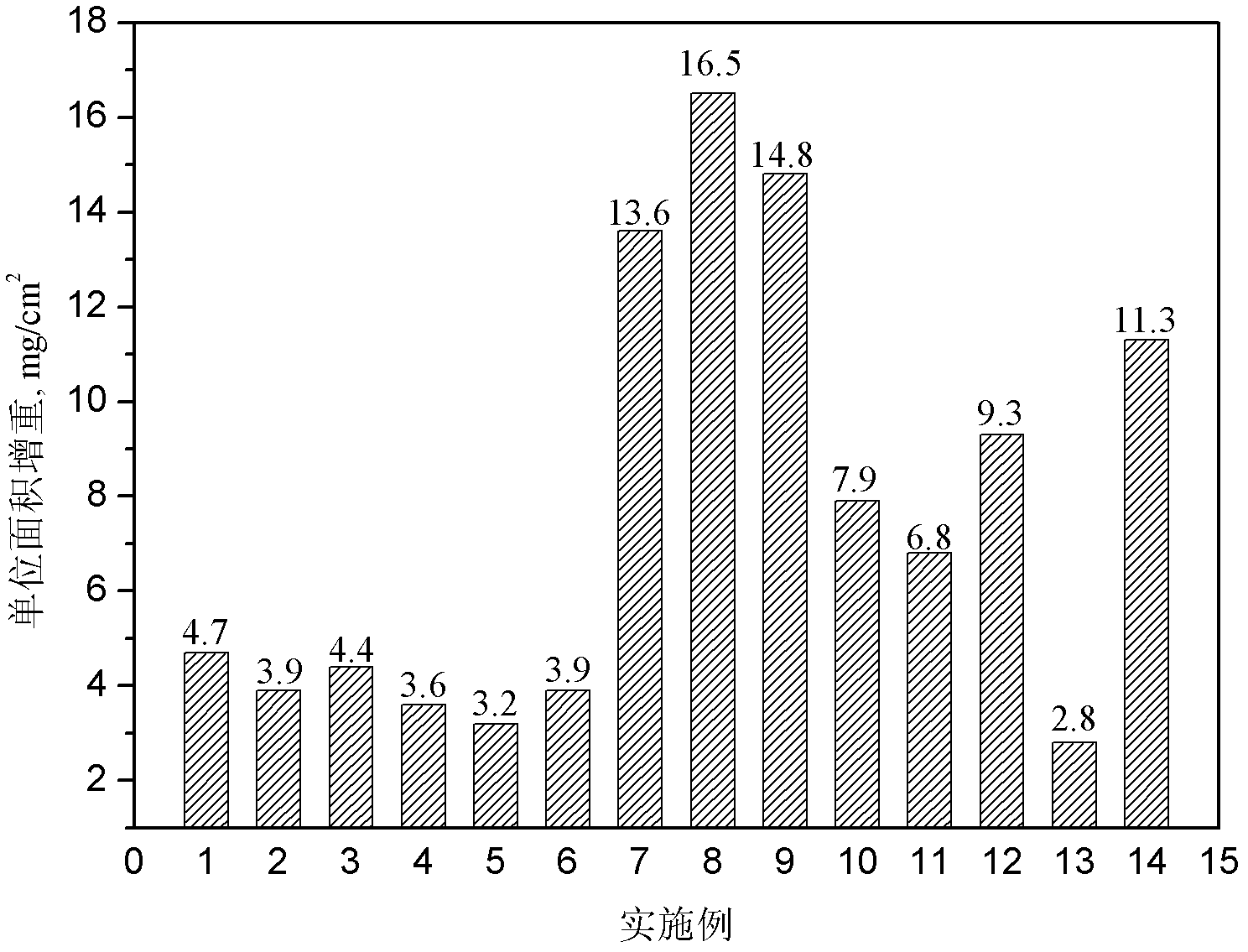

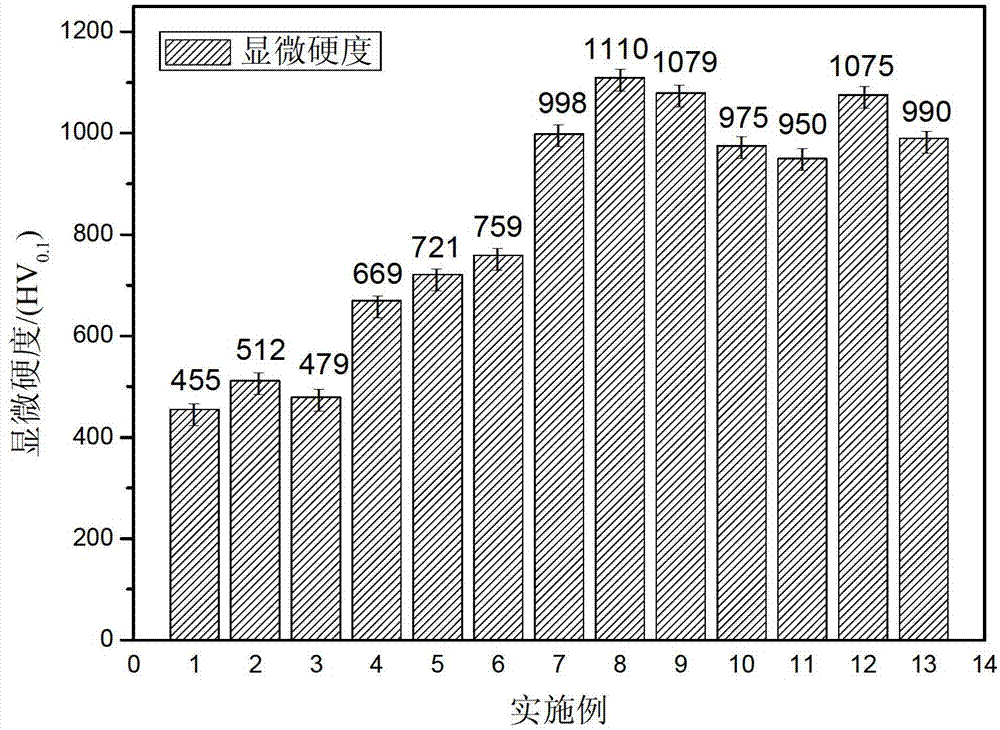

A kind of preparation method and application of powder core wire material for nickel-based coating, coating

The invention discloses a powder core wire material for preparing a nickel-based coating, a preparation method and application of the coating, and belongs to the field of thermal spraying in material processing engineering. The atomic percentage of the drug core composition is: Cr: 20-35at.%; B: 30-55at.%; C: 2.5-5.5at.%; Ni: balance; the tape used for the powder core wire sheath is Ni-Cr tape ;Powder core wire material filling rate: 32%. When preparing nickel-based coatings containing Cr23C6 ceramic particles reinforced phase by arc spraying, the substrate needs to be pretreated first. Spraying process: voltage 28-34V; current 160-220A; spraying distance 190-210mm; compressed air pressure 0.5-0.6MPa . The invention can obtain a coating with high hardness, good wear resistance and corrosion resistance, and improves the service stability of water-cooled wall tubes and superheater tubes in waste recycling WTE garbage incinerators.

Owner:BEIJING UNIV OF TECH

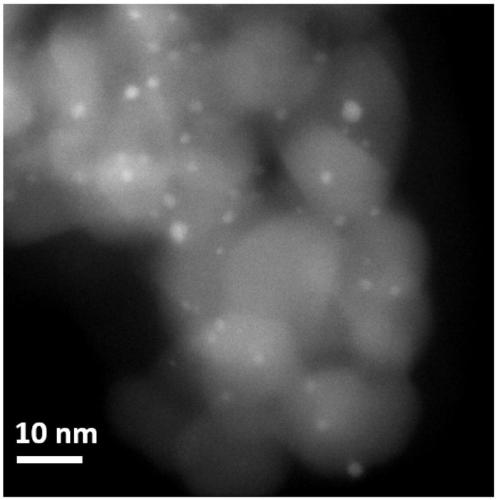

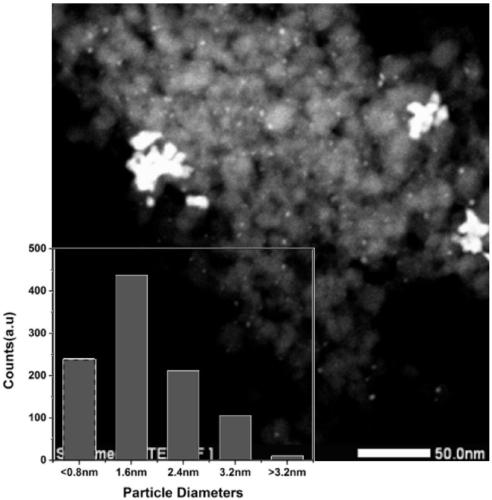

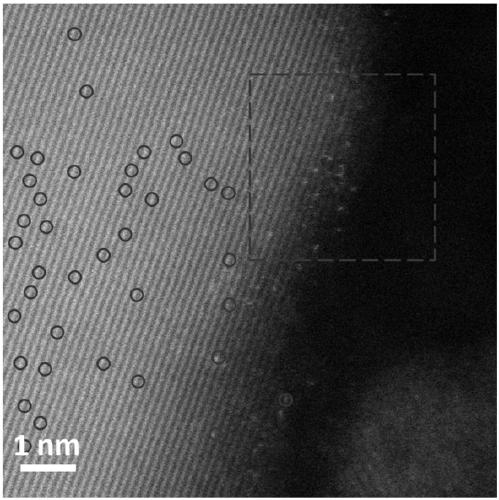

Precious metal single-atom dispersion type cleaning catalyst and preparation method thereof

ActiveCN109433192AReduce unit consumptionReduce manufacturing costCatalyst activation/preparationCarbon monoxideCoprecipitationMetal powder

The invention discloses a precious metal single-atom dispersion type cleaning catalyst and a preparation method thereof. The catalyst comprises the following components in percentages by weight: 97% to 99.99% of a nano metal oxide carrier and 0.01% to 3% of a precious metal. The method comprises the following steps: taking the nano metal oxide carrier, dispersing the nano metal oxide carrier intoa precious metal salt solution to form a mixed solution, and using a coprecipitation method to generate a precursor of which the precious metal is loaded on the surface of the carrier; mixing the precursor and metal powder in the proportion of 1: (1 to 100), and carrying out calcinations to generate a precursor after heat treatment, and after washing and drying, obtaining the precious metal single-atom dispersion type cleaning catalyst. In the catalyst prepared by the method, the precious metal is in single-atom dispersion type, the method is low in processing method, simple in preparation technology and high in H2 removal rate and has extremely high stability, the catalyst cannot be inactivated after continuous application for 60 h, and the loss of CO is relatively small.

Owner:NORTHEASTERN UNIV

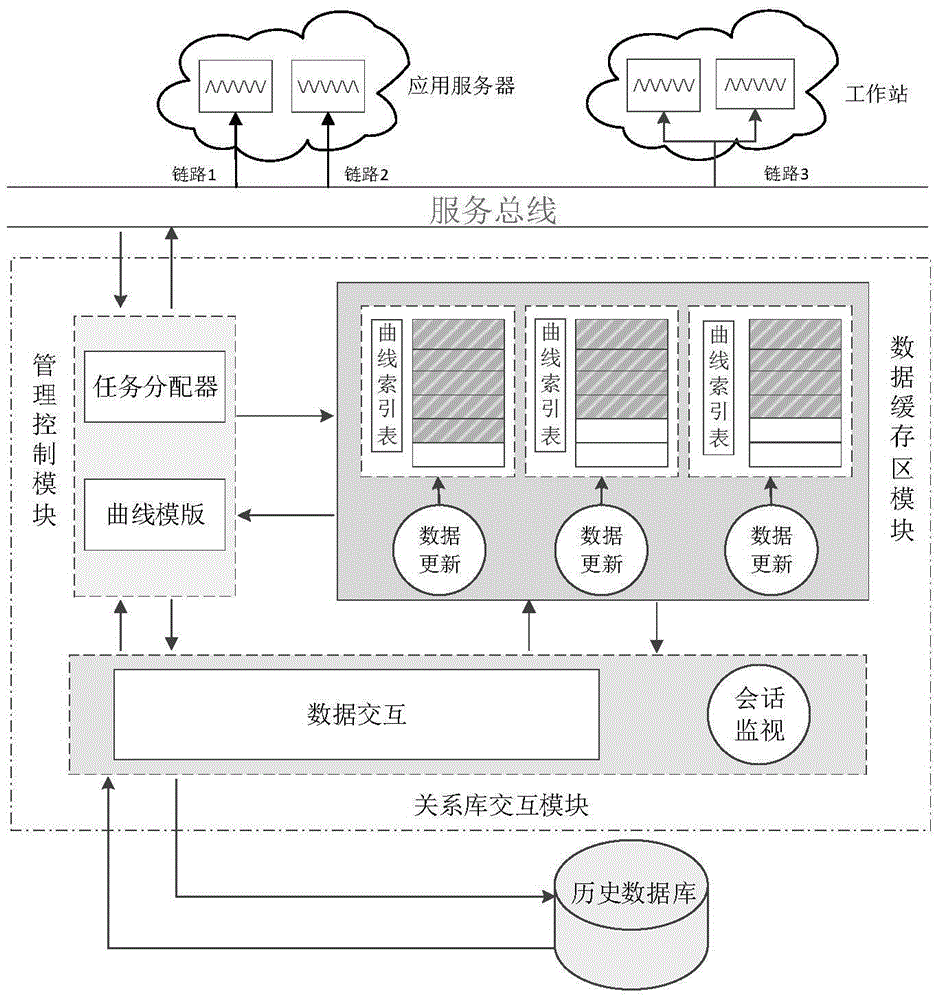

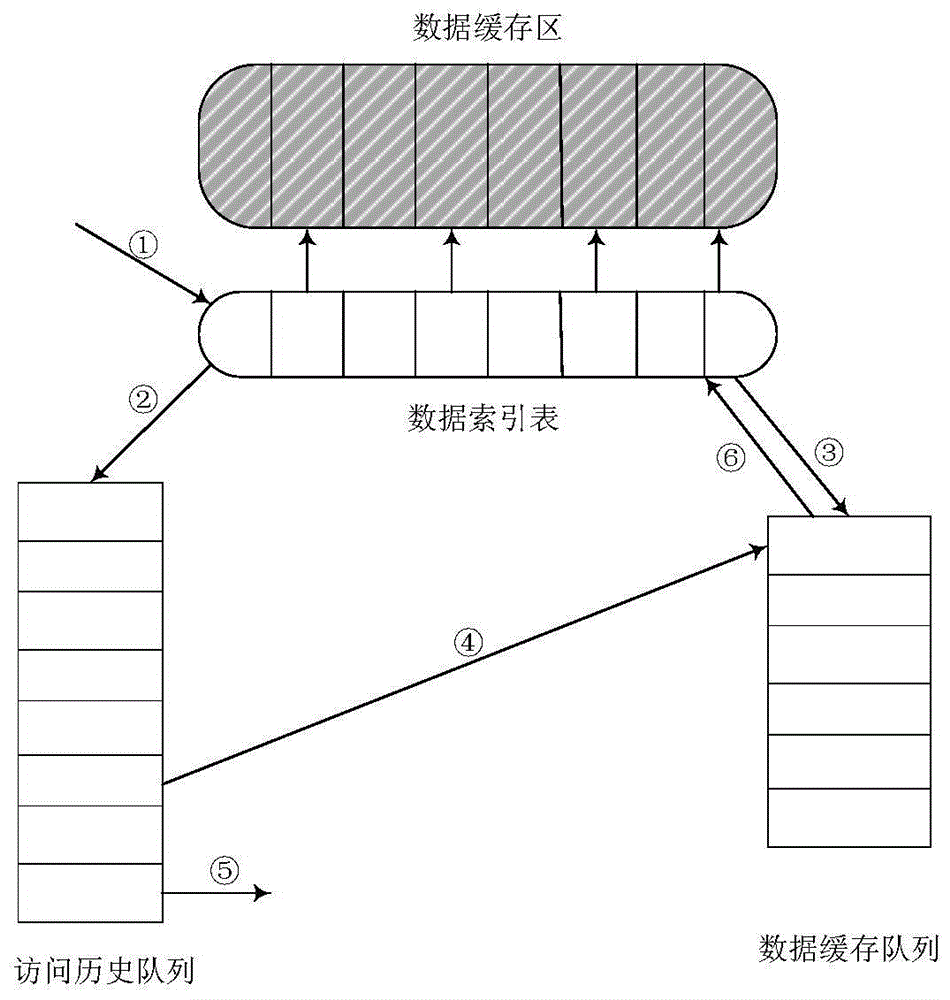

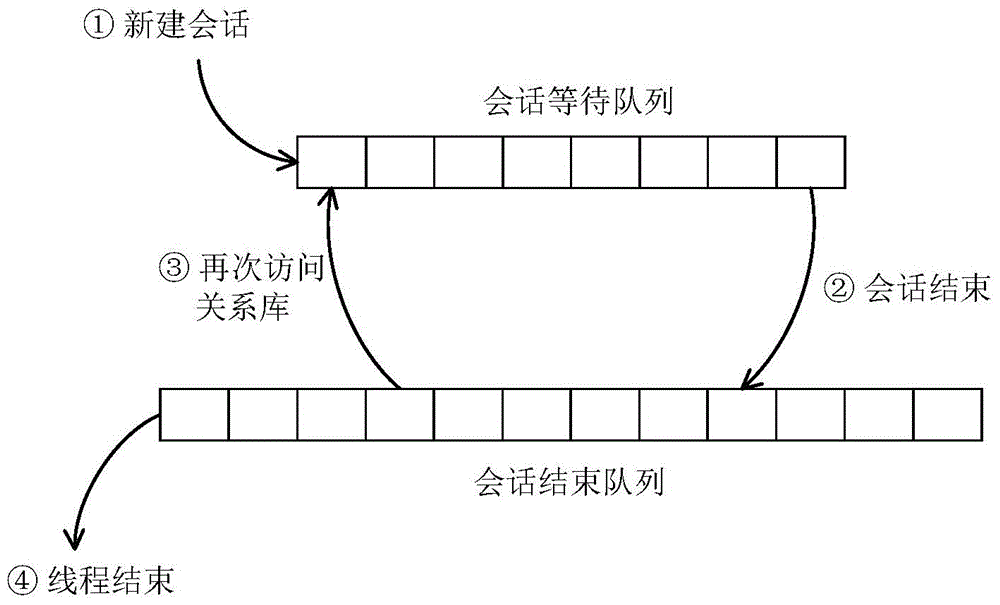

Historical data service system used for smart power grid dispatching control system

InactiveCN105740352AEfficiencyReduce the frequency of direct accessData processing applicationsRelational databasesData synchronizationRelational database

The invention discloses a historical data service system used for a smart power grid dispatching control system, and inquires historical data on the basis of a cache management mechanism and a historical library access monitoring mechanism. The historical data service system comprises a management control module, a data cache region module and a relational database interaction module, wherein the management control module consists of a curve template and a task distributor module; the data cache region module consists of a data cache region, a data index table, a cache data synchronization module and a data point replacement algorithm module; and the relational database interaction module consists of a data interaction module and a dialogue monitoring module. The historical data service system adopts a historical data cache management mechanism to improve service query efficiency and lighten relational database load. A database dialogue monitoring mechanism is adopted to improve service stability.

Owner:CENT CHINA BRANCH OF STATE GRID CORP OF CHINA

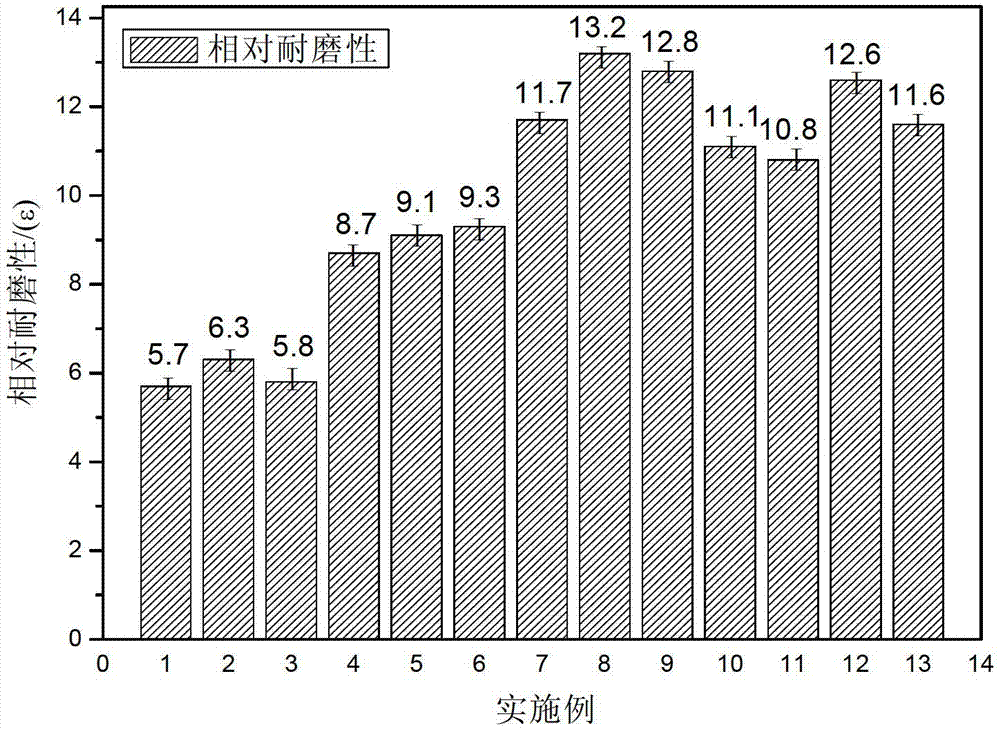

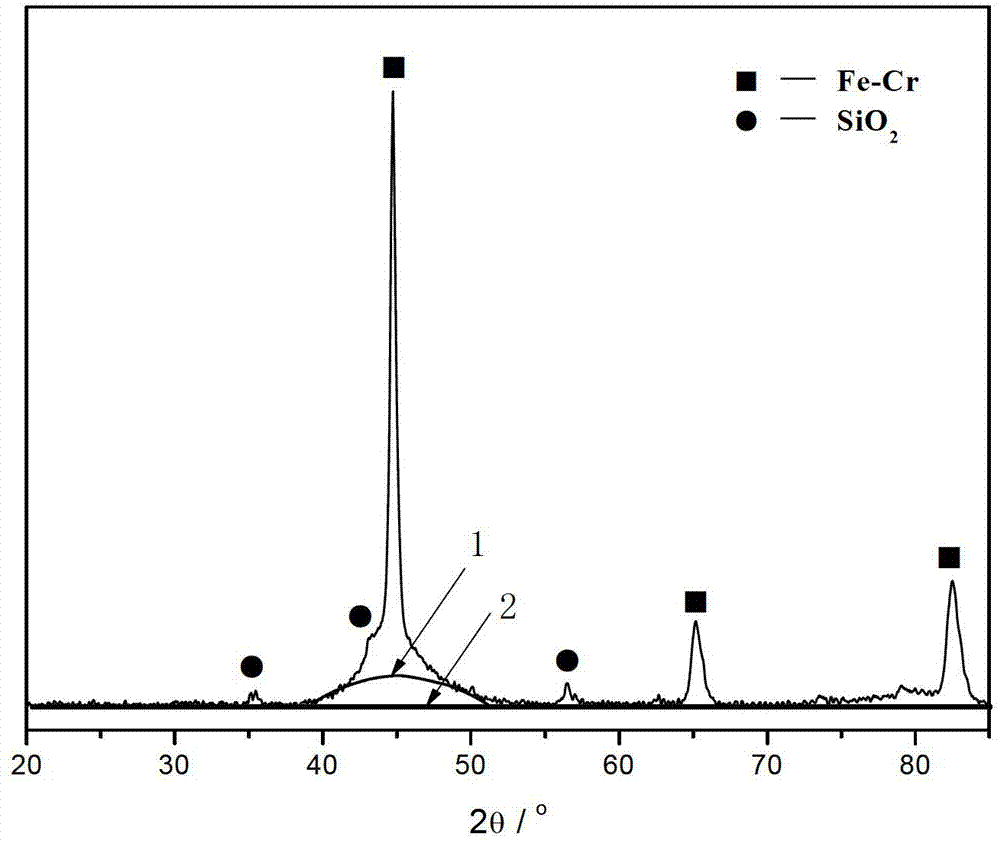

Cored wire for preparing iron-based coating as well as preparation method and application thereof

InactiveCN103088280AImprove corrosion resistanceCorrosion resistant barrierMolten spray coatingThermal sprayingFilling rate

The invention provides a cored wire for preparing an iron-based coating as well as a preparation method and application thereof and belongs to the field of thermal spraying in material processing engineering. The flux composition comprises 15-35 at.% of Cr, 5-25 at.% of B, 5-25 at.% of Si, 2.5 to 5.5 at.% of C and the balance of Fe; a strip material for a sheath of the cored wire is a stainless steel band; and the filling rate of the cored wire is 33%. When electric-arc spraying is used for preparing an iron-based amorphous / nanocrystal coating containing ceramic phase SiO2, firstly a matrix is pretreated, and according to a spraying technology, the voltage is 28-34V, the electric current is 160-220A, the spraying distance is 190-210mm, and the compressed air pressure is 0.4-0.6Mpa. The coating can be widely applied to repair and protection of equipment parts in industries such as metallurgy, electricity and petroleum. The coating with the advantages of corrosion resistance, high hardness and high wearing resistance is obtained according to the preparation method.

Owner:BEIJING UNIV OF TECH

Preparation and application of rare earth-containing nickel-based powder core wire material and coating

ActiveCN103924182AHeat and corrosion resistantGood heat and corrosion resistanceMolten spray coatingThermal sprayingRare earth

The invention discloses preparation and application of a rare earth-containing nickel-based powder core wire material and a coating, belonging to the field of thermal spraying in the material machining engineering. A core the following components in percentage by mass: 20-35% of pure metal chromium powder, 10-31% of nickel boron powder, 0.1-0.3% of rare earth and the balance of nickel, wherein the outer skin of the powder core wire material is made of a 80Ni-20Cr strip; the filling rate of the powder core wire material is 32%; when the rare earth-containing nickel-based coating is prepared in an electric arc spraying mode, a substrate needs to be pretreated; the spraying parameters are as follows: the voltage is 28-34V, the current is 160-220A, the spraying distance is 190-210mm, and the pressure of compressed air is 0.5-0.6MPa. A coating which is good in thermal conversion property and corrosion resistance can be obtained, and the service stability of a water-cooling wall tube and a superheater tube in a waste resource WTE (Waste To Energy) garbage incinerator is improved.

Owner:唐山宝航机械制造有限公司

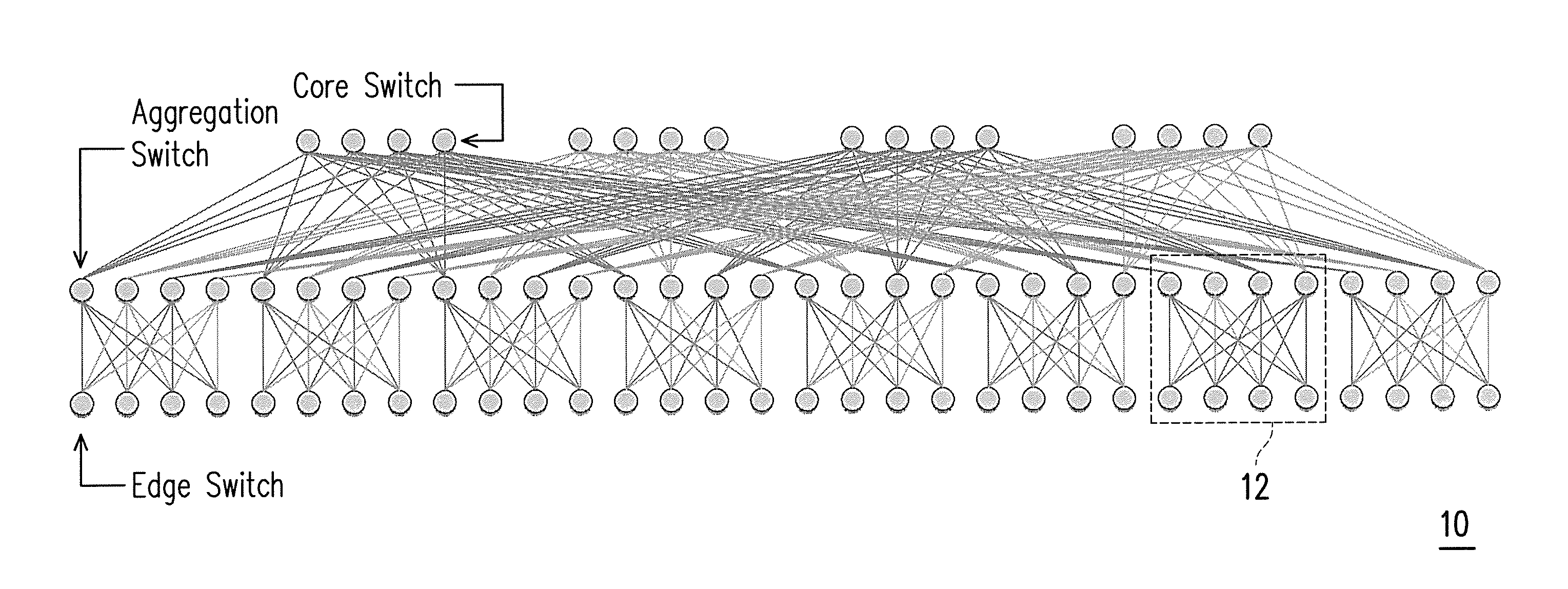

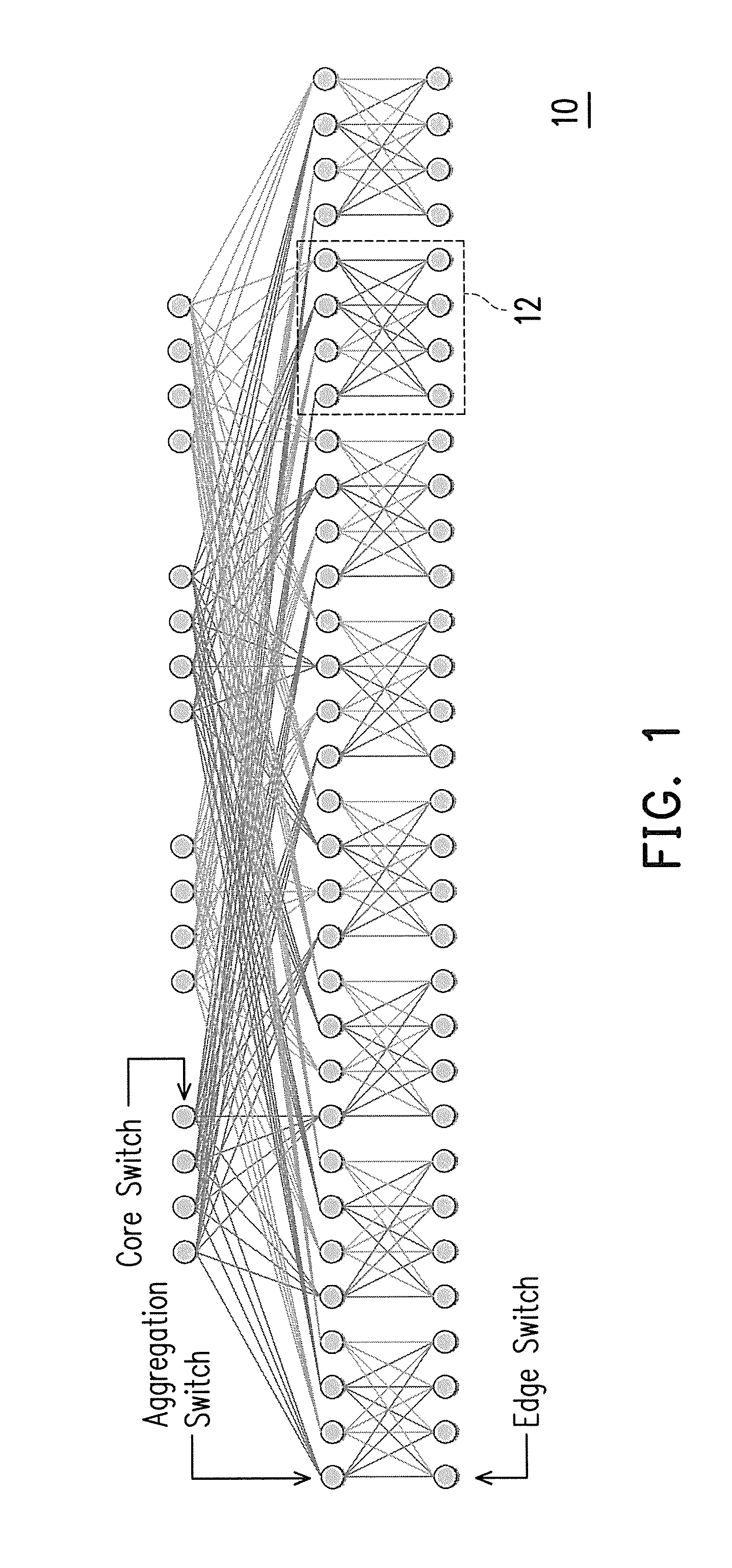

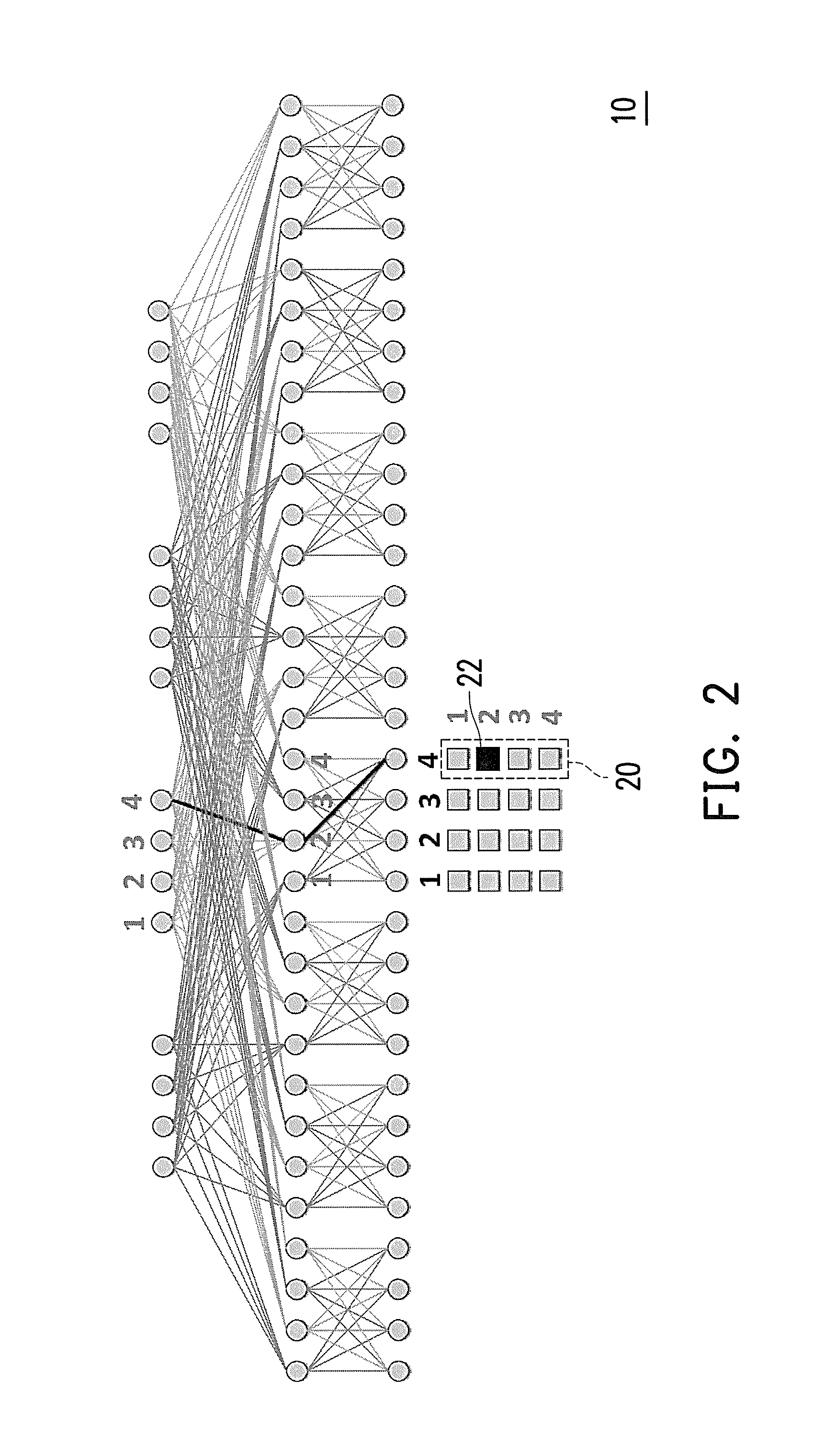

Dynamic planning method for server resources of data center

ActiveUS20150207755A1Optimizing resource utilization rateImprove network efficiencyDigital computer detailsData switching networksDynamic planningDynamic programming

A dynamic planning method for server resources of a data center is provided. The data center includes multiple pods and each pod includes multiple racks configurable with multiple servers. In the method, a rack having a remaining space larger than or equal to d is searched from the pods and used for configuring d servers. If the rack cannot be configured with the d servers, a single pod reallocation is executed on one of the pods to empty a rack so that the remaining space of the rack is larger than or equal to d and configurable with the d servers. If there is no rack that can be emptied, a cross-pod reallocation is executed to empty corresponding server positions of corresponding racks in the pods so that the remaining space of the corresponding server positions is larger than or equal to d and configurable with the d servers.

Owner:ACER INC

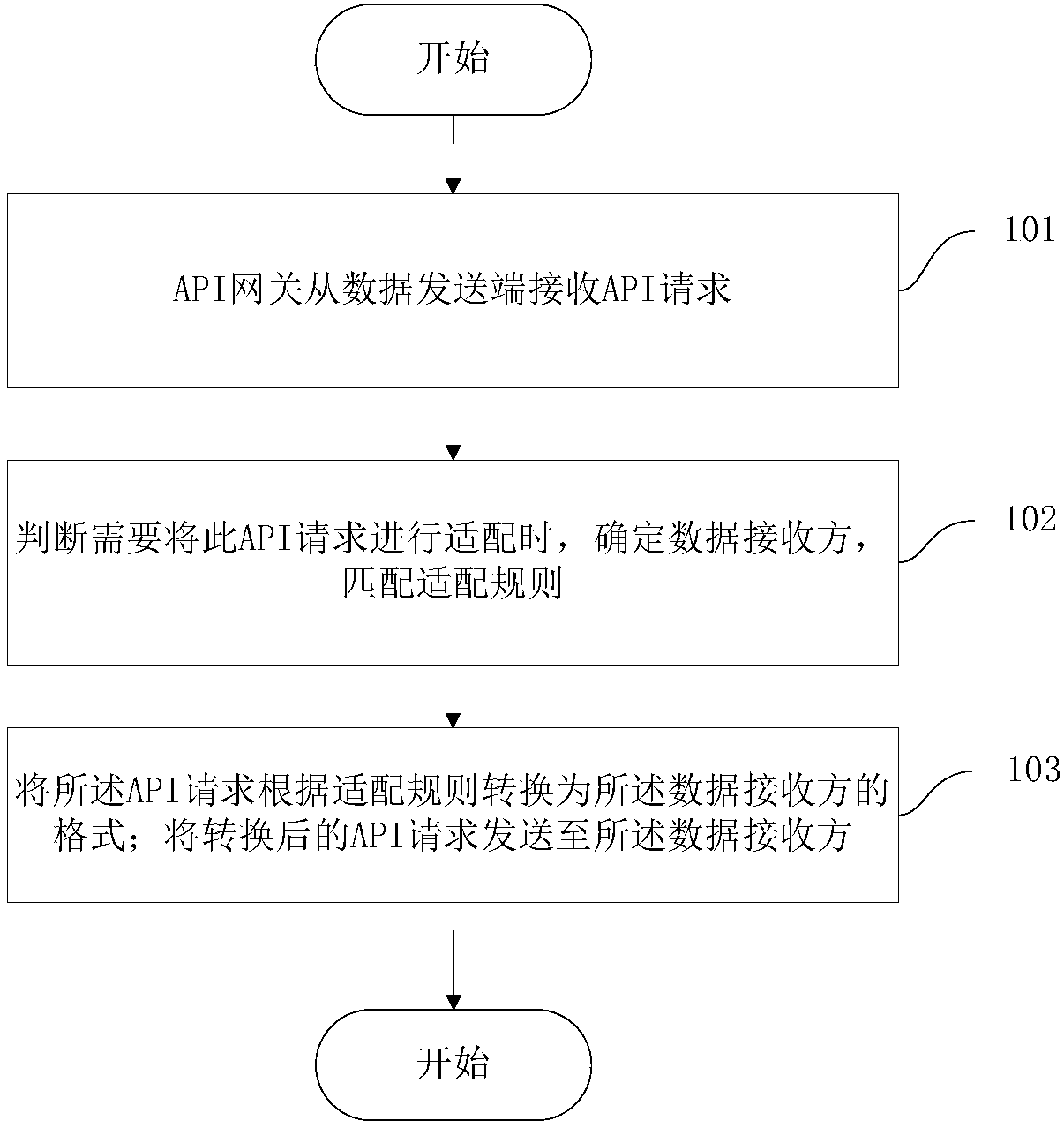

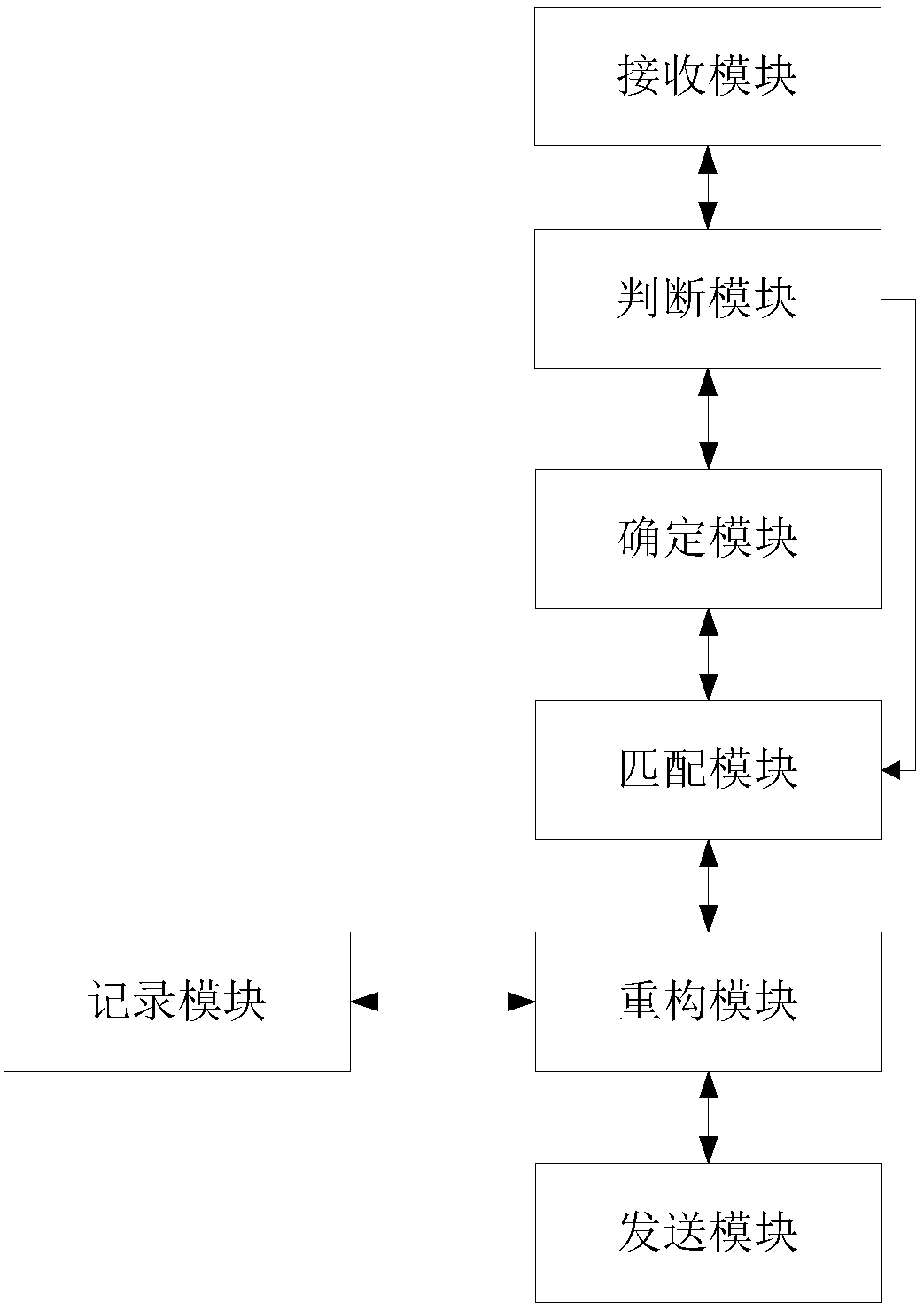

Request handling method and device based on API intelligent adaption

The invention discloses a request handling method and device based on API intelligent adaption. The method comprises the following steps: receiving an API request from a data transmitting terminal byan API gateway; when a fact that the API request needs to be adapted is judged, determining a data receiver, and matching an adaption rule; converting the API request into a format of the data receiver according to the adaption rule; and sending the converted API request to the data receiver. The method disclosed by the invention can intelligently adapt to clients and server sides in different formats, protocol adaptation and conversion of API input and output are guaranteed, and a function of modifying the rule by a user is supported, so that management of a service supplier can be facilitated, service stability is effectively improved, management cost is reduced and usage experience of the user is improved; and API monitoring also can be carried out, and statistical analysis on interfacedata is realized.

Owner:BEIJING SHUJU XINYUN TECH CO LTD

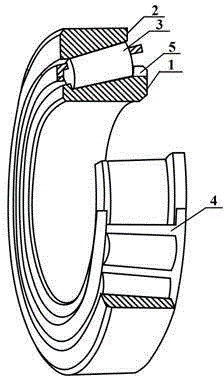

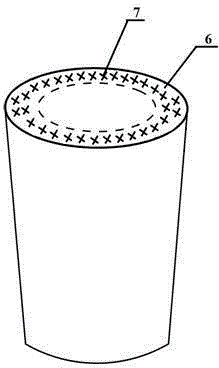

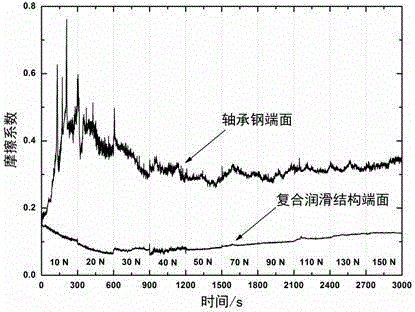

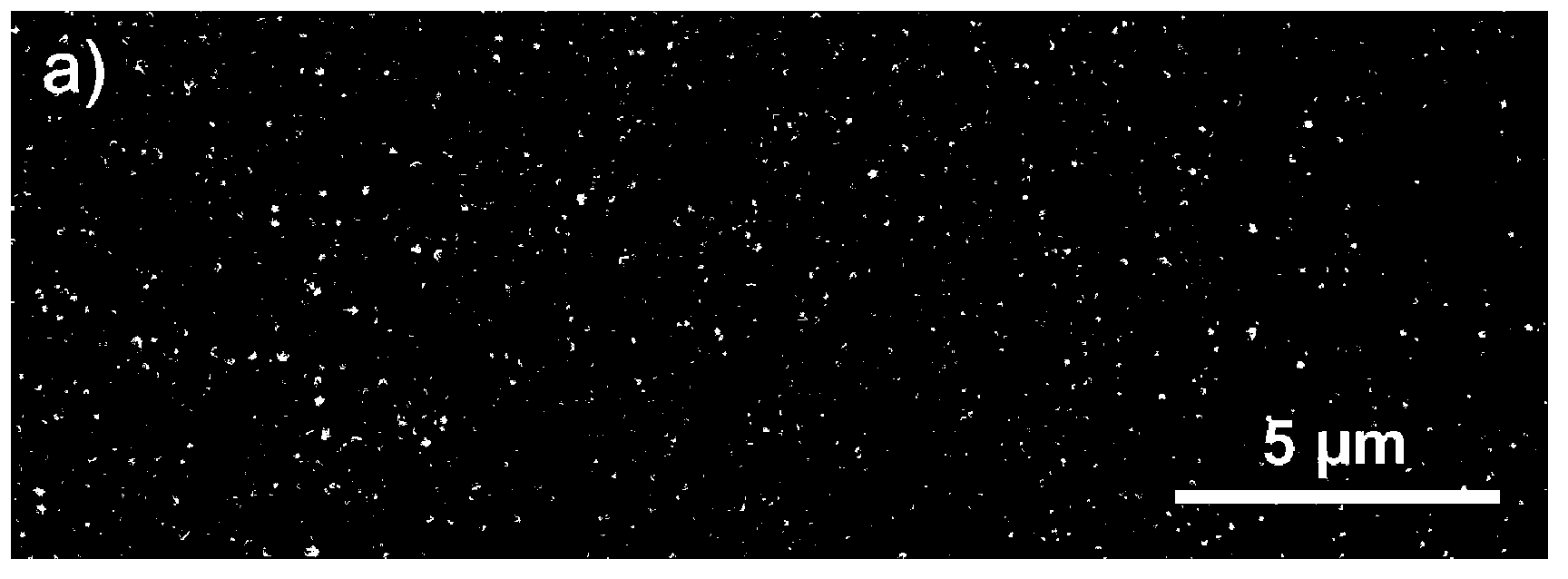

Roller bearing

InactiveCN104930054AAchieve continuous lubricationImprove bearing capacityRoller bearingsBearing componentsEngineeringHeavy load

The invention discloses a roller bearing, which comprises an inner ring with a raceway on the outer periphery, an outer ring with a raceway on the inner circumference, a roller between the inner ring raceway and the outer ring raceway, a cage and a thrust structure. A thrust contact region on the roller end face is a composite lubricating structure which comprises a solid lubricating coating and a surface microtexture, wherein the surface microtexture is a uniformly distributed micro-pit array. The roller bearing provided by the invention has the advantages of anti-jamming capability enhancement, low friction and high service stability, and is applicable to efficient transmission of a spindle mechanism bearing axial or axial-radial joint load under harsh conditions of high speed, heavy load, impact load and dust.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

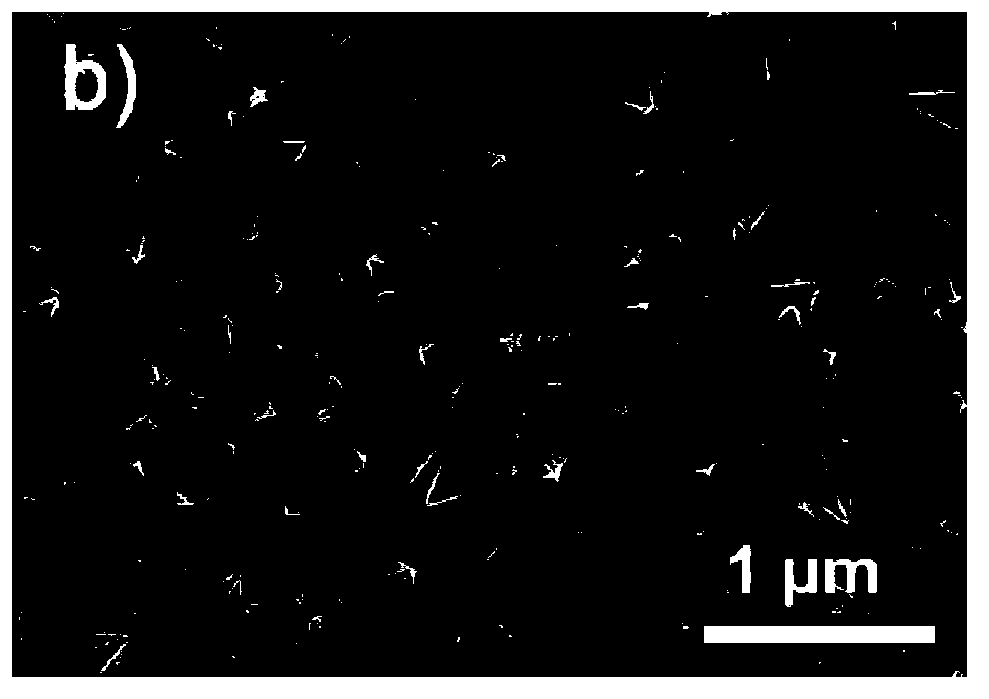

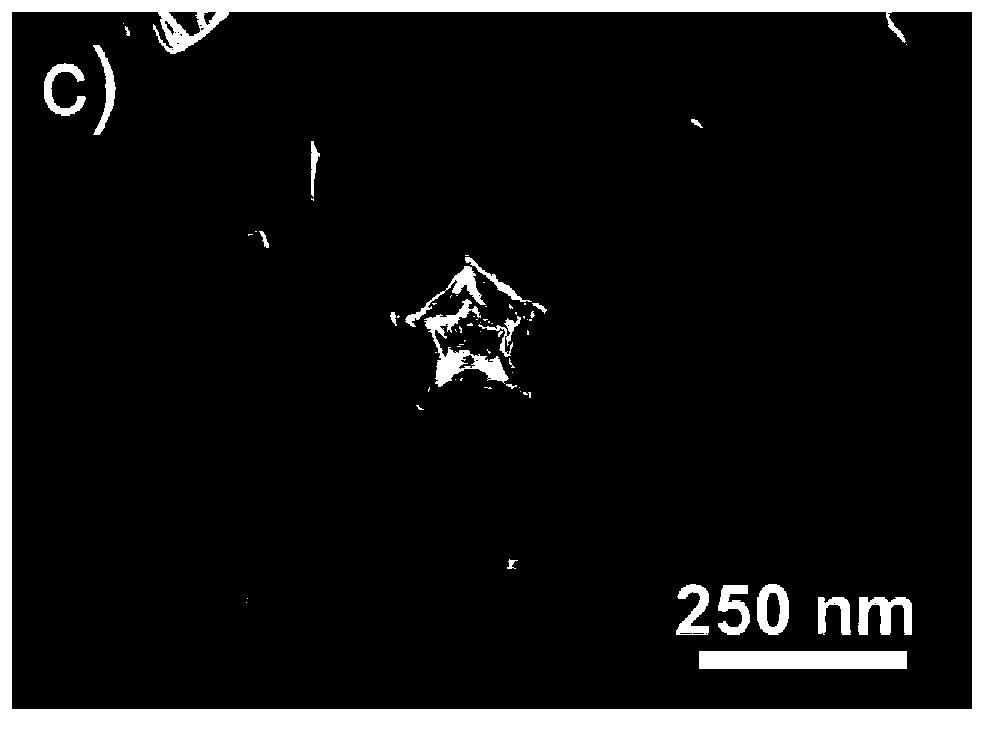

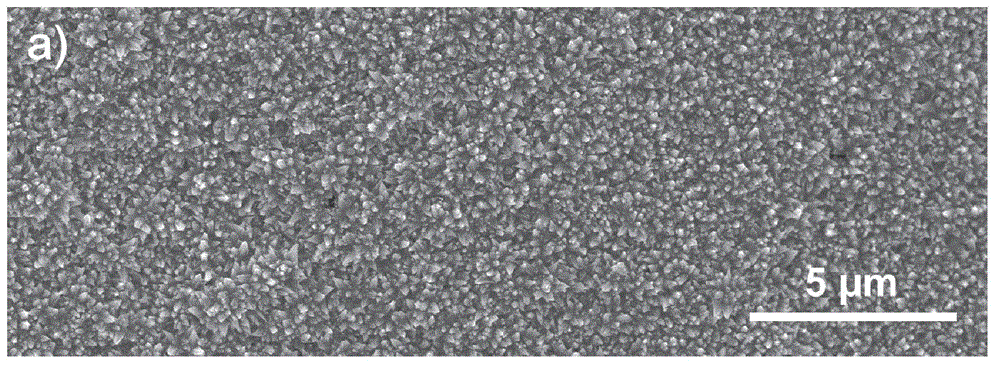

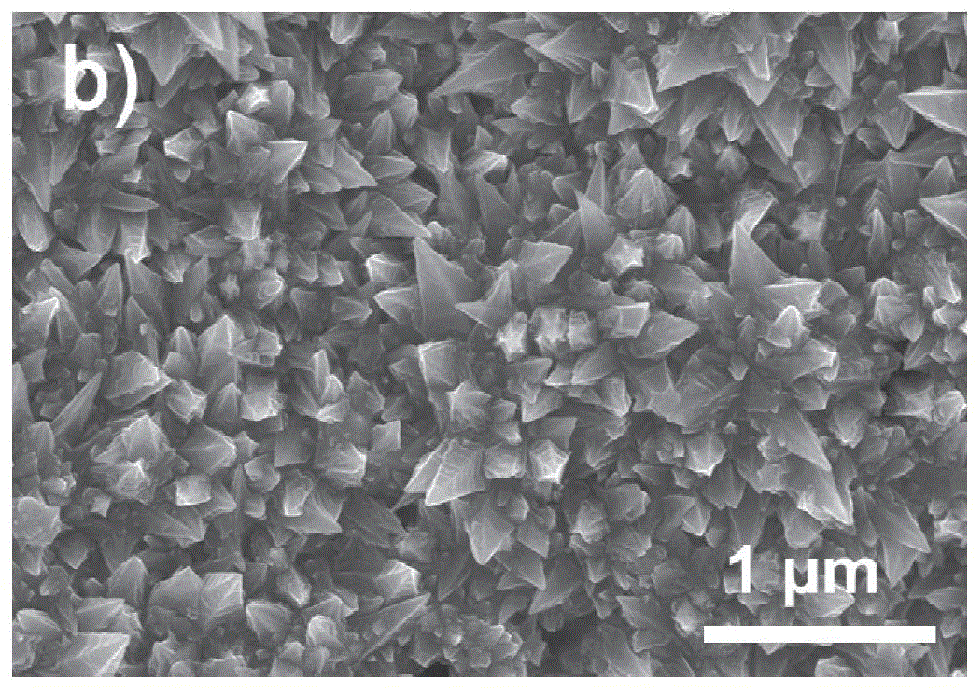

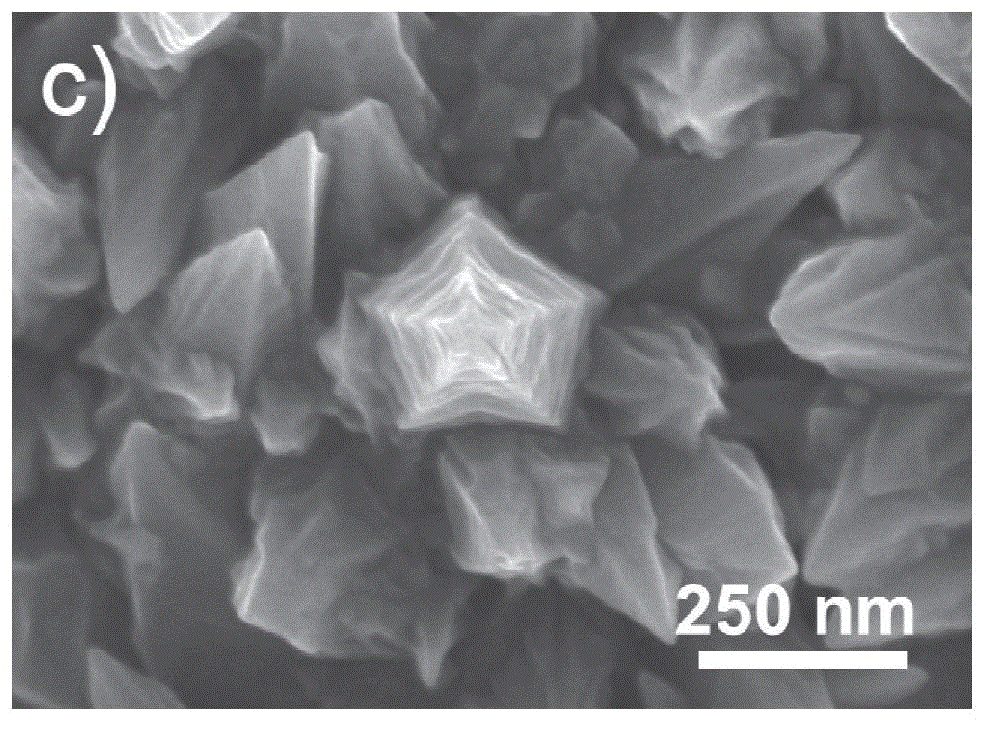

Nanometer copper material capable of transferring heat with high efficiency, and preparation method thereof

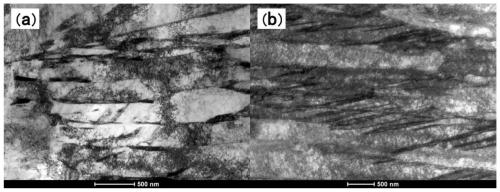

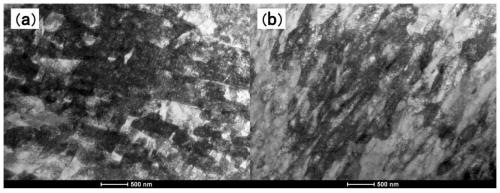

The invention discloses a nanometer copper material capable of transferring heat with high efficiency, and a preparation method thereof. The surface of the nanometer copper material is coated with an ultra-thin nano or micro-nano composite porous nickel film with super wetting ability; the ultra-thin nano composite porous nickel film comprises a porous structure which is mainly made of nickel nano flowers; and the ultra-thin micro-nano composite porous nickel film comprises a porous structure which is mainly formed by accumulation of micron or nanometer nickel triangular sheets. The preparation method comprises following steps: a substrate is taken as working electrode; the working electrode, a counter electrode and a reference electrode are placed in a weak acid nickel salt electrolyte so as to form a reduction system; reduction current is provided between the working electrode and the counter electrode so as to realized nickel electro-deposition on the surface of the substrate; and then the ultra-thin nano or micro-nano composite porous nickel film is formed on the surface of the substrate. The ultra-thin nano or micro-nano composite porous nickel film is capable of increasing utilization stability of the nanometer copper material, and improving filmwise condensation heat transfer performance, boiling heat transfer performance and spray cooling heat dissipation performance of the nanometer copper material greatly. The formula of the electrode needed in the preparation method is simple; raw material are cheap and easily available; optional range of electroplating mode is wide; and the preparation method is suitable for industrialized large-scaled application.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

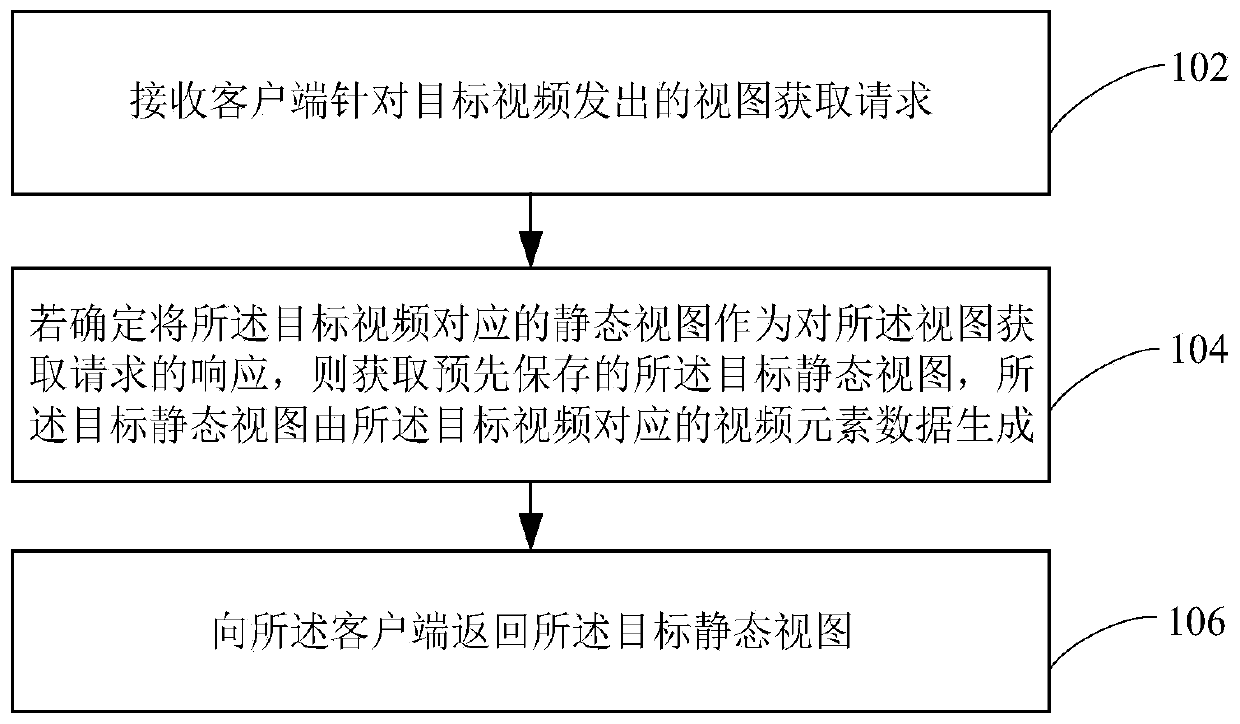

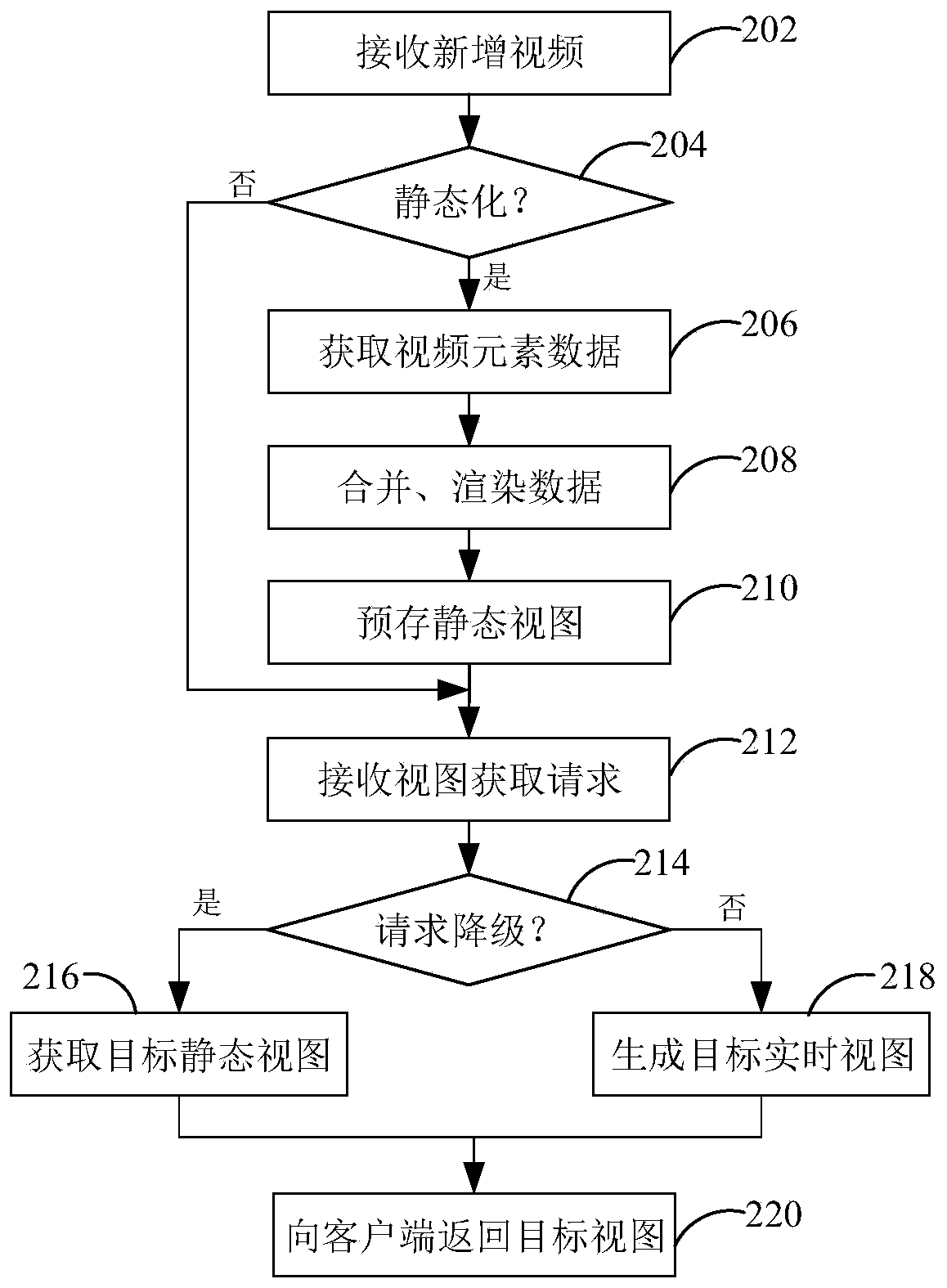

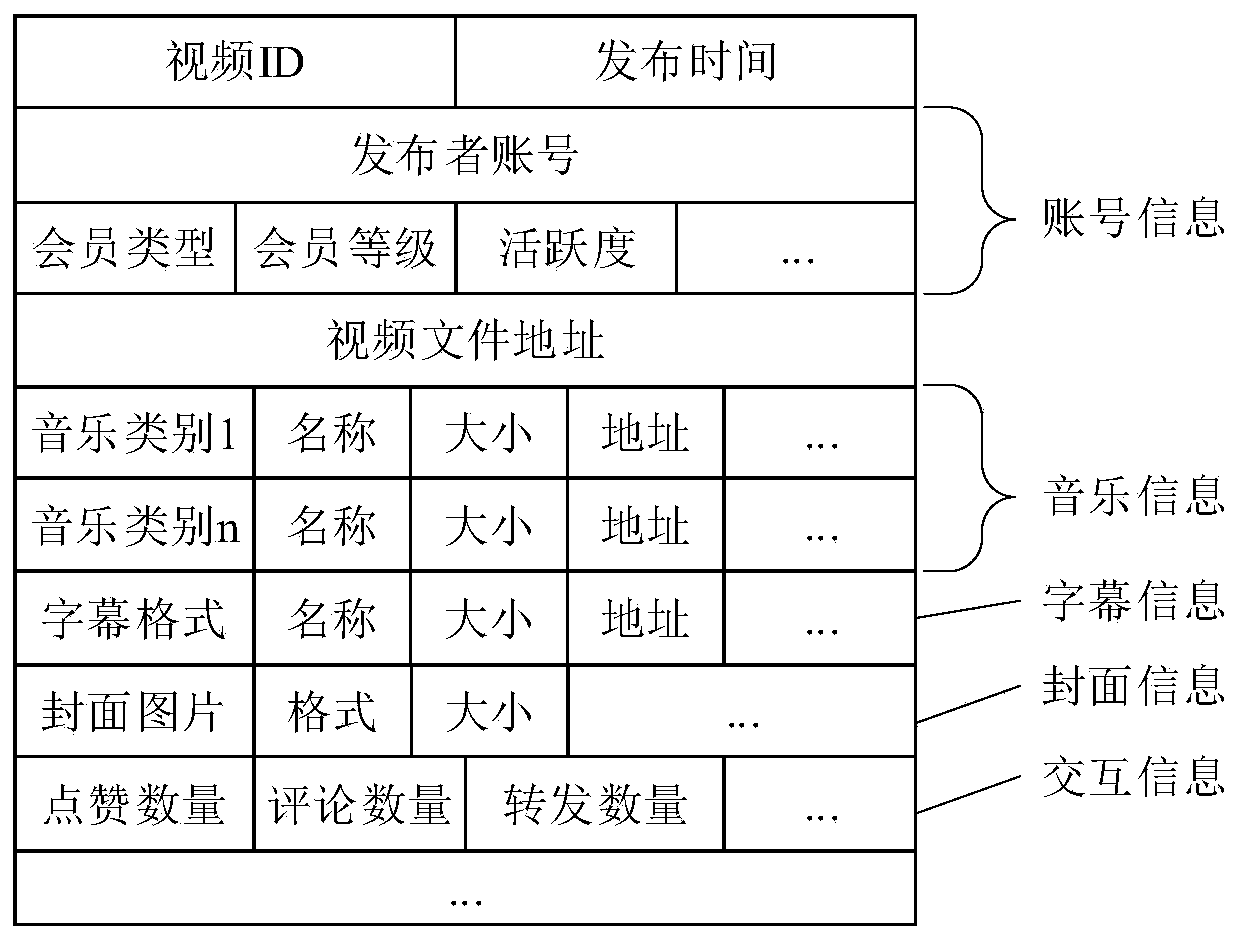

Video service providing method and device, electronic equipment and storage medium

PendingCN111581434AImprove experienceImprove display speedResource allocationVideo data browsing/visualisationComputer hardwareEngineering

The invention relates to a video service providing method and device, electronic equipment and a storage medium, and the method is applied to a server, and comprises the steps: receiving a view obtaining request sent by a client for a target video; if it is determined that the static view corresponding to the target video serves as a response to the view acquisition request, acquiring the pre-stored target static view, and the target static view is generated by video element data corresponding to the target video; and returning the target static view to the client. According to the method of the invention, video element data are acquired in advance, and a target static view generated according to the video element data is cached; the cached target static view is directly used for responding to the request of the client to realize degradation processing of the request of the client, so that the load pressure of massive requests on the server is reduced, the system stability is improved,the request response time is shortened, and the user experience is improved.

Owner:BEIJING DAJIA INTERNET INFORMATION TECH CO LTD

Preparation method of moisture-proof wave transmission quartz fiber/phosphate ceramic composite material

InactiveCN106242550ASolve the problem of high moisture absorption characteristicsLong storage periodWater bathsCeramic composite

The invention relates to a preparation method of a moisture-proof wave transmission quartz fiber / phosphate ceramic composite material. The method includes the steps of: preparing an aluminum phosphate solution: introducing an aluminum salt into a phosphoric acid aqueous solution, setting the water bath temperature at 60-100DEG C to obtain a transparent aluminum dihydrogen phosphate water solution; preparing a ceramic slurry containing one or two of silicon nitride, boron nitride, alumina or silicon oxide, taking ethanol or methanol as the solvent, and adopting fluorine containing silane as the dispersing agent; adding the obtained aluminum dihydrogen phosphate water solution into the ceramic slurry, further conducting ball milling to obtain a ceramic particle / aluminum phosphate composite ceramic slurry, employing vibration molding, letting the obtained ceramic particle / aluminum phosphate composite ceramic slurry fully impregnate quartz fiber cloth, stacking up the obtained fiber cloth layer by layer, and conducting compression molding at a pressure of 2-10MPa so as to obtain a composite impregnation material; and putting the composite impregnation material into a drying box to conduct curing treatment at a curing temperature of 80-200DEG C for 12-72h, thus obtaining the quartz fiber / phosphate ceramic composite material.

Owner:HARBIN INST OF TECH

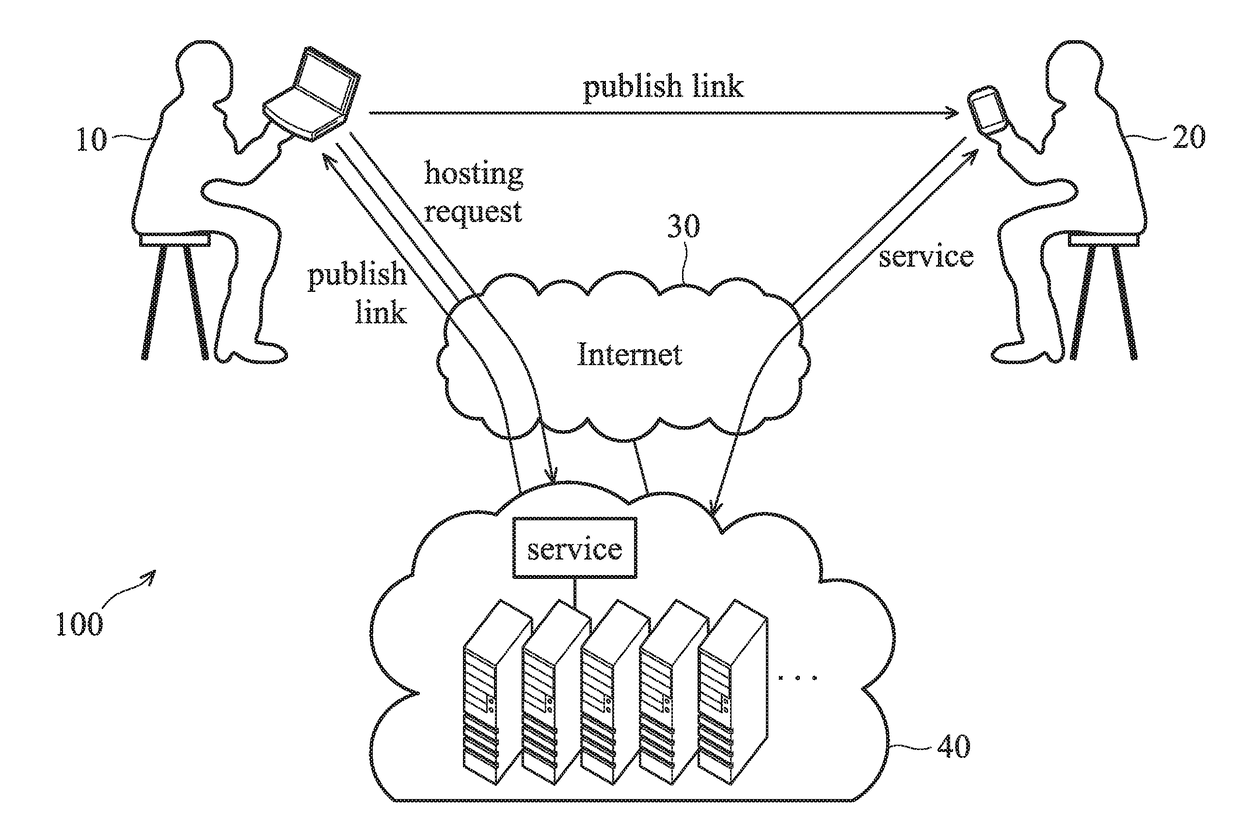

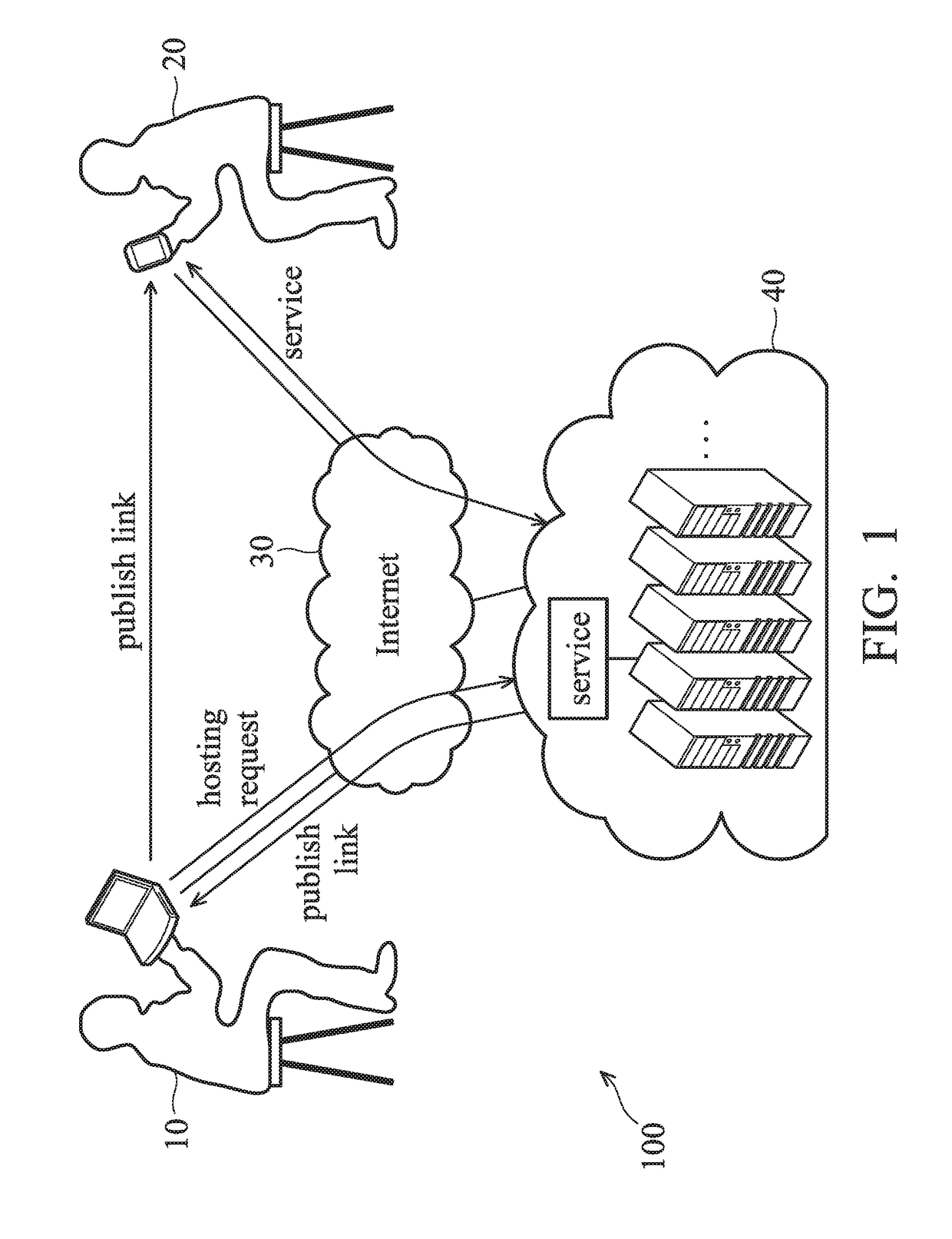

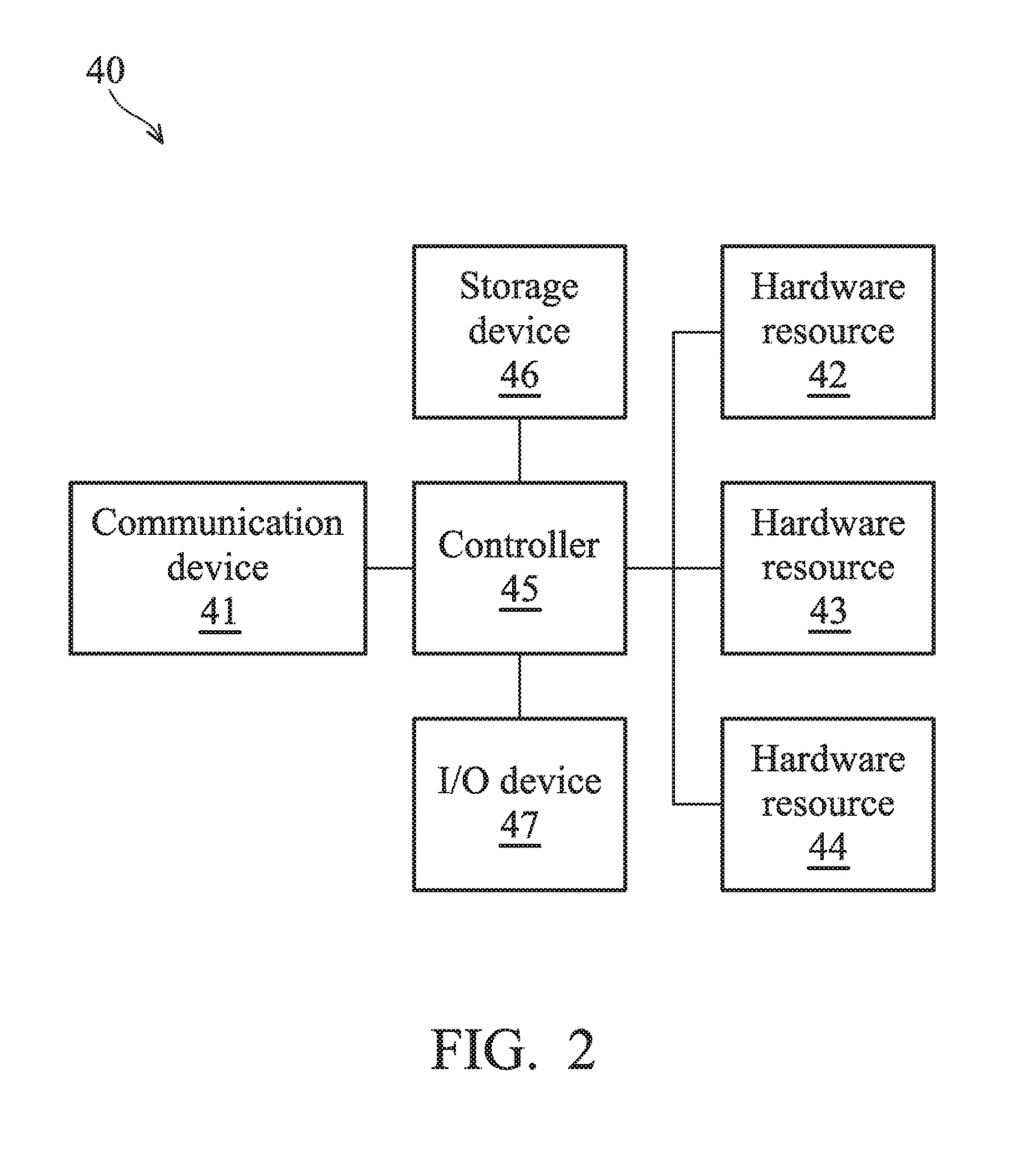

Cloud servers and methods for handling dysfunctional cloud services

ActiveUS20180196724A1Improving cloud service stabilityImprove service stabilityHardware monitoringProgram loading/initiatingVirtual machineCommunication device

A cloud server including a communication device, a plurality of hardware resources, and a controller is provided. The communication device provides a network connection to the Internet and an electronic computing device on the Internet. A respective virtual machine is instantiated for service execution on each of the hardware resources. The controller receives a hosting request for a service from the electronic computing device via the communication device, allocates one of the hardware resources to execute the service according to the hosting request and determine a link for accessing the service from outside of the cloud server in response to the hosting request, tests whether the service is functional by accessing the service from the Internet according to the link via the communication device, and transfers the service to be executed by another one of the hardware resources when the service is dysfunctional.

Owner:QUANTA COMPUTER INC

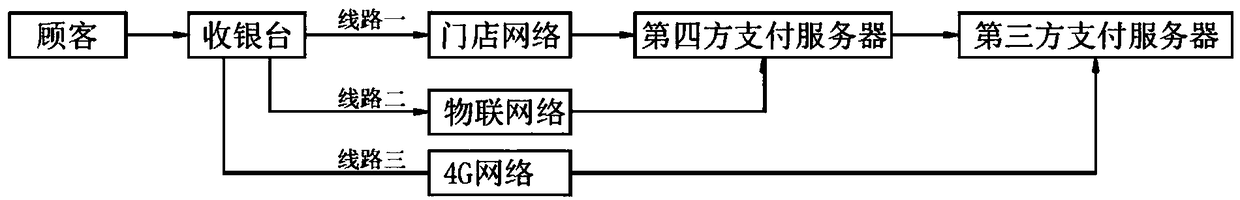

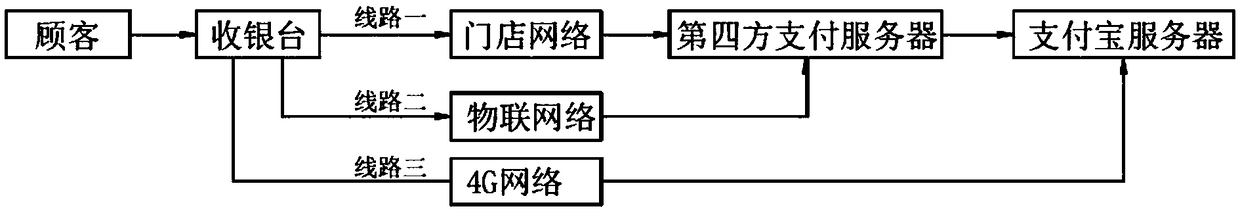

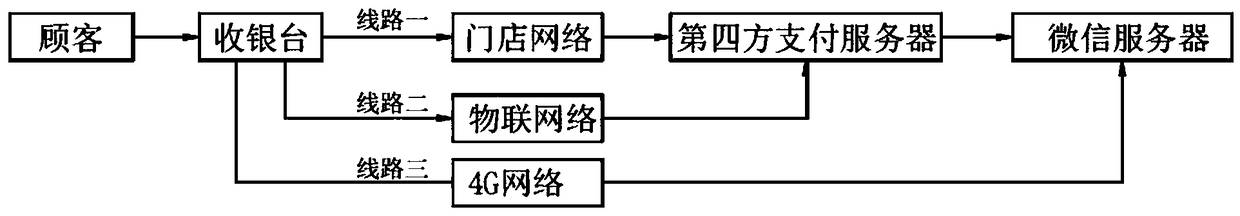

A method and system for building a highly reliable mobile cash register system

InactiveCN109447620AImprove service stabilityImprove stabilityPayment protocolsPoint-of-sale network systemsThird partyThe Internet

The invention discloses a method and system for building a highly reliable mobile cash register system, which adopts three cash register modes that the normal running line is line one, and two groupsof standby lines are line two and line three respectively, wherein the line one is from a customer, a cash register, a store network, a fourth party payment server to a third party payment server; theline 2 is from the customer, the cashier, the internet of things, the fourth party payment server to the third party payment server; the line 3 is from the customer, the cashier, the 4G network to the third party payment server. Through the design of line 2, the mobile cash register business can be kept uninterrupted under the condition of the outage of the store. Through the design of the line 3, and when the fourth-party server is down, the store will exchange information with the third-party payment server directly, and synchronize the information with the fourth-party payment server afterthe fourth-party payment server is restored. The online rate of mobile cash register service can be approximated to the official online rate of the third-party payment server by this scheme.

Owner:成都慧联天下信息技术有限公司

IPv6 over IPv4 transition method and apparatus for improving performance of control server

InactiveUS8891551B2Easy to manageImprove controlTime-division multiplexNetworks interconnectionExtensibilityComputer terminal

The present invention relates to a method and apparatus for performing IPv6 over IPv4 transition to improve performance of a control server. When an edge router selected by the control server according to a tunnel creation request of an IPv6 terminal receives a tunnel creation request message from the control server, the edge router transmits a tunnel creation response message for the received tunnel creation request message to the IPv6 terminal through the control server, and the edge router performs IPv6 over IPv4 transition through a tunnel created by the IPv6 terminal that received the tunnel creation response message so as to improve the performance of the control server. Therefore, loads of the control server occurred because all terminals set control tunnels to the control server can be prevented, and service extensibility due to the increase in the number of subscribers can be guaranteed.

Owner:ELECTRONICS & TELECOMM RES INST

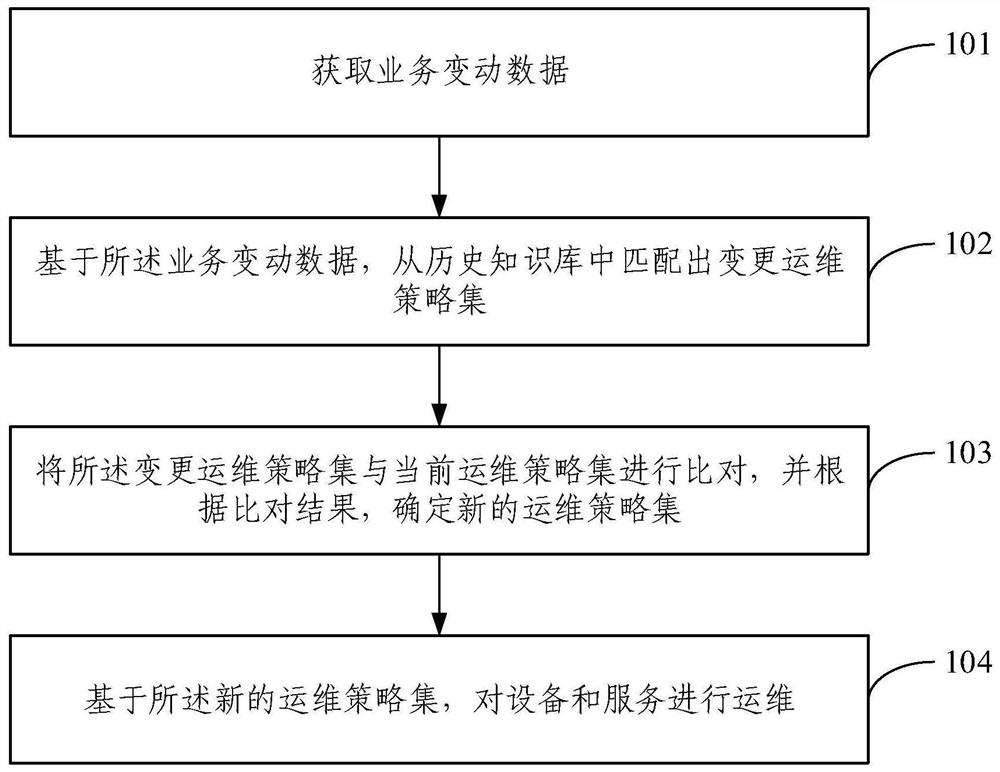

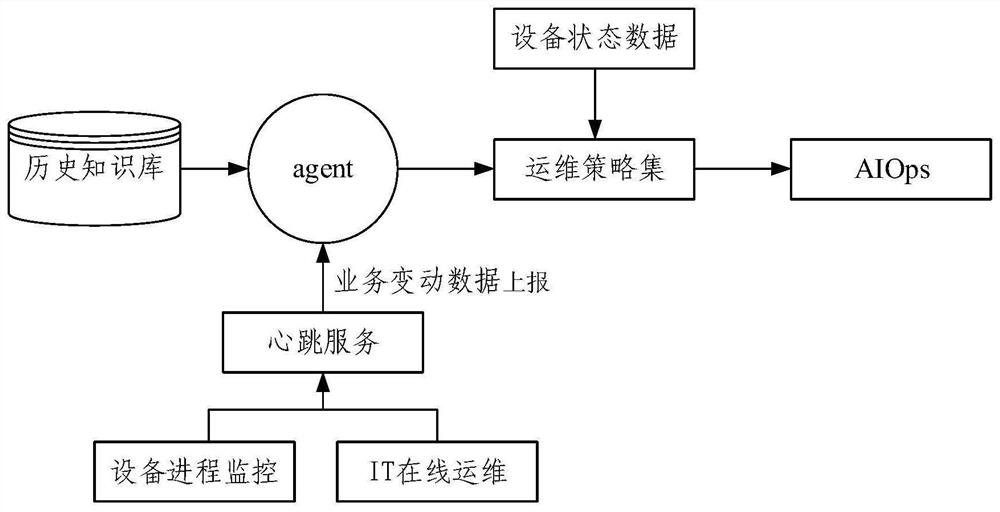

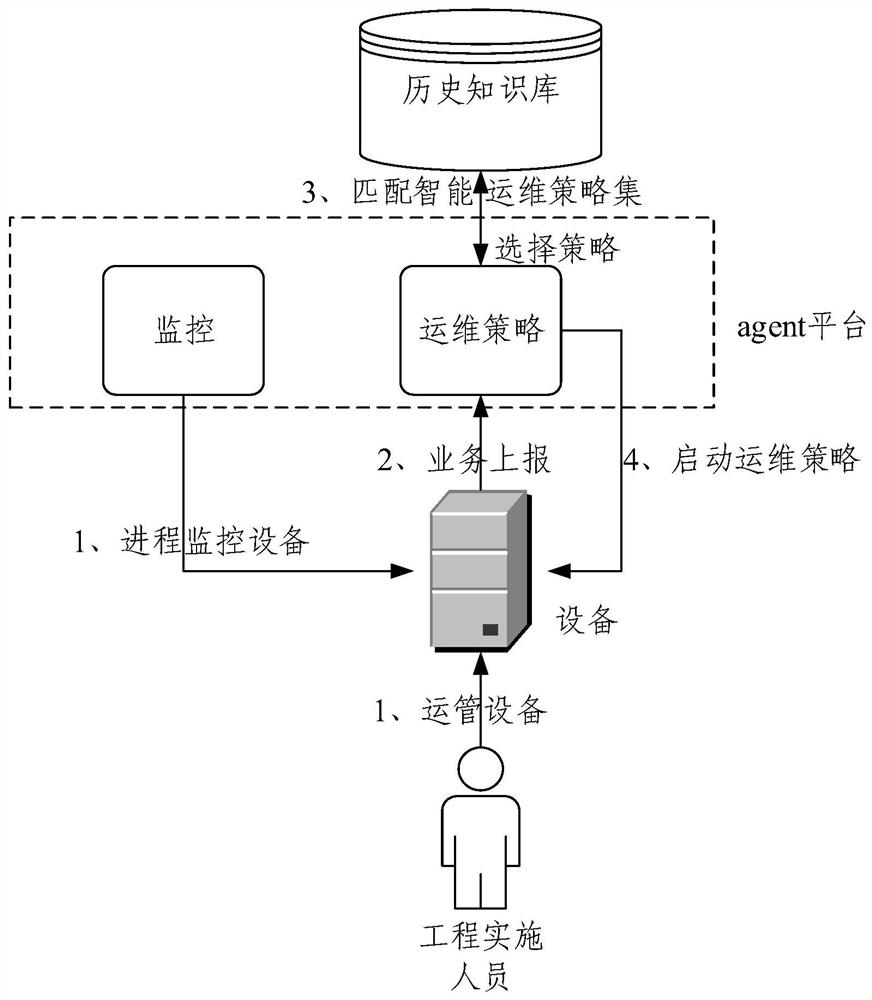

Intelligent operation and maintenance method and device, electronic equipment and storage medium

PendingCN113516244AEfficient analysisEffective positioningDatabase updatingSoftware maintainance/managementMaintenance strategyBusiness data

The invention provides an intelligent operation and maintenance method and device, electronic equipment and a storage medium. The method comprises the steps of obtaining service change data; based on the business change data, matching a change operation and maintenance strategy set from a historical knowledge base; comparing the changed operation and maintenance strategy set with a current operation and maintenance strategy set, and determining a new operation and maintenance strategy set according to a comparison result; and carrying out operation and maintenance on the equipment and the service based on the new operation and maintenance strategy set. According to the invention, through acquiring the change data of the operation business on the equipment and accurately matching the operation and maintenance strategy set in the historical knowledge base, the operation and maintenance events related to the business data are analyzed and positioned more effectively and decisions are made by using the targeted and customized operation and maintenance strategies in the operation and maintenance strategy set, so the operation and maintenance efficiency is improved. And the IT resource utilization rate and the system service stability are improved.

Owner:盛景智能科技嘉兴有限公司

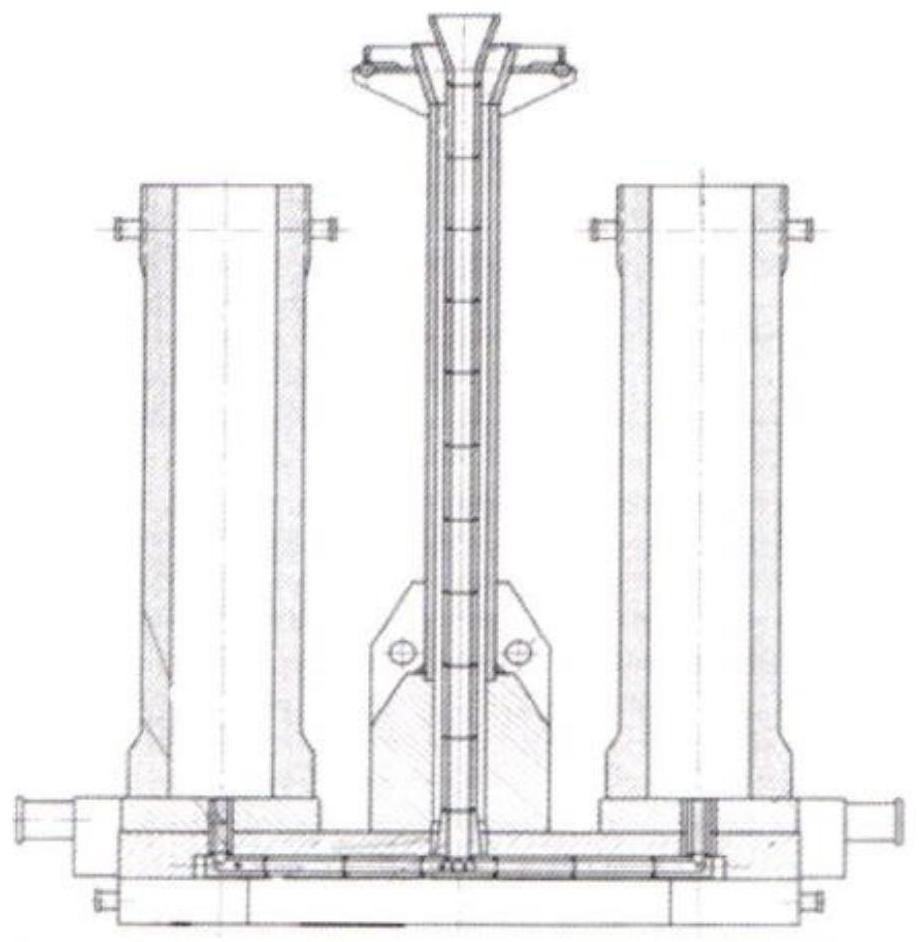

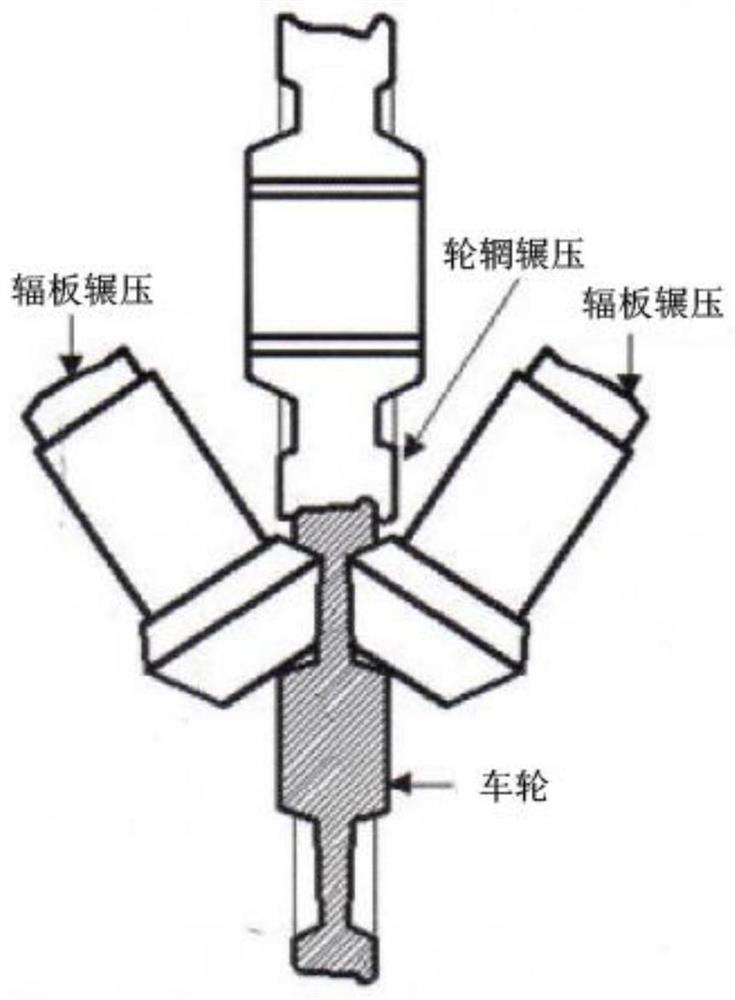

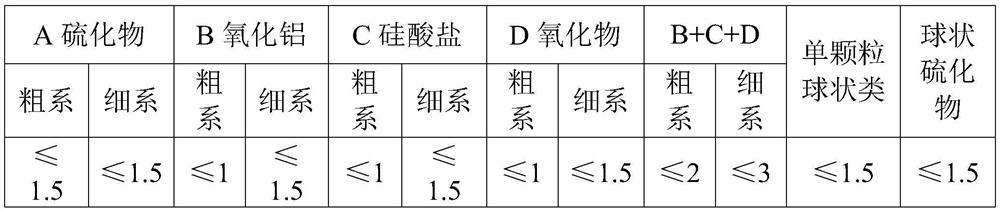

Material for locomotive wheels

PendingCN113667901AInhibit growthInhibits deformation recrystallization of austenite and prevents growthEngineeringMechanical engineering

The invention belongs to the field of locomotives, and discloses a material for locomotive wheels. The material comprises the following microalloy components of, in percentage by mass, 0.57 to 0.70 of C, 0.50 to 1.10 of Mn, less than or equal to 0.40 of Ni, less than or equal to 0.06 of Ti, less than or equal to 0.06 of V, and less than or equal to 0.30 of Cr. Compared with ER8 and ER9 materials which are frequently used in China at present, the material for the locomotive wheels has high yield strength, tensile strength, plastic deformation resistance and rolling contact fatigue resistance, the hardness of a rim is improved to 265 HBW or above under the same condition, in addition, microalloy elements Nb and Ti are added into steel, the microalloy element V is combined for use, on one hand, deformation recrystallization of austenite can be inhibited and growth of crystal grains of the austenite can be prevented in the hot working process, on the other hand, the precipitation strengthening effect of Nb, V and Ti can be exerted through strain induced precipitation of carbon-nitrogen compounds of the austenite, so that the crack initiation resistance of the material is improved, crack propagation is delayed, the service stability of the whole life cycle is promoted, and the service life and the operation mileage are prolonged.

Owner:ZHIBO LUCCHINI RAILWAY EQUIP +1

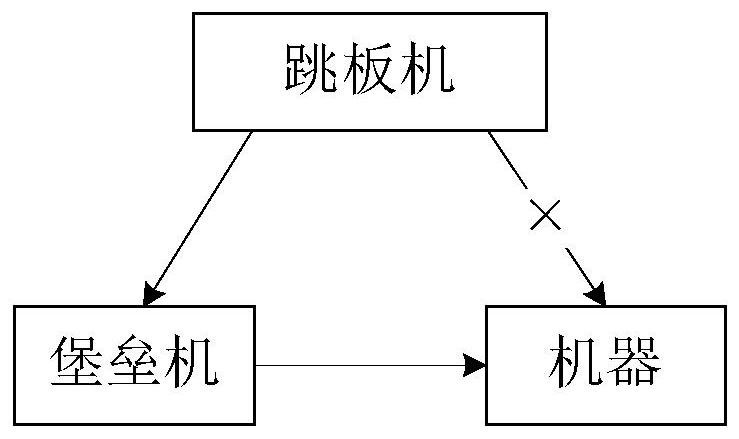

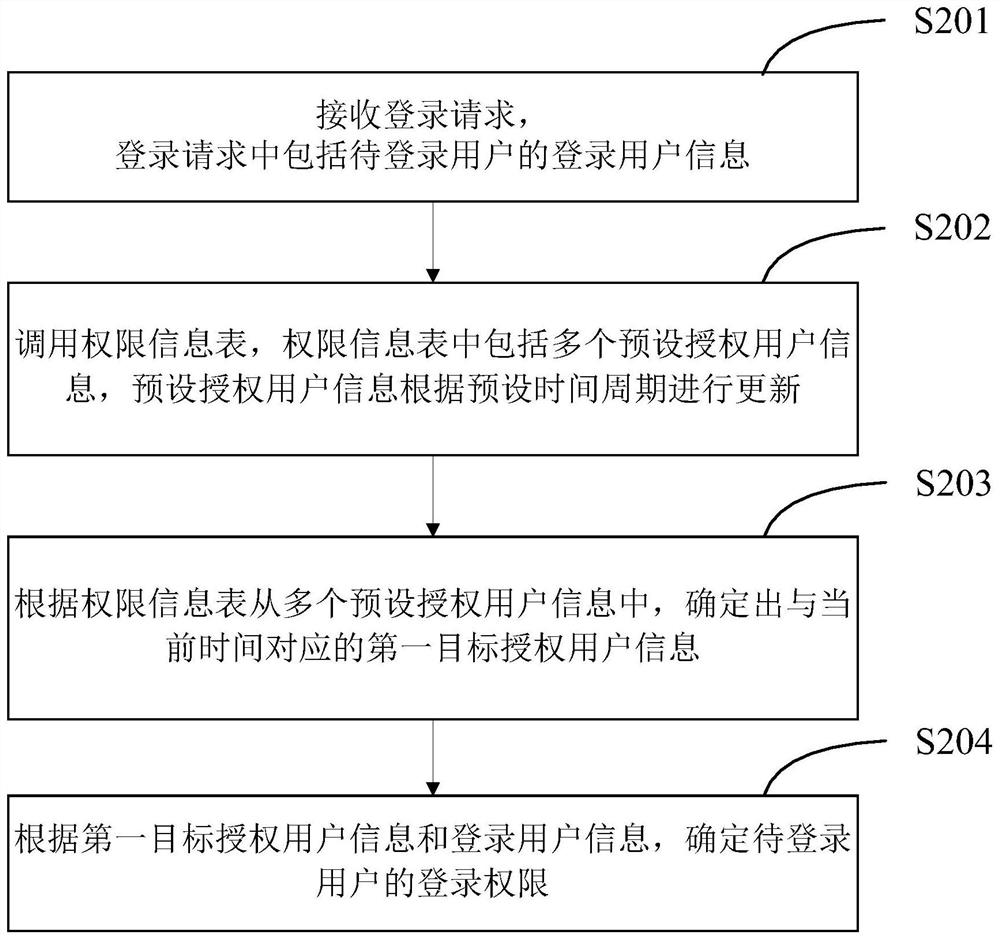

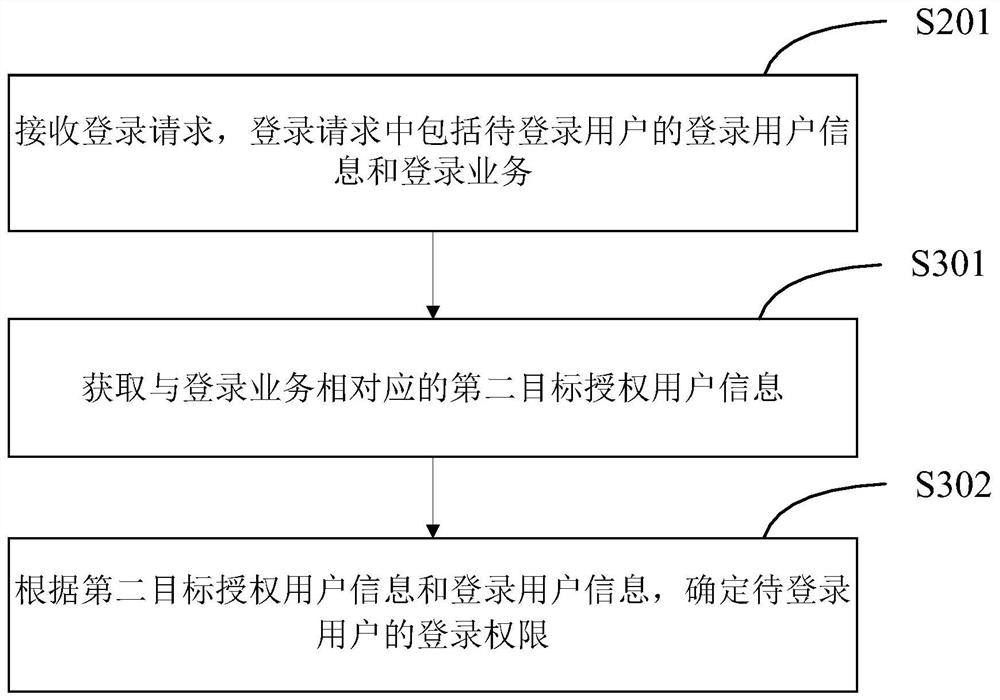

Authority management method and device, equipment and storage medium

PendingCN112328985AReduce misuseImprove service stabilityDigital data authenticationCloud computingComputer security

Owner:BEIJING BAIDU NETCOM SCI & TECH CO LTD

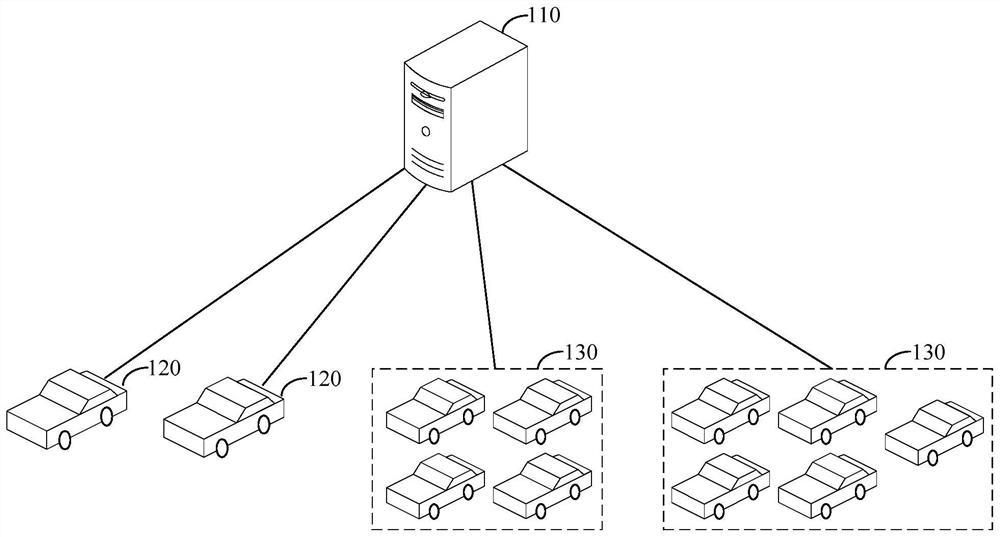

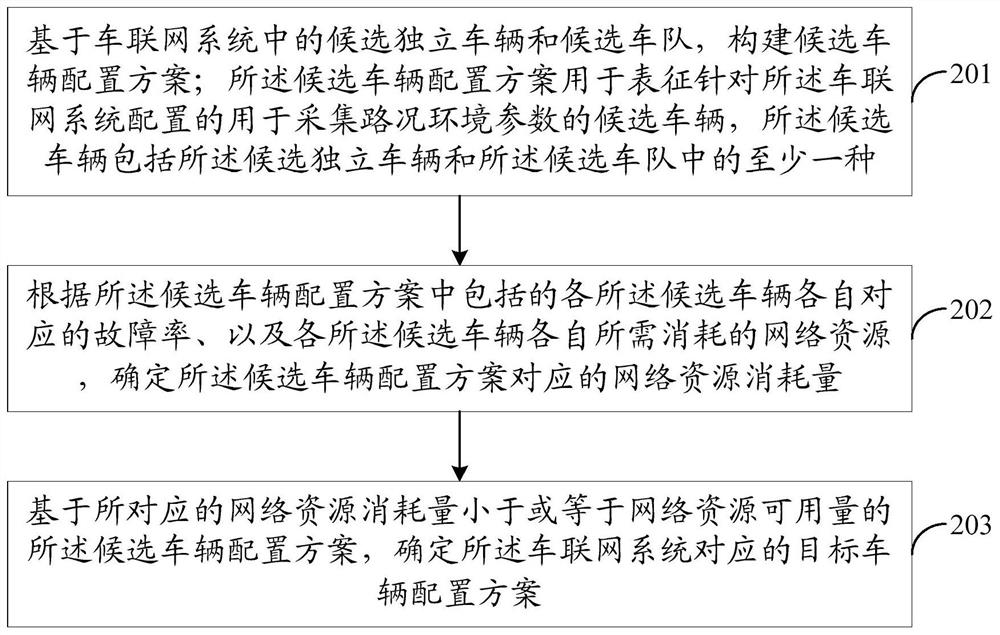

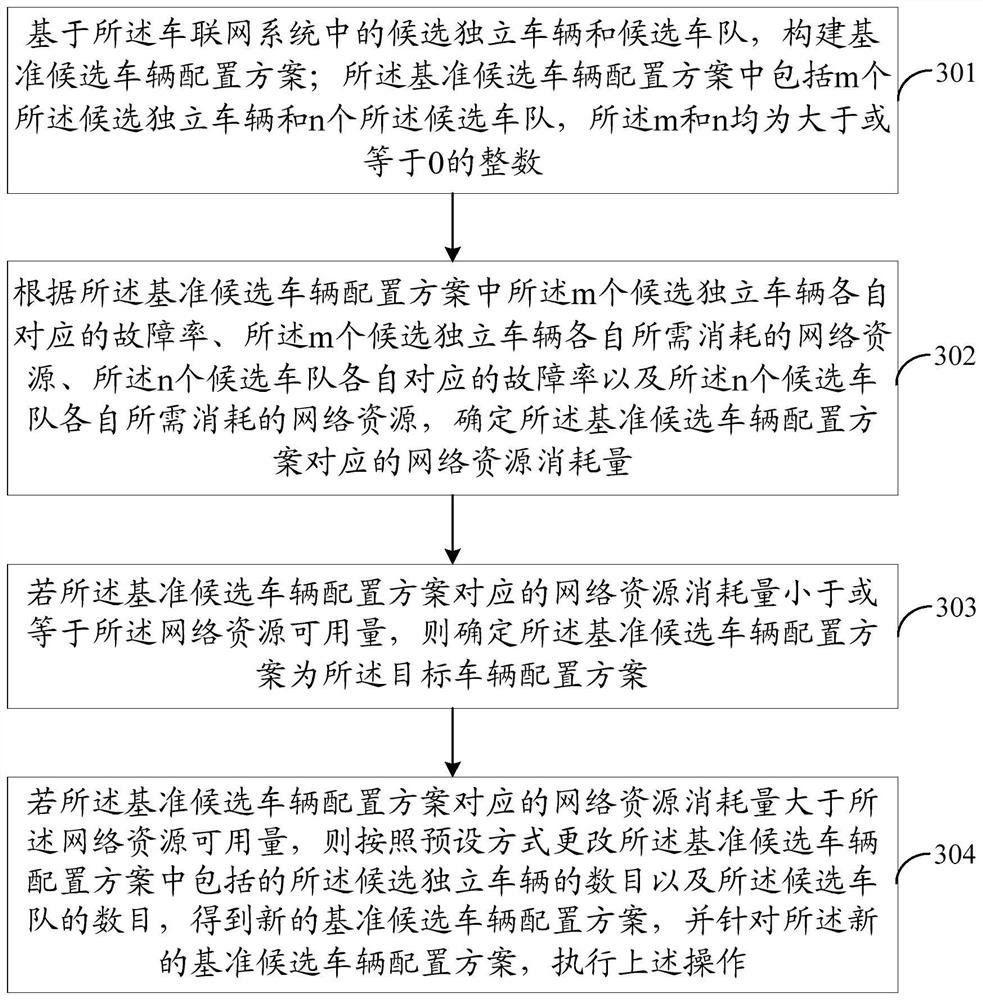

Vehicle configuration method and device in Internet of Vehicles system, equipment and storage medium

PendingCN112235750AReduce failureImprove service stabilityParticular environment based servicesDetection of traffic movementThe InternetEngineering

The embodiment of the invention discloses a vehicle configuration method and device in an Internet of Vehicles system, equipment and a storage medium. The method comprises the following steps: constructing a candidate vehicle configuration scheme based on candidate independent vehicles and candidate motorcades in the Internet of Vehicles system, wherein the candidate vehicle configuration scheme is used for representing candidate vehicles configured for the Internet of Vehicles system and used for collecting road condition environment parameters, and the candidate vehicles comprise at least one of candidate independent vehicles and candidate motorcades; determining the network resource consumption corresponding to the candidate vehicle configuration scheme according to the failure rate corresponding to each candidate vehicle included in the candidate vehicle configuration scheme and the network resource required to be consumed by each candidate vehicle; and determining a target vehicleconfiguration scheme corresponding to the Internet of Vehicles system based on the candidate vehicle configuration scheme of which the corresponding network resource consumption is less than or equalto the available network resource consumption. According to the scheme, the effectiveness of the road condition environment parameters can be improved, and the service stability of the Internet-of-Vehicles system is improved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

High-efficiency heat transfer nano-copper material and preparation method thereof

The invention discloses a nanometer copper material capable of transferring heat with high efficiency, and a preparation method thereof. The surface of the nanometer copper material is coated with an ultra-thin nano or micro-nano composite porous nickel film with super wetting ability; the ultra-thin nano composite porous nickel film comprises a porous structure which is mainly made of nickel nano flowers; and the ultra-thin micro-nano composite porous nickel film comprises a porous structure which is mainly formed by accumulation of micron or nanometer nickel triangular sheets. The preparation method comprises following steps: a substrate is taken as working electrode; the working electrode, a counter electrode and a reference electrode are placed in a weak acid nickel salt electrolyte so as to form a reduction system; reduction current is provided between the working electrode and the counter electrode so as to realized nickel electro-deposition on the surface of the substrate; and then the ultra-thin nano or micro-nano composite porous nickel film is formed on the surface of the substrate. The ultra-thin nano or micro-nano composite porous nickel film is capable of increasing utilization stability of the nanometer copper material, and improving filmwise condensation heat transfer performance, boiling heat transfer performance and spray cooling heat dissipation performance of the nanometer copper material greatly. The formula of the electrode needed in the preparation method is simple; raw material are cheap and easily available; optional range of electroplating mode is wide; and the preparation method is suitable for industrialized large-scaled application.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

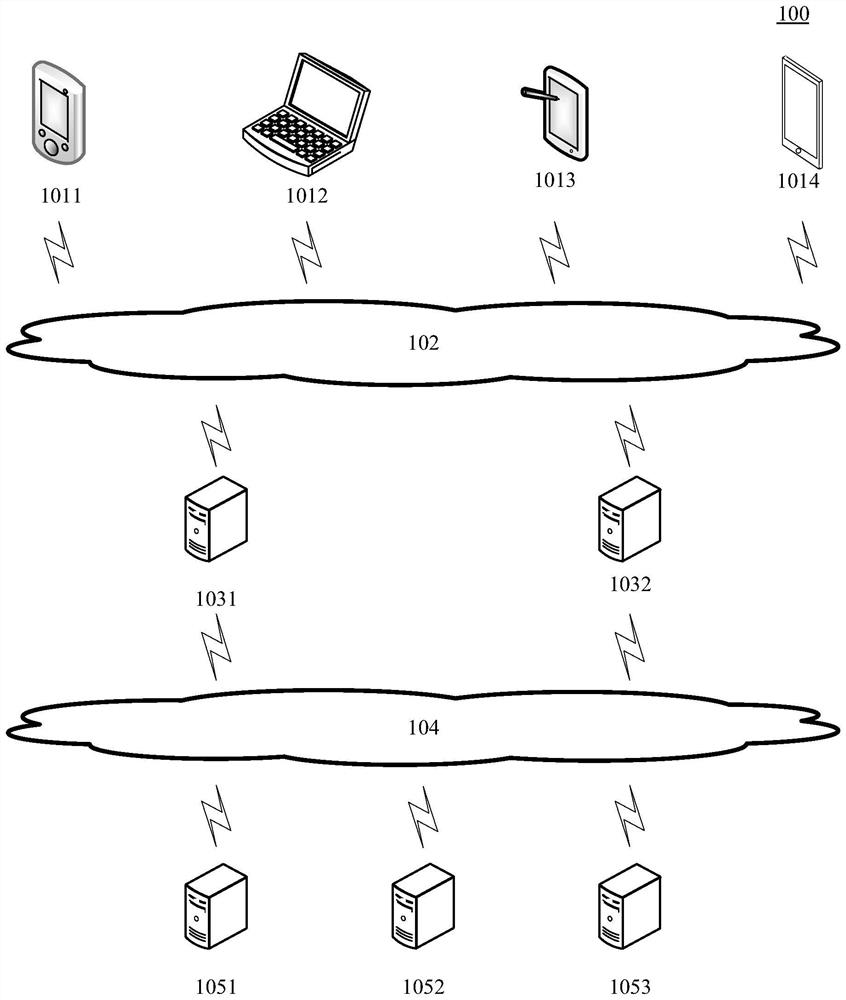

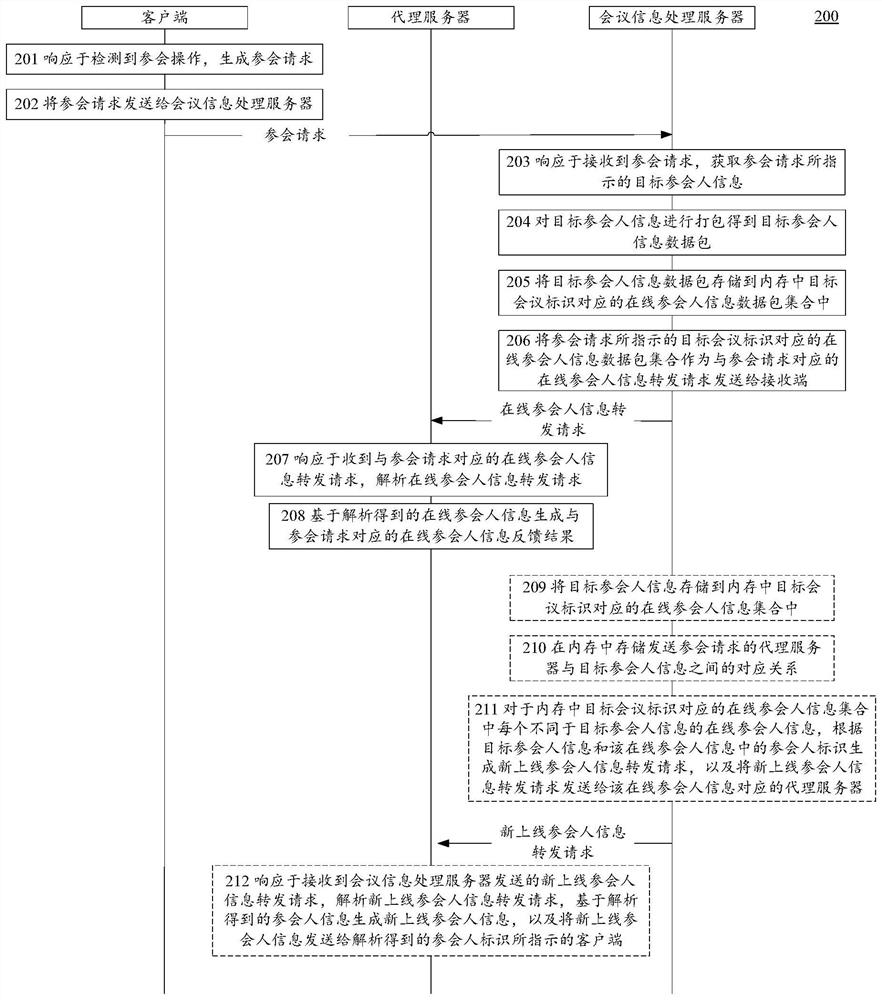

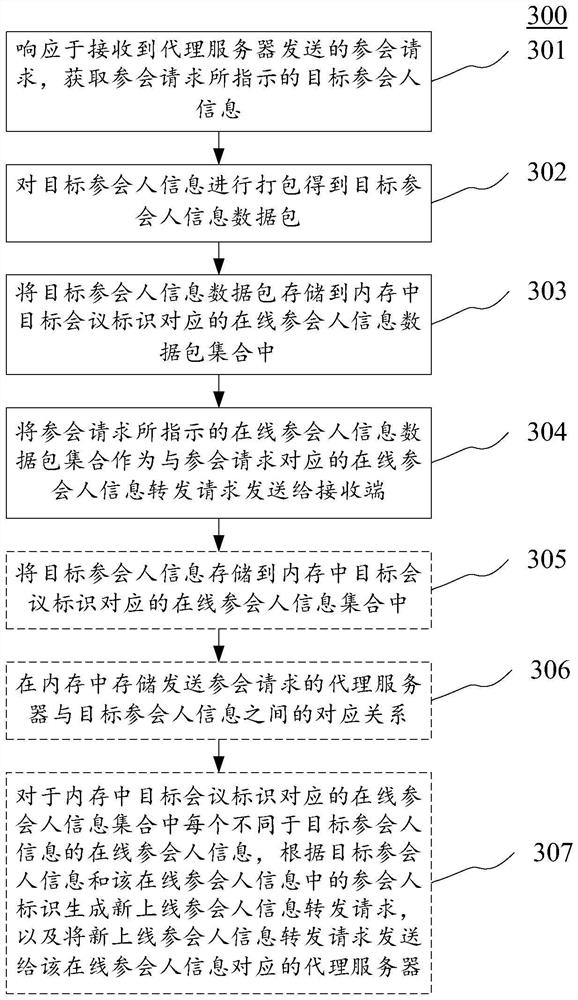

Information processing method, device and system, server, and storage medium

ActiveCN112866622AImprove service stabilityReduce the pressure of instantaneous concurrent computingTelevision conference systemsOffice automationData packConcurrent computing

The invention provides an information processing method, device and system, a server, and a storage medium, and the method comprises the steps: carrying out the independent packaging of the information of each new online participant in a conference information processing server, and storing the packaged information in a memory; and then returning the online participant information data packet of the same conference stored in the memory to a proxy server for analysis, and then packaging into a format which can be analyzed by a client. Therefore, the packaging calculation amount of the conference information processing server is reduced, the instantaneous concurrent calculation pressure of the conference information processing server is relieved, and the service stability of the conference information processing server is improved.

Owner:BEIJING ZITIAO NETWORK TECH CO LTD

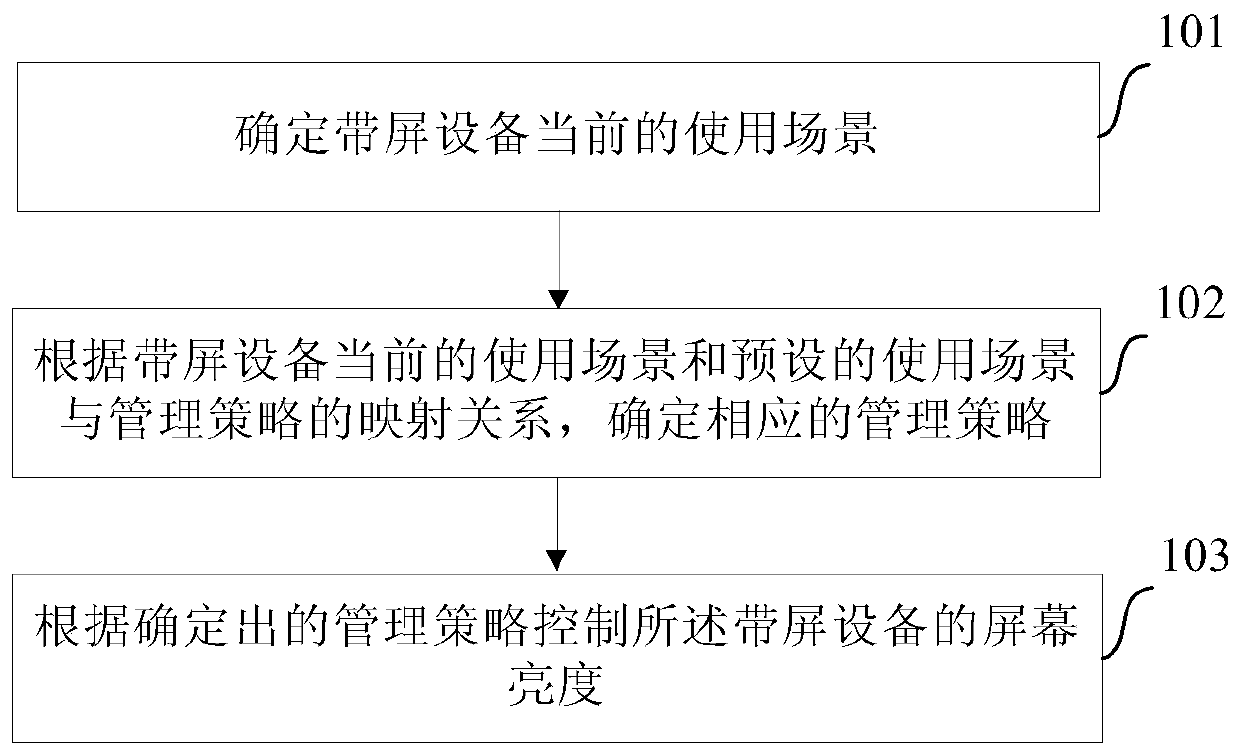

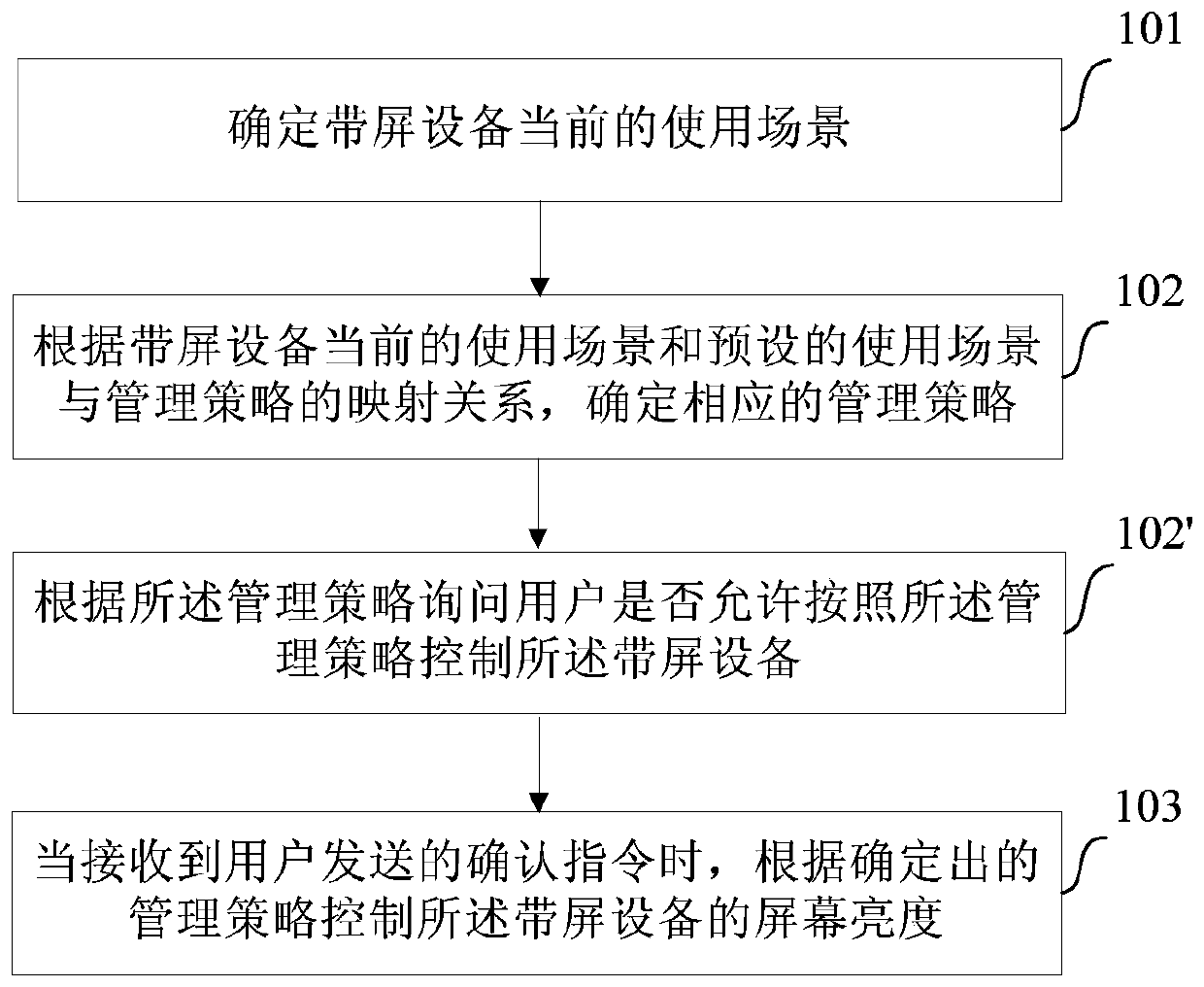

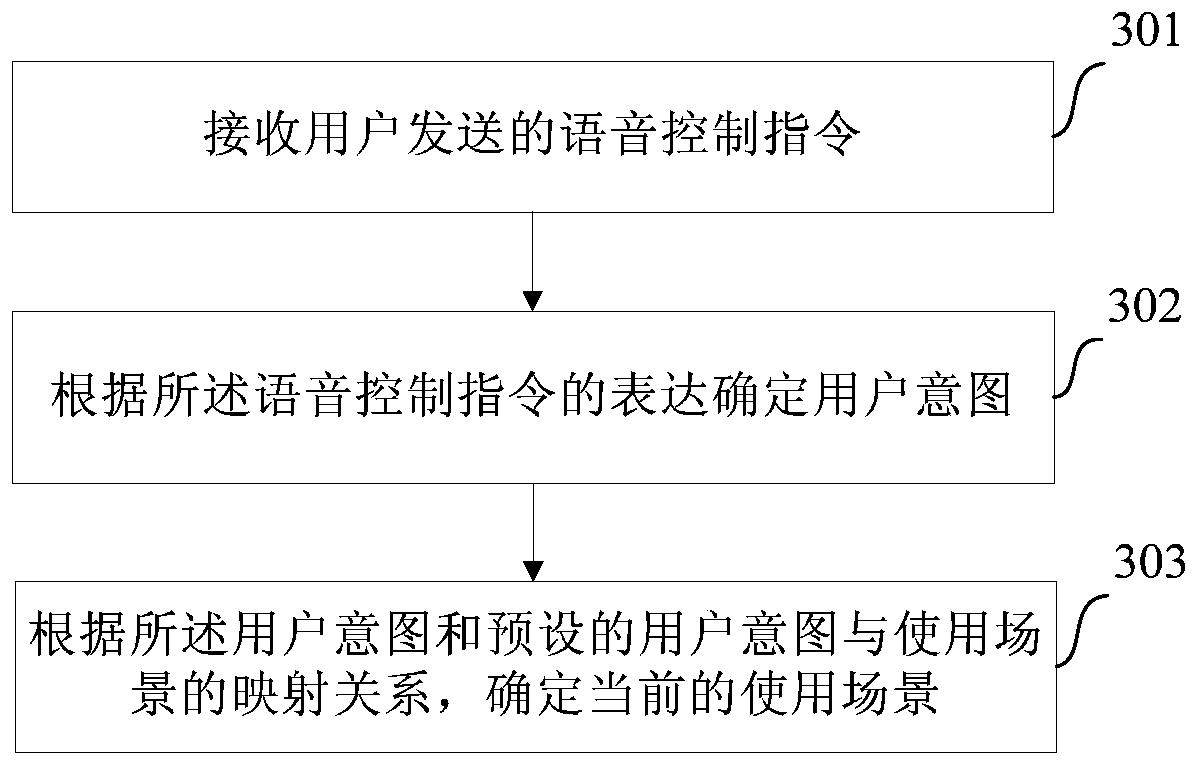

Control method and device for equipment with screen and computer readable medium

ActiveCN109887474ARelieve dealing with stressImprove service stabilityCathode-ray tube indicatorsSpeech recognitionManagement strategyLight pollution

The invention provides a control method for equipment with a screen. The mapping relation between the use scene and the management strategy is established, the screen brightness is controlled based onthe current use scene of the equipment with the screen, the cloud server can be prevented from processing a large number of requests at the same time, the processing pressure of the cloud server is relieved, the service stability is improved, and the effects of reducing energy consumption, avoiding light pollution and the like can be achieved. Moreover, the management strategy can be manually setand adjusted in time, so that the personalized requirements of the user can be met. The invention further provides a device and a computer readable medium.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD +1

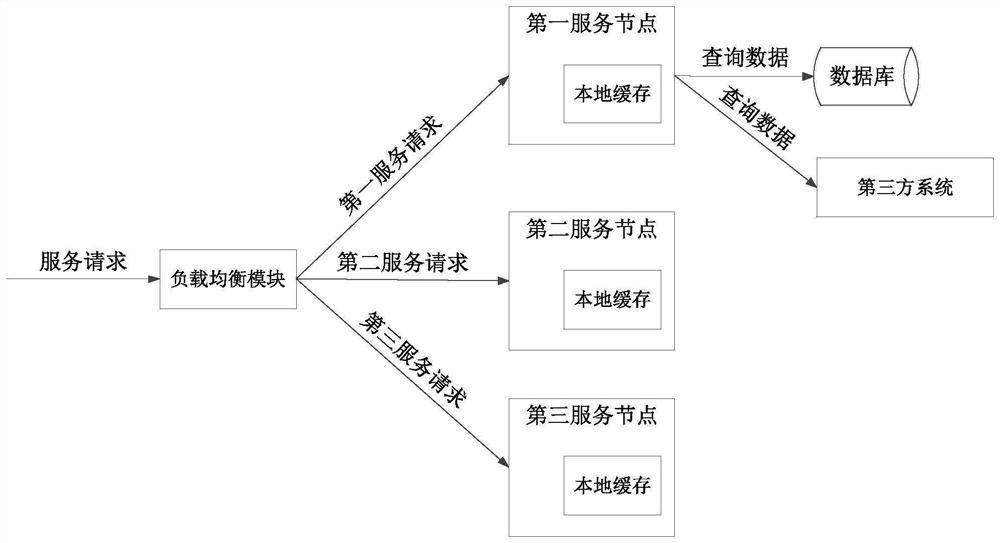

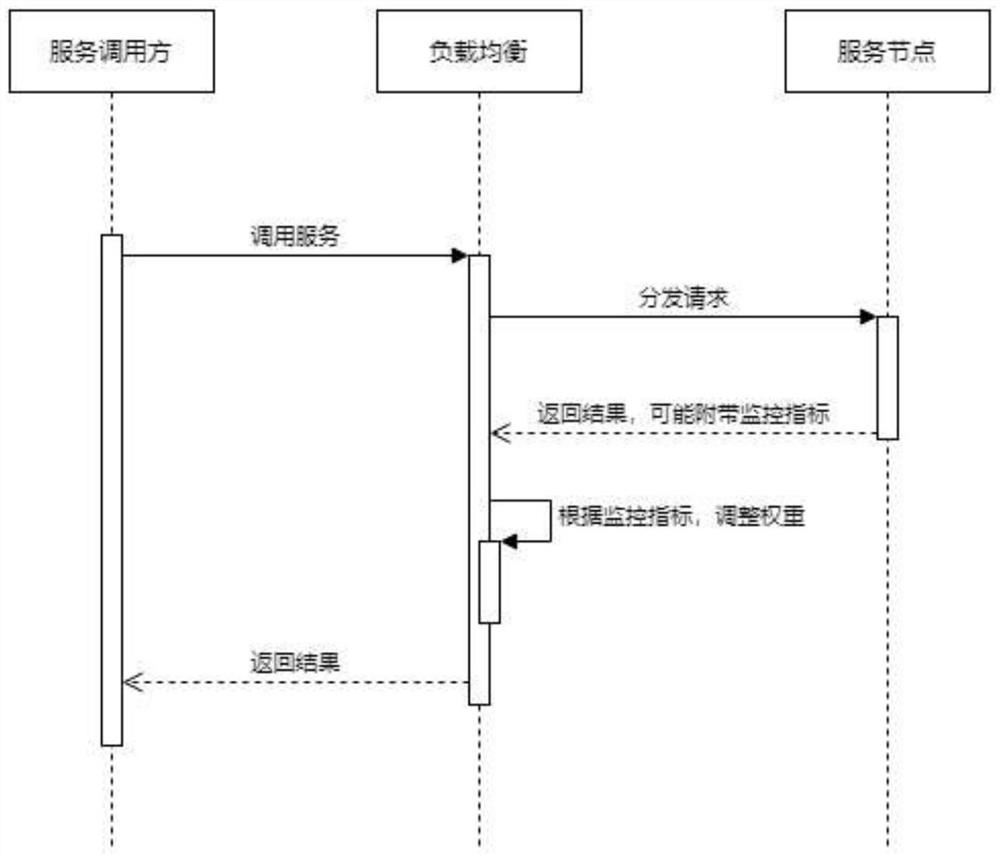

Load balancing method and server

The invention discloses a load balancing method and a server. The problem that the service is unstable due to the fact that the distributed request quantity of the service node is overloaded is solved. The load balancing method comprises the following steps: receiving a service request; determining a weight corresponding to each service node; wherein each service node comprises a first service node and a second service node; the first service node is a node of which the cache amount of the local cache is lower than a first threshold value; the second service node is a node of which the cache amount of the local cache is higher than a second threshold value; the first threshold value is not greater than the second threshold value, the weight corresponding to the first service node is a first weight, and the weight corresponding to the second service node is a second weight; the first weight is smaller than the second weight; and according to the weight, the service request is distributed to each service node, so that the service node obtains data according to the distributed service request and stores the data in a local cache of the service node, and the probability of obtaining the service request by the first service node is lower than that of obtaining the service request by the second service node.

Owner:JUHAOKAN TECH CO LTD

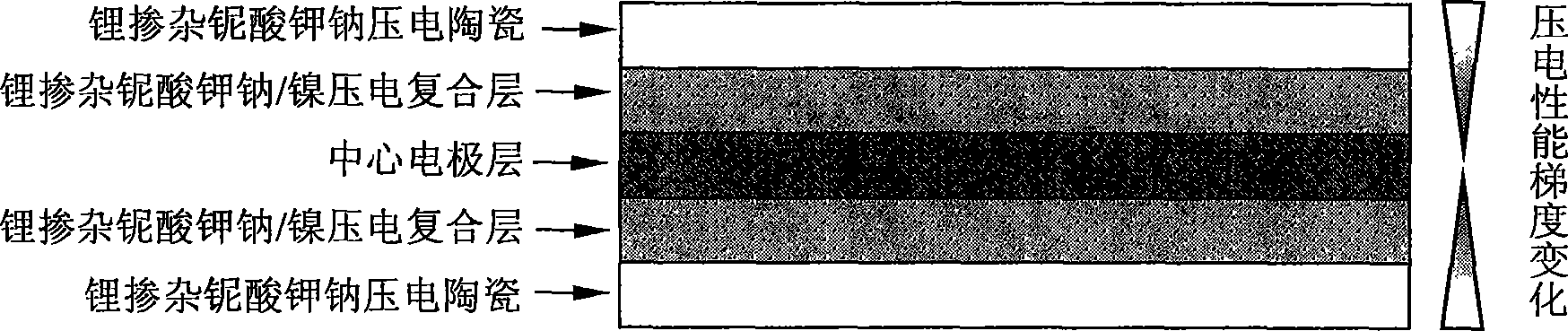

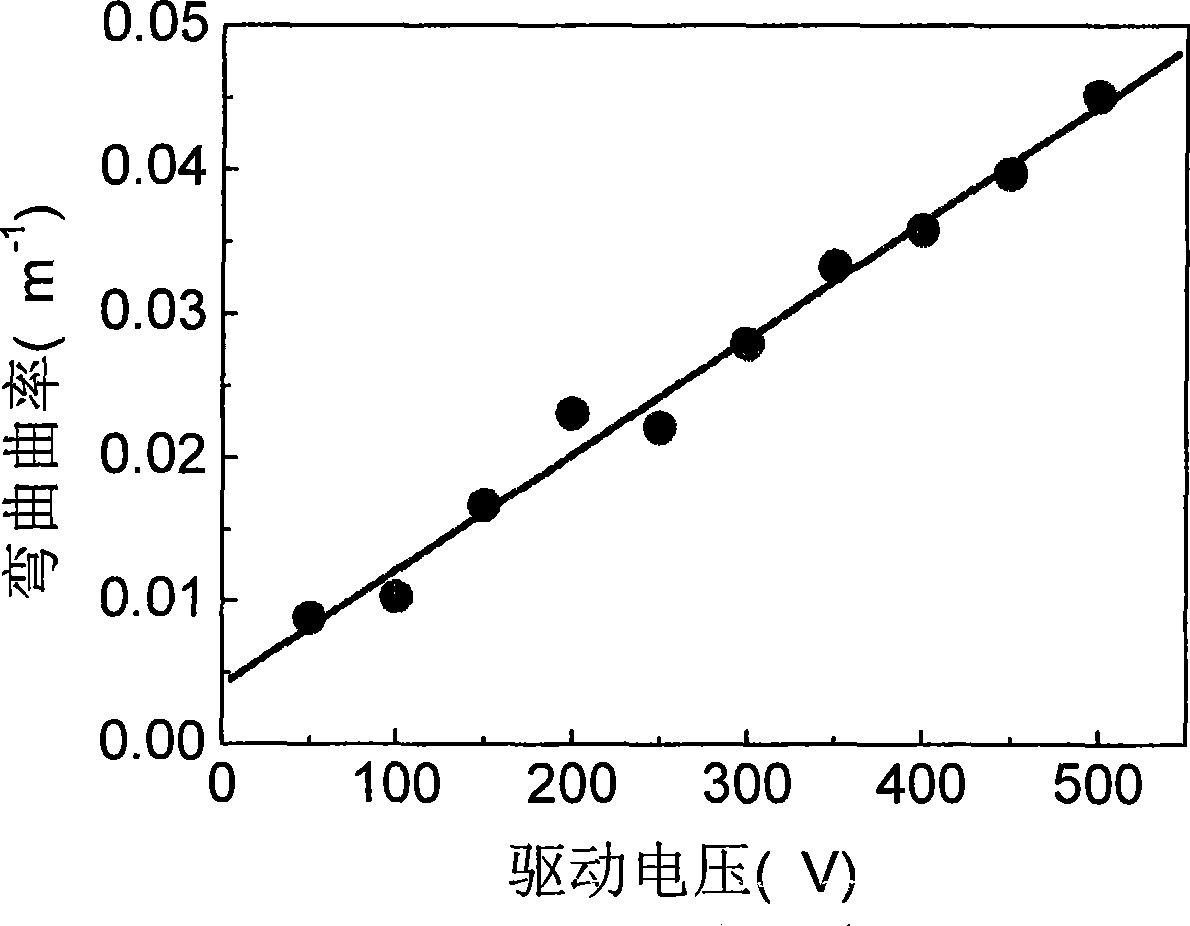

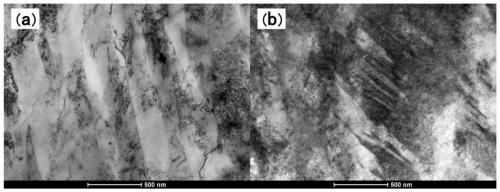

Preparation method of piezoelectric driver with nickle particle decentralization lithium doping by niobic acid kalium natrium

InactiveCN101510739AImprove service stabilitySolve interface peelingPiezoelectric/electrostriction/magnetostriction machinesStress concentrationSilver electrode

The invention discloses a preparation method for a piezoelectric actuator with nickel particle dispersed lithium doped potassium-sodium niobate and pertains to the technical field of the piezoelectric actuator. The oxide mixing method is adopted to compound lithium doped potassium-sodium niobate powder, metal nickel powder is added in a composition range of 1 to 40vol percent of Ni to obtain the compound powder of lithium doped potassium / sodium niobate with different contents, the powder is paved layer by layer in a mold and molded by compression according to the set gradient morphology of nickel composition, multi-layer composite materials of nickel particle dispersed lithium doped potassium-sodium niobate is prepared by agglomeration under controlled atmosphere. The protective atmosphere thereof contains 0.0003 to 0.5vol percent of oxygen and the air pressure is 1.1 to 2 atmospheric pressures. After the technical steps of cutting molding, coating silver electrode, pulling wires, polarization process and the like, a piezoelectric actuator of lithium doped potassium-sodium niobate is assembled, wherein, the thickness of each composite layer is 0.2 to 0.5 millimeter and the number of layers is 3 to 7. The preparation method reduces the interface stress concentration and cracking failure of traditional dual-chip type drivers and improves the chemical performance of the piezoelectric actuator.

Owner:UNIV OF SCI & TECH BEIJING

A method of micro-deformation strengthening martensitic stainless steel

ActiveCN109777933BGuaranteed plasticityGrain refinementMartensitic stainless steelSS - Stainless steel

The invention discloses a method for martensitic stainless steel after micro deformation strengthening. The method is characterized by using high-load loading for micro plastic deformation of the martensitic stainless steel to induce deformation twins, and comprises the following steps: 1) martensitic stainless steel samples are positioned in an ultralow-temperature environment for low-temperaturetreatment for full cooling; 2) after full cooling of the martensitic stainless steel samples, the low-temperature stretching test is performed on one part of the samples to obtain low-temperature stretching test data, and low-temperature yield strength data sigma 0.2 of the materials is recorded; and 3) the fixed high-load repeated stretching is performed on the other part of the martensitic stainless steel samples after full cooling for repeated stretching to obtain the martensitic stainless steel after micro deformation strengthening. The method improves the low-temperature yield strength of the martensitic stainless steel by above 10%, and meanwhile, is lower in influence on plasticity index.

Owner:SOUTHEAST UNIV

Hollow fiber desalination membrane assembly and equipment for brackish water desalination

InactiveCN109464913AApplicable process systemImprove anti-pollution performanceSemi-permeable membranesMembranesHollow fibreBrackish water

The invention discloses a hollow fiber desalination membrane assembly and equipment for brackish water desalination. The hollow fiber desalination membrane assembly comprises a pressure container anda desalination membrane unit arranged in the pressure container, wherein the desalination membrane unit comprises a membrane casing and a hollow fiber membrane unit arranged in the membrane casing; the hollow fiber membrane unit comprises a six-hole guide plate, a central water producing pipe, multiple desalination membrane wires winding around the peripheral side of the central water producing pipe as well as a water inlet end fixing layer and a water producing end fixing layer which are fixed at the two ends of the desalination membrane wires respectively; a water inlet, a water producing port and a concentrated water port are formed in the hollow fiber desalination membrane assembly. The hollow fiber desalination membrane assembly for the brackish water desalination is applicable to a technological system of the brackish water desalination, has higher anti-pollution capacity and longer service life, is good in service stability, long in service period and low in operating cost.

Owner:XINJIANG DELAND

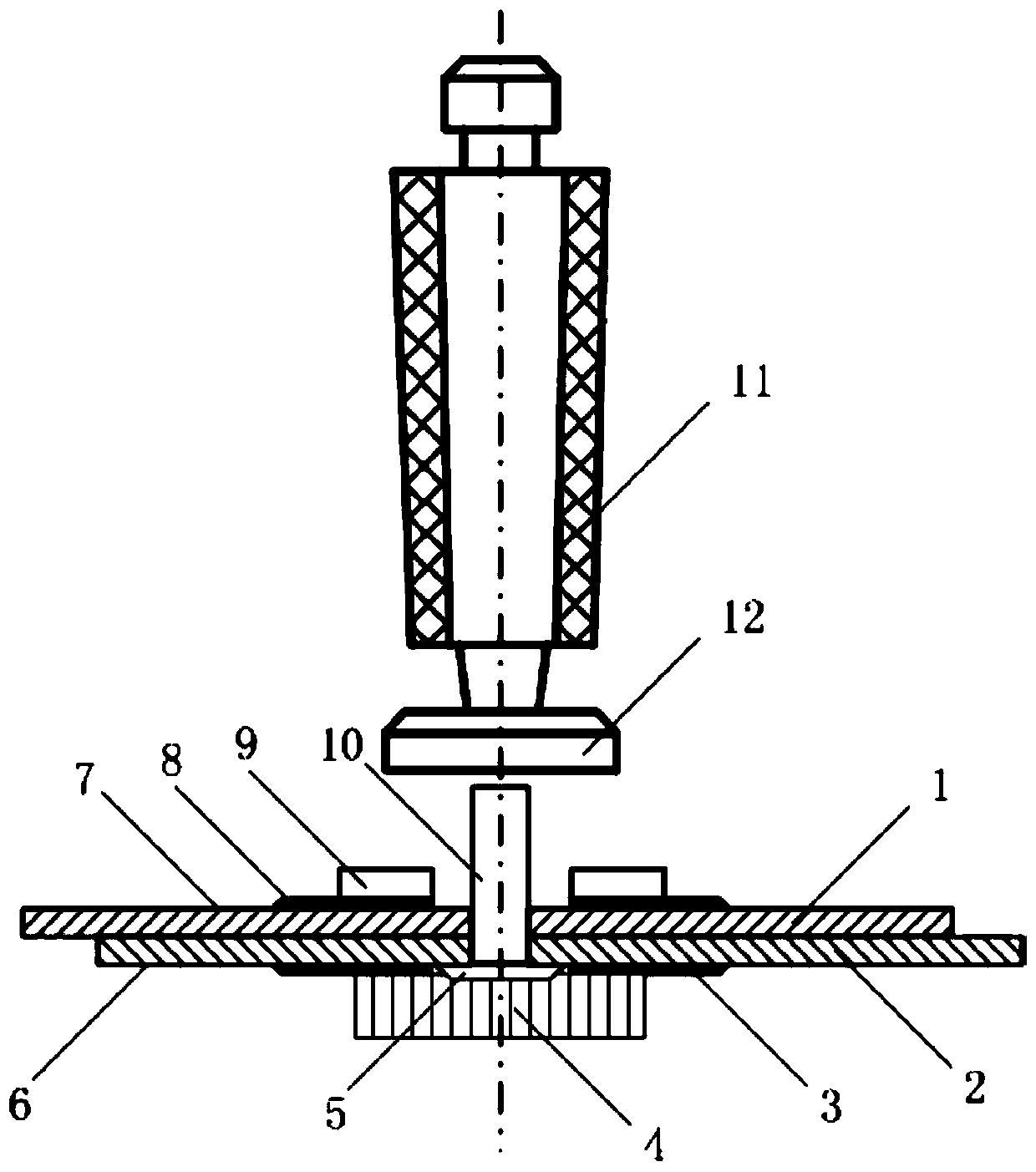

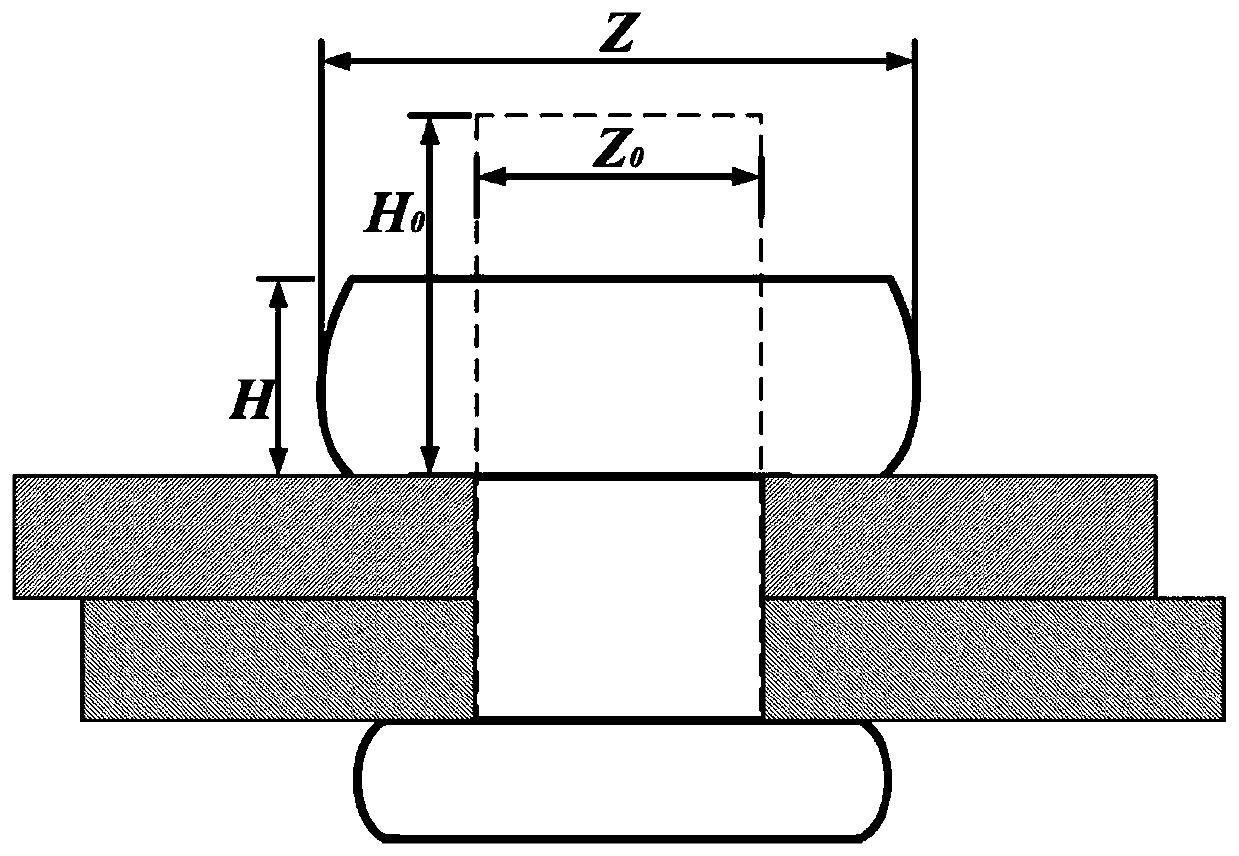

A riveting method and device for novel hybrid composite materials for aviation

ActiveCN107662350BSolving riveting problemsGuaranteed fatigue lifeAircraft assemblyDomestic articlesEngineeringRivet

The invention discloses a riveting method and device for a novel hybrid composite material for aviation. The device comprises a top handle, a riveter, a riveter punch, an upper composite material gasket, a lower composite material gasket and a metal gasket; a sunken portion for accommodating the head of a rivet is formed in the top of the top handle; the head of the rivet is placed in the sunken portion of the top handle; the rod portion of the rivet penetrates through a rivet hole of the hybrid composite material, the lower composite material gasket is arranged between the top handle and thebottom of the hybrid composite material, a cavity is formed in the middle of the lower composite material gasket, the head of the rivet can pass through the cavity, and under protection of the top handle and the lower composite material gasket, the head of the rivet does not deform in a riveting and hammering process. According to the method and device disclosed by the invention, the riveting process problem of a fiber-metal super-hybrid layer plate can be effectively solved, and the service stability of the layer plate riveting structure is prolonged remarkably and the fatigue life is remarkably prolonged.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com