Material for locomotive wheels

A locomotive wheel and content technology, applied in the field of locomotives, can solve problems such as high cost and poor service performance, and achieve the effects of suppressing deformation recrystallization, polygon problems, improving rolling contact fatigue resistance, and improving crack initiation resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

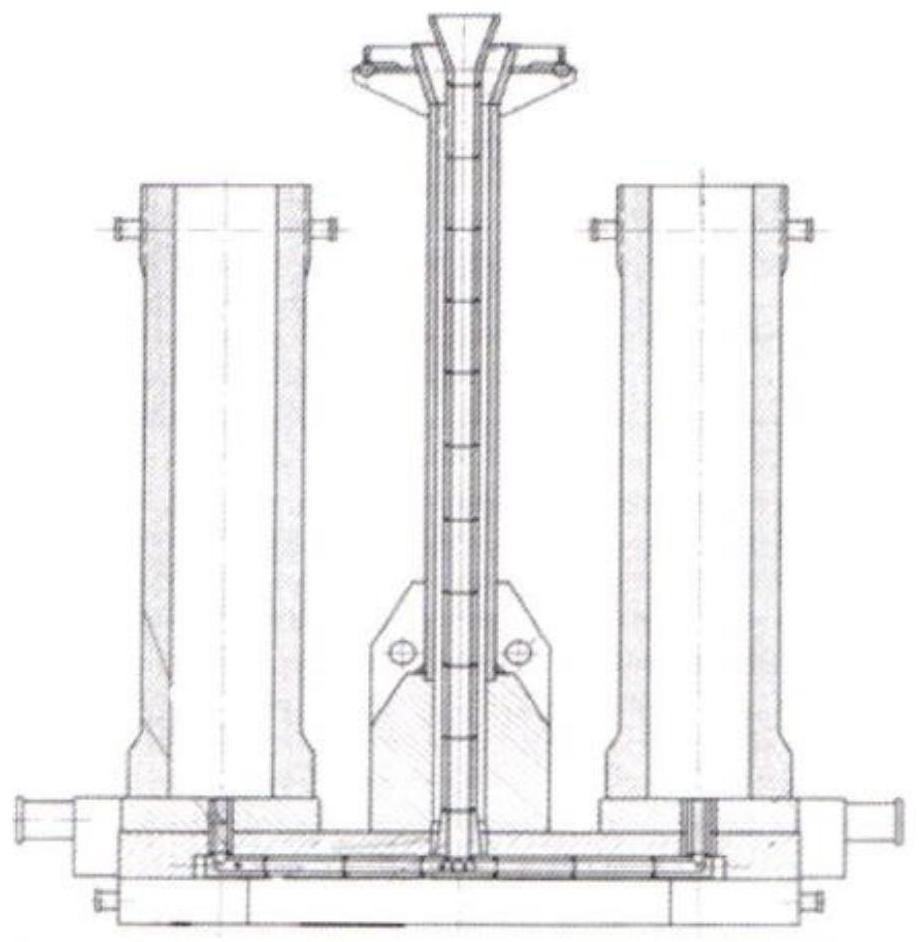

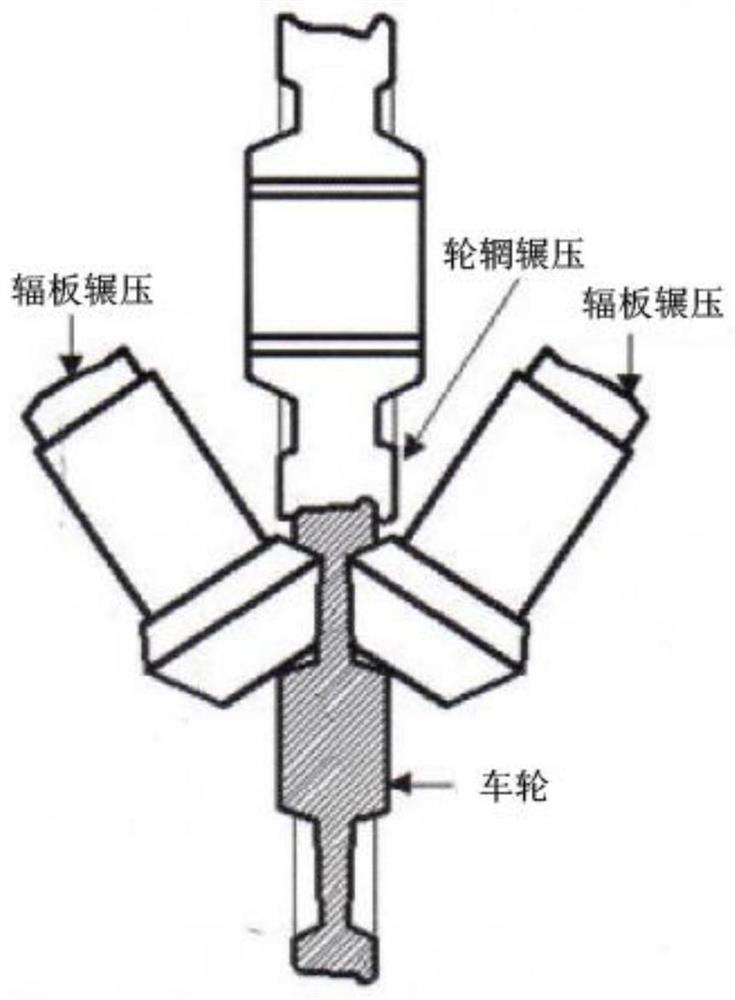

[0022] Preparation of materials for locomotive wheels:

[0023] Step 1, using steel scrap as raw material, smelting in a 50-ton ultra-high-power electric arc furnace, controlling the temperature of molten steel to 1600°C, and controlling the contents of C, P, Si, Mn and other elements within the range required in Table 1;

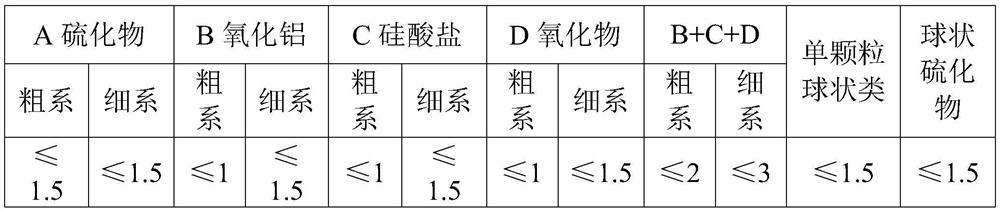

[0024] Step 2, use the LF furnace to carry out deep desulfurization, deep deoxidation, and removal of inclusions through the refining slag, so that the content of S element is controlled within the range required in Table 1, and the content of non-metallic inclusions is controlled within the range required in Table 2; deoxidation, desulfurization At the end, fine-tune the micro-alloy composition, adjust Cr by adding high-carbon ferrochromium, and adjust the content of alloy elements by adding alloy materials such as nickel plate, copper plate, ferromolybdenum, ferro-vanadium, ferro-niobium, ferro-titanium, and aluminum; after fine-tuning, you can pass The w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com