Patents

Literature

61results about How to "Retard crack growth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

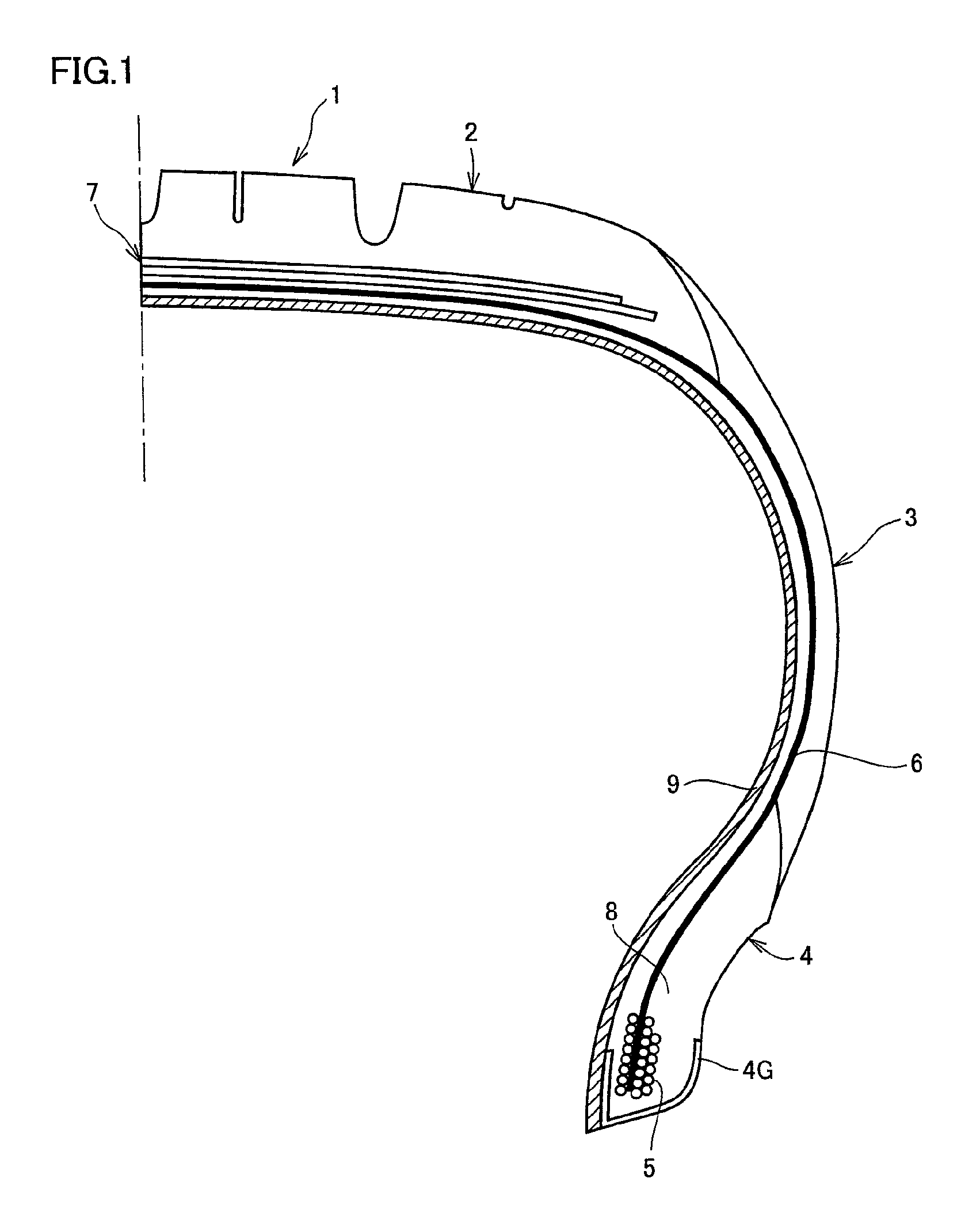

Lightweight structure particularly for an aircraft

ActiveUS20050112348A1Simple structureEasily damagedSynthetic resin layered productsNon-woven fabricsHigh intensityFibrous composites

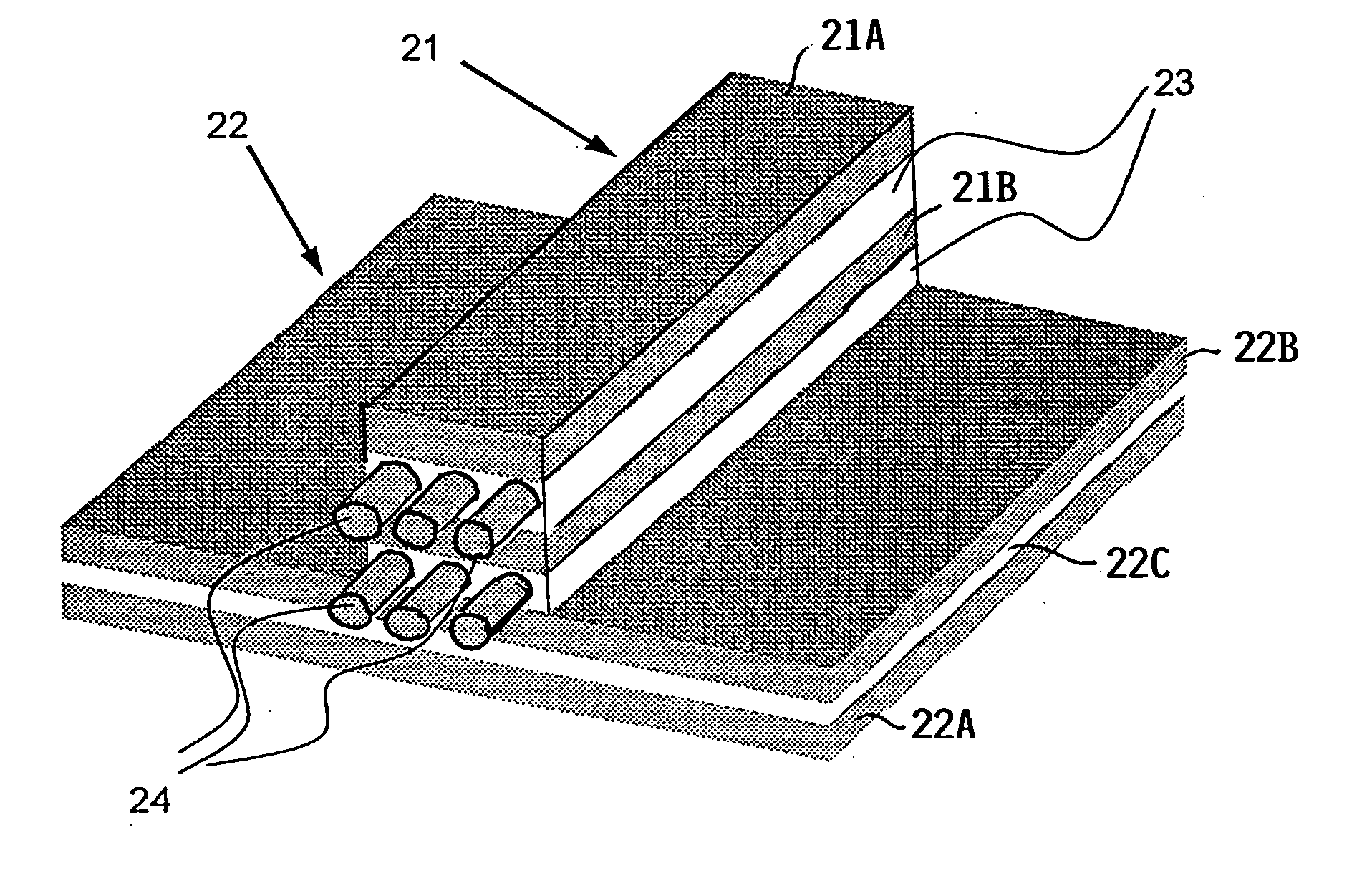

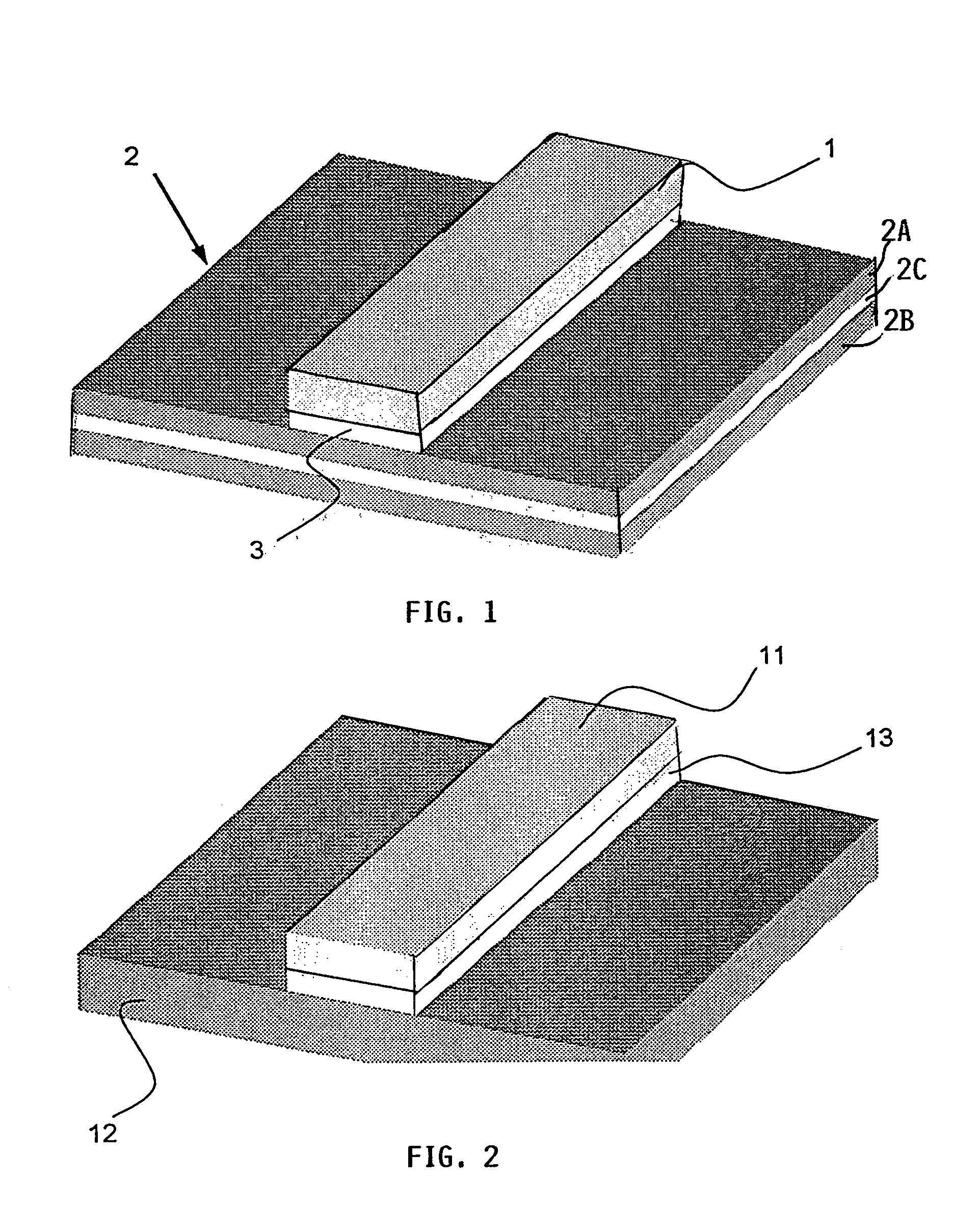

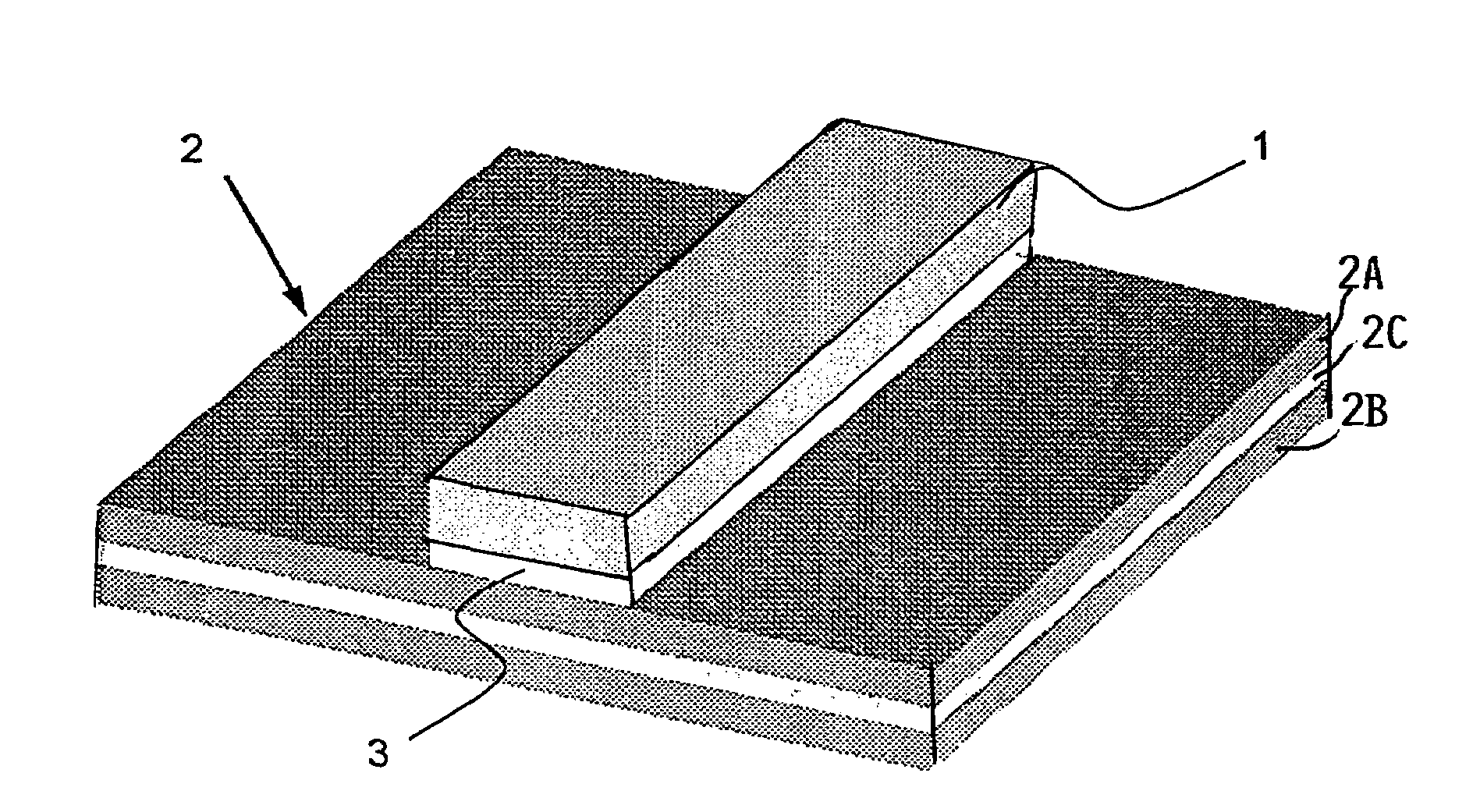

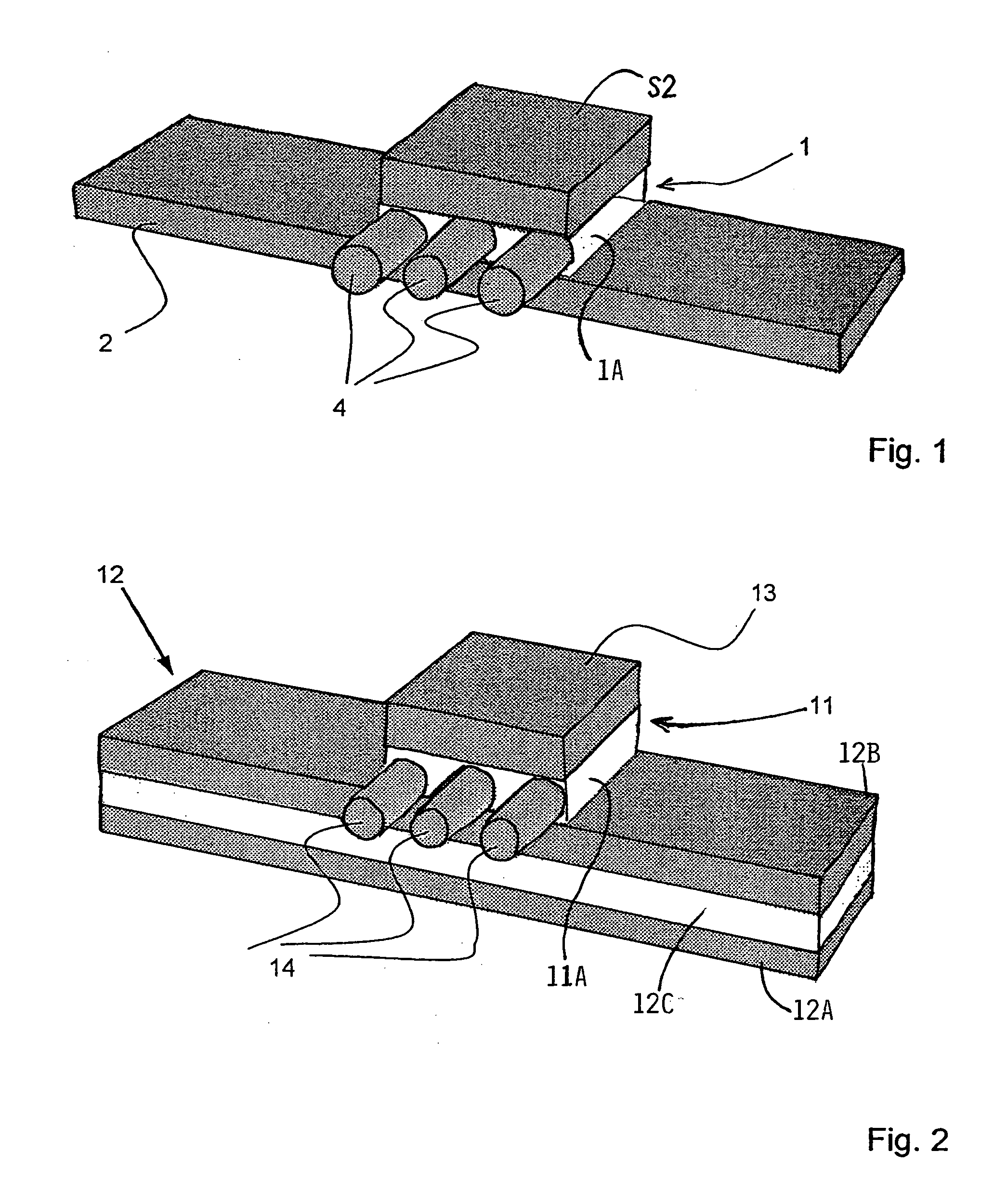

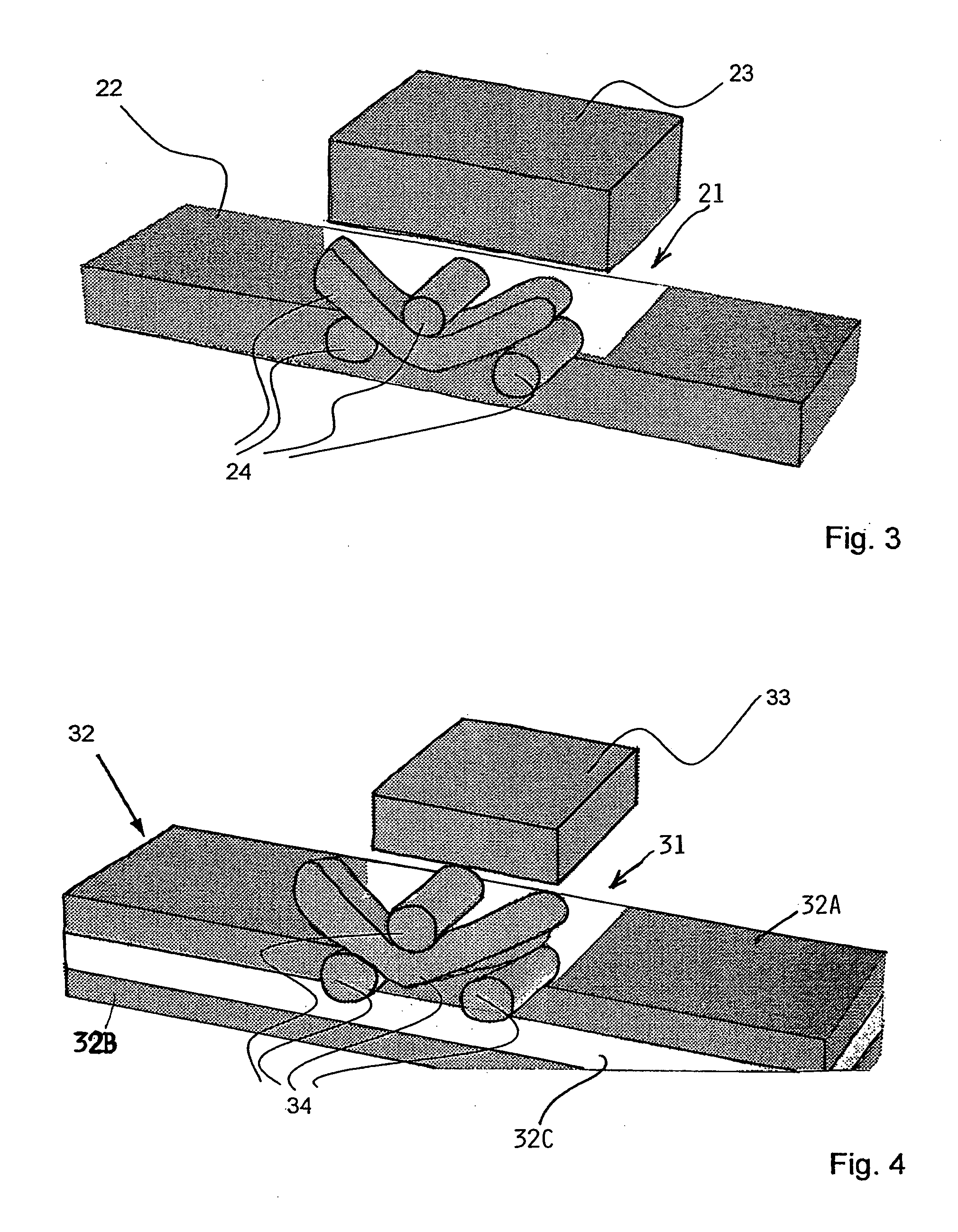

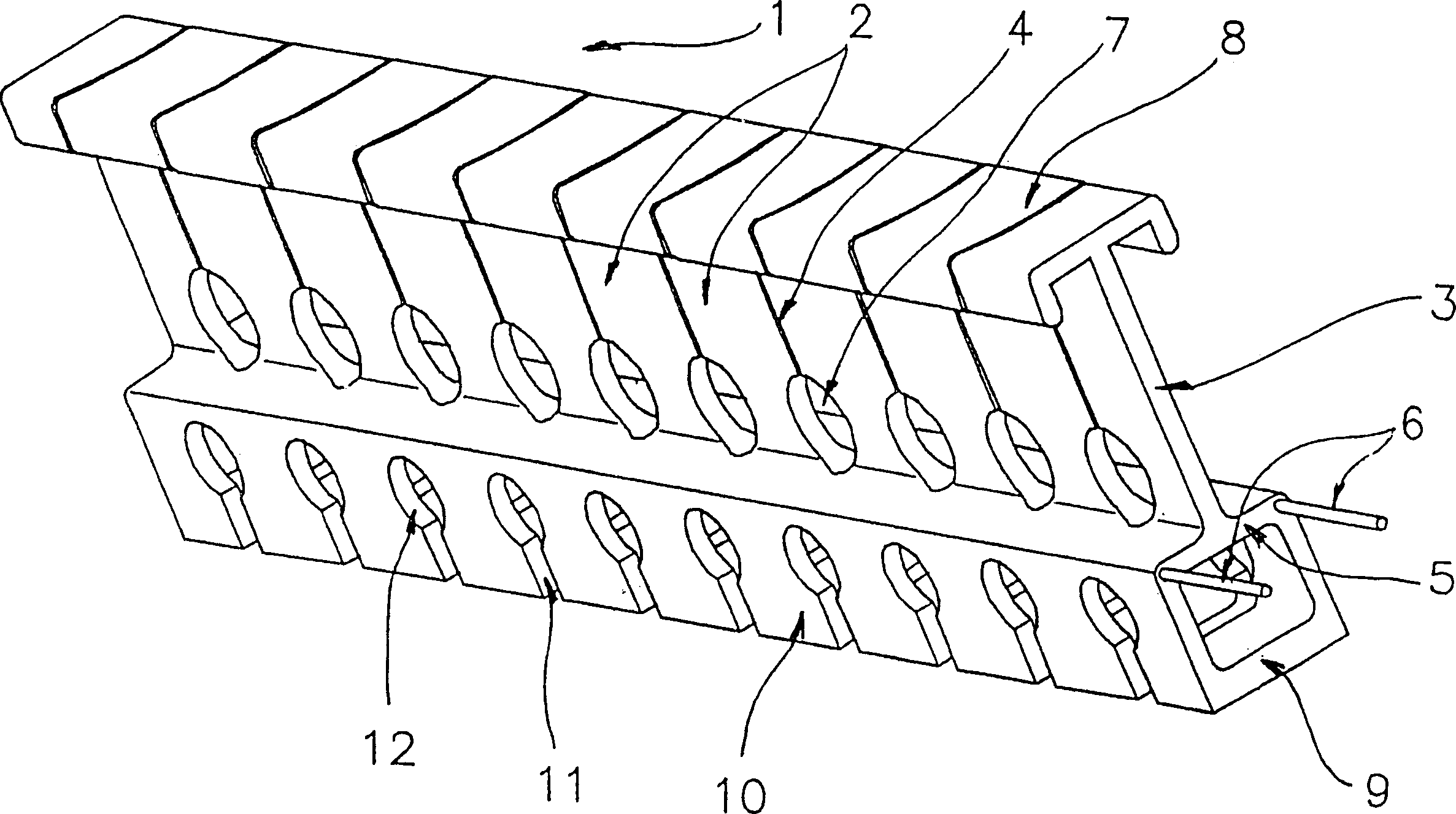

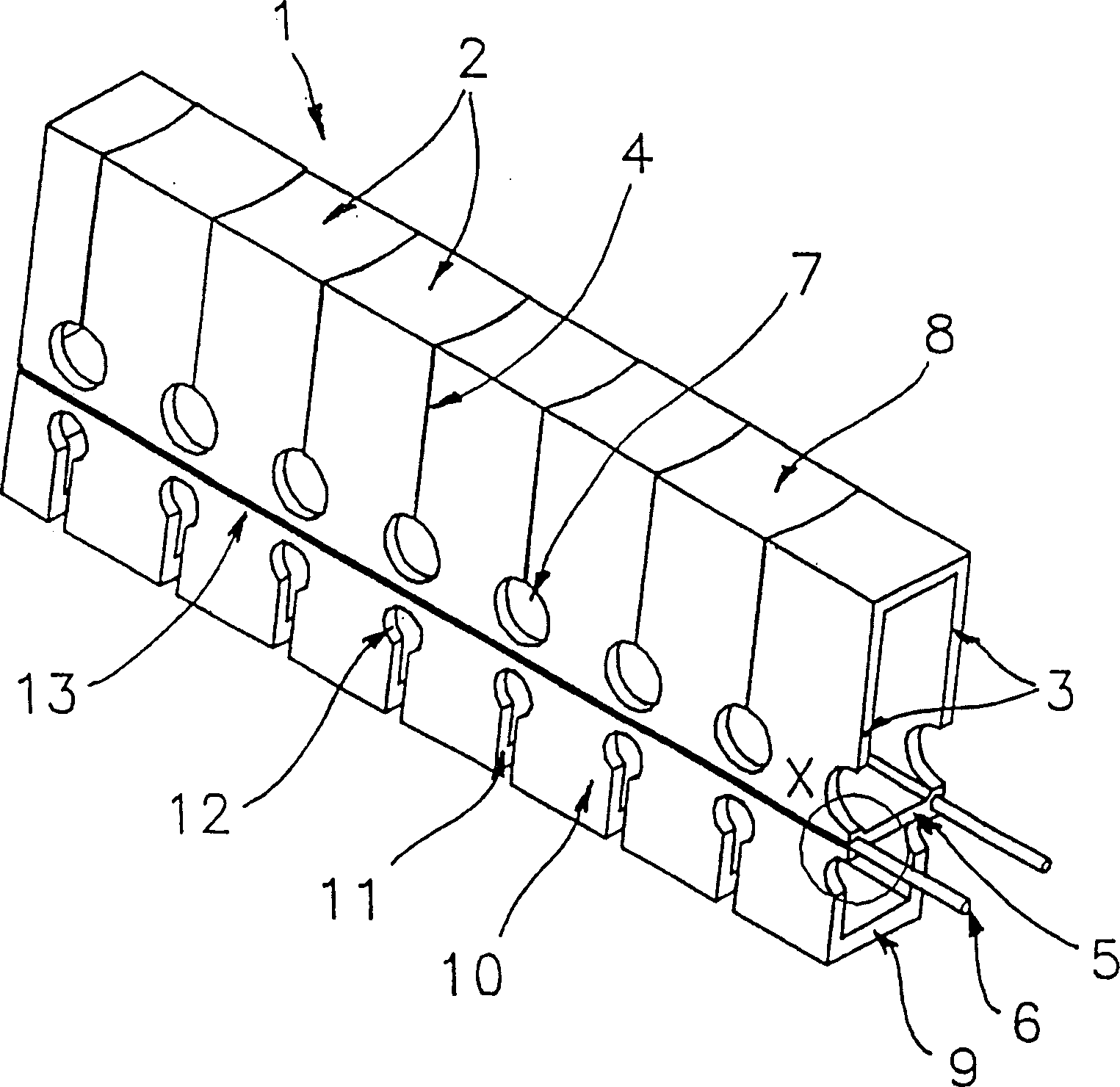

An outer skin, for example of an aircraft body, is supported by a frame of longitudinal girders and circumferential ribs interconnecting the girders. Additionally, the outer skin is strengthened by reinforcing strips adhesively bonded to the outer skin between the ribs and girders. The reinforcing strips are made of material that is damage tolerant, for example high strength aluminum alloys and fiber composite materials are suitable for making the reinforcing strips. These reinforcing strips may extend in parallel to the stringers and / or the ribs and preferably form a lattice work. The reinforcing strips need not cross each other at right angles but should cross a crack propagation direction in the outer skin.

Owner:AIRBUS OPERATIONS GMBH

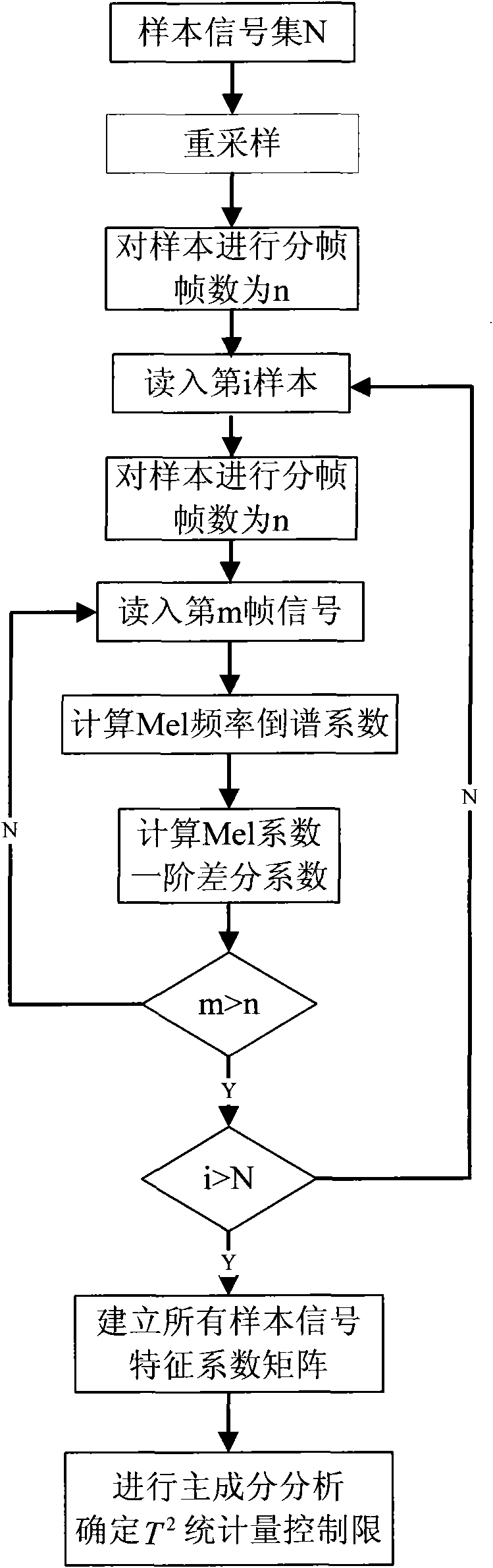

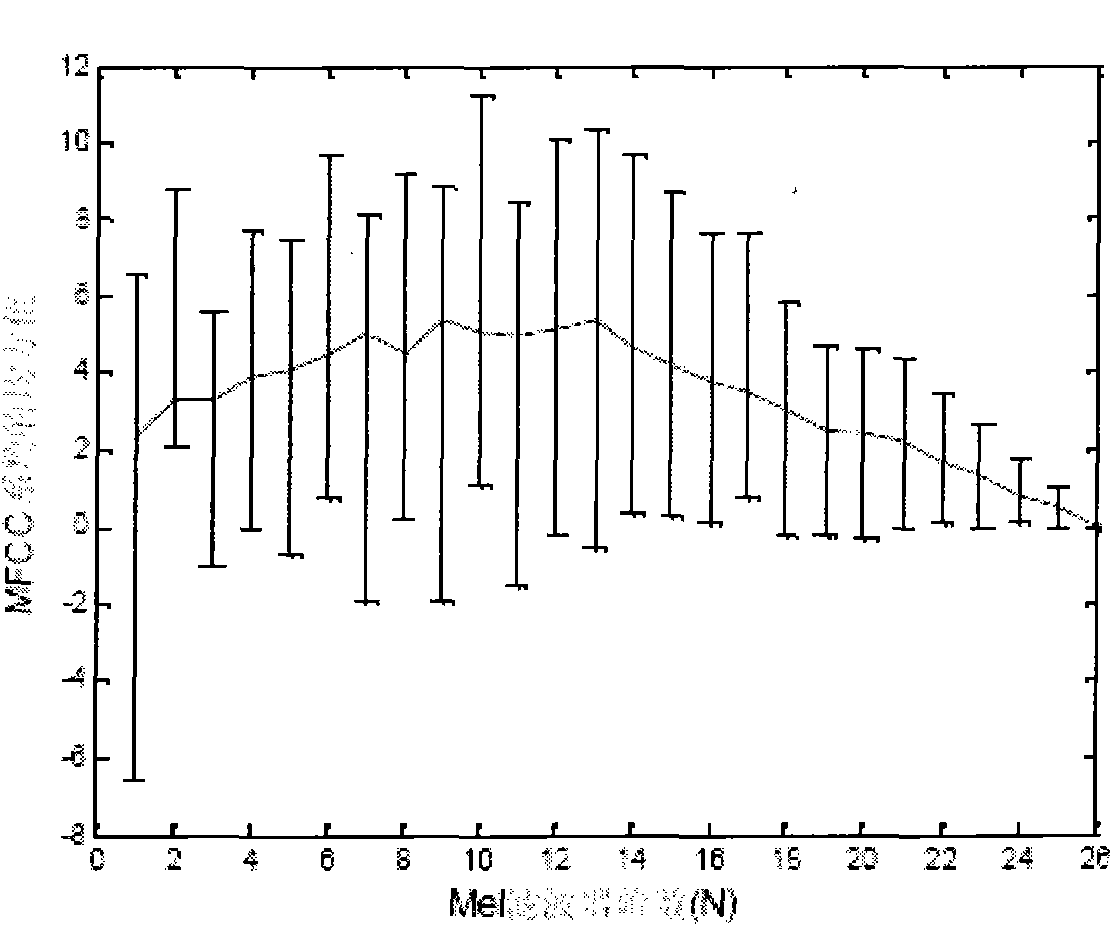

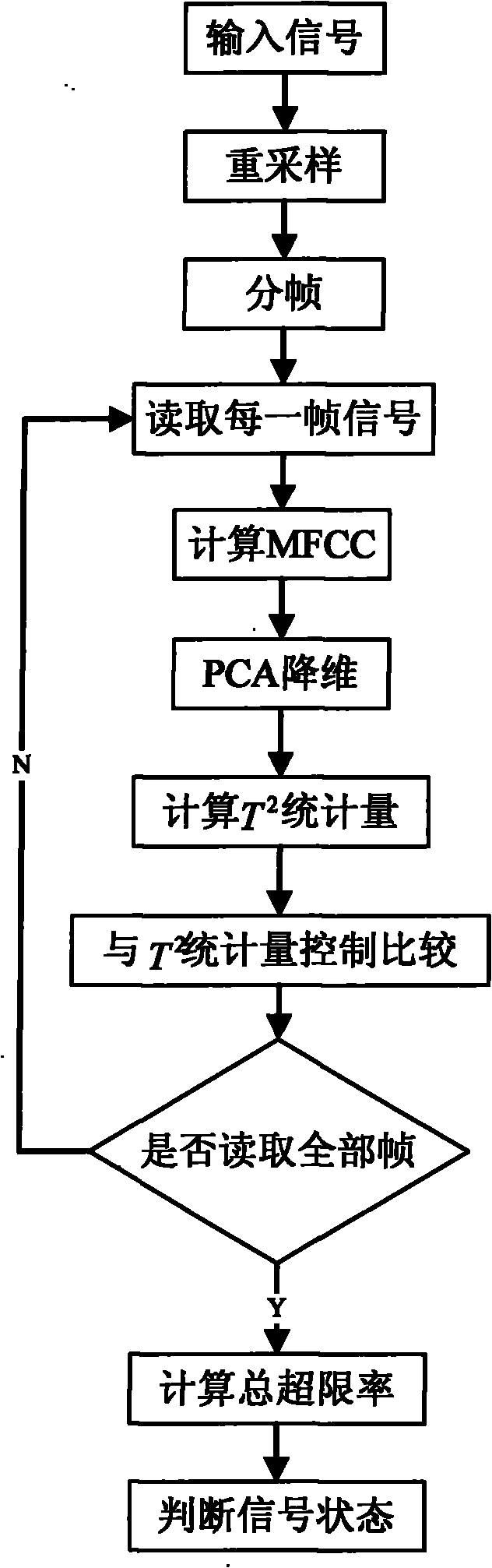

Drift fault recognition method of hot-rolling strip steel based on sound signals

ActiveCN101829689AHigh detection and recognition rateEffective judgmentMeasuring devicesMetal rolling arrangementsDefect preventionPre treatment

The invention provides a drift fault recognition method of hot-rolling strip steel based on sound signals. The method comprises the following steps of: preprocessing a signal by combining the features of a hot-rolling production line and adopting a resampling and framing technology, carrying out feature extraction on the signal by adopting a Mel frequency cepstrum technology and carrying out feature selection and recognition by adopting a principal component analysis method and a multivariate statistic process T2 control diagram so as to realize the diagnosis of drift faults of the hot-rolling strip steel. The invention has the advantages that the drift phenomenon can be judged accurately and rapidly on line by utilizing an acoustic detection method, the roller replacement time can be reasonably arranged, the roller consumption can be effectively reduced, the production cost can be controlled, and the quality defect prevention capacity and the production operability of the product can be improved.

Owner:UNIV OF SCI & TECH BEIJING

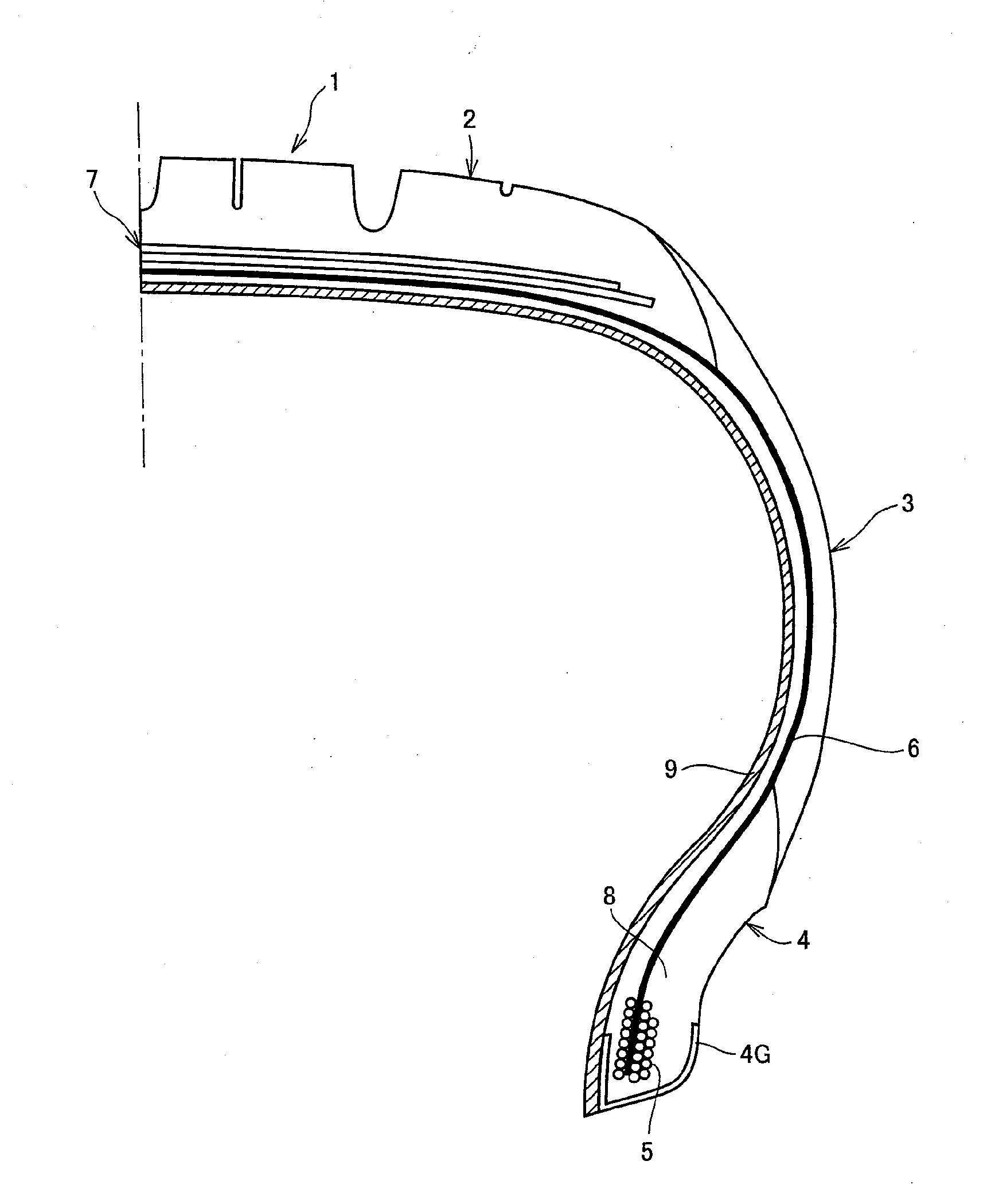

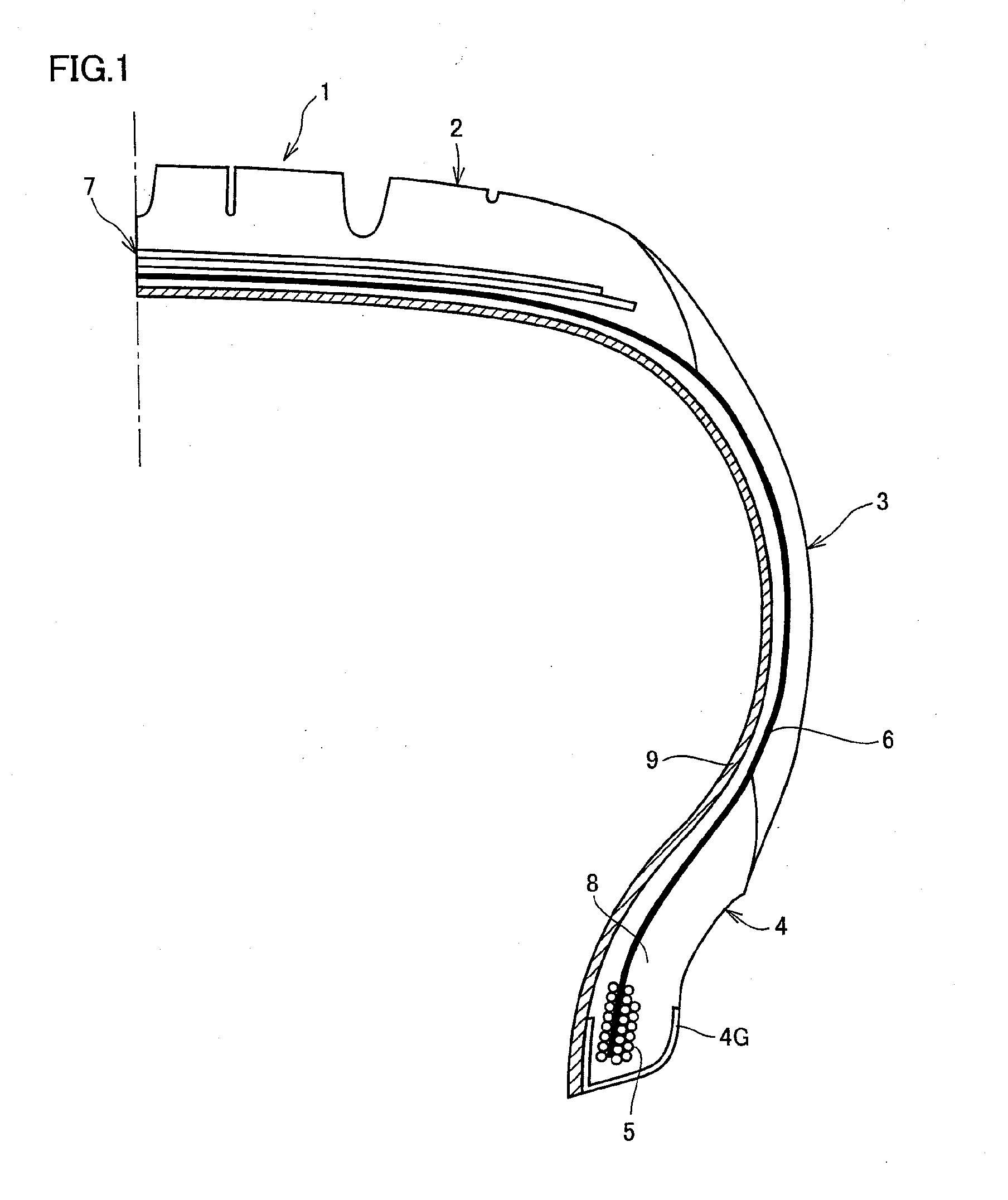

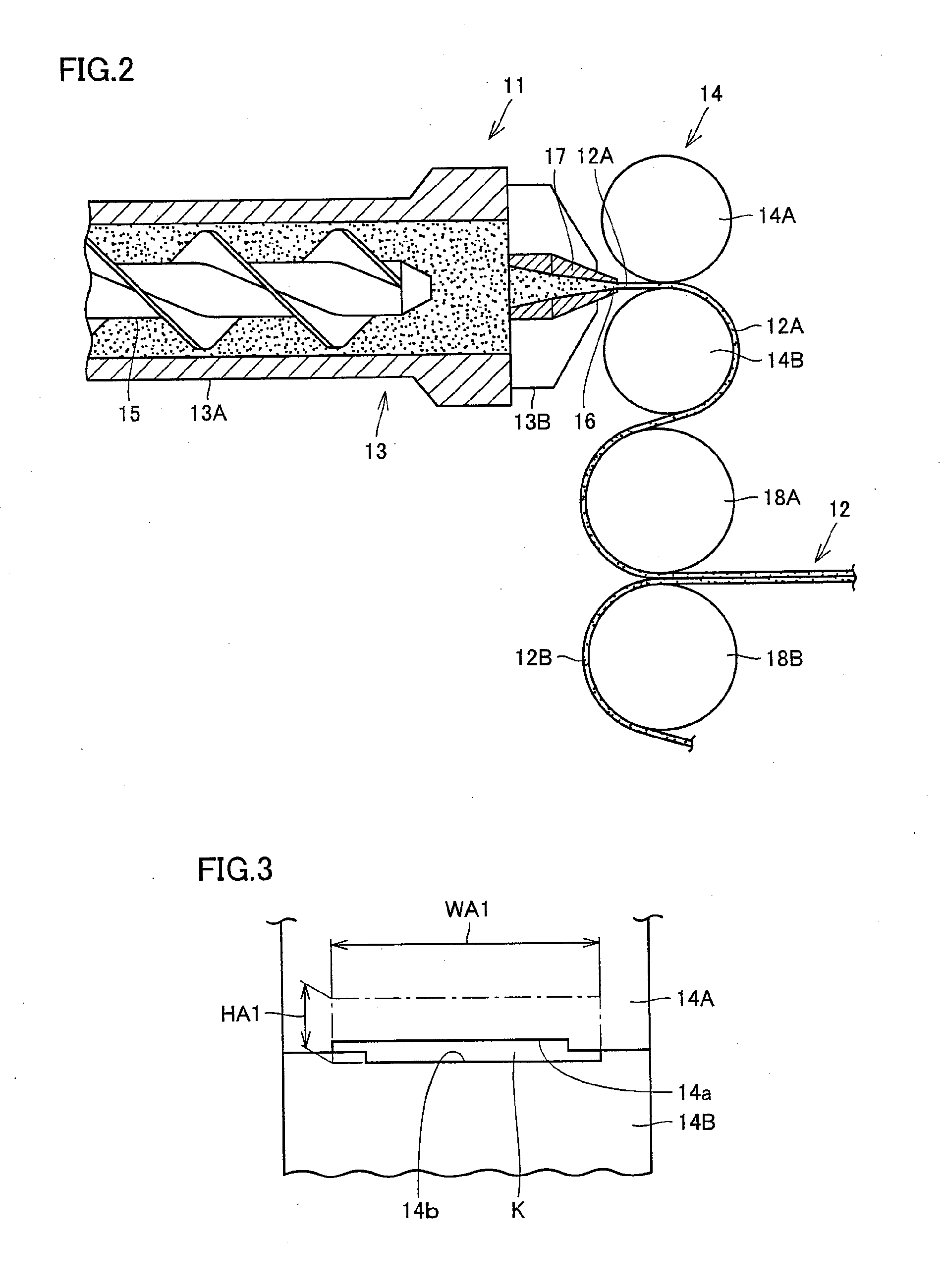

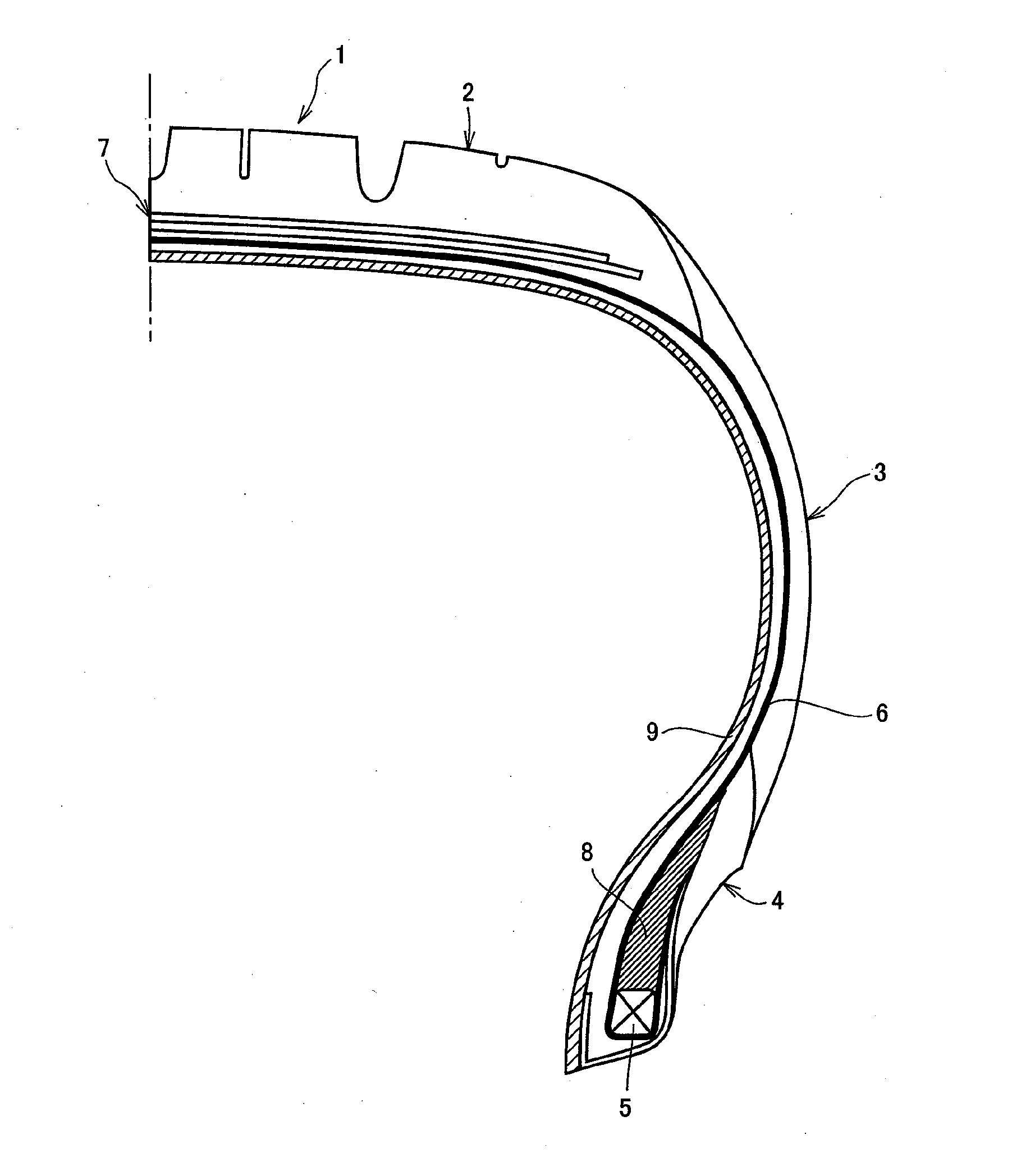

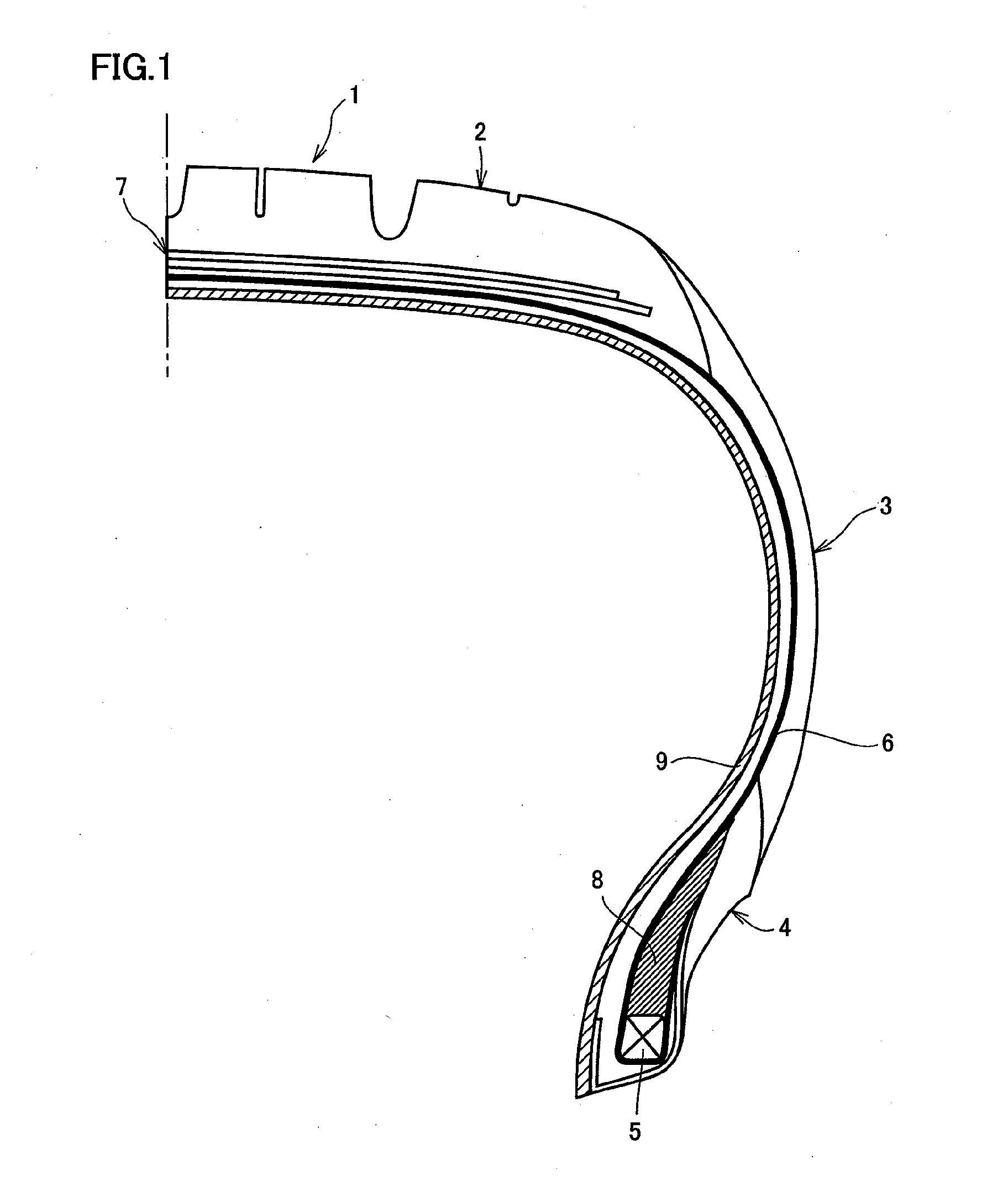

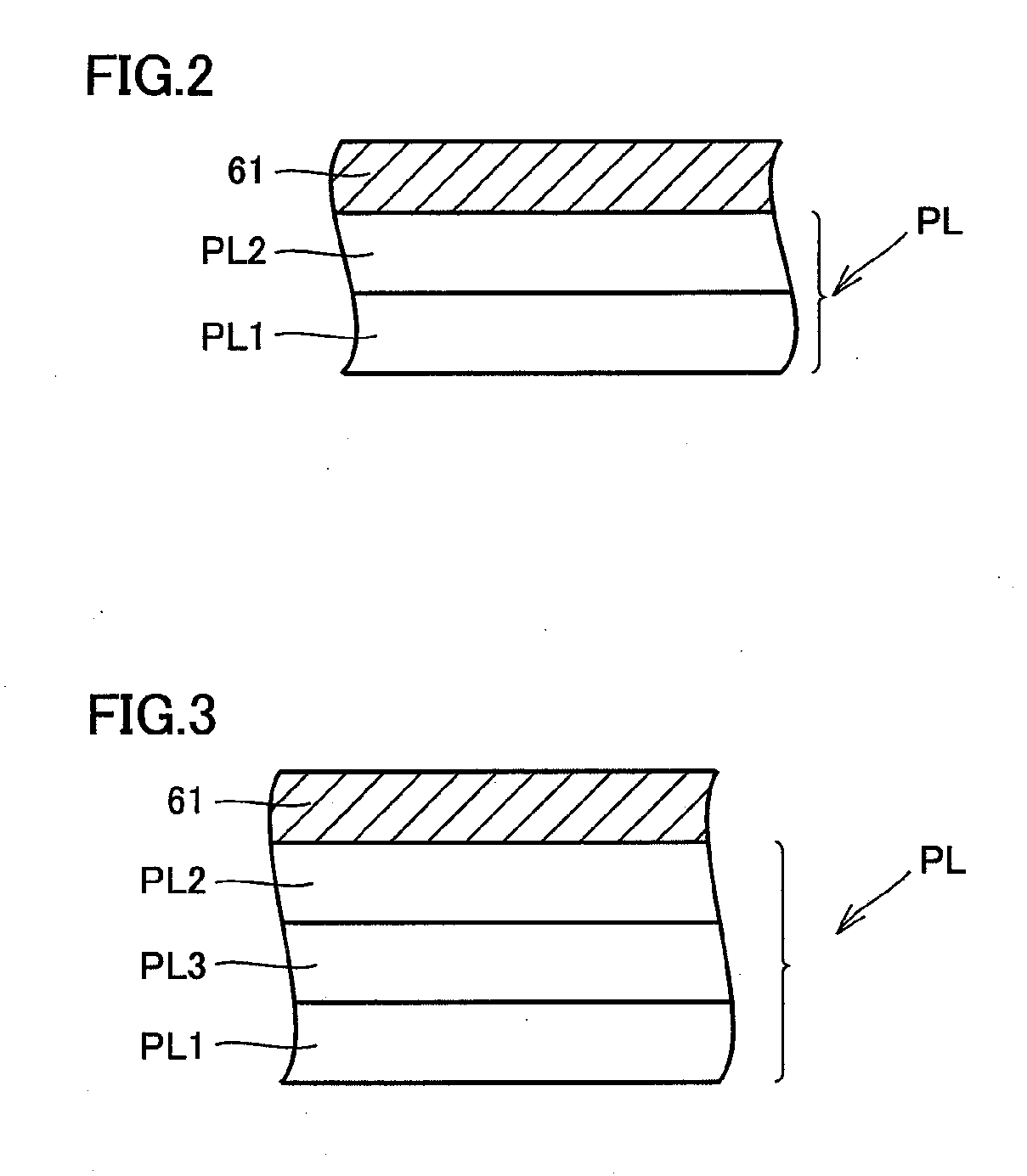

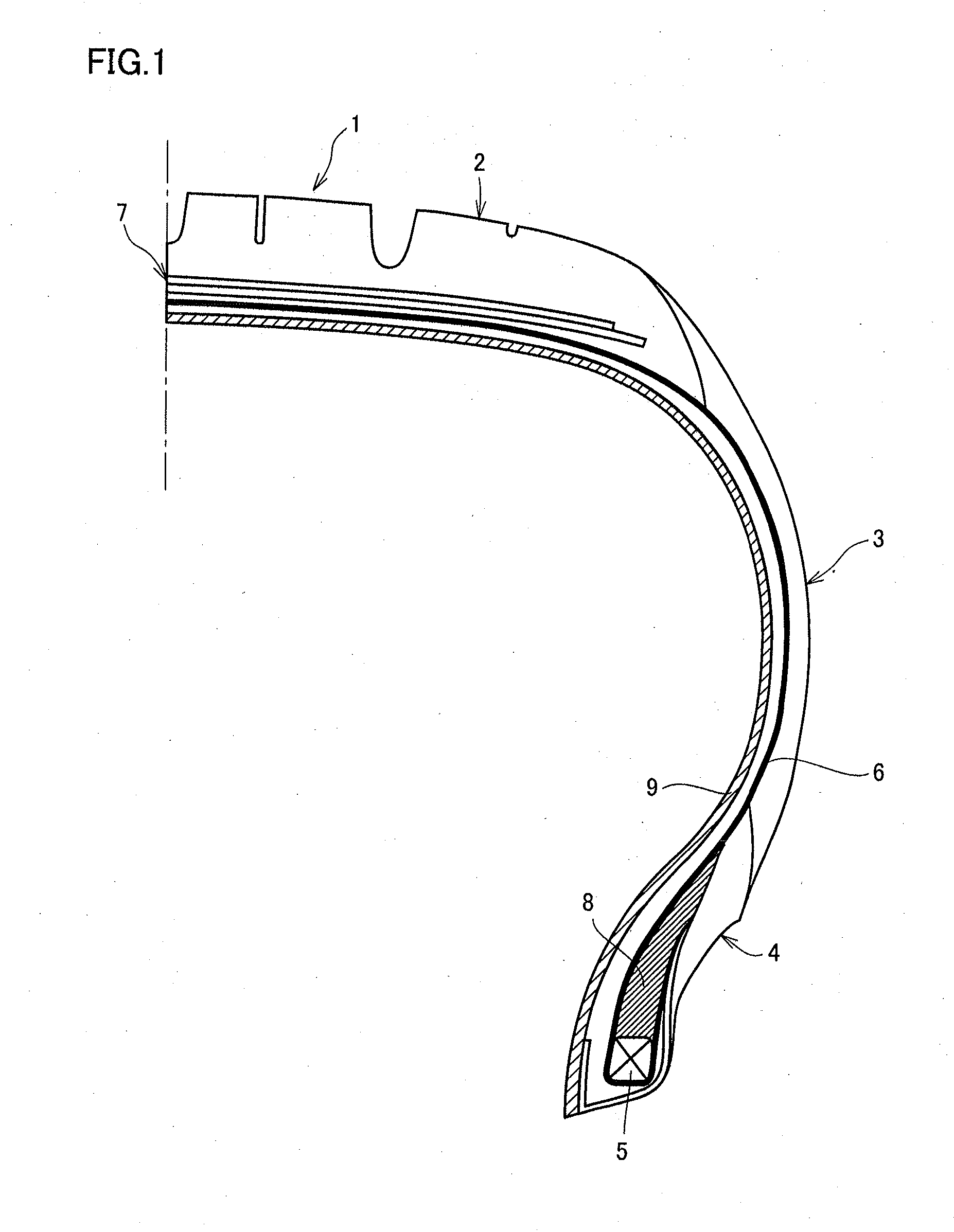

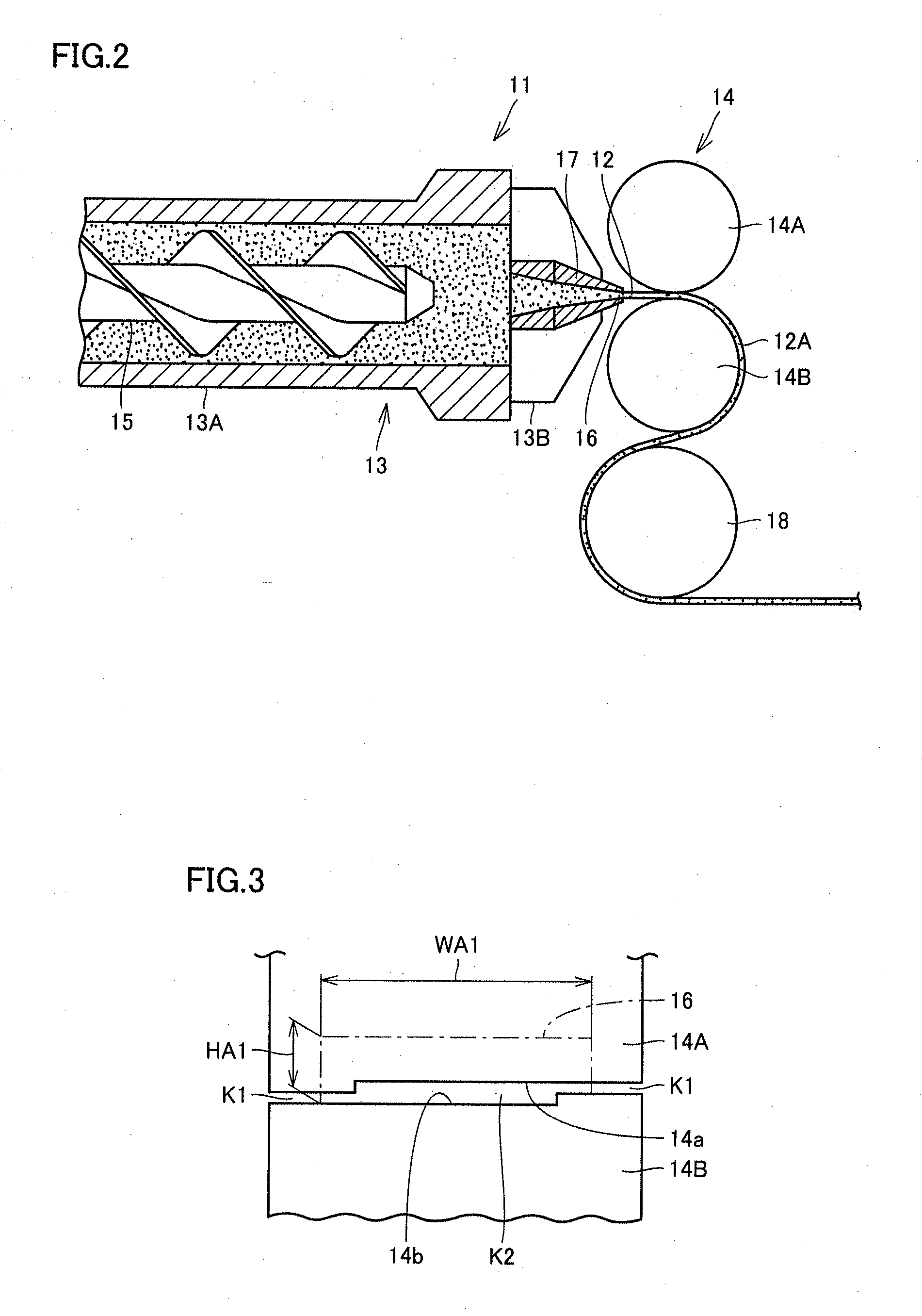

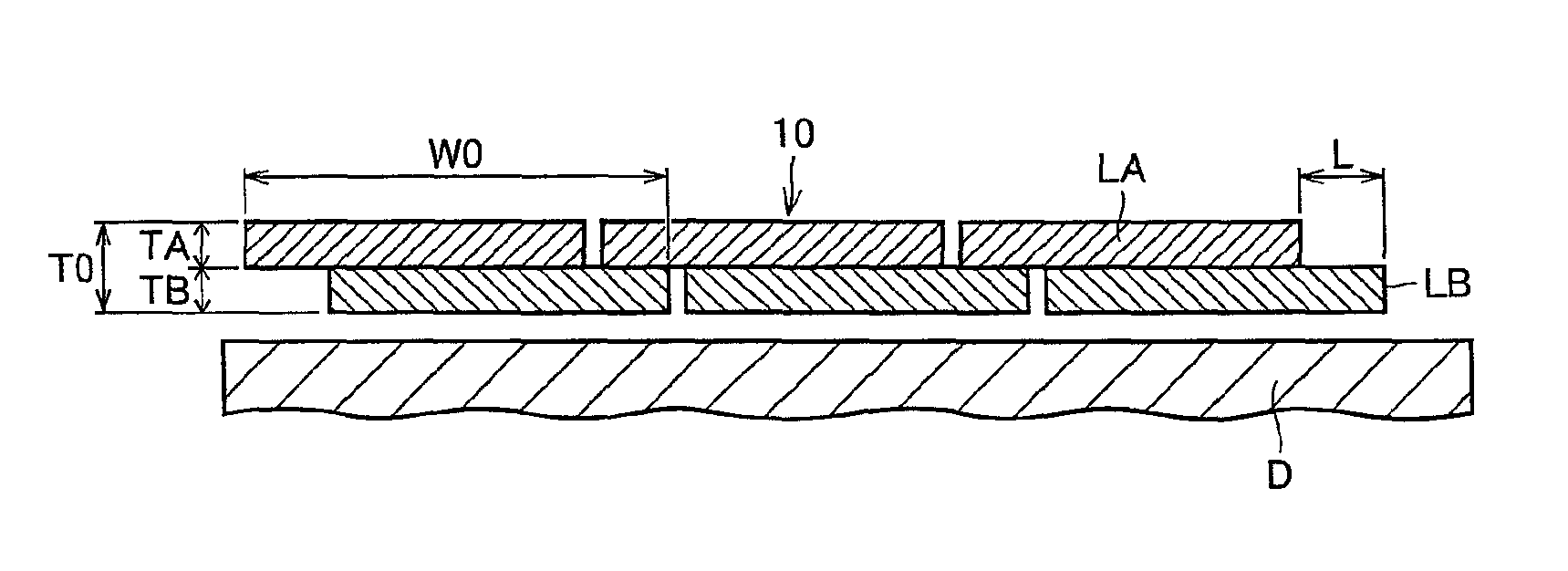

Strip, method for manufacturing the same, and method for manufacturing pneumatic tire

ActiveUS20130248085A1Step differenceImprove adhesive propertiesWithout separate inflatable insertsSynthetic resin layered productsChemistryComposite material

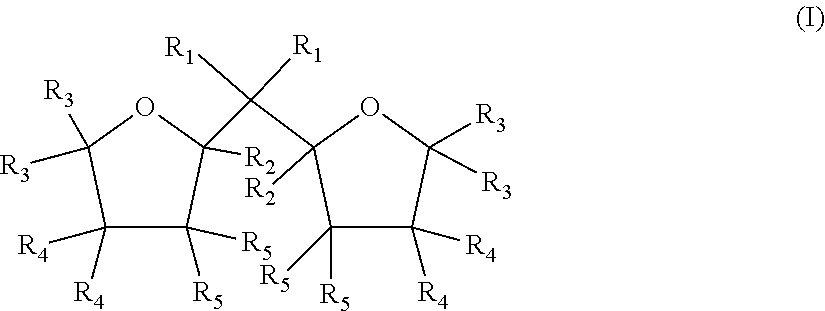

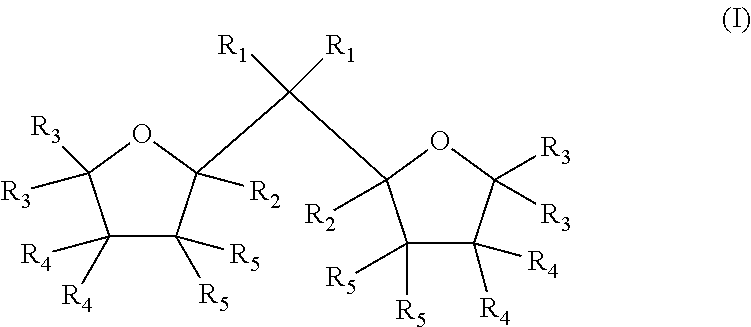

The present invention relates to a ribbon-shaped strip used for an inner liner and a method for manufacturing the strip. The strip is to be wound on an outer circumferential surface of a tire molding drum or a core body to form an inner liner. The strip has an inner layer disposed inwardly in a tire and an outer layer disposed outwardly in the tire. The inner layer and the outer layer are bonded to each other with their ends offset by 0.5 mm to 30 mm in a widthwise direction. At least one layer of the inner layer is formed of an elastomer composition containing a styrene-isobutylene-styrene block copolymer. At least one layer of the outer layer is formed of a thermoplastic elastomer composition.

Owner:SUMITOMO RUBBER IND LTD

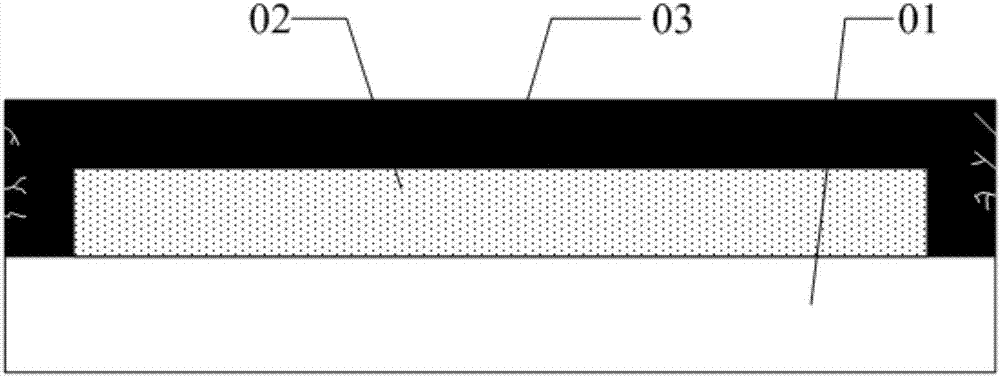

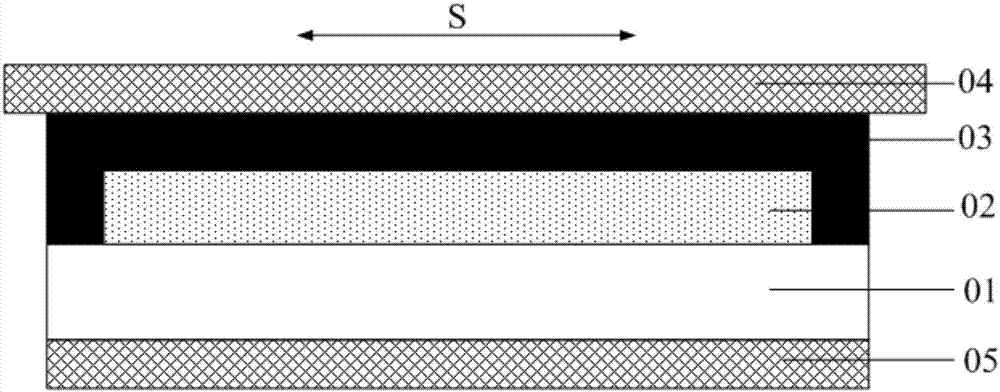

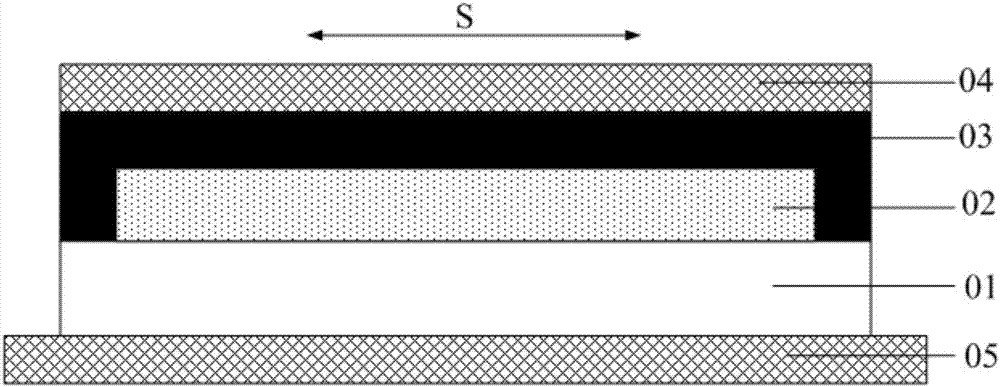

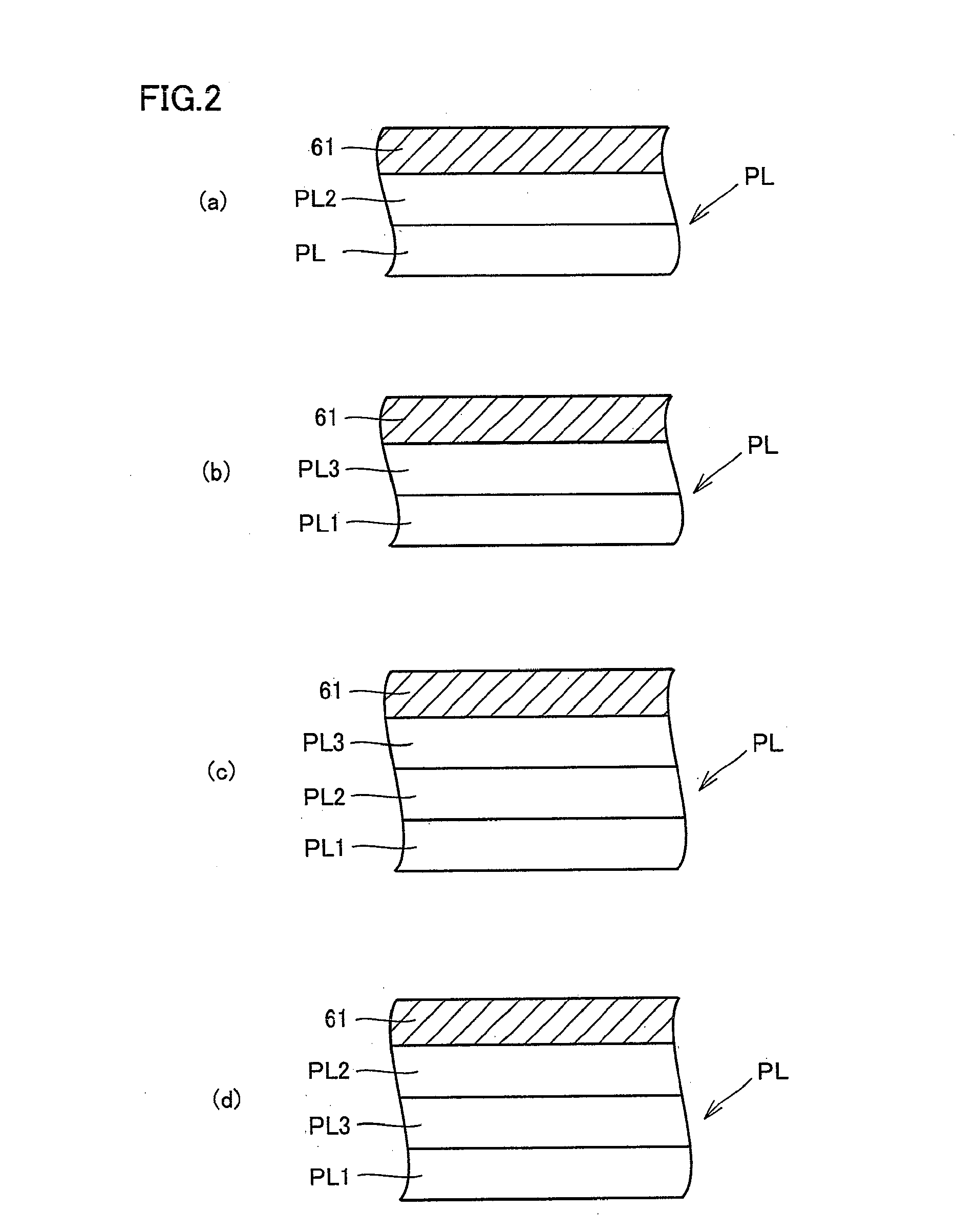

Flexible display panel and display device

ActiveCN106876603AAvoid edge concentration problemsRetard crack growthSolid-state devicesSemiconductor/solid-state device manufacturingOrganic electroluminescenceEngineering

The invention discloses a flexible display panel and a display device. The flexible display panel comprises a substrate, an organic light emitting structure and a package thin film layer, wherein the organic light emitting structure is arranged on the substrate, the package thin film layer covers the organic light emitting structure, the flexible display panel also comprises a first upper protection layer and a first lower protection layer, the first upper protection layer is attached onto one side, deviating from the organic light emitting structure, of the package thin film layer, the first lower protection layer is attached onto one side, deviating from the organic light emitting structure, of the substrate, the first upper protection layer exceeds a region where the substrate is located at least in a bending shaft direction of the flexible display panel, and / or the first lower protection layer exceeds a region where the substrate is located at least in the bending shaft direction. The problem that stress is concentrated at an edge of the package thin film layer when the flexible display panel is bent is prevented by a part of the first upper protection layer or the first lower protection layer exceeding the substrate, so that the problem of crack expansion caused by bending of the flexible display panel can be solved.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

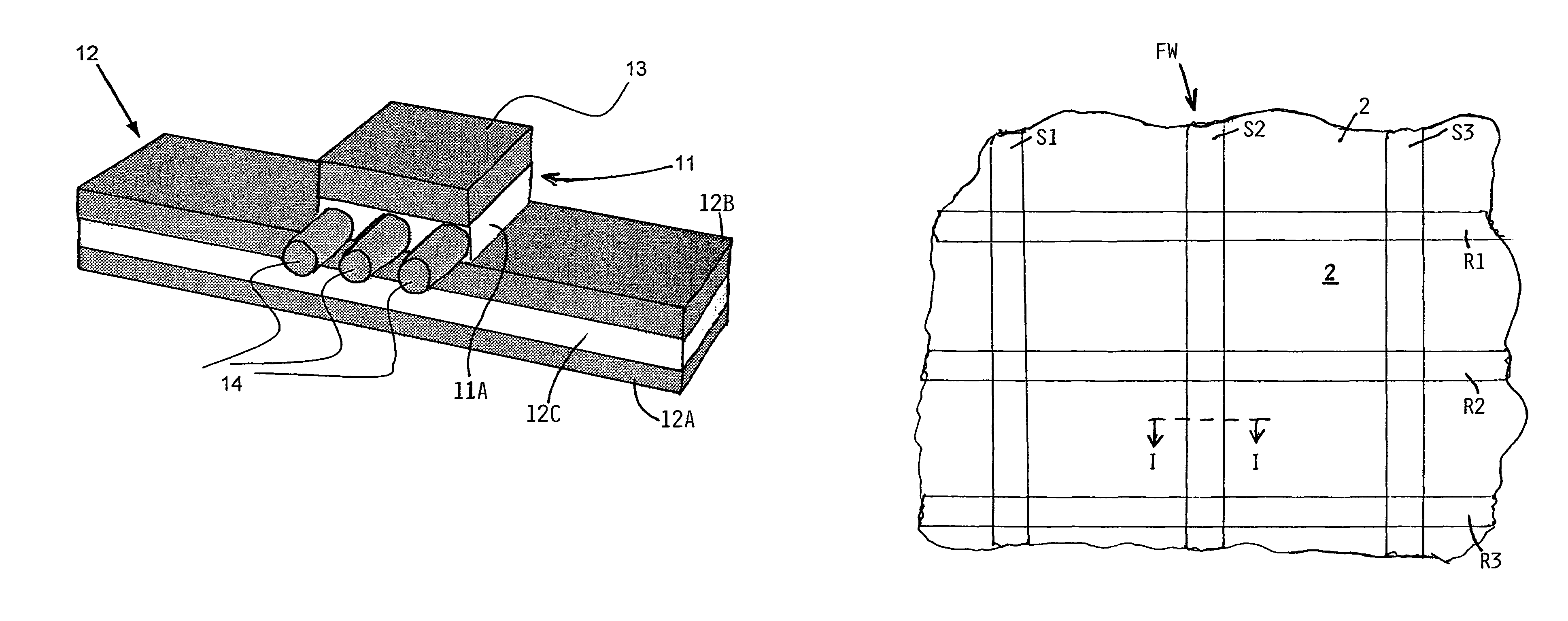

Lightweight structure particularly for an aircraft

ActiveUS7285326B2Simple structureEasily damagedSynthetic resin layered productsNon-woven fabricsHigh intensityFibrous composites

An outer skin of an aircraft body is supported by a frame of longitudinal stringers and circumferential ribs or frame elements interconnecting the stringers. Additionally, the outer skin is strengthened by a reinforcing strip formation adhesively bonded to the inwardly facing surface of the outer skin between the ribs and stringers. The reinforcing strips are made of a material that is damage tolerant, for example high strength aluminum alloys and fiber composite materials are suitable for making the reinforcing strip formation. The reinforcing strips of the strip formation may extend in parallel to the stringers and / or the ribs and preferably form a lattice work. The reinforcing strips need not cross each other at right angles but should cross a crack propagation direction in the outer skin.

Owner:AIRBUS OPERATIONS GMBH

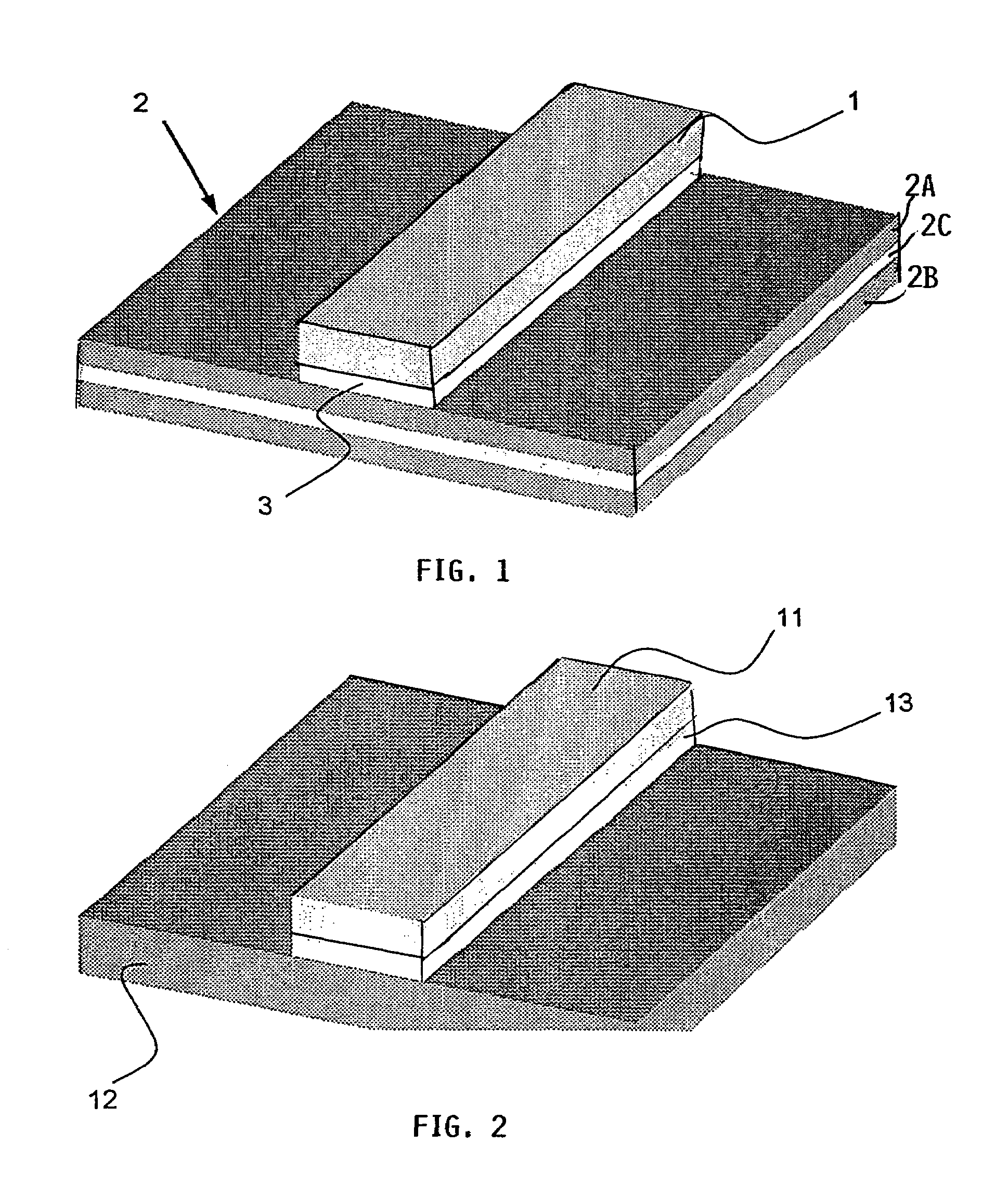

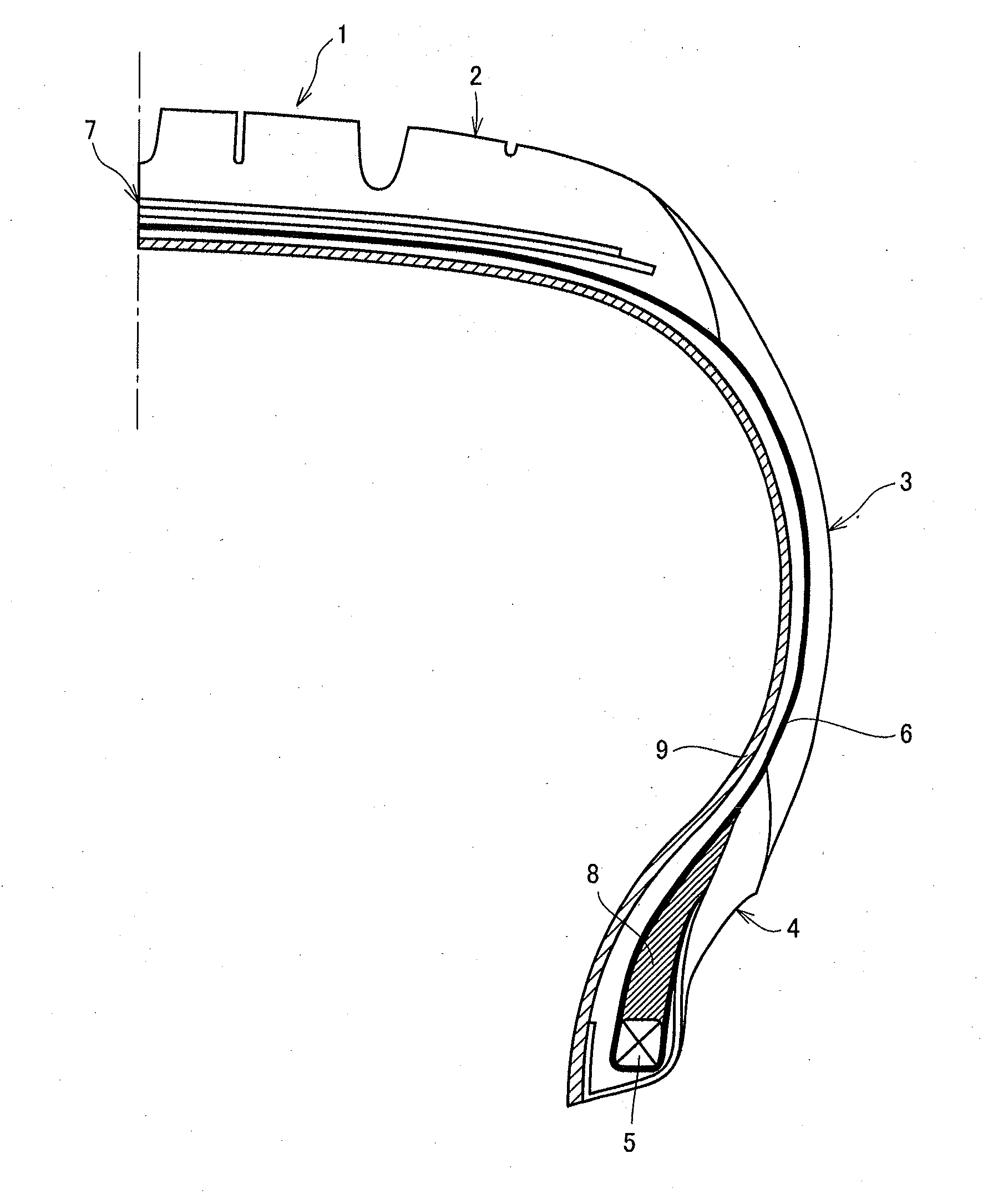

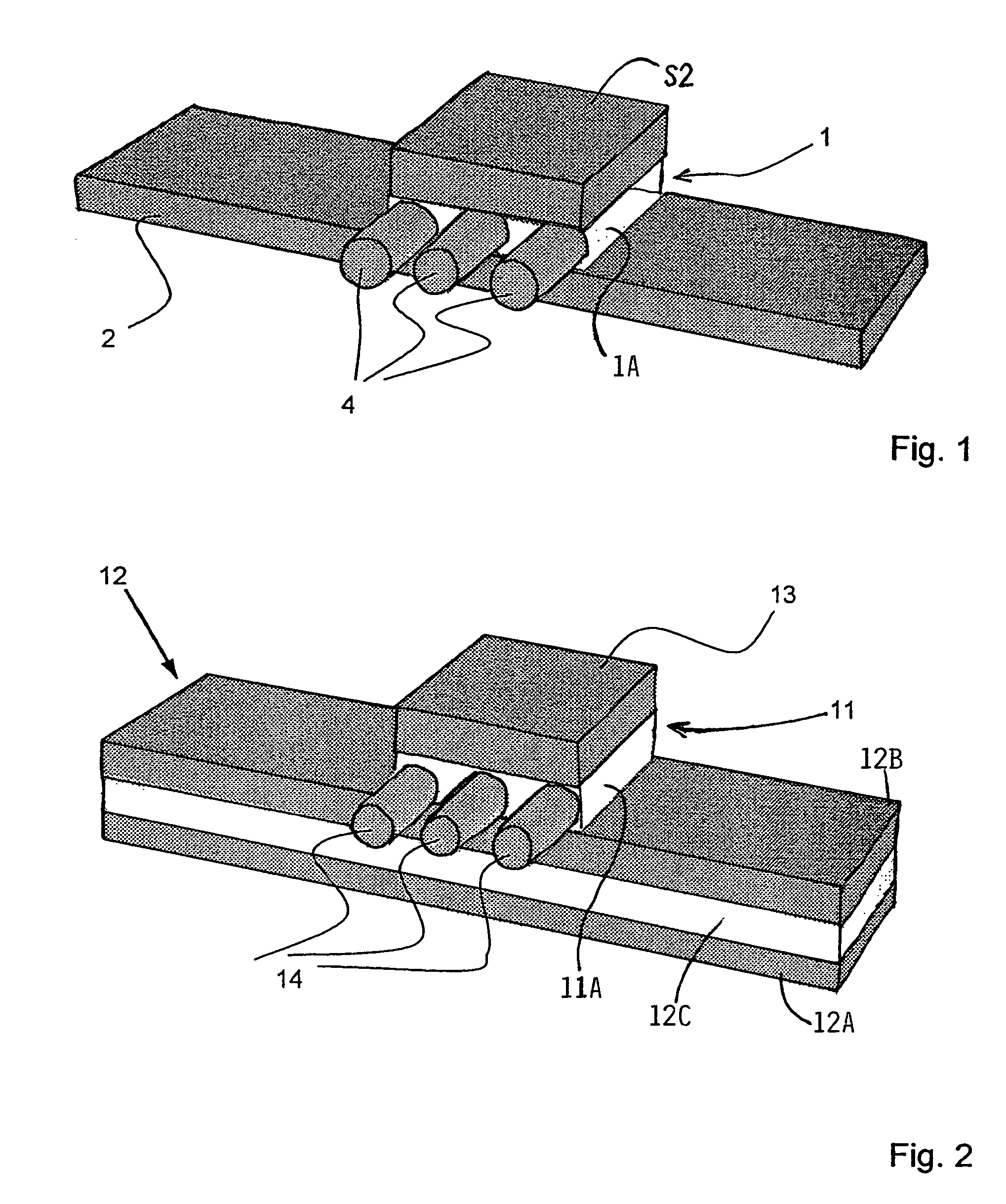

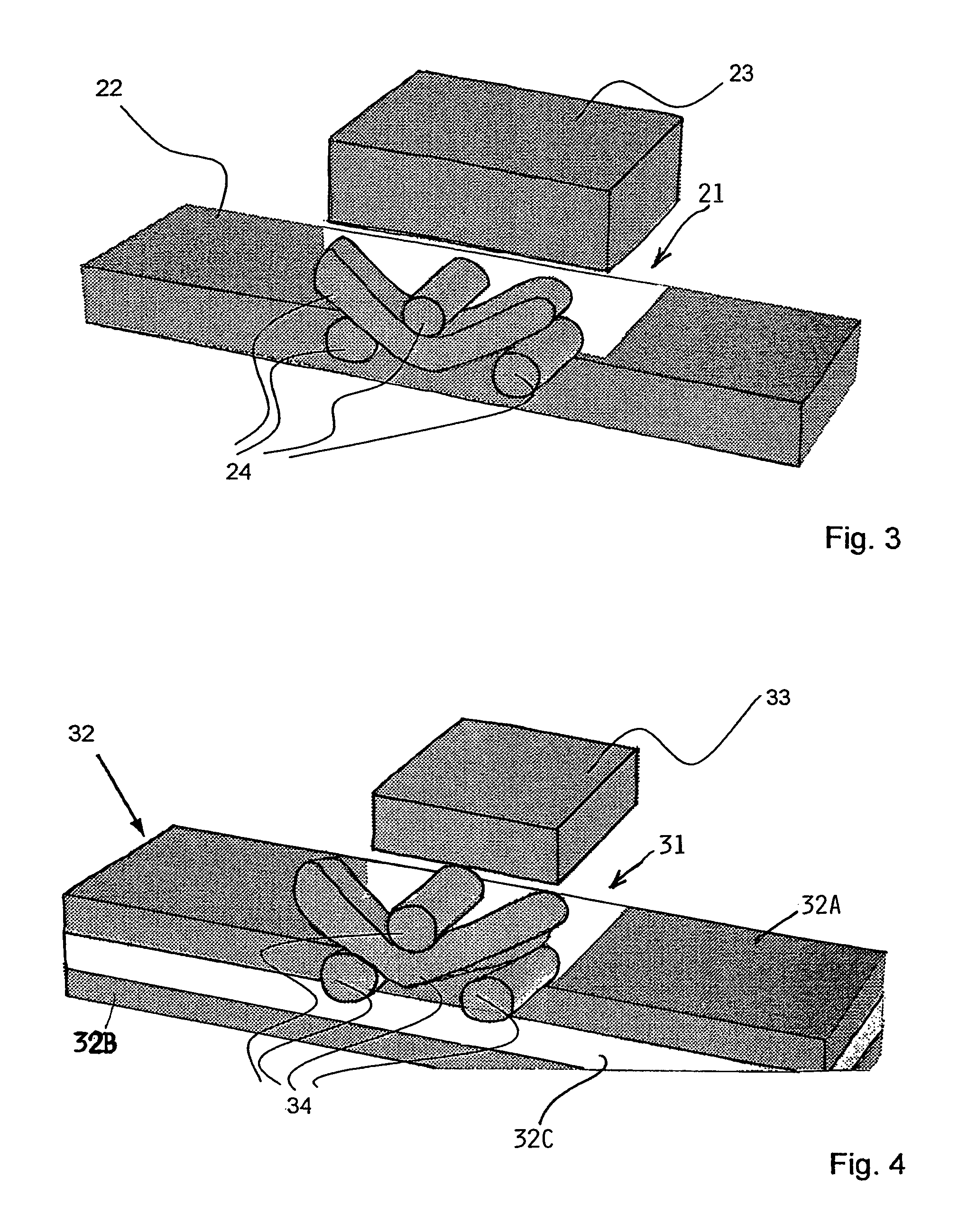

Lightweight structure especially for an aircraft and method for making such a structure

ActiveUS20050112347A1Decrease their propagationExtended service lifeNon-woven fabricsThin material handlingEngineeringParallel fiber

An additional fiber reinforced layer reduces crack propagation in a lightweight structure of an outer skin adhesively bonded to a reinforcing frame. For this purpose the additional fiber reinforced layer is interposed between the outer skin and the frame and adhesively bonded to the outer skin and to the frame. The additional layer has reinforcing fibers extending in parallel to each other or the reinforcing fibers are woven into a fabric embedded in a synthetic adhesive bonding material. The embedding of the parallel fibers or of the fiber fabric in the bonding material is performed either prior to the bonding or during the bonding of the additional layer to the outer skin and to the reinforcing frame.

Owner:AIRBUS OPERATIONS GMBH

Method for preparing ultra-coarse-grain tungsten-cobalt hard alloy

The invention discloses a method for preparing a high-tenacity super-coarse-grained tungsten and cobalt hard alloy. The method comprises the following process steps of: mixing raw materials, performing wet grinding, drying, pre-sintering, performing wet mixing, drying, adding a forming agent, palletizing, performing compression moulding and performing integral sintering in vacuum under low pressure, wherein in the step of mixing the raw materials, cobalt powder and tungsten carbide powder are blended in the mass ratio of 2.4-2.6:97.4-97.6; metal cobalt powder and Co2W4C nanoparticles are added into the pre-sintered mixture in which the mass ratio of cobalt to tungsten carbide is 8-13:87-92; and the adding amount of the Co2W4C nanoparticles is accordant with the condition that the mass ratio of the cobalt to the Co2W4C nanoparticles is 1:0.045-0.055. The WC average grain size of the prepared hard alloy is up to 4.0 to 5.2mu m; the bending strength is up to 3,000 to 3,400MPa; and the hardness HRA is up to 88.0 to 90.8.

Owner:HUNAN CENTURY SPECIAL ALLOY

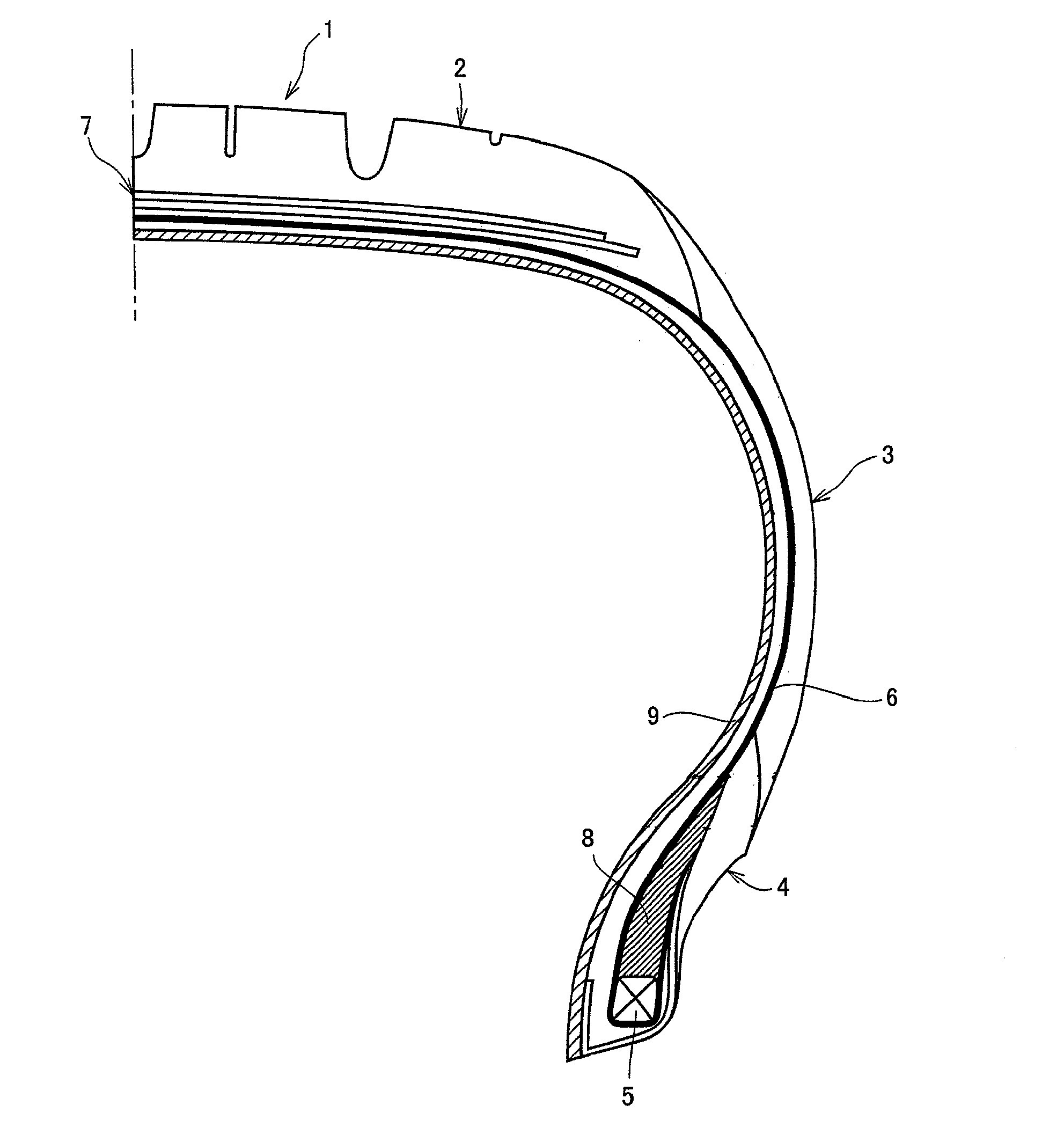

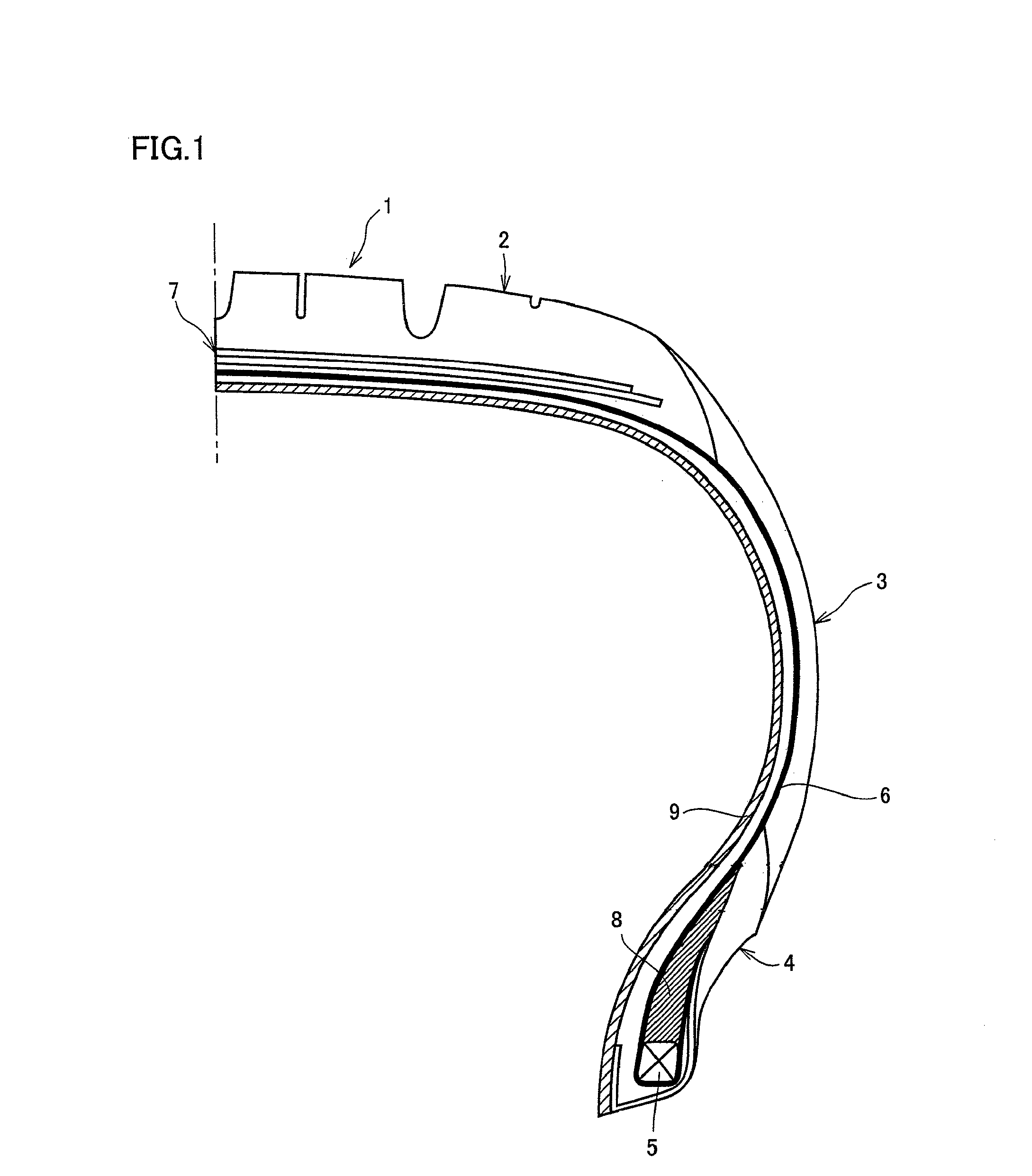

Pneumatic tire

InactiveUS20130199687A1Increased durabilityImprove adhesionWithout separate inflatable insertsWith separate inflatable insertsThermoplastic elastomerEngineering

A pneumatic tire includes an inner liner disposed inwardly in the tire relative to a carcass ply bridged between a pair of bead portions, the inner liner being formed of a first layer disposed inwardly in the tire, and a second layer disposed in contact with a rubber layer of the carcass ply, the first layer being a thermoplastic elastomer composition mainly containing a styrene-isobutylene-styrene block copolymer, the second layer being a styrene-based thermoplastic elastomer composition, (a) at least one of the thermoplastic elastomer compositions of the first and second layers containing a tackifier by 0.1 part by mass to 100 parts by mass relative to 100 parts by mass of a thermoplastic elastomer component, or (b) the second layer containing the styrene-isobutylene-styrene block copolymer by 10 mass % to 80 mass % relative to a thermoplastic elastomer component thereof.

Owner:SUMITOMO RUBBER IND LTD

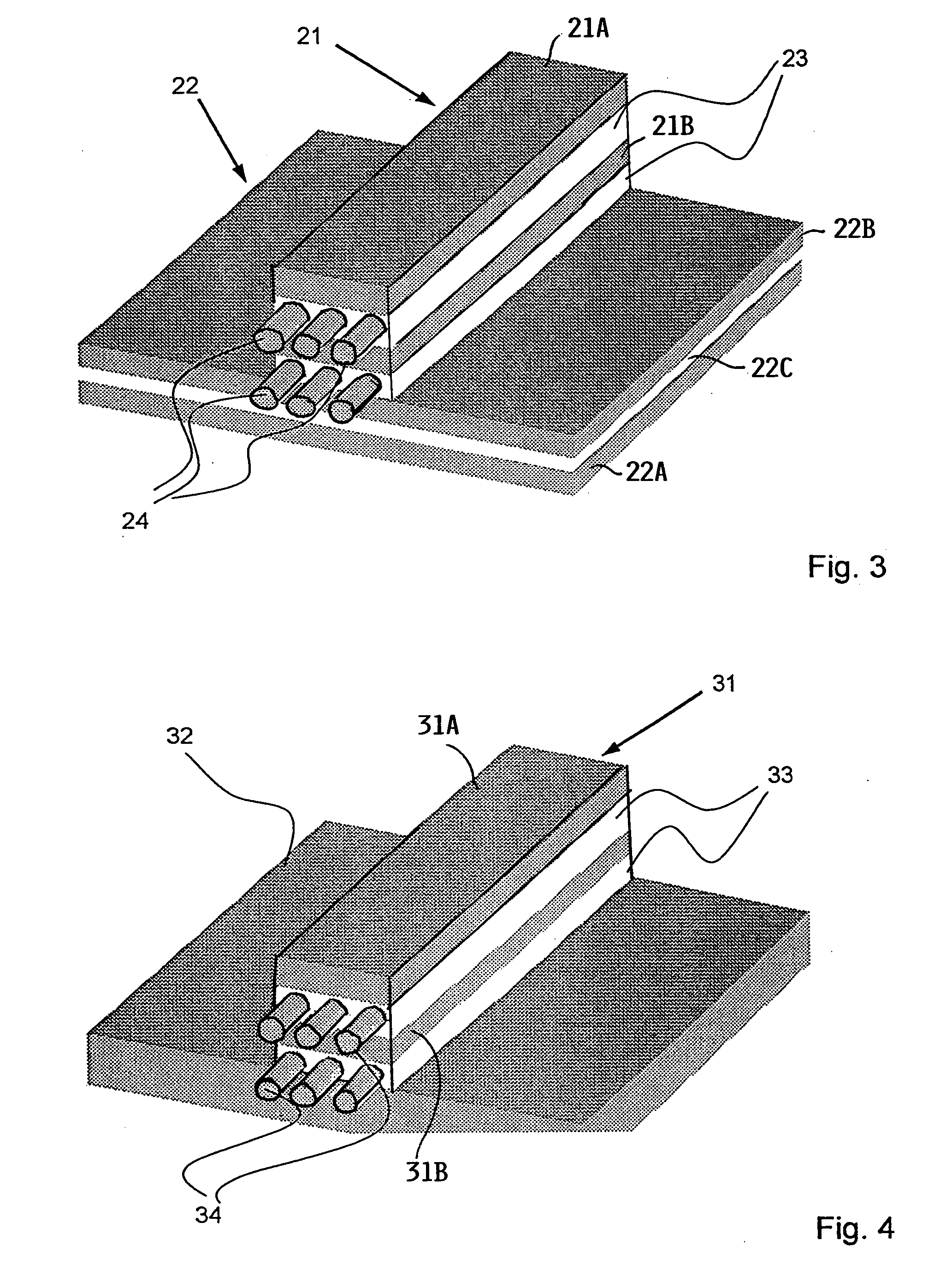

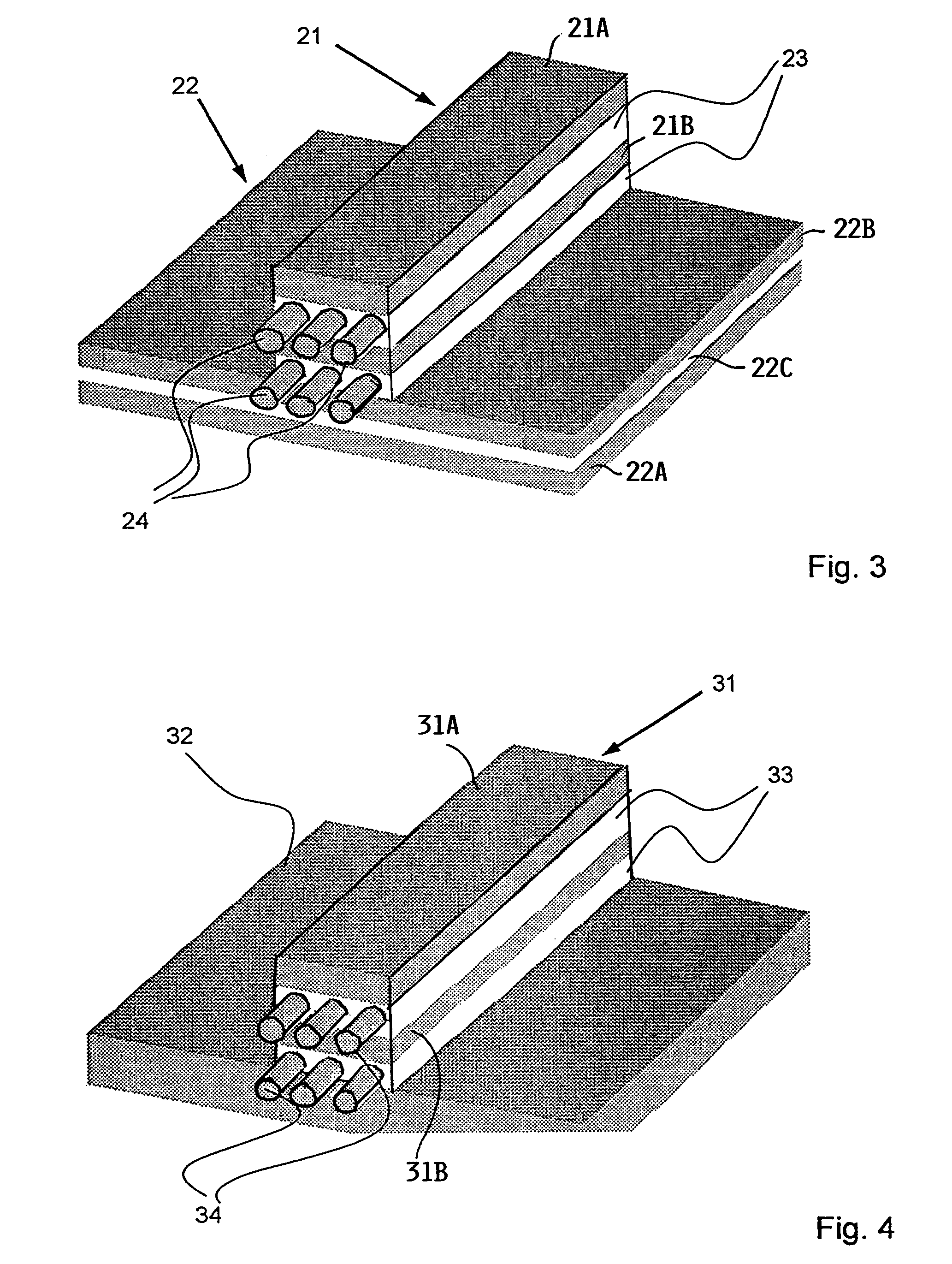

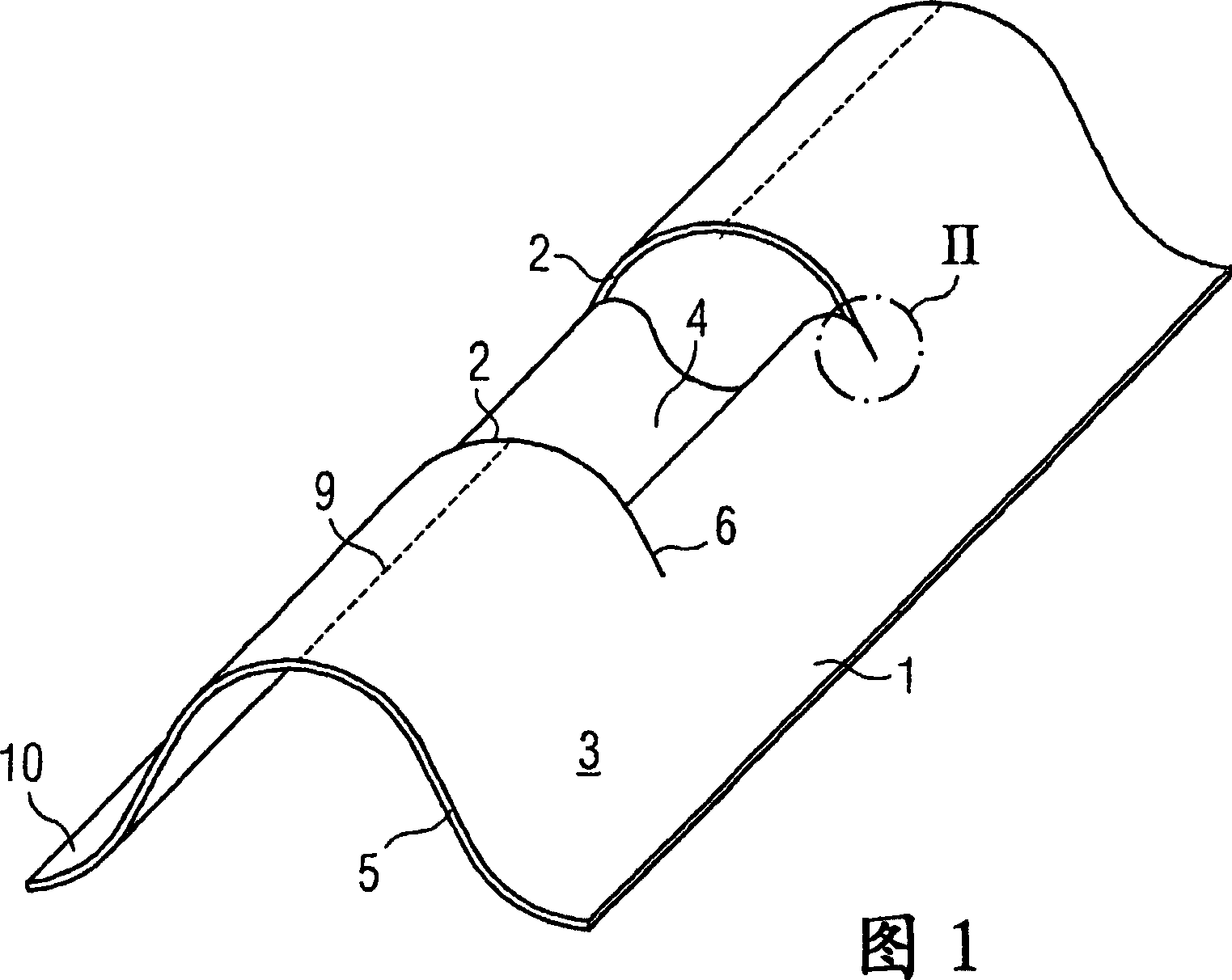

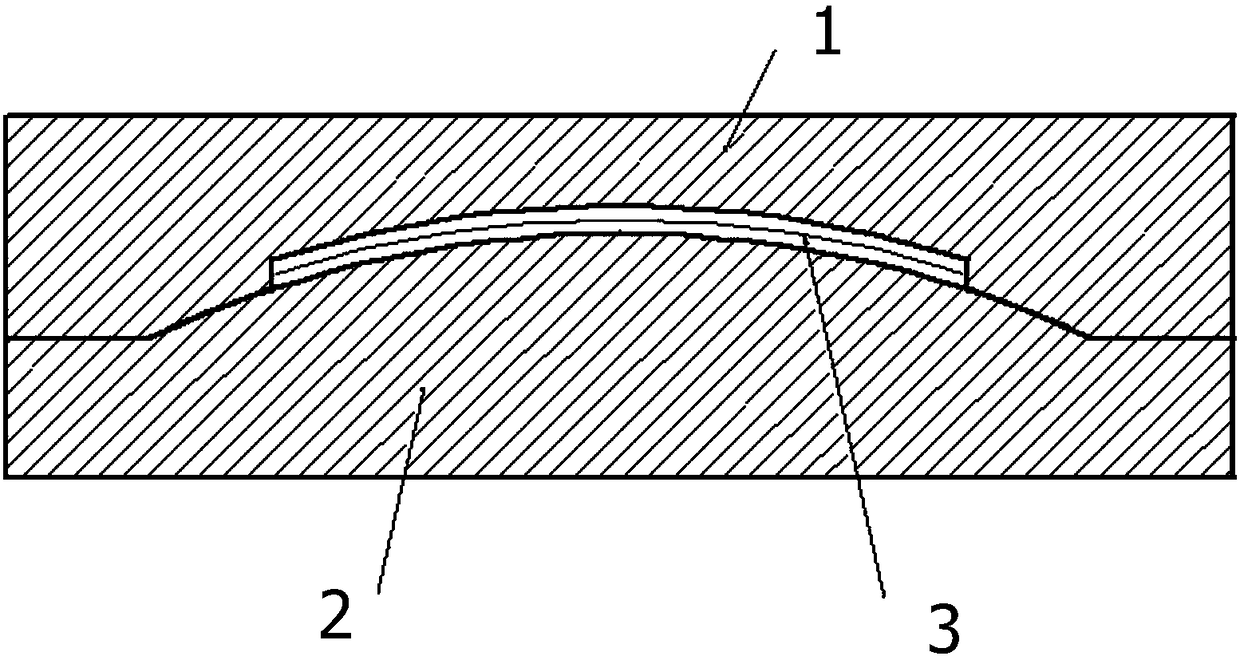

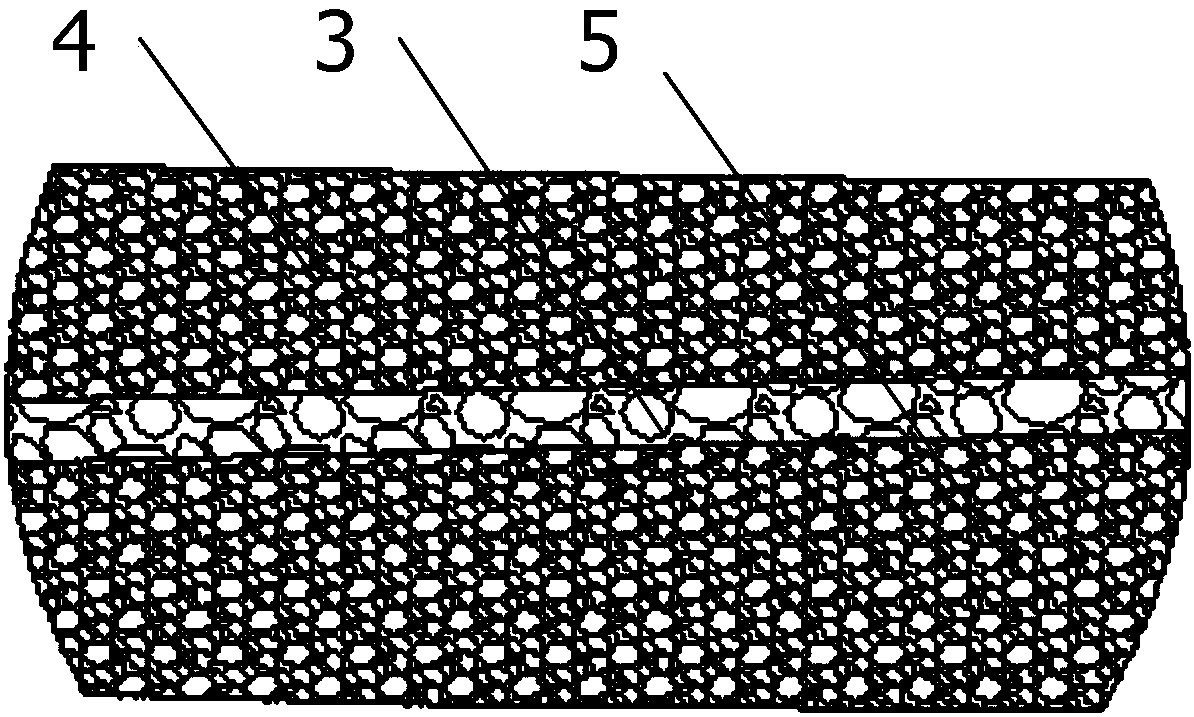

A microstructure relieved of notching

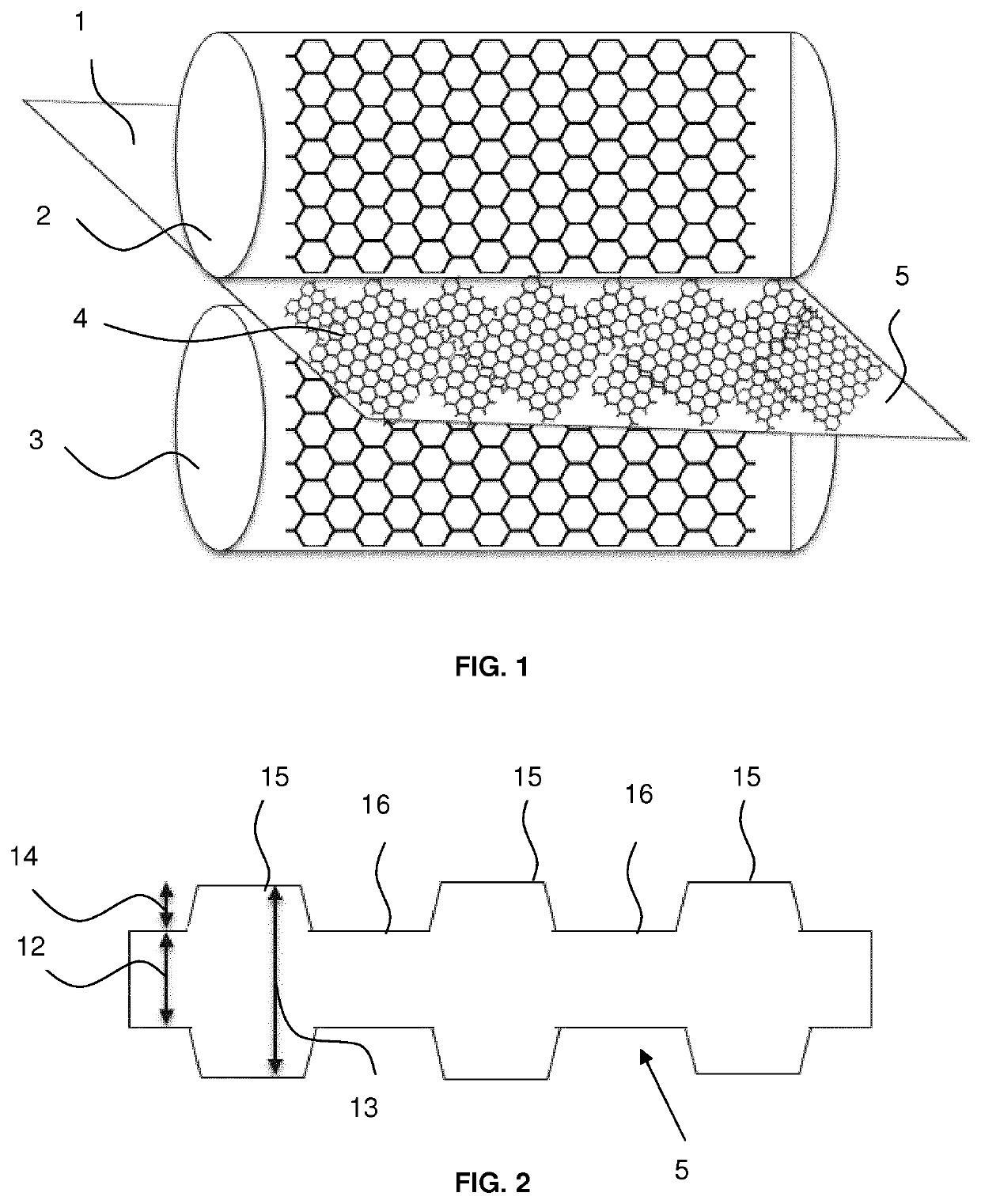

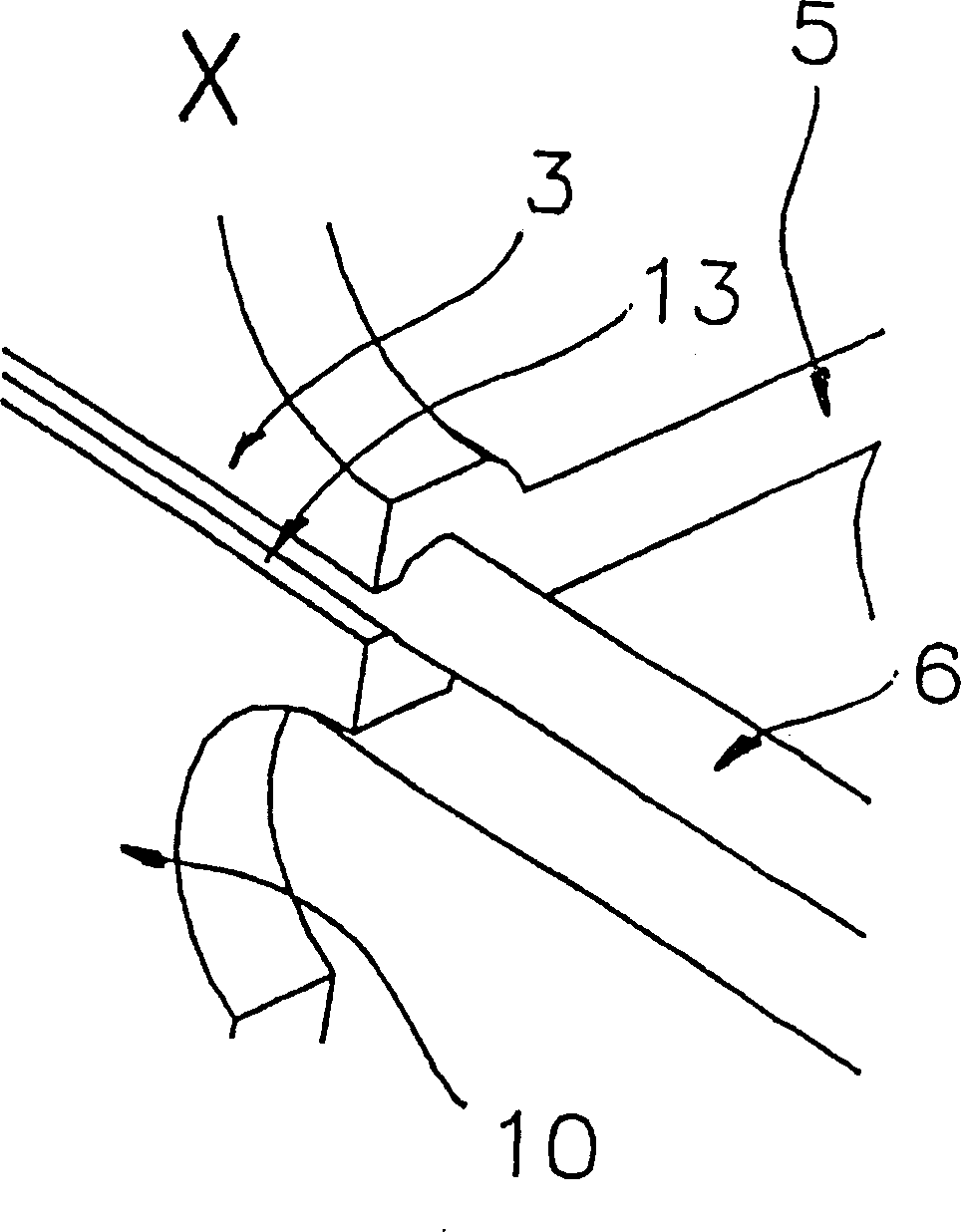

InactiveCN1798610AExtended service lifeMuch longer service lifePhysical/chemical process catalystsSilencing apparatusThin metalSurface structure

The invention relates to a thin metal sheet (1) comprising at least one slit (2) that is located in an inner region (3) of the thin metal sheet (1) and at least partially defines a microstructure (4) created on the thin metal sheet (1) and protruding out of a surface structure (5) thereof. Said thin metal sheet is characterised in that the at least one slit (2) has a recess (7) in at least one edge region (6). The invention also relates to a carrier body (21) for a component used to purify exhaust gases, said carrier body comprising a plurality of at least partially structured thin metal sheets (1) that are stacked and / or wound up in such a way that a fluid can flow through the same, at least one of said thin metal sheets (1) being embodied as above.

Owner:EMITEC EMISSIONSTECHNIK

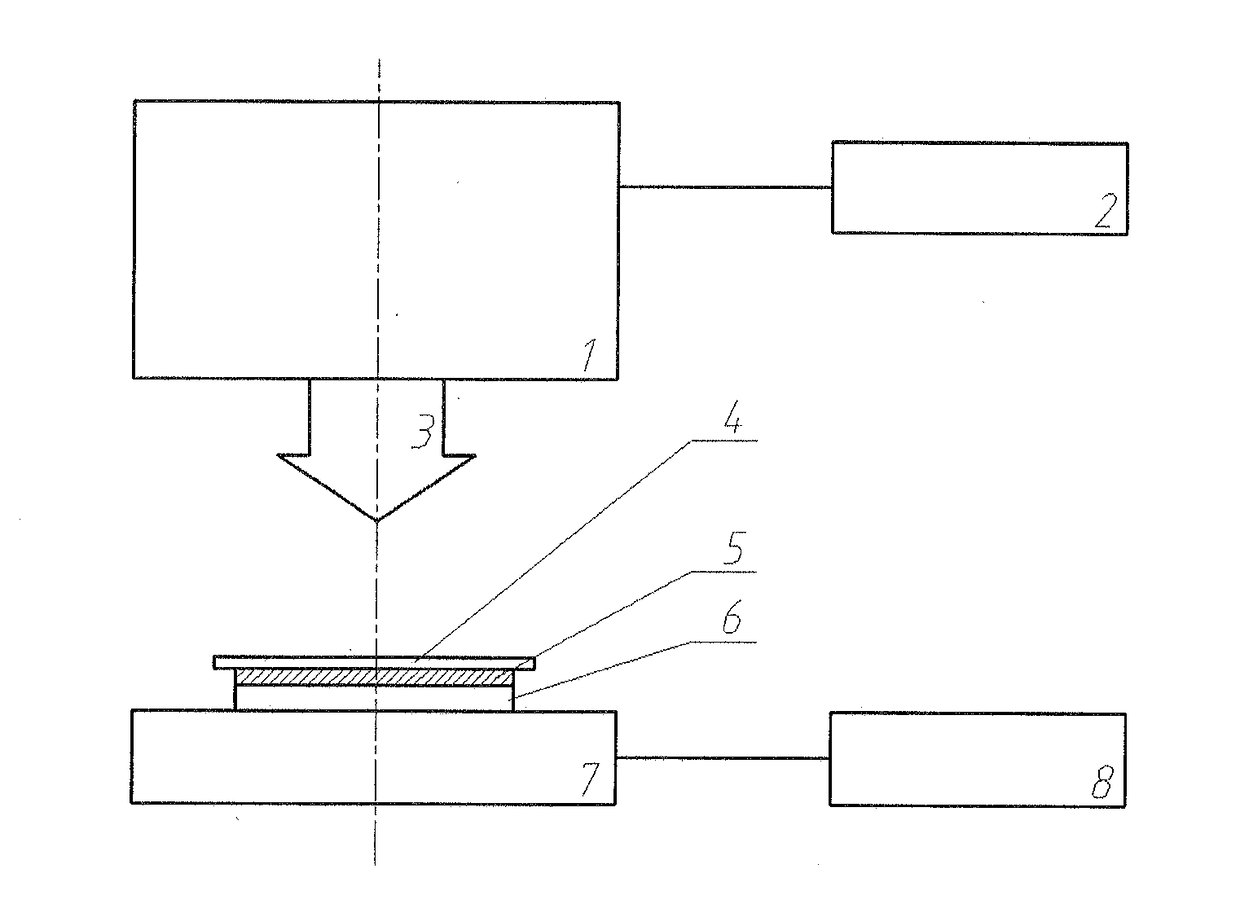

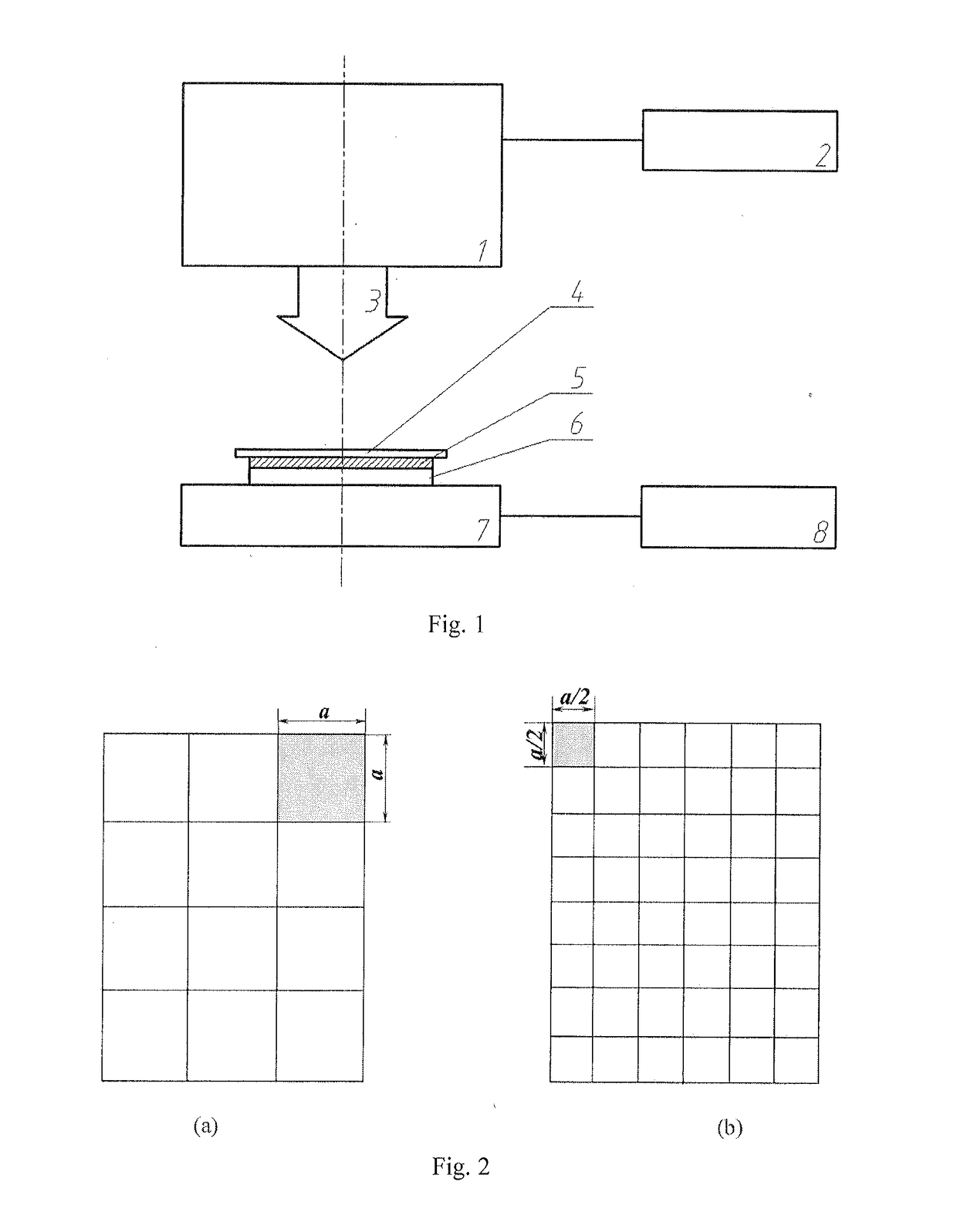

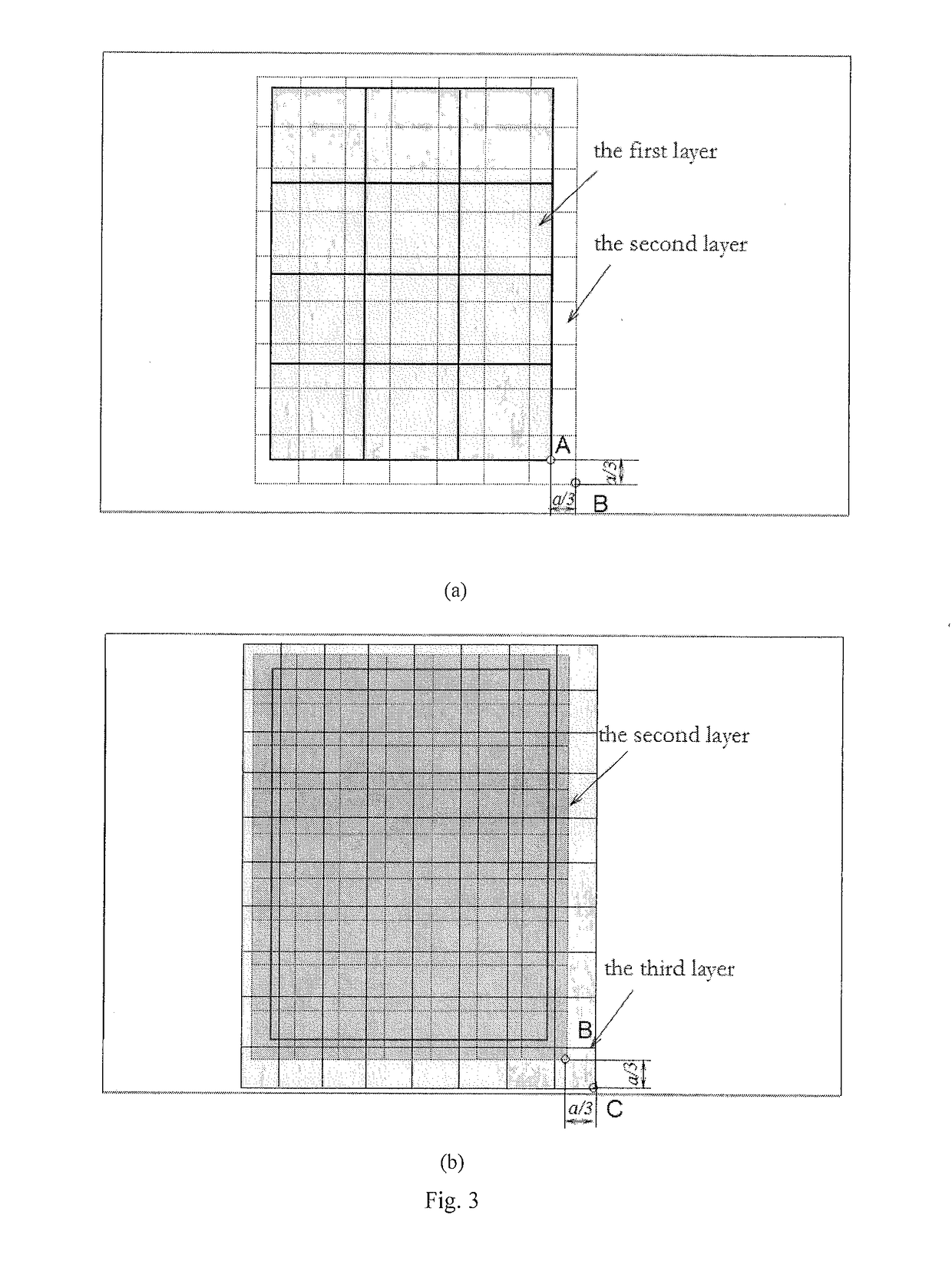

A kind of uniform strengthening methods of turbine blade subjected to varied square-spot laser shock peening with stagger multiple-layer

ActiveUS20180258509A1Increase low cycle fatigue (LCF) lifeReduce crack growth rateBlade accessoriesMachines/enginesBoundary effectsTurbine blade

A method for laser shock peening (LSP) to uniformly strengthen metallic components uses varied square-spot LSP with stagger multiple-layer. Each layer is subjected to square-spot LSP treatment, without overlapping. The length of square-spot in the first layer is larger than those in the second layer and third layers, and the length of square-spot in the second layer is equal to that in the third layer. The first layer treated by LSP is used to reduce deeper localized compressive residual stress, and the second and third layers imparted by square-spot LSP with staggered distance are used to eliminate of the boundary effect and decrease surface roughness.

Owner:JIANGSU UNIV

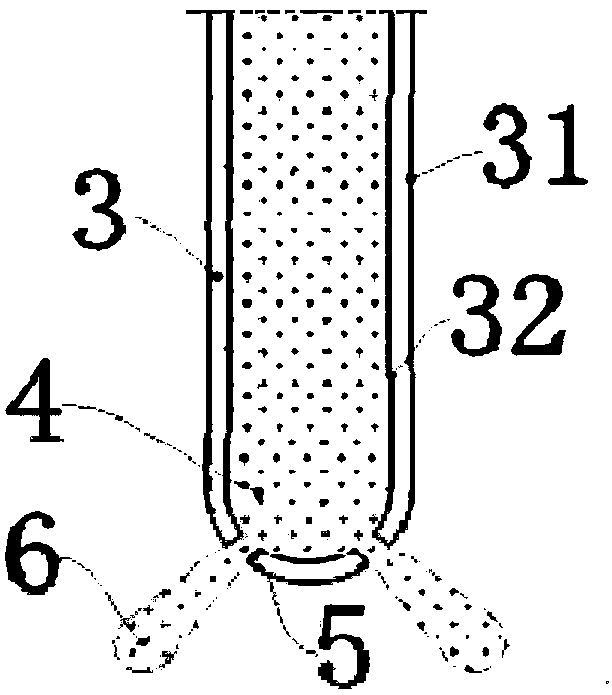

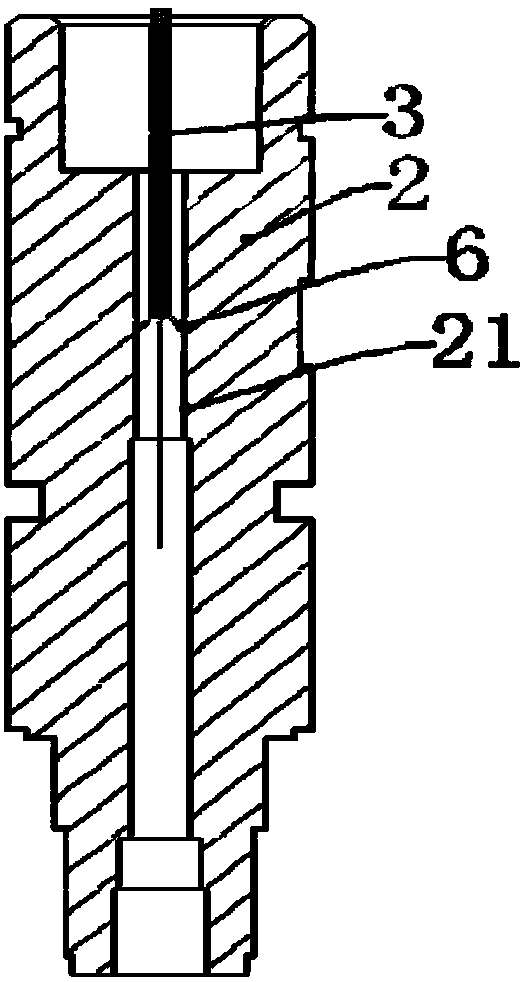

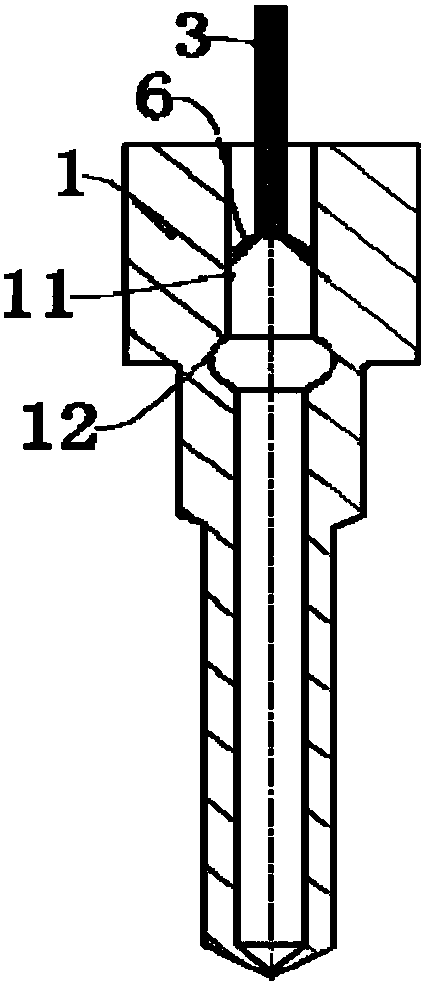

Device for strengthening inner wall surfaces of center holes of oil injectors and method for applying device

InactiveCN108533434ASolve inner surface strengthening processingImprove fatigue lifeFuel injection apparatusMachines/enginesCavitationSpray nozzle

The invention belongs to the field of surface strengthening, relates to hole wall inner surface strengthening, and particularly relates to a device for strengthening inner wall surfaces of center holes of oil injectors and a method for applying the device. The device comprises a cavitation nozzle. An inlet which is connected with high-pressure fluid is formed in one end of the cavitation nozzle, and two and more orifices are formed in the other end of the cavitation nozzle; the outer diameter of the cavitation nozzle is not larger than the inner diameters of the center holes of the oil injectors. The device and the method have the advantage that the device is suitable for strengthening treatment on the inner wall surfaces on high-precision finished components and semi-finished components and the inner wall surfaces of thin-walled components.

Owner:CHINA FIRST AUTOMOBILE

Preparation method of bulletproof ceramic entire board

ActiveCN108516831AWon't breakImproved resistance to multiple bulletsCeramic shaping apparatusArmour platesHigh pressureForming processes

The invention discloses a preparation method of a bulletproof ceramic entire board. The preparation method of the bulletproof ceramic entire board is characterized by comprising the following steps of(1) preparing a slurry: placing raw materials into a mixing and pulping device, ball milling for 10 to 24h, and uniformly stirring to obtain the slurry; (2) adopting a high-pressure grouting formingmachine for injecting the prepared slurry into a mold; (3) adopting a two-step pressurizing manner for pressurizing and grouting forming; (4) drying a ceramic green body in a drying oven at the temperature of 30 to 150 DEG C for 5 to 24 hours, and obtaining a ceramic dry blank; (5) sintering the ceramic dry blank in a sintering furnace so as to obtain a ceramic inserting plate. The method can be used for processing the layered bulletproof ceramic entire board at one step through changing a formula of the ceramic slurry and two-step forming process conditions, and is simple in preparation process and excellent in bulletproof performance.

Owner:NINGBO HATAILEI CARBIDE

Neutron and gamma ray synergistic protection glass-ceramic material and preparation method thereof

The invention discloses a neutron and gamma ray synergistic protection glass-ceramic material and a preparation method thereof. According to the technical scheme, the preparation method comprises thesteps: ball-milling, drying and crushing aluminum borate powder to obtain an aluminum borate precursor; taking 30.0 to 40.0 wt% of boron oxide, 20.0 to 30.0 wt% of bismuth oxide, 5.0 to 10.0 wt% of phosphorus oxide, 5.0 to 10.0 wt% of silicon oxide, 10.0 to 15.0 wt% of barium oxide and 5.0 to 10.0 wt% of gadolinium oxide as raw materials, mixing, melting at the temperature of 1400-1600 DEG C, quenching with water, drying and crushing to obtain a glass shielding agent containing a radiation shielding component; and mixing the aluminum borate precursor, the glass shielding agent containing the radiation shielding component and a binding agent, carrying out mechanical pressing molding, drying, carrying out heat preservation at the temperature of 1000-1500 DEG C for 60-300 min, and carrying out furnace cooling to prepare the neutron and gamma ray synergistic protection glass-ceramic material. The prepared product is high in compressive strength, excellent in shielding performance, high inhydrothermal erosion resistance, excellent in irradiation resistance and good in thermal shock resistance.

Owner:WUHAN UNIV OF SCI & TECH

Pneumatic tire

InactiveUS20140048192A1Improve adhesionImprove the immunityWithout separate inflatable insertsWith separate inflatable insertsAdductPolyprenol

Provided is a pneumatic tire including an inner liner on a tire inner side of a carcass ply laid between a pair of bead parts, the inner liner having a first layer made of a first polymer composition, the first polymer composition containing not less than 0.5 parts by mass and not more than 70 parts by mass of at least one selected from the group consisting of liquid polyisoprene, a maleic anhydride adduct of liquid polyisoprene, and a maleic acid monomethyl ester adduct of liquid polyisoprene, relative to 100 parts by mass of a styrene-isobutylene-styrene triblock copolymer.

Owner:SUMITOMO RUBBER IND LTD

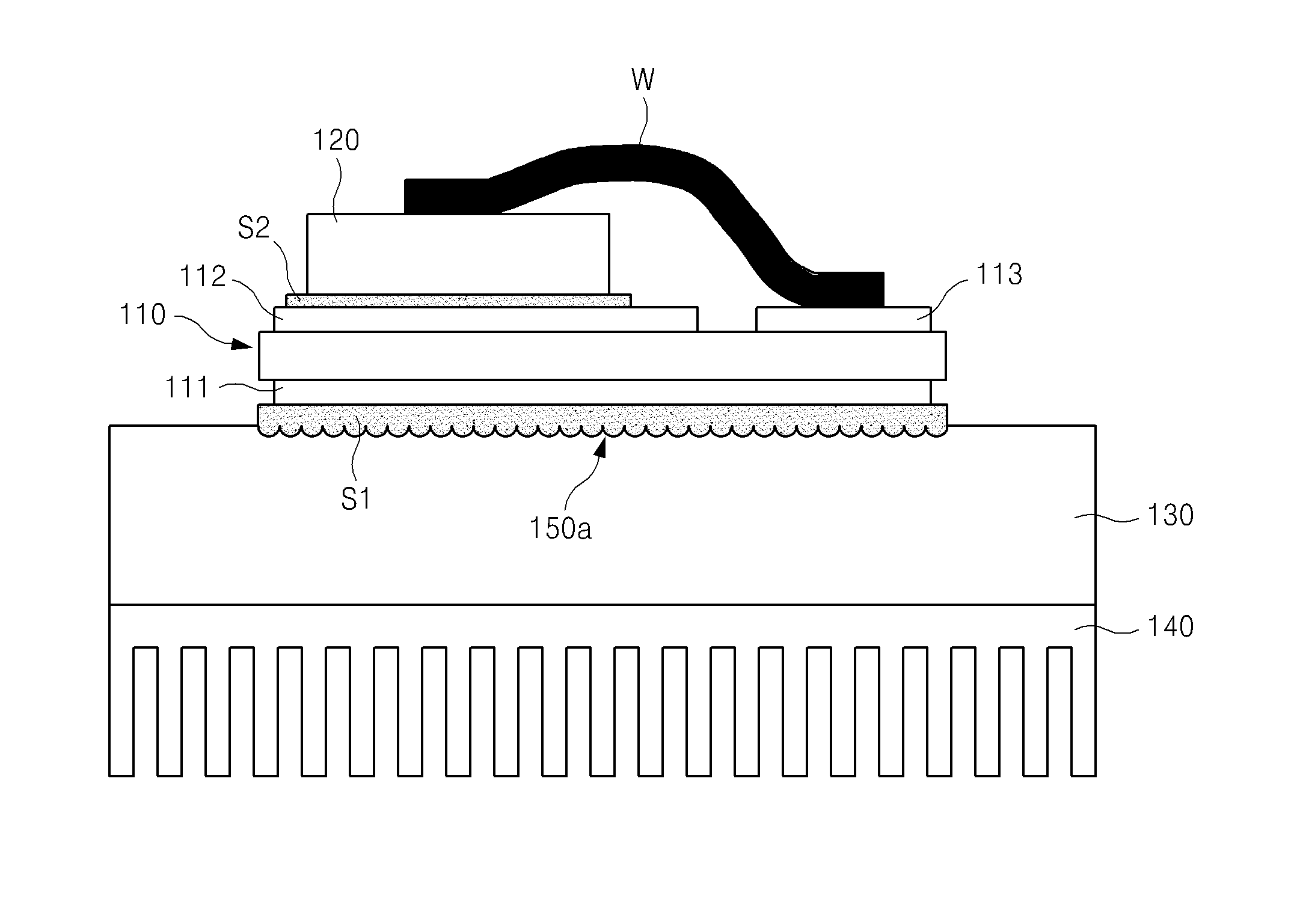

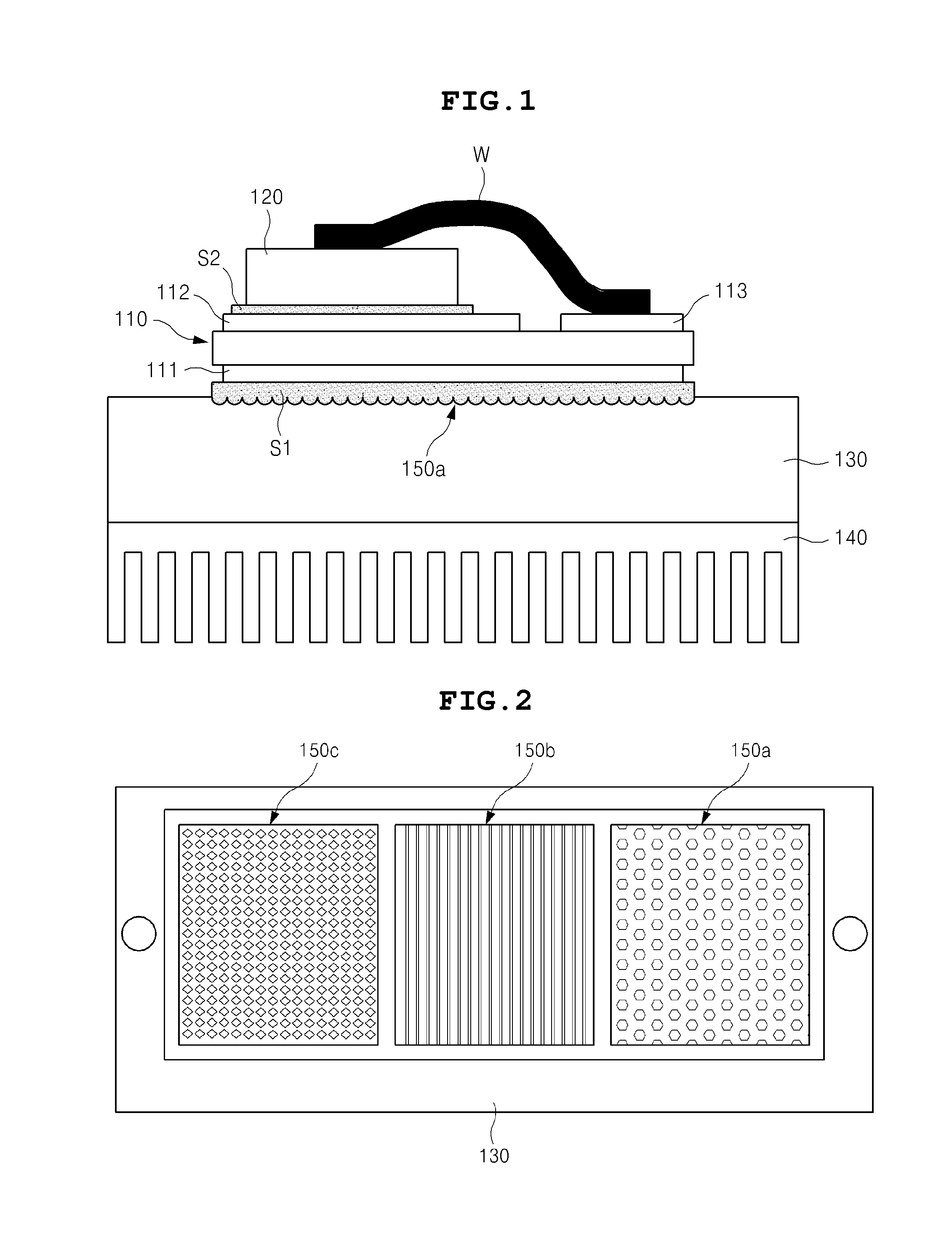

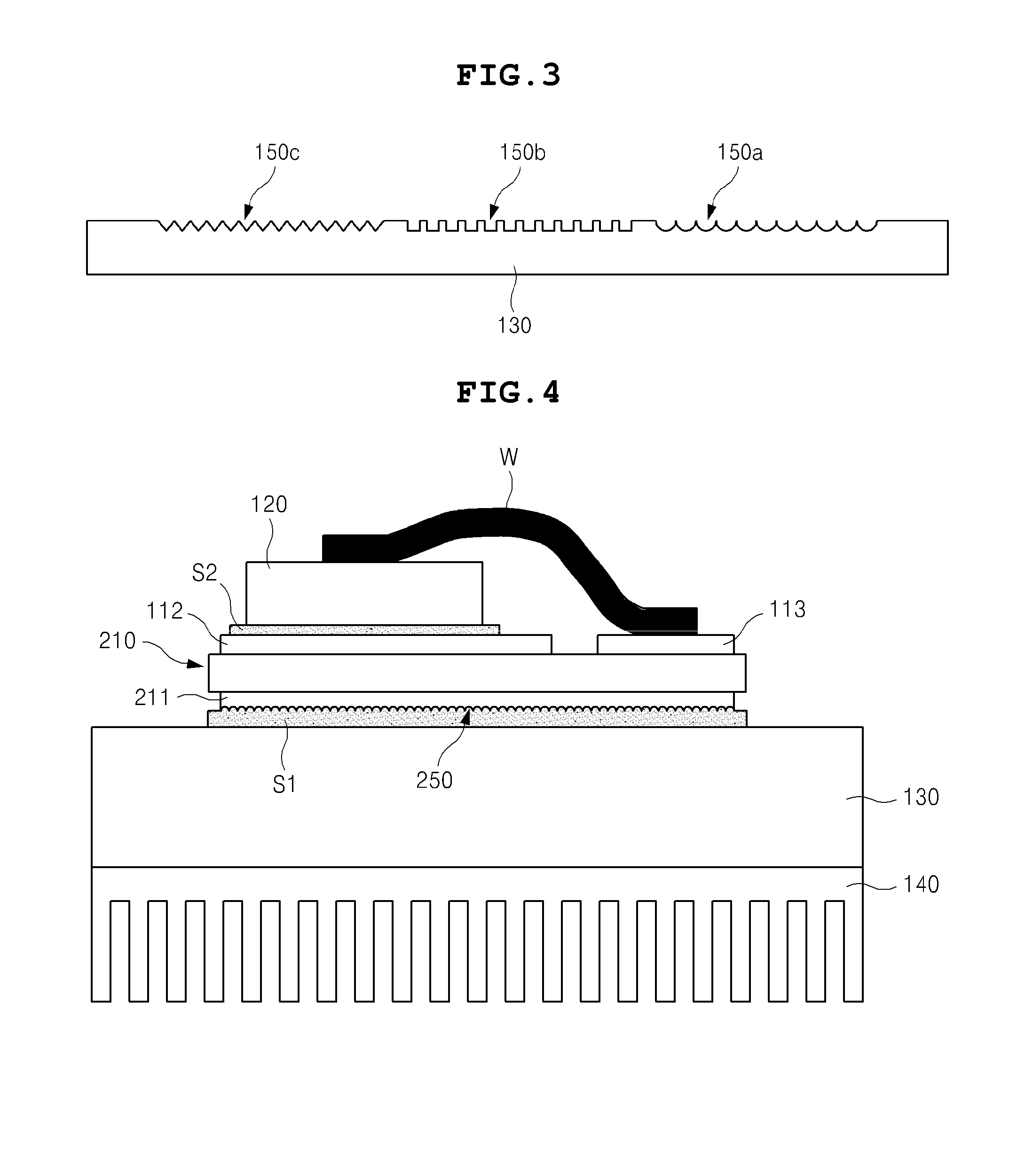

Power semiconductor module

InactiveUS20140138839A1Long-term reliabilityEasy dischargeSemiconductor/solid-state device detailsSolid-state devicesEngineeringSemiconductor

Disclosed herein is a power semiconductor module including a substrate having a first metal conductive track formed on one surface thereof, and a base plate made of a metal and solder-joined to the substrate in the first metal conductive track region, wherein a first uneven pattern is formed in the solder junction region formed between the substrate and the base plate.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

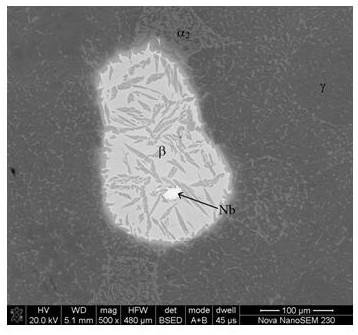

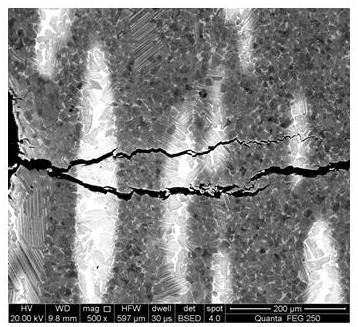

High-fracture-toughness two-state titanium-aluminum-based composite material and preparation method thereof

The invention discloses a high-fracture-toughness two-state titanium-aluminum-based composite material and a preparation method thereof. The high-fracture-toughness two-state titanium-aluminum-based composite material is prepared from, by atomic percentage components, 2-5% of Nb element powder and balance Ti-XAl-YNb-0.4W (at.%) prealloyed powder, wherein X is 40-50, and Y is 5-10. The toughened high Nb-TiAl composite material containing plastic Nb particles is prepared through a powder metallurgy technology and canned forging, the preparation method is simple and easy to operate, and the preparation process is simple. The structure of the prepared two-state titanium-aluminum-based composite material contains fine gamma-TiAl matrix structure and the Nb particles of which the sizes are abot100 micros and randomly distributed in the matrix structure, and the Nb particles are composed by pure Nb phases and beta phases and strip-shaped omega phases which surround the pure Nb phases, so that the crack propagation in the titanium-aluminum-based alloy is effectively delayed, thereby improving the fracture toughness, strength and plasticity of the composite material, and therefore the high-fracture-toughness two-state titanium-aluminum-based composite material is expected to be used for aerospace high-temperature structural components, and the application range of the titanium-aluminum-based composite material is effectively widened.

Owner:CHONGQING UNIV

Strip, method for manufacturing the same, and method for manufacturing pneumatic tire

InactiveUS20140190619A1Increased durabilityImprove propertiesWithout separate inflatable insertsSpecial tyresClay mineralsThermoplastic elastomer

The present invention is a strip of a thermoplastic elastomer composition to be wound spirally on a cylindrical drum to form an inner liner for a tire. The strip is composed of a layer stack of a first layer made of a thermoplastic elastomer composition containing 0.1 part by mass to 50 parts by mass of an organic derivative of clay mineral relative to 100 parts by mass of a styrene-isobutylene-styrene triblock copolymer, and a second layer made of a thermoplastic elastomer composition containing at least one of a styrene-isoprene-styrene triblock copolymer and a styrene-isobutylene diblock copolymer. The strip has a strip main body with a thickness of 0.05 mm to 1.0 mm and ear portions with a thickness thinner than the thickness of the strip main body and a width of 0.5 mm to 5.0 mm disposed on opposite sides thereof.

Owner:SUMITOMO RUBBER IND LTD

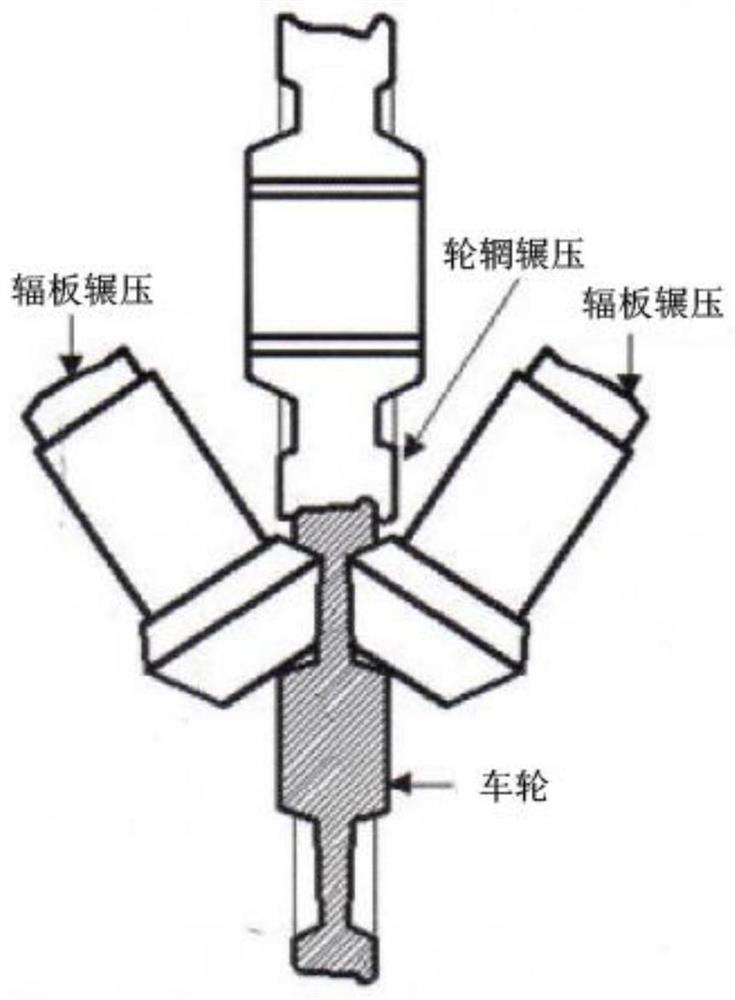

Material for locomotive wheels

PendingCN113667901AInhibit growthInhibits deformation recrystallization of austenite and prevents growthEngineeringMechanical engineering

The invention belongs to the field of locomotives, and discloses a material for locomotive wheels. The material comprises the following microalloy components of, in percentage by mass, 0.57 to 0.70 of C, 0.50 to 1.10 of Mn, less than or equal to 0.40 of Ni, less than or equal to 0.06 of Ti, less than or equal to 0.06 of V, and less than or equal to 0.30 of Cr. Compared with ER8 and ER9 materials which are frequently used in China at present, the material for the locomotive wheels has high yield strength, tensile strength, plastic deformation resistance and rolling contact fatigue resistance, the hardness of a rim is improved to 265 HBW or above under the same condition, in addition, microalloy elements Nb and Ti are added into steel, the microalloy element V is combined for use, on one hand, deformation recrystallization of austenite can be inhibited and growth of crystal grains of the austenite can be prevented in the hot working process, on the other hand, the precipitation strengthening effect of Nb, V and Ti can be exerted through strain induced precipitation of carbon-nitrogen compounds of the austenite, so that the crack initiation resistance of the material is improved, crack propagation is delayed, the service stability of the whole life cycle is promoted, and the service life and the operation mileage are prolonged.

Owner:ZHIBO LUCCHINI RAILWAY EQUIP +1

Carbon fiber/epoxy resin composite material for bicycle and preparing method thereof

The invention discloses a carbon fiber / epoxy resin composite material for a bicycle. The carbon fiber / epoxy resin composite material is prepared from, by weight, 1-3 parts of carbon fiber, 30-50 parts of epoxy resin, 2-5 parts of floating bead, 3-8 parts of gelatin, 2-3 parts of medical stone powder, 1.5-3 parts of coupling agent, 2-5 parts of curing agent and 1-2 parts of accelerant. The invention further discloses a preparing method of the composite material. The composite material is high in heat and abrasion resistance, high in specific strength and excellent in impact resistance and has certain corrosion resistance.

Owner:陆志强

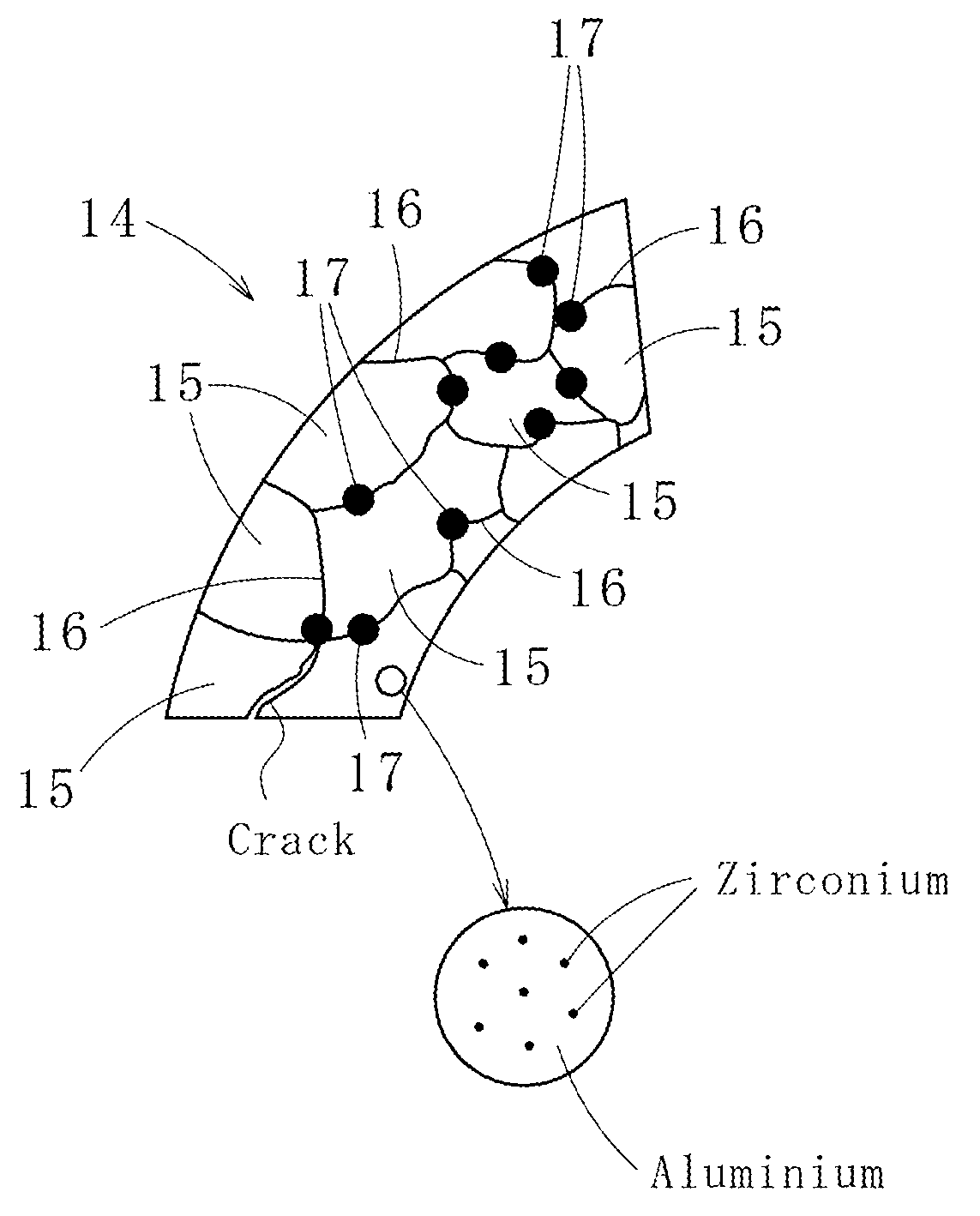

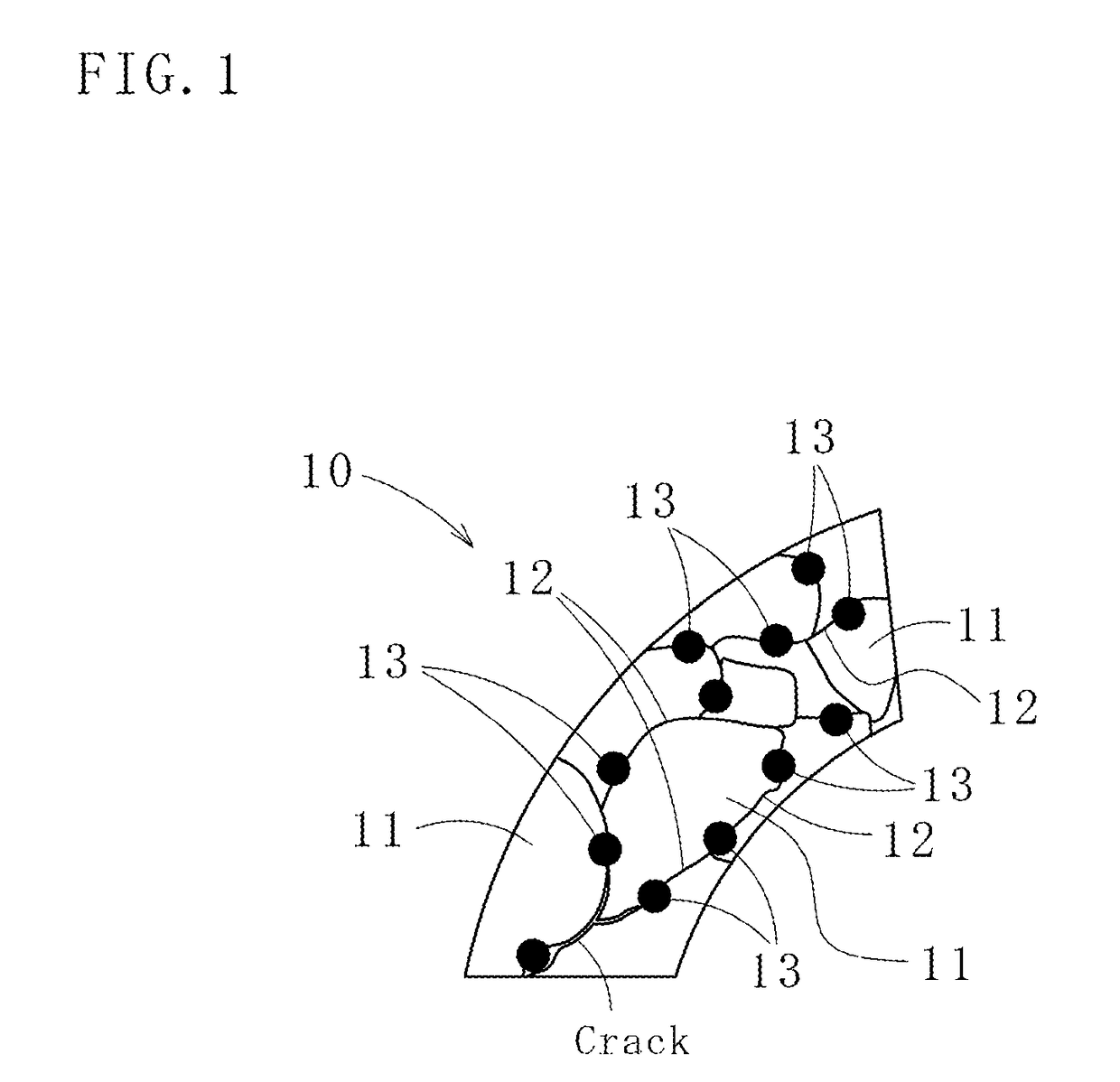

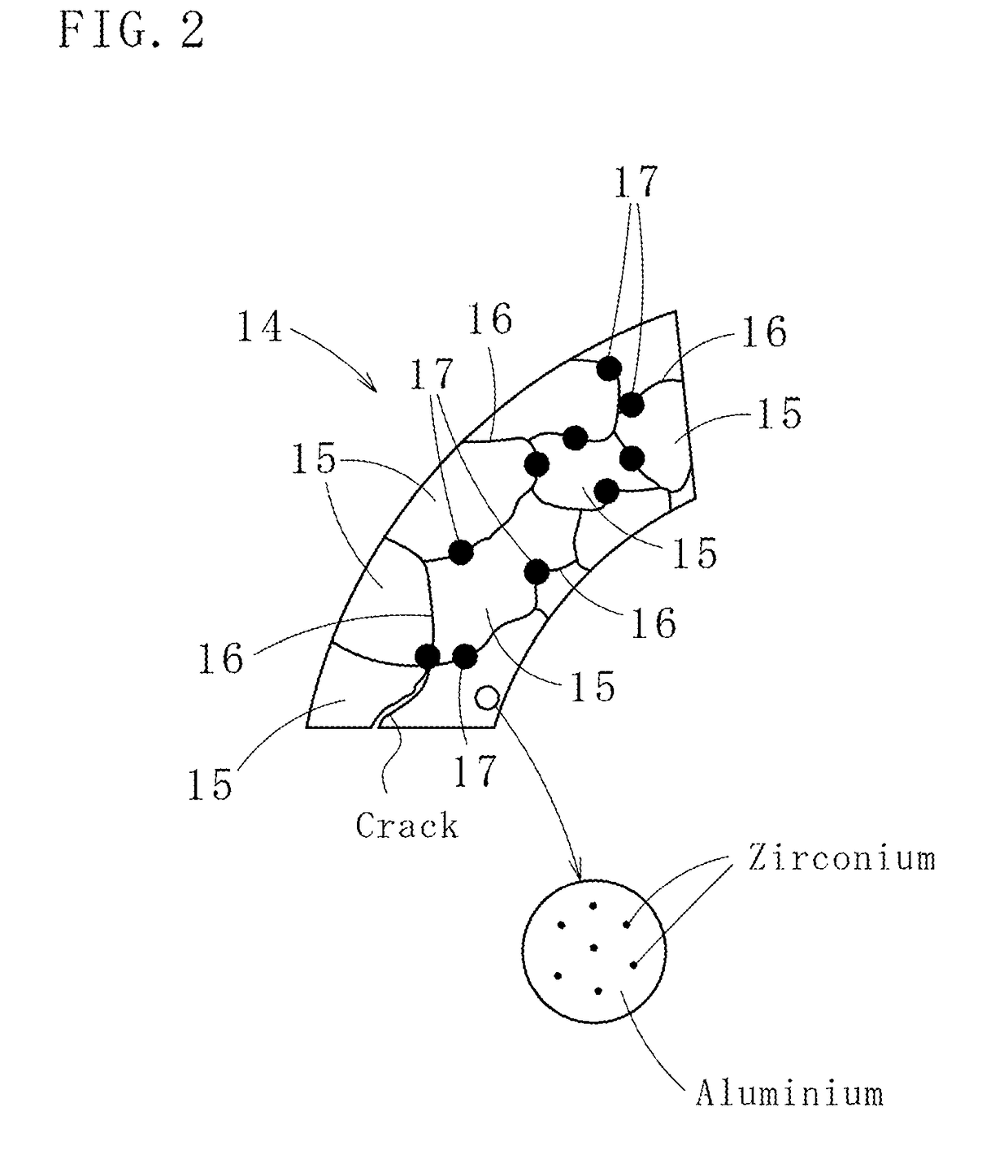

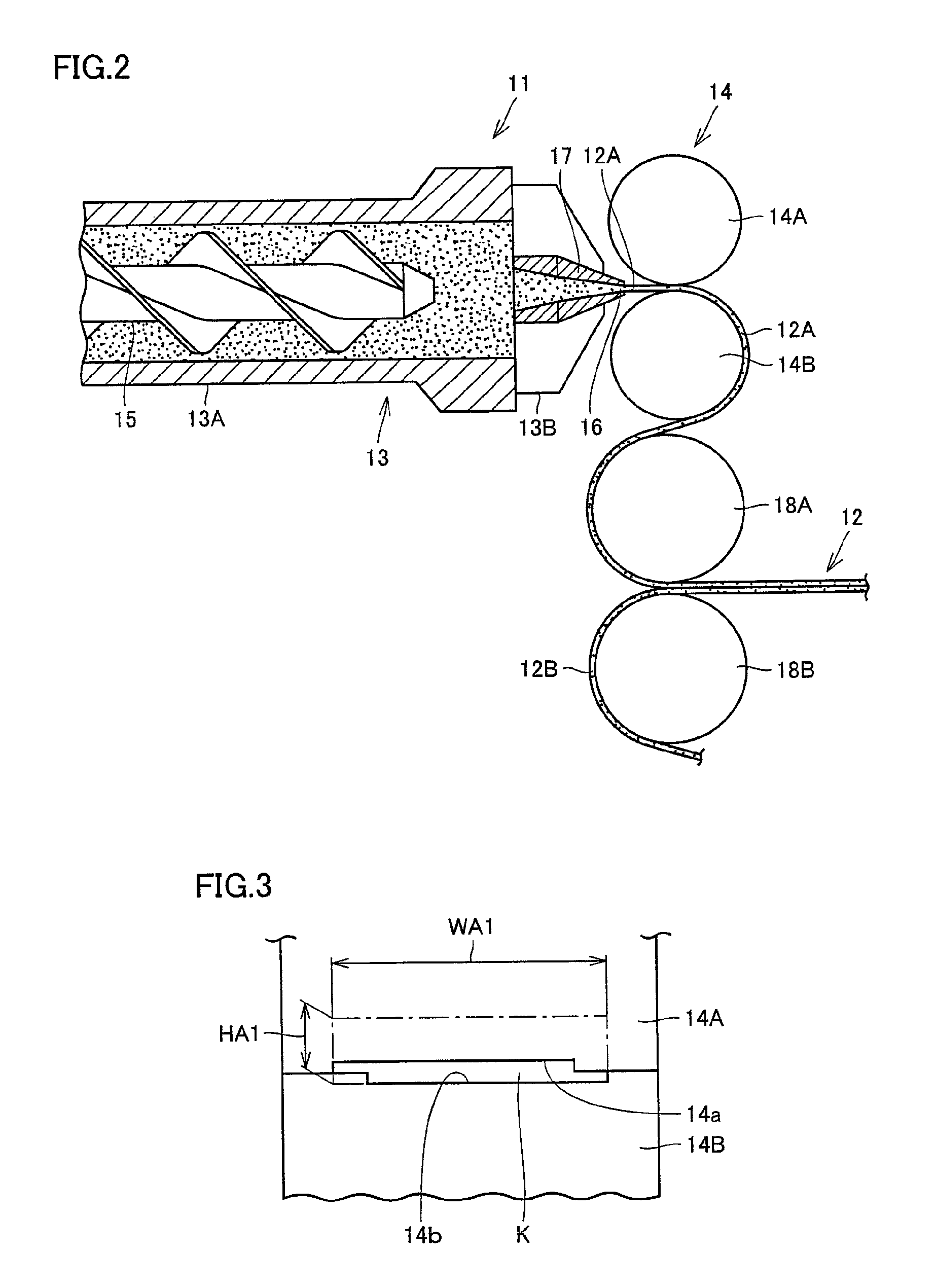

Aluminum-based conductive material and electric wire and cable using the same

ActiveUS9779849B2Improve reliabilityReduce operating costsMaterial nanotechnologyConductive materialConductive materialsNanometre

An aluminium-based conductive material used in a driving part of robots or various devices and used, for example, in a wiring that is loaded with cyclic bending, as well as an electric wire and a cable using the same, contains 0.1 to 1.0 mass % of scandium and further contains, as a rest part, aluminium and unavoidable impure substances and is formed of a metal texture 10 having crystal grains 11 with an average grain size of 2 μm or less and aluminium-scandium series nanoprecipitates generated in a grain boundary 12 of the crystal grains 11. Further, it is preferable that the metal texture 10 contains the crystal grains 11 of 1 μm or less at a cross sectional ratio of 15% or more.

Owner:DAIDEN CO LTD +2

Lightweight structure especially for an aircraft and method for making such a structure

ActiveUS7753312B2High damage toleranceExcellent fatigue propertiesThin material handlingFuselagesSkin surfaceMechanical engineering

Owner:AIRBUS OPERATIONS GMBH

Strip, method for manufacturing the same, and method for manufacturing pneumatic tire

InactiveUS9149996B2Step differenceAir-in can be eliminatedWithout separate inflatable insertsSynthetic resin layered productsElastomerThermoplastic elastomer

The present invention relates to a ribbon-shaped strip used for an inner liner and a method for manufacturing the strip. The strip is to be wound on an outer circumferential surface of a tire molding drum or a core body to form an inner liner. The strip has an inner layer disposed inwardly in a tire and an outer layer disposed outwardly in the tire. The inner layer and the outer layer are bonded to each other with their ends offset by 0.5 mm to 30 mm in a widthwise direction. At least one layer of the inner layer is formed of an elastomer composition containing a styrene-isobutylene-styrene block copolymer. At least one layer of the outer layer is formed of a thermoplastic elastomer composition.

Owner:SUMITOMO RUBBER IND LTD

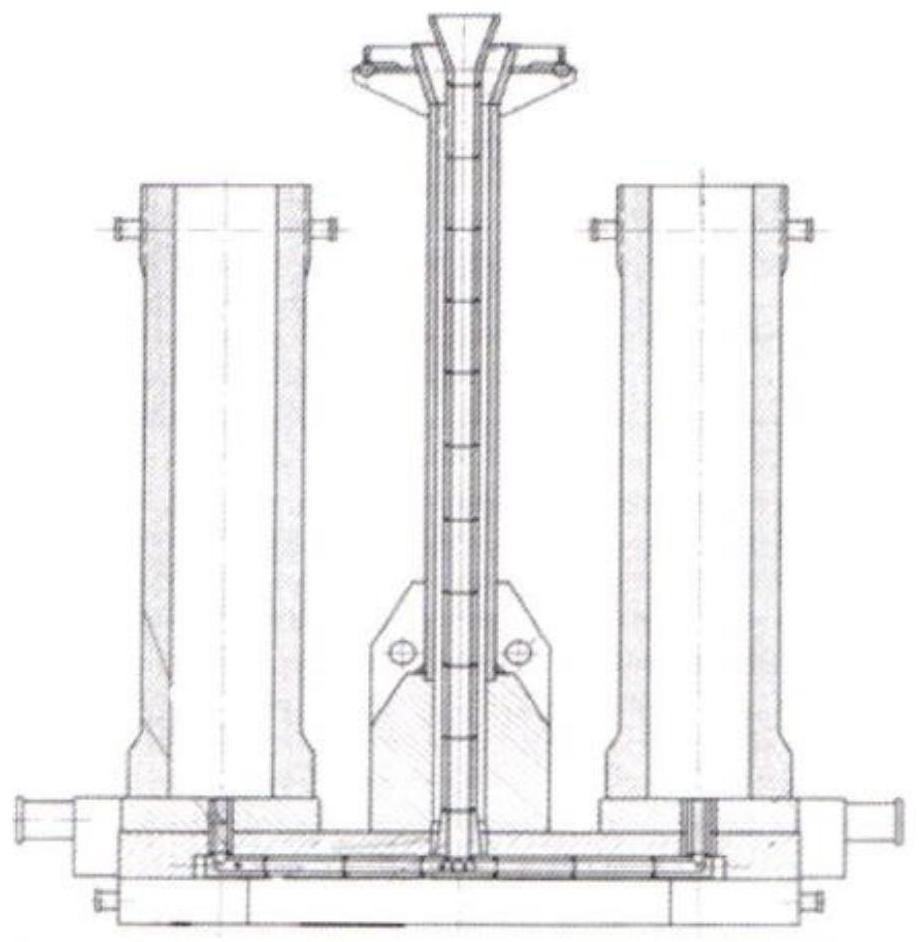

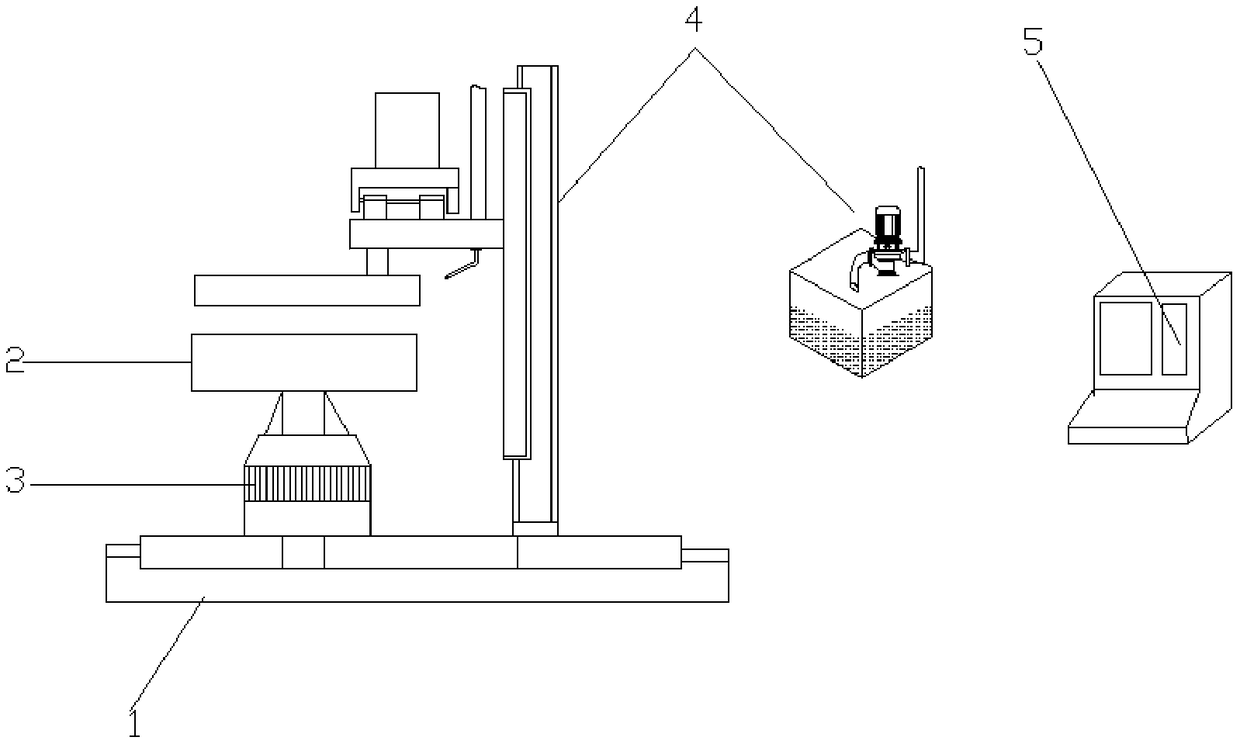

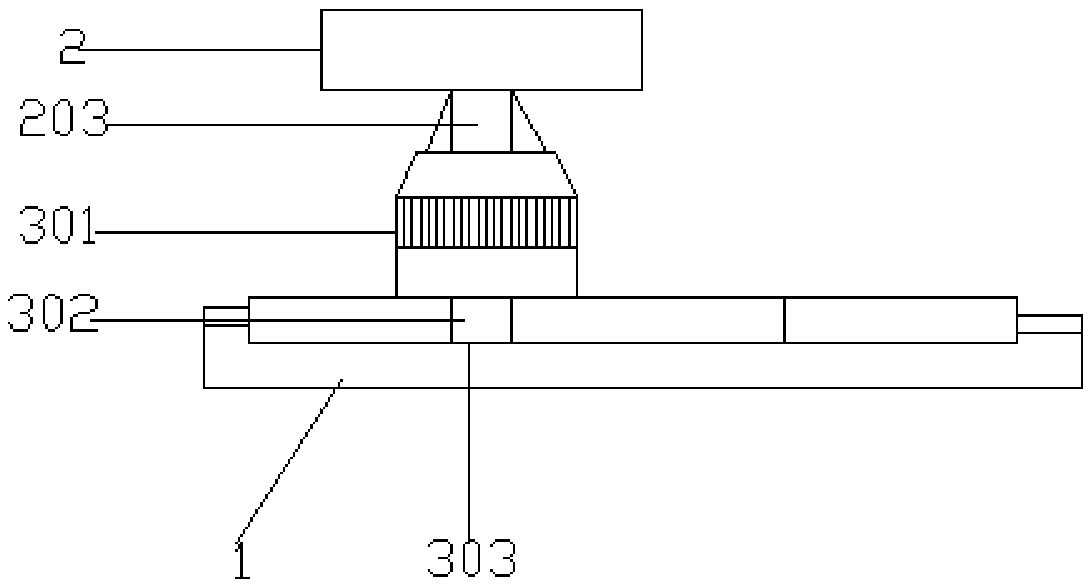

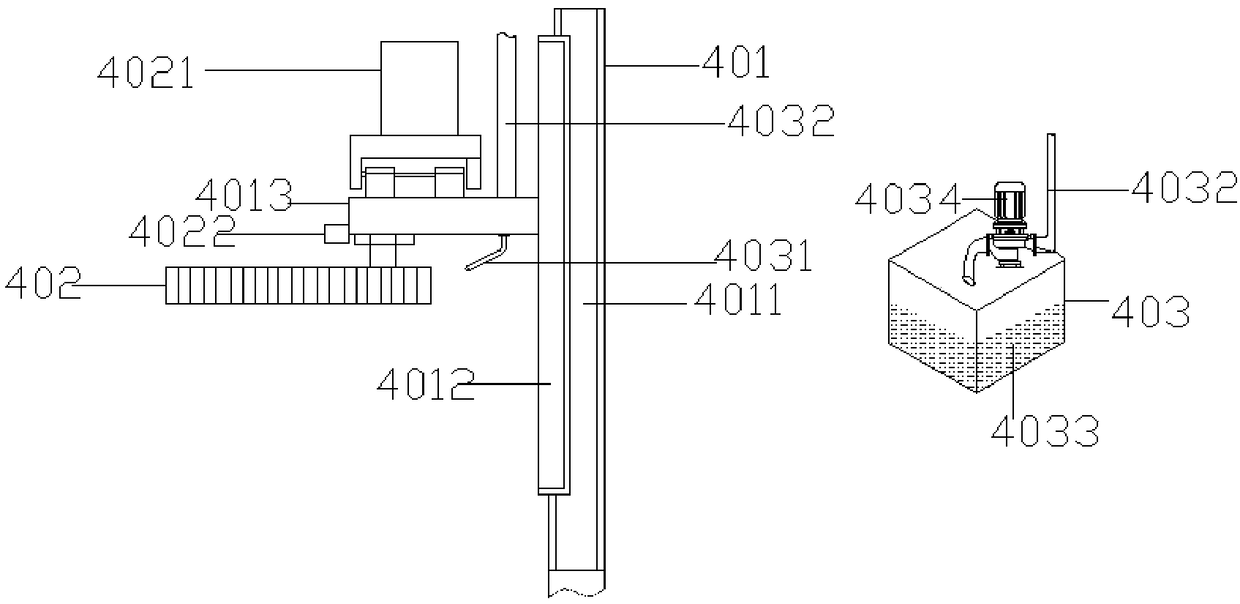

Integral gear quenching equipment and process thereof

InactiveCN108774680ASimple methodEasy to operateFurnace typesHeat treatment process controlMonitoring systemGear tooth

The invention discloses integral gear quenching equipment and a process thereof. The integral gear quenching equipment comprises a base and a gear positioning device, wherein the gear positioning device is located on the base and is used for fixing a gear, gear quenching equipment is arranged above the gear positioning device, the gear quenching equipment comprises a longitudinal adjustment fixedseat, a heating device and an oil spraying and cooling device which are arranged on the longitudinal adjustment fixed seat and are matched with a tooth groove of the gear, the heating device and the oil spraying and cooling device are connected with a gear monitoring system which is used for monitoring the gear processing state in real time by virtue of a controller, the gear is fixed to a platform on the base by the gear positioning device, and the position and the precision of the heating device and the oil spraying and cooling device are controlled by the controller according to quenching depth requirements so as to integrally quench the load surface of the gear. The gear quenching equipment has the advantages of integrality in quenching and simple method, the product quality and yieldare obviously increased, and processed gear teeth have the advantages of high strength, good wear resistance, long service life and high bearing capacity.

Owner:苏州远征魂车船技术有限公司

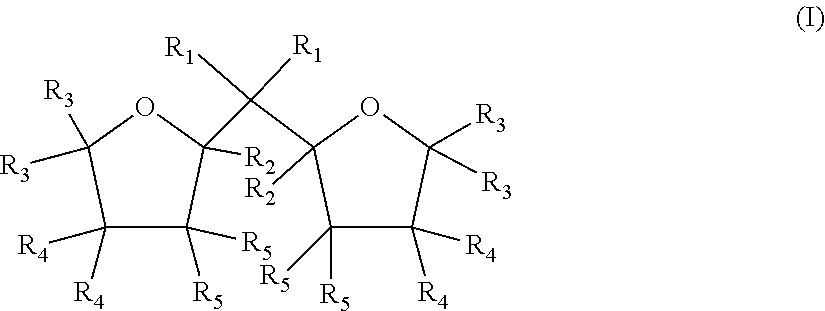

Polyethylene composition for high pressure resistant pipes with improved homogeneity

PendingUS20210317290A1Increasing complex viscositySuitable processabilityRigid pipesPolymer sciencePipe fitting

The present invention relates to a polyethylene composition comprising a base resin having a density of from 952.0 kg / m3 to 960.0 kg / m3, determined according to ISO 1183, wherein the polyethylene composition has a melt flow rate MFR21 (190° C., 21.16 kg), of from 1.0 to 7.5 g / 10 min, determined according to ISO 1133, a complex viscosity at a frequency of 0.05 rad / s eta0.05 of from 750 kPa #s to 1900 kPa #s, determined according to ISO 6721-1 and ISO 6721-10, and a white spot rating of not more than 12.0, determined according to ISO 18553, a polyethylene composition obtainable by a multi-stage process, a process for producing said polyethylene composition, an article, such as a pipe or pipe fitting, comprising said polyethylene composition and the use of said polyethylene composition for the production of an article.

Owner:BOREALIS AG

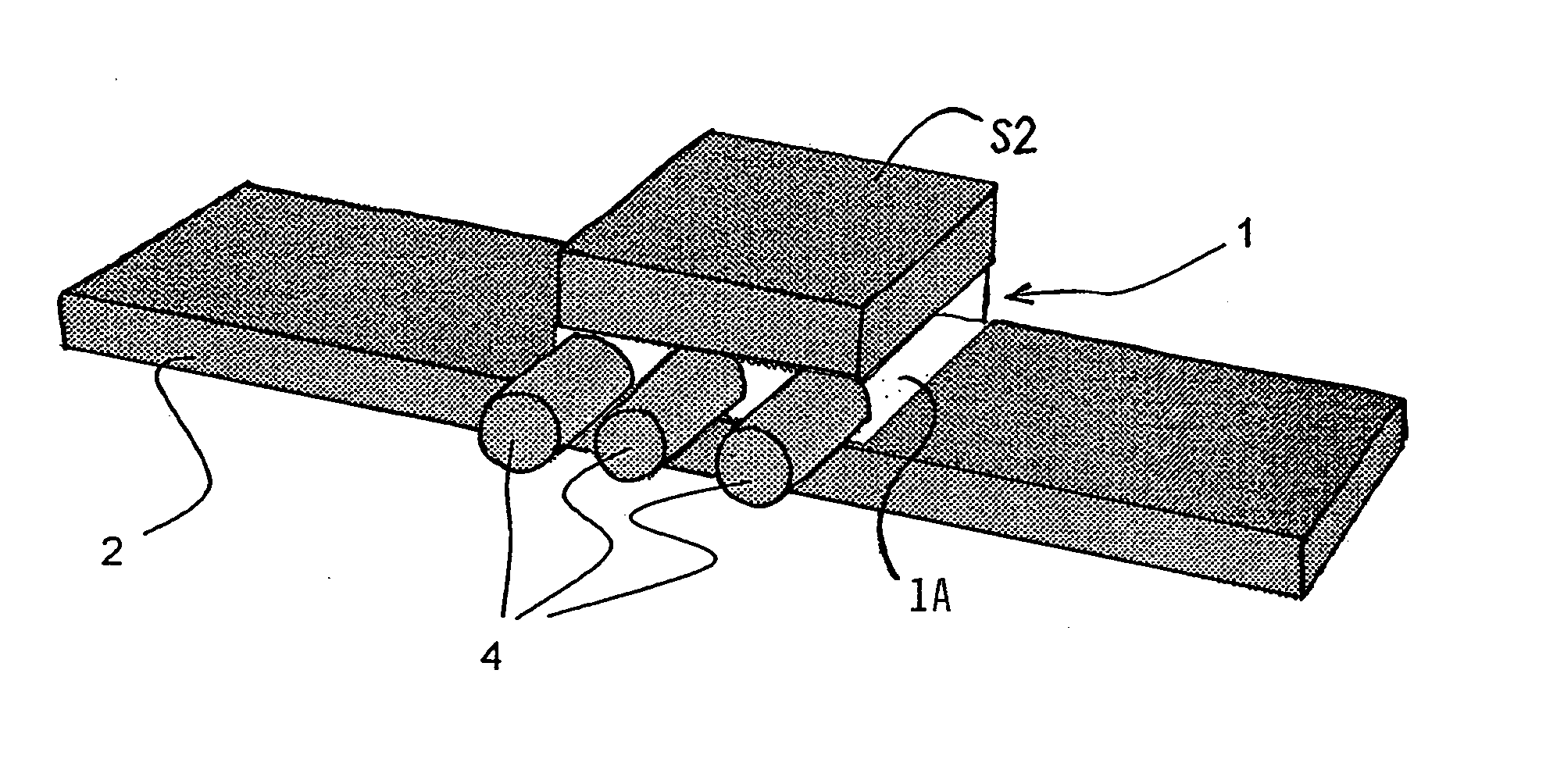

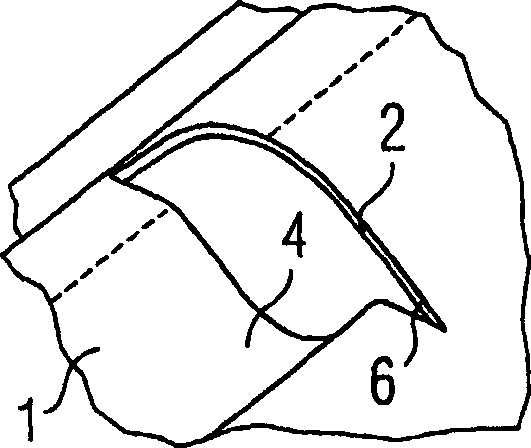

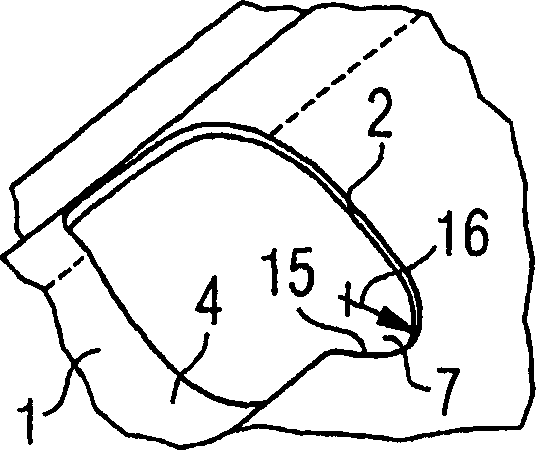

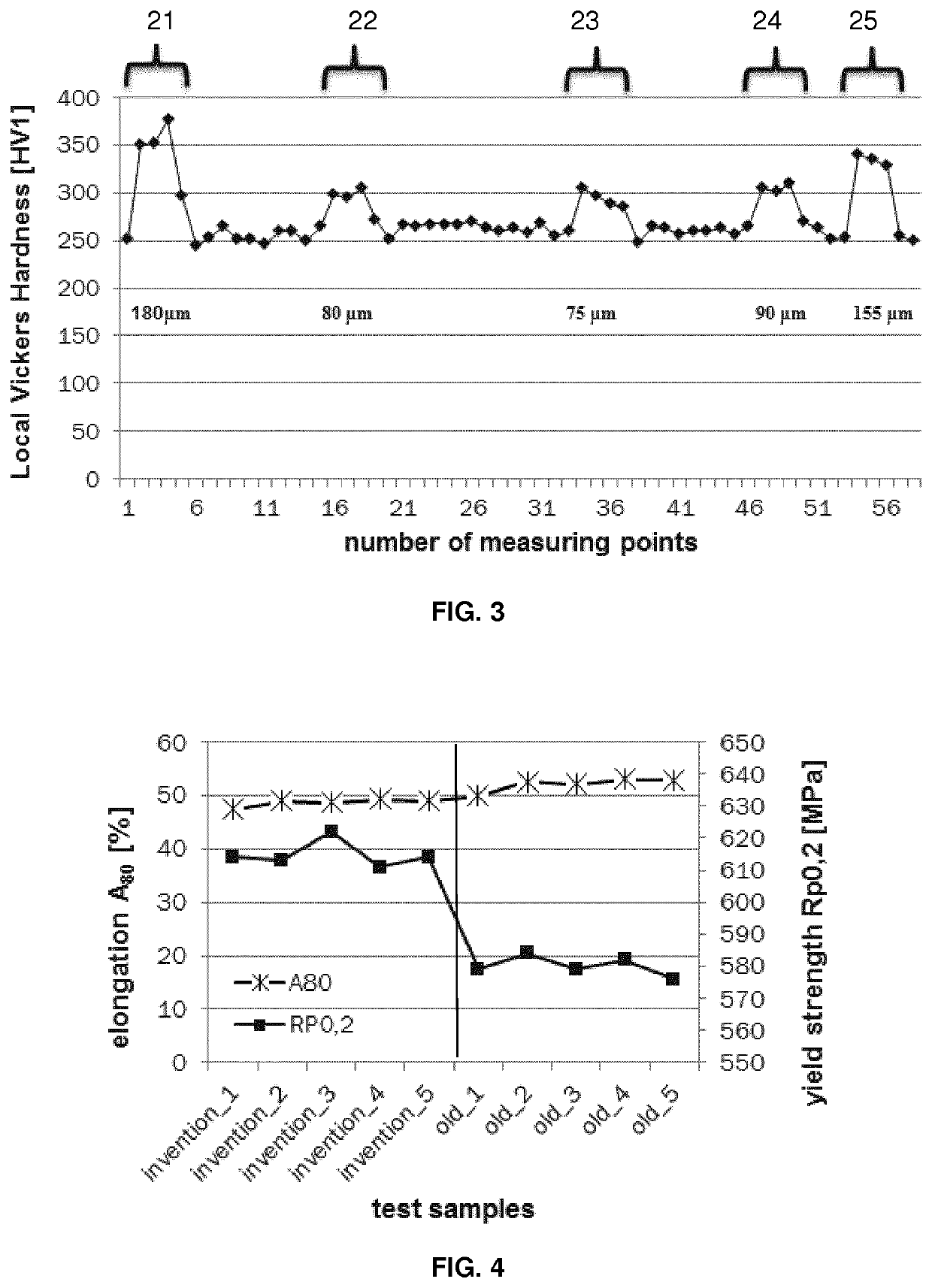

Method for manufacturing a component of austenitic TWIP or TRIP/TWIP steel

ActiveUS11247252B2Drawback can be obviatedHigh elongationRollsMetal rolling arrangementsAusteniteHigh strength steel

The present invention relates to a method for manufacturing a component of austenitic TWIP or TRIP / TWIP steel. A flat product (1) is deformed by achieving at least one indentation (16) on at least one surface of the flat product (1) in order to have in the deformed product (5) areas of a high strength steel embedded in a matrix of a ductile material. The invention also relates to the use of the component where areas of a high strength steel embedded in a matrix of a ductile material are required in the same component.

Owner:OUTOKUMPU OY

Preparation method of graphene-silicon carbide fiber reinforced metal composite material

InactiveCN108660398AMany forksHigh strengthMaterial nanotechnologyChemical vapor deposition coatingFreeze-dryingSic fiber

The invention relates to a preparation method of graphene-silicon carbide fiber synergetically reinforced metal composite material and belongs to the field of metal-base composite materials. The preparation method comprises the following steps: carrying out in-situ growth of silicon carbide fibers on the surface of graphene by means of chemical vapor deposition; putting the obtained composite powder and metal powder which are sheared and mixed at a high speed in liquid nitrogen to be quickly frozen and then carrying out freeze drying to obtain graphene-silicon carbide / metal composite powder; and carrying out spark plasma sintering on the composite powder to obtain the high density graphene-silicon carbide / metal composite material. The composite material metal matrix prepared by the invention is compactly combined with a reinforced phase, the tissues are compact, and the material has relatively high strength and keeps good toughness simultaneously. The preparation method provided by theinvention is simple in process and low in cost. An interface strengthening action is generated when the silicon carbide fibers of in-situ growth and a metal are compounded, so that the toughness of the metal matrix is further improved.

Owner:LANZHOU JIAOTONG UNIV

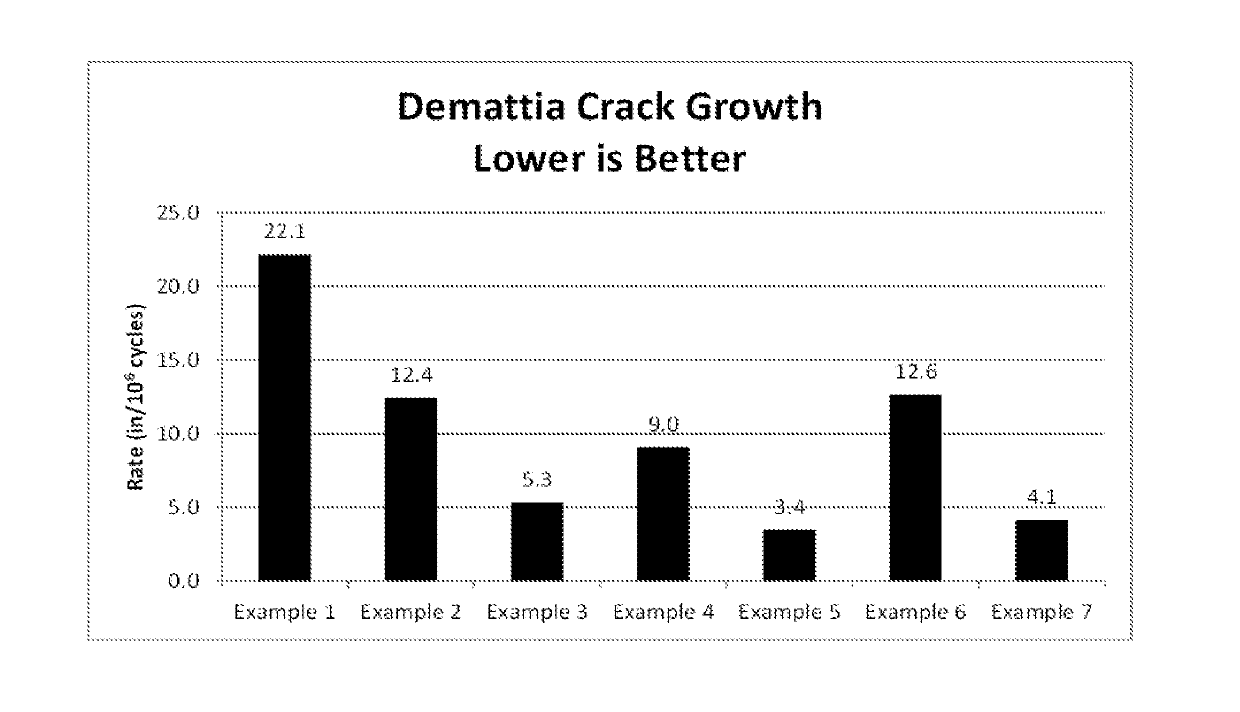

Tire having crack resistant sidewalls

ActiveUS10286729B2Improved sidewall crack resistanceRetard crack growthSpecial tyresTyre tread bands/patternsEngineeringPolybutadiene

This invention discloses a tire having crack resistant sidewalls which include a micronized rubber powder. These tires are comprised of a generally toroidal-shaped carcass with an outer circumferential tread, two spaced beads, at least one ply extending from bead to bead and sidewalls extending radially from and connecting said tread to said beads, wherein said tread is adapted to be ground-contacting, and wherein the sidewalls are comprised of 20 phr to 80 phr of natural rubber, 20 phr to 80 phr of polybutadiene rubber, and 3% over batch weight to 20% over batch weight of micronized rubber powder, wherein the micronized rubber powder has a particle size which is within the range of 40 Mesh to 300 Mesh.

Owner:LEHIGH TECH INC

Polyethylene composition for high pressure resistant pipes

The present invention relates to a polyethylene composition comprising a base resin having a density of from 950.0 kg / m3 to 962.0 kg / m3, determined according to ISO 1183, wherein the polyethylene composition has a melt flow rate MFR21 (190° C., 21.16 kg), of from 1.0 to 9.0 g / 10 min, determined according to ISO 1133 and a viscosity at a constant shear stress of 747 Pa eta747 of from 3500 kPa #s to 20000 kPa #s, a polyethylene composition obtainable by a multi-stage process, a process for producing said polyethylene composition, an article, such as a pipe or pipe fitting, comprising said polyethylene composition and the use of said polyethylene composition for the production of an article, such as a pipe or pipe fitting.

Owner:BOREALIS AG

Line and method for producing fibre reinforced line of wiring arrangement

InactiveCN1293687CIncrease the number of duty cyclesExtend your lifeHauling chainsHoisting chainsFiberSynthetic materials

According to the invention, a line (1) consisting of synthetic material is provided for a wiring arrangement. Said line is provided with segments (2) that are articulated to one another and are defined crosswise in relation to the longitudinal direction of the line (1) by means of transversal separations (4) that extend as far as the proximity of a supporting wall area (5). The line (1) is at least partially provided with a reinforcement fibre (6) that extends essentially in parallel in relation to the line direction and is essentially arranged in the supporting wall area (5). The line (1) is extruded and the segments (2) are configured. At least one reinforcement fibre (6) is provided before or after said configuration.

Owner:KABELSCHLEPP GMBH

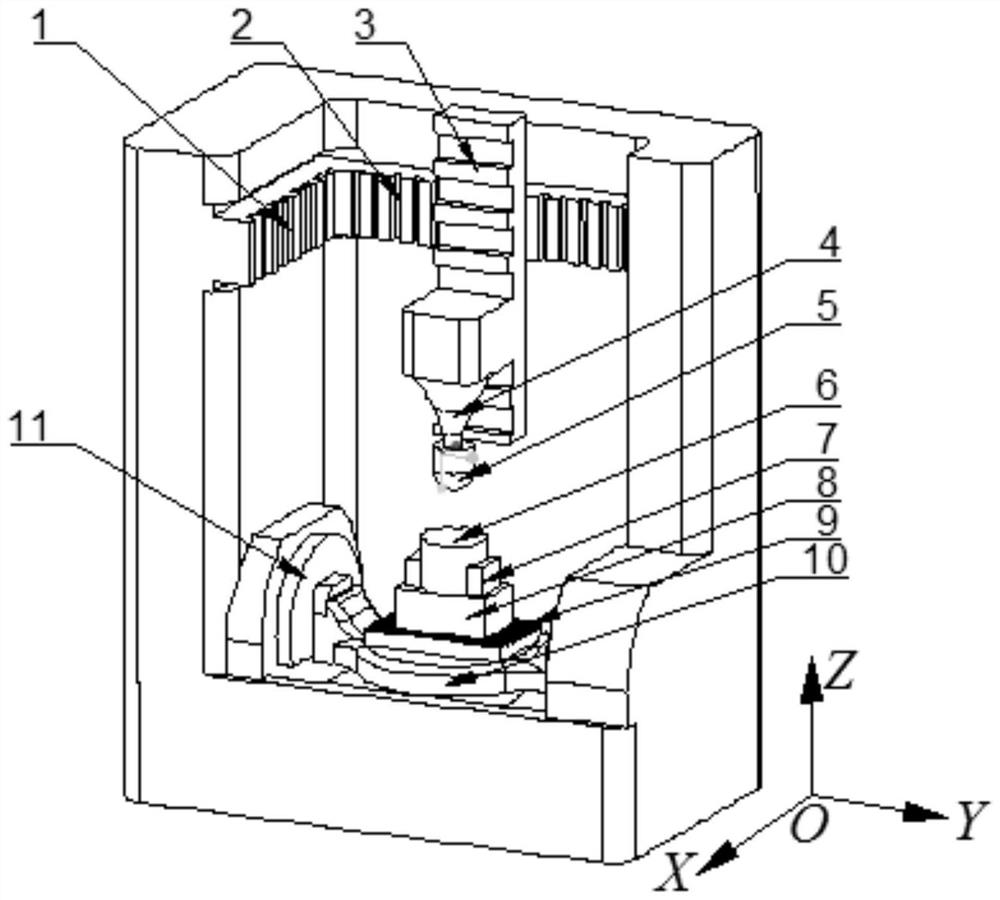

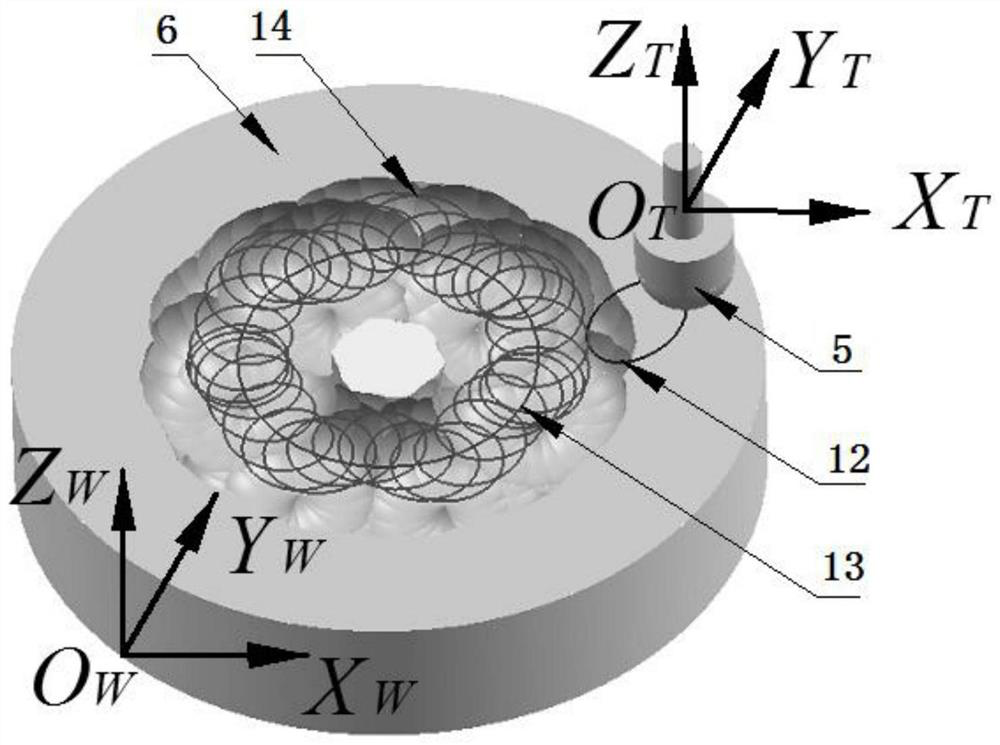

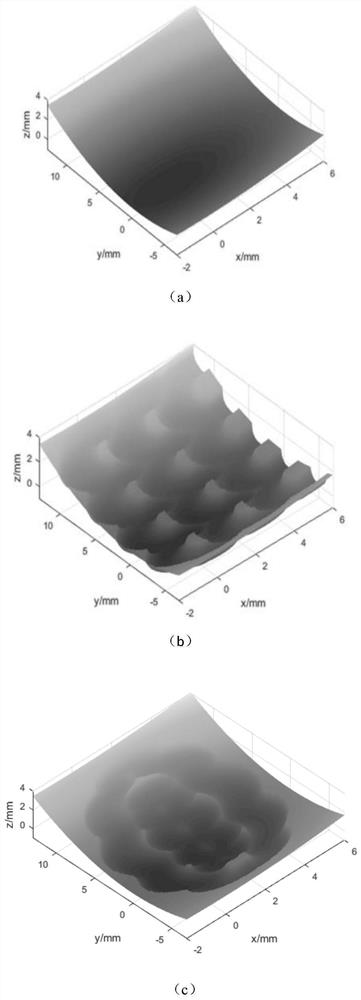

Three-dimensional vibration-assisted milling processing system and three-dimensional vibration-assisted milling method for structural surface

ActiveCN112846323BReduce processing forceRetard crack growthWatercraft hull designMilling equipment detailsNumerical controlMachined surface

The invention discloses a three-dimensional vibration-assisted milling method for a structured surface, comprising the following steps: establishing a mathematical model of the surface topography of a tool and a workpiece, setting a three-dimensional vibration device and a running path of a numerically controlled machine tool, calculating the tool and the workpiece each time in the processing process The position and attitude relationship at a moment, the structure morphology after vibration-assisted milling is obtained by comparative analysis. The vibration-assisted milling method proposed by the present invention can realize the preparation of micro-structures on various complex free-form surfaces in combination with the characteristics of high degree of freedom of numerical control milling, rich types of machined surfaces, wide operating frequency range of the vibration device, and high running accuracy. surface.

Owner:广东致志精密塑胶模具有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com