Line and method for producing fibre reinforced line of wiring arrangement

A technology of guiding device and guiding chain, applied in the field of manufacturing guiding chain, can solve problems such as cracks, influence of the life of wire guiding device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

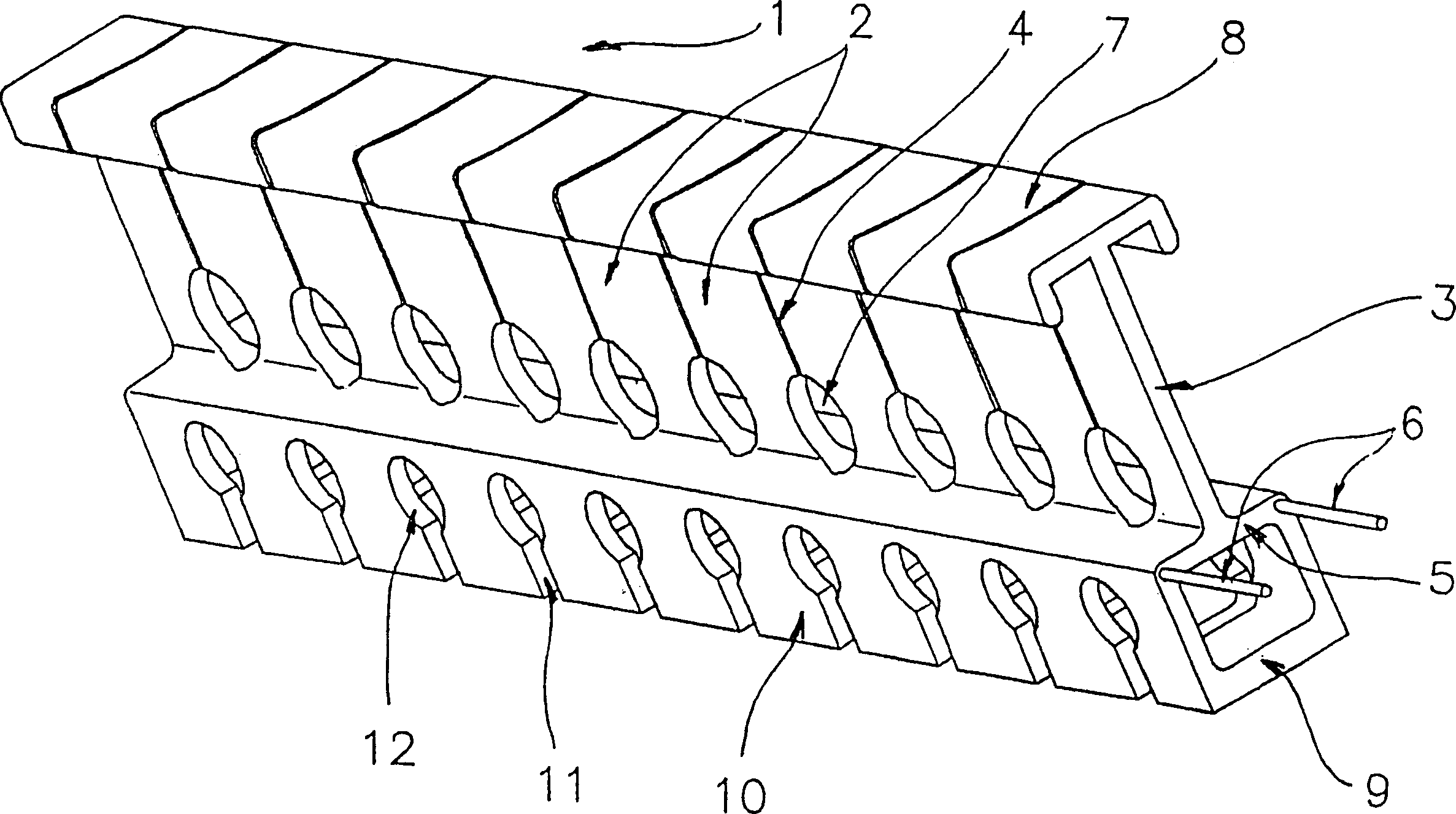

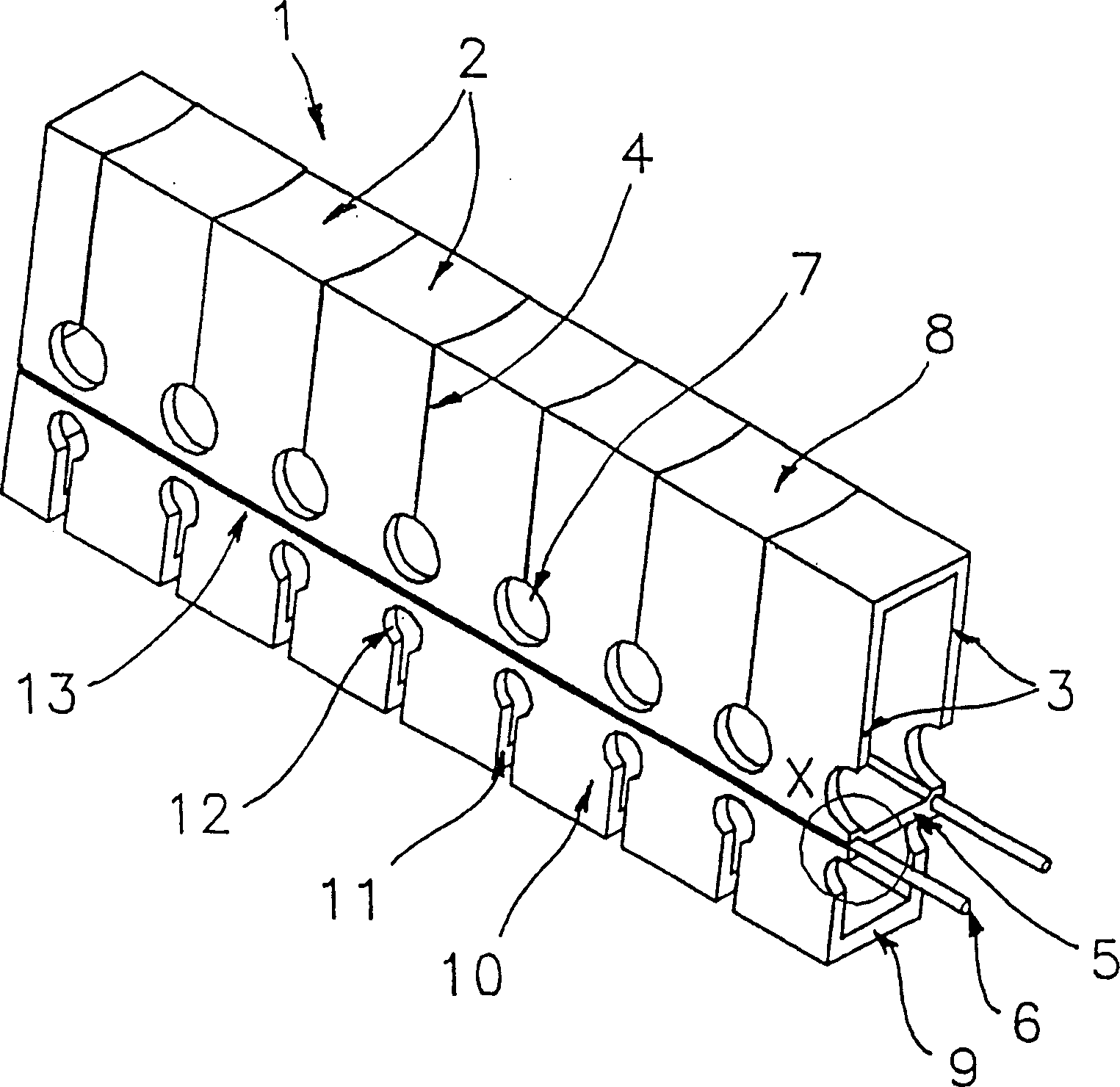

[0031] figure 1 A guide chain 1 for a wire guiding device is shown. figure 1 The wire guides are not shown for clarity.

[0032] The plastic guide chain 1 has mutually articulated sections 2 which have side wall regions 3 in the direction of the guide chain. The segments 2 are separated from each other by webs 4 .

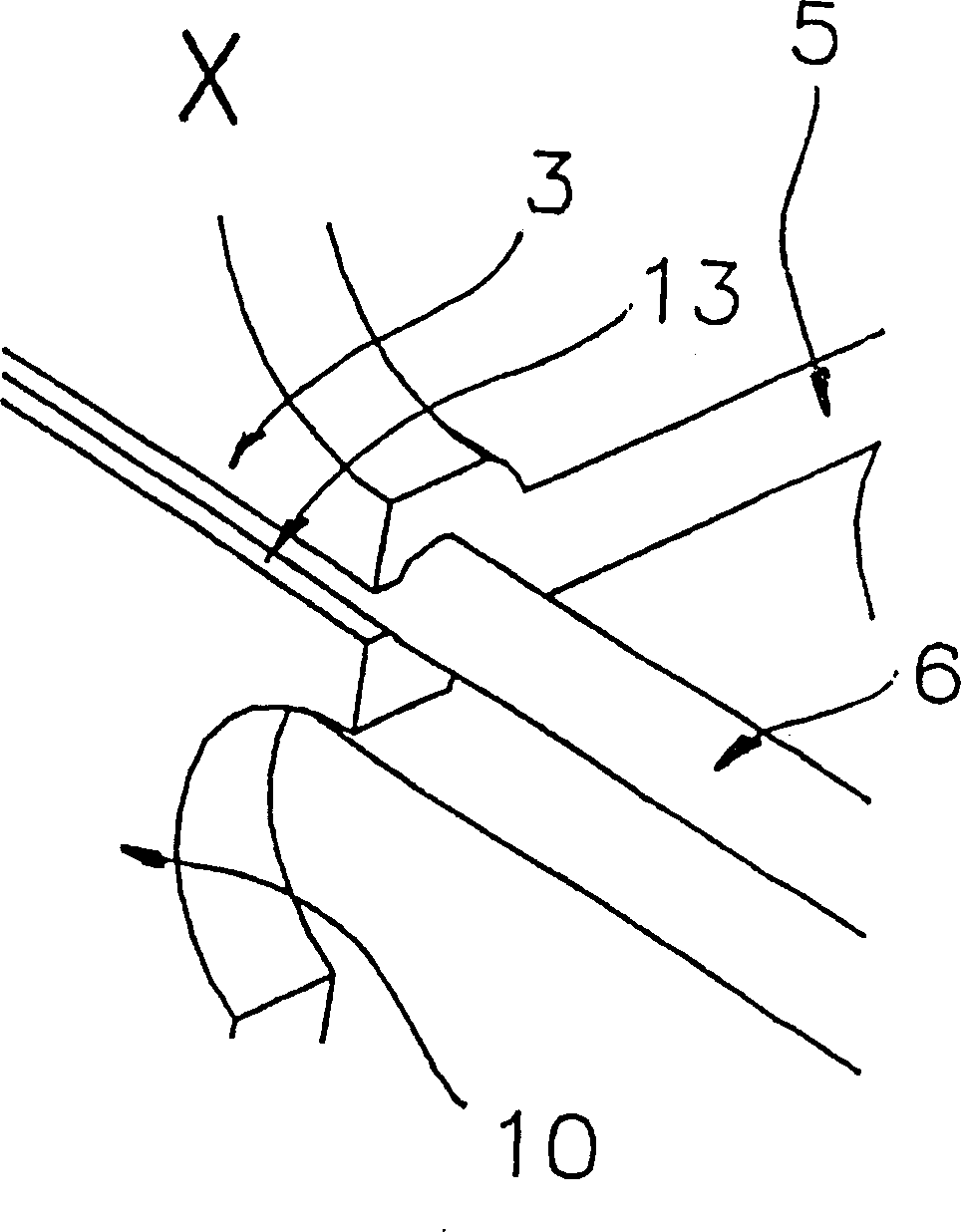

[0033] In the exemplary embodiment shown, the chain guide 1 is designed at least partially as a hollow profile. The hollow profile has a support wall region 5 and a bottom wall region 9 . The support wall region 5 and the bottom wall region 9 are connected by two side walls 10 running essentially parallel to one another. The guide chain 1 in the form of a hollow profile is substantially rectangular in the illustrated embodiment. The side wall region 3 is formed substantially centrally on the support wall region 5 . Opposite the side wall region 3 of the hollow profile there is a top wall region 8 . It is arranged centrally on the side wall region 3 and is fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com