A microstructure relieved of notching

A technology of microstructure and surface structure, applied in physical/chemical process catalysts, machines/engines, transportation and packaging, etc., can solve problems such as high stagnation pressure, obstructed exhaust gas, channel blockage, etc., and achieve material stress reduction and crack resistance The effect of extending the reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

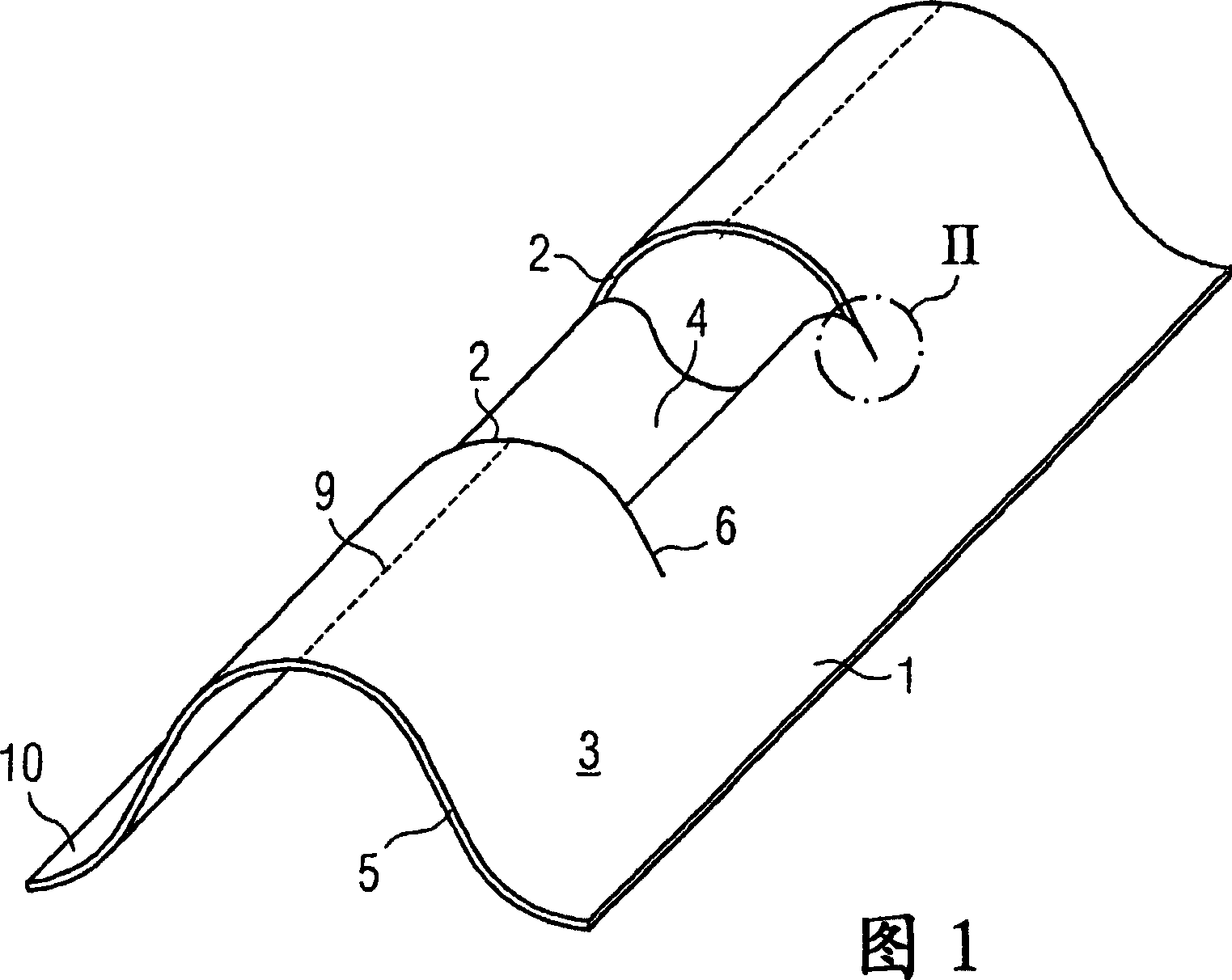

[0064] FIG. 1 shows a schematic perspective view of a part of a thin plate 1 with a microstructure 4 . In this partial view shown, the sheet metal 1 includes a microstructure 4 partially delimited by two slits 2 , the slits 2 extending only in the inner region 3 of the sheet metal 1 . The microstructures 4 protrude from the surface structures 5 of the sheet metal 1 . The surface structure 5 is made with crests 9 and troughs 10 . As shown, the edge area 6 of the slit 2 is below Figure 2.1 , 2.2 and 2.3 are shown enlarged.

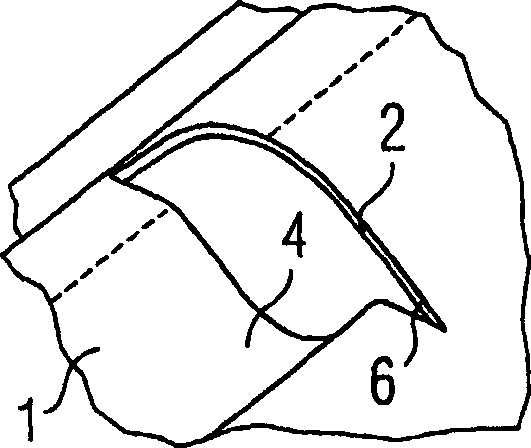

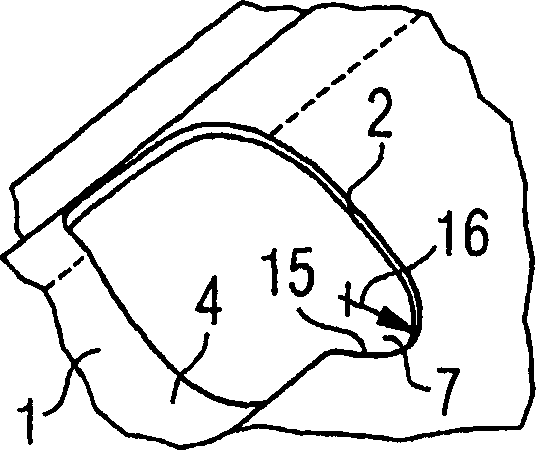

[0065] Figure 2.1 , 2.2 and 2.3 show a partial view of the microstructure 4 defined by the slit 2 . Slits 2 allow microstructures 4 to be formed from sheet metal 1 in such a way that they protrude beyond surface structure 5 . Among them in Figure 2.1 The central edge region 6 is shown as a simple slot 2 , ie without the recess 7 according to the invention. The point junction in the edge region 6 forms a gap, so that further expansion of the slit 2 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com