Preparation method of bulletproof ceramic entire board

A technology of bulletproof plates and ceramics, which is applied in the direction of protective equipment, ceramic molding machines, armor plate structures, etc. It can solve the problems of cumbersome process, easy generation of air bubbles, and difficulty in forming laminated ceramics in one step.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) 70wt% silicon carbide powder, 5wt% carbon black, 0.5wt% ammonium polyacrylate, 0.5wt% phenolic resin, and 24wt% deionized water were ball milled and mixed for 24 hours to obtain the required slurry.

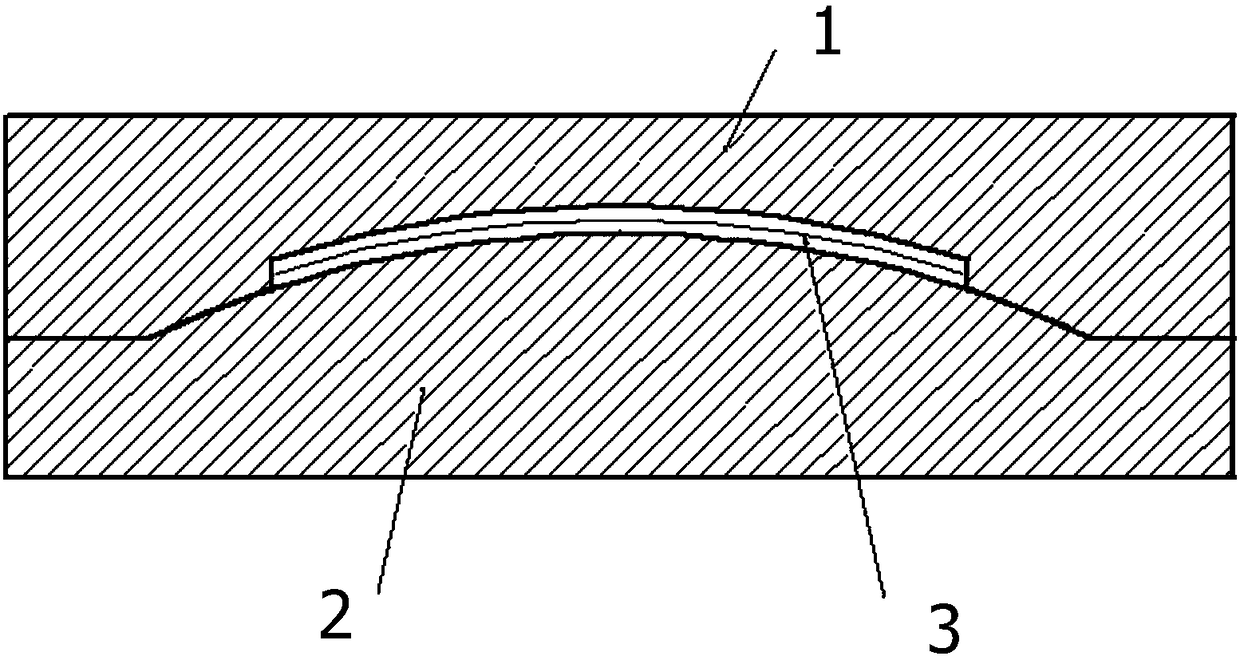

[0035] (2) Use a high-pressure grouting machine to inject the prepared slurry into the mold, wherein the front mold 1 and the rear mold 2 of the mold are both porous resin molds, and the internal shape of the front mold 1 is a cavity that is the same shape as the overall bulletproof plate body, wherein the inner wall of the cavity of front mold 1 is provided with a grouting hole, and the rear mold 2 is a curved surface with the same curvature as the concave surface of the overall bulletproof plate. ;

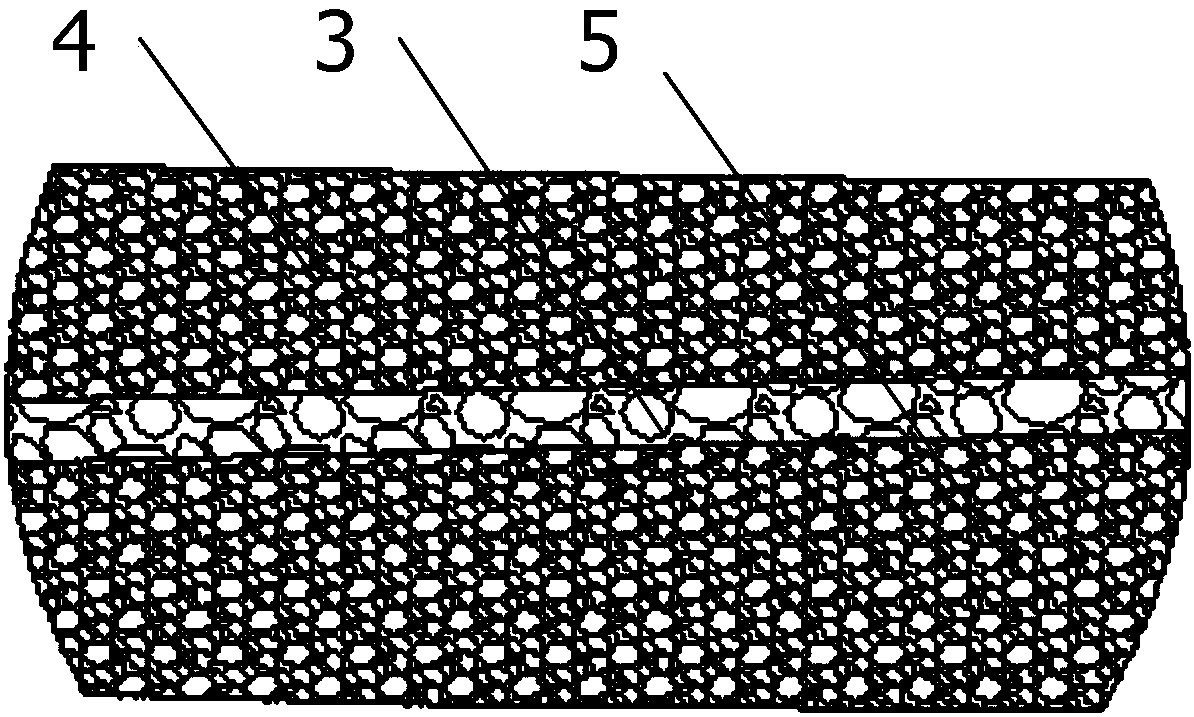

[0036] (3) The above-prepared slurry is molded into the required green sample by a high-pressure grouting machine. Keep the pressure for 200s; at this time, the upper layer 4 and the lower layer 5 of the integral bulletproof plate are formed; then reduce the grouting pr...

Embodiment 2

[0040] (1) 70wt% silicon carbide powder, 5wt% carbon black, 0.5wt% ammonium polyacrylate, 0.5wt% phenolic resin, and 24wt% deionized water were ball milled and mixed for 24 hours to obtain the required slurry.

[0041] (2) Use a high-pressure grouting machine to inject the prepared slurry into the mold, wherein the front mold 1 and the rear mold 2 of the mold are both porous resin molds, and the internal shape of the front mold 1 is a cavity that is the same shape as the overall bulletproof plate body, wherein the inner wall of the cavity of front mold 1 is provided with a grouting hole, and the rear mold 2 is a curved surface with the same curvature as the concave surface of the overall bulletproof plate. ;

[0042](3) The above-prepared slurry is molded into the required green sample by a high-pressure grouting machine. Keep the pressure for 220s; at this time, the upper layer 4 and the lower layer 5 of the integral bulletproof plate are formed; then reduce the grouting pre...

Embodiment 3

[0046] (1) 65wt% boron carbide powder, 8wt% graphite powder, 1.0wt% ammonium polyacrylate, 0.5wt% xanthan gum, and 25.5wt% deionized water were ball milled and mixed for 24 hours to obtain the required slurry.

[0047] (2) Use a high-pressure grouting machine to inject the prepared slurry into the mold, wherein the front mold 1 and the rear mold 2 of the mold are both porous resin molds, and the internal shape of the front mold 1 is a cavity that is the same shape as the overall bulletproof plate body, wherein the inner wall of the cavity of front mold 1 is provided with a grouting hole, and the rear mold 2 is a curved surface with the same curvature as the concave surface of the overall bulletproof plate. ;

[0048] (3) The above-prepared slurry is molded into the required green sample by a high-pressure grouting machine, wherein the grouting condition is that the grouting molding pressure is increased from 0.1MPa to 5MPa within 50s, and at a high pressure of 5MPa Hold the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com