Carbon fiber/epoxy resin composite material for bicycle and preparing method thereof

A technology of epoxy resin and composite materials, which is applied in the field of composite materials, can solve the problems of reduced heat resistance and impact resistance of composite materials, and achieve the effects of easy operation, excellent mechanical properties and low raw material prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

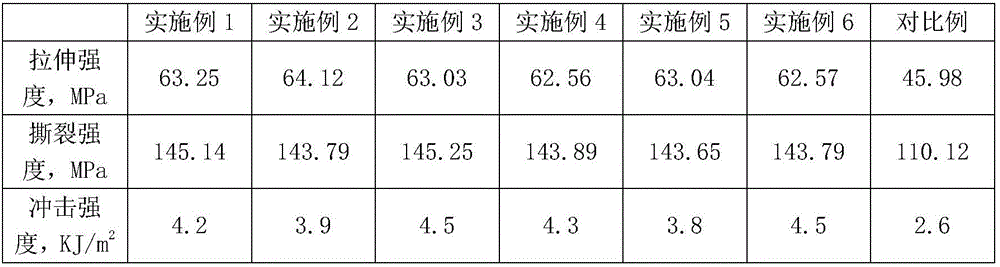

Examples

Embodiment 1

[0033] A carbon fiber / epoxy resin composite material for bicycles, in parts by weight, comprising the following components:

[0034] 1 part of carbon fiber, 30 parts of epoxy resin,

[0035] 2 parts of floating beads, 3 parts of gelatin,

[0036] 2 parts of medical stone powder, 1.5 parts of coupling agent,

[0037] 2 parts of curing agent, 1 part of accelerator.

[0038] Its preparation method comprises the following steps:

[0039] (1) Mix and stir carbon fiber, coupling agent, floating beads, medical stone powder and absolute ethanol evenly, sonicate for 1 hour at a power of 800W, remove the solvent, mix and stir evenly with liquid bisphenol A phenolic resin, and transfer to an autoclave , sonicated at 100°C for 30 minutes to obtain mixture A;

[0040] (2) Mix the solid bisphenol A type epoxy resin and gelatin evenly, add the mixture A obtained in step (1), ultrasonicate for 1h, add curing agent and accelerator, stir and mix evenly, after vacuuming to remove air bubbles...

Embodiment 2

[0042] A carbon fiber / epoxy resin composite material for bicycles, in parts by weight, comprising the following components:

[0043] 3 parts of carbon fiber, 50 parts of epoxy resin,

[0044] 5 parts of floating beads, 8 parts of gelatin,

[0045] 3 parts of medical stone powder, 3 parts of coupling agent,

[0046] 5 parts of curing agent, 2 parts of accelerator.

[0047] Its preparation method comprises the following steps:

[0048] (1) Mix and stir carbon fiber, coupling agent, floating beads, medical stone powder and absolute ethanol evenly, sonicate for 2 hours at 800W power, remove solvent, mix and stir evenly with liquid bisphenol A phenolic resin, and transfer to an autoclave , sonicated at 120°C for 60 minutes to obtain mixture A;

[0049] (2) Mix the solid bisphenol A type epoxy resin and gelatin evenly, add the mixture A obtained in step (1), ultrasonicate for 2 hours, add curing agent and accelerator, stir and mix evenly, after vacuuming to remove air bubbles, t...

Embodiment 3

[0051] A carbon fiber / epoxy resin composite material for bicycles, in parts by weight, comprising the following components:

[0052] 1.5 parts of carbon fiber, 35 parts of epoxy resin,

[0053] 3 parts of floating beads, 4 parts of gelatin,

[0054] 2.2 parts of medical stone powder, 1.8 parts of coupling agent,

[0055] 3 parts of curing agent, 1.2 parts of accelerator.

[0056] Its preparation method comprises the following steps:

[0057] (1) Mix and stir carbon fiber, coupling agent, floating beads, medical stone powder and absolute ethanol evenly, sonicate at 800W for 1.2h, remove solvent, mix and stir evenly with liquid bisphenol A phenolic resin, and transfer to an autoclave , sonicated at 105°C for 40 minutes to obtain mixture A;

[0058] (2) Mix solid bisphenol A type epoxy resin and gelatin evenly, add the mixture A obtained in step (1), ultrasonic 1.2h, add curing agent, accelerator, stir and mix evenly, after vacuumizing to get rid of air bubbles, put The mixt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com