Drift fault recognition method of hot-rolling strip steel based on sound signals

A hot-rolled strip, fault identification technology, applied in metal rolling, metal rolling, length measuring devices, etc., can solve the problems of lack of online detection methods, high noise, and complexity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0105] The original signal is resampled at a frequency of 11kHz, the frame length is 1000 data points, and the frame shift is 340 data points. The selection of each parameter is listed in Table 1, from which the recognition rate of tail-flick faults can be 97.47%, and the recognition rate of normal state is 97%.

[0106] Table 1 Selection of parameters

[0107] Number of pivot k

Embodiment approach 2

[0109] The original signal is resampled at a frequency of 11kHz, the frame length is 1000 data points, and the frame shift is 340 data points. The selection of each parameter is listed in Table 2, from which the identification rate of tail-flick fault is 96.2%, and the identification rate of normal state is 96%.

[0110] Table 2 Selection of parameters

[0111] Number of pivot k

Embodiment approach 3

[0113] The original signal is resampled at a frequency of 11kHz, the frame length is 1000 data points, and the frame shift is 340 data points. The selection of each parameter is listed in Table 3, from which the identification rate of tail-flick faults is 98.73%, and the identification rate of normal state is 95%.

[0114] Table 3 Selection of parameters

[0115] Number of pivot k

Confidence test level a

Distribution value F

Total overrun rate ρ

18

0.001

2.336

0.06

[0116] Summarizing the above description, it can be seen that the present invention includes the following steps:

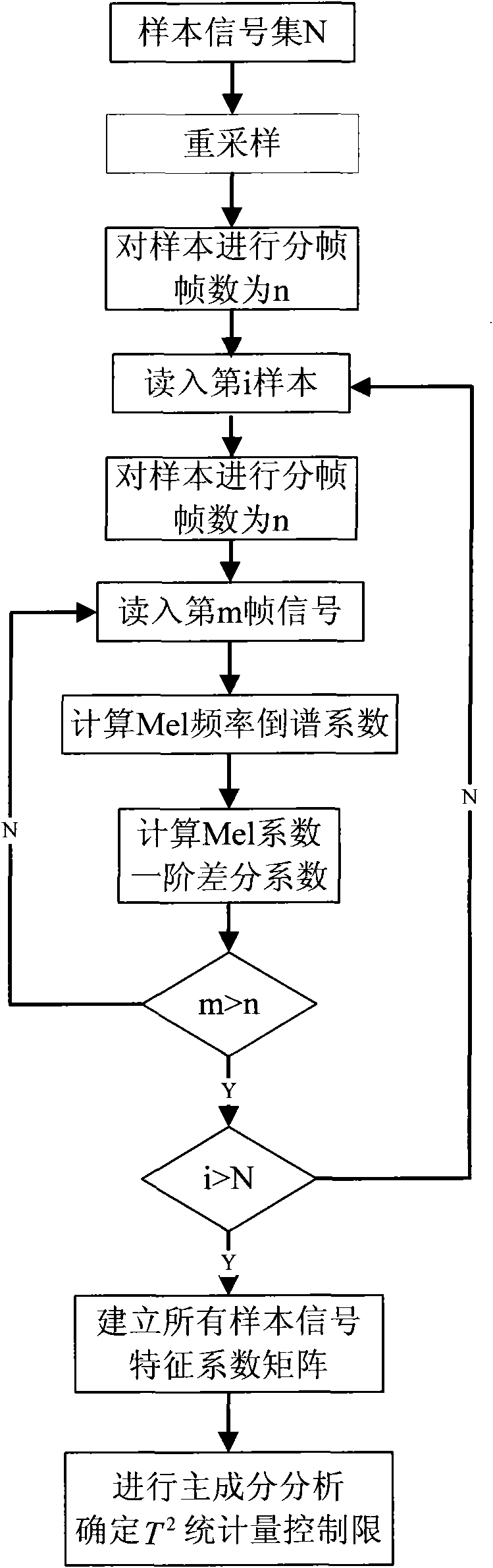

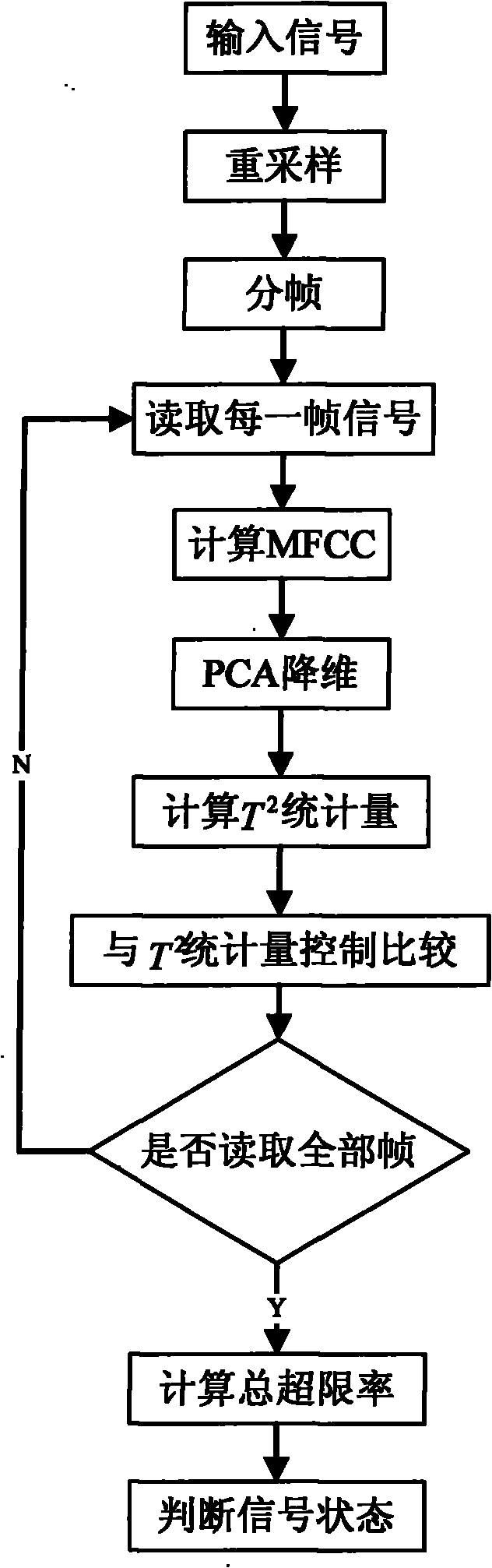

[0117] 1) Preprocessing of re-sampling and framing of the input signal.

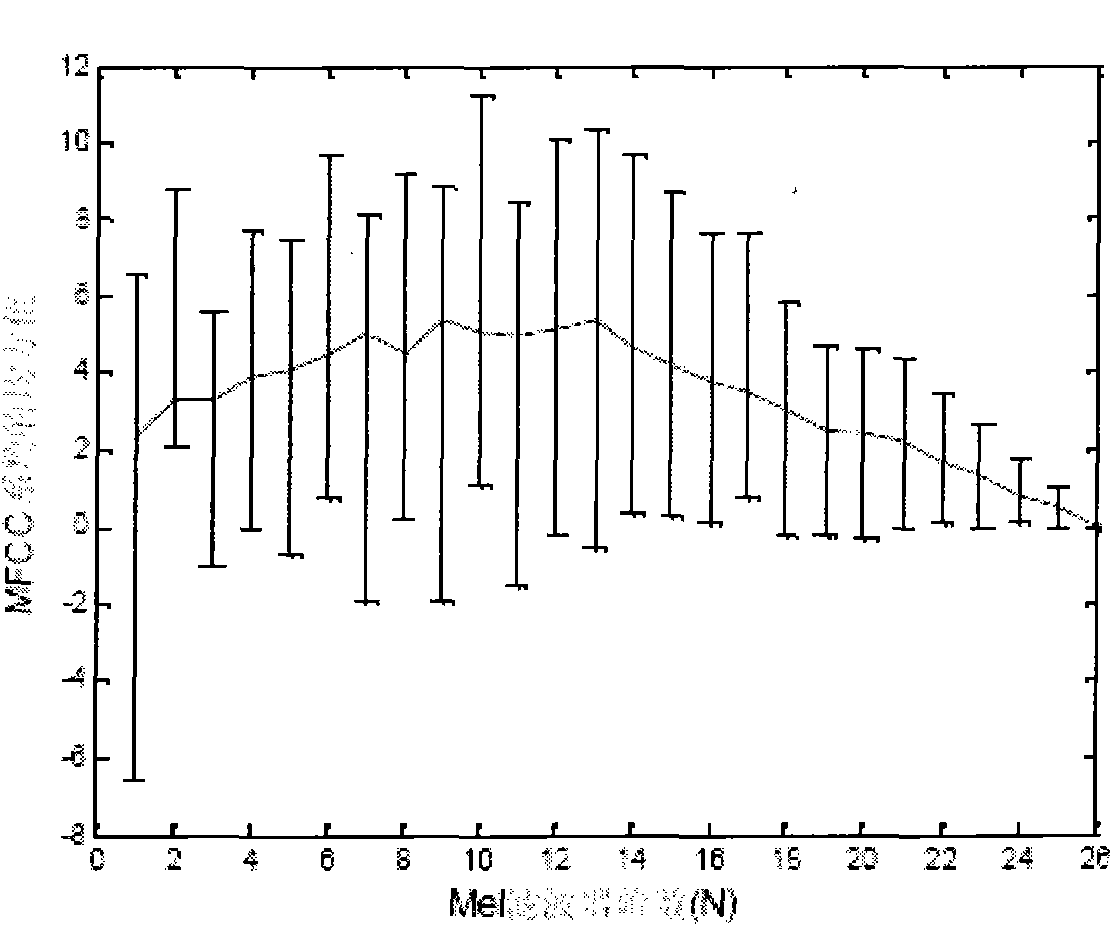

[0118] 2) Using Mel frequency cepstrum technology to extract features of the strip flick signal.

[0119] 3) Principal component analysis method and multivariate statistical process control chart are used for feature selection, and a tail-flick recognition model is established.

[0120] 4) Use the built model to recognize the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com