Preparation method of piezoelectric driver with nickle particle decentralization lithium doping by niobic acid kalium natrium

A potassium sodium niobate piezoelectric and piezoelectric driver technology, which is applied in the direction of piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc., can solve problems such as interface peeling, and achieve improved Effects of mechanical properties, prolonging service life, and improving mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

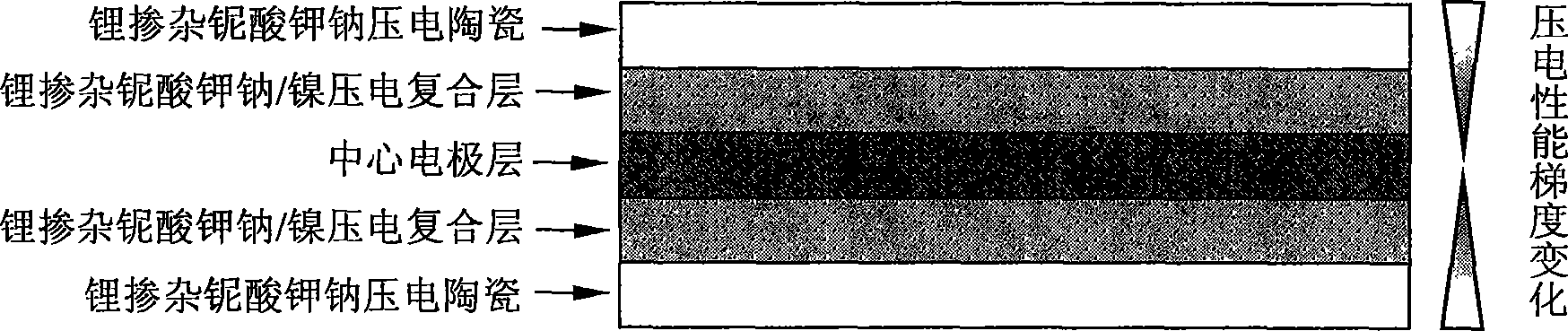

[0019] Take the commercially available K 2 CO 3 Powder (Beijing Chemical Reagent Factory, purity 99%), Na 2 CO 3 Powder (Beijing Chemical Reagent Factory, purity 99.8%), Li 2 CO 3 Powder (Beijing Chemical Reagent Factory, purity 99.5%) and Nb 2 o 5 Powder (Jiangxi Yifeng Guizu Tantalum and Niobium Co., Ltd., purity 99.4%) is raw material, adopts atomic percentage according to chemical formula Li 0.06 (K 0.5 Na 0.5 ) 0.94 NbO 3 Perform batching, mixing, and roasting; grind and mix the synthesized lithium-doped potassium sodium niobate (LKNN) powder with Ni powder (Beijing Bailingwei Chemical Technology Co., Ltd., purity >99.9%, particle size ~325 mesh), and mix the powder according to the setting The composition and morphology of the material were laid layer by layer in the mold and molded; LKNN / 5%Ni / 40%Ni / 5%Ni / LKNN was sintered at 1060°C in a nitrogen protective atmosphere with an oxygen content of 0.5vol%. Five-layer composite disc-shaped products, the thickness of...

Embodiment 2

[0021] Take the commercially available K 2 CO 3 Powder (Beijing Chemical Reagent Factory, purity 99%), Na 2 CO 3 Powder (Beijing Chemical Reagent Factory, purity 99.8%), Li 2 CO 3 Powder (Beijing Chemical Reagent Factory, purity 99.5%) and Nb 2 o 5 Powder (Jiangxi Yifeng Guizu Tantalum and Niobium Co., Ltd., purity 99.4%) is raw material, adopts atomic percentage according to chemical formula Li 0.06 (K 0.5 Na 0.5 ) 0.94 NbO 3 Perform batching, mixing, and roasting; grind and mix the synthesized lithium-doped potassium sodium niobate (LKNN) powder with Ni powder (Beijing Bailingwei Chemical Technology Co., Ltd., purity >99.9%, particle size ~325 mesh), and mix the powder according to the setting The composition and morphology of the material were laid layer by layer in the mold and formed by compression molding; LKNN / 5%Ni / 40%Ni / 5%Ni / LKNN was prepared by sintering at 1030°C in a nitrogen protective atmosphere with an oxygen content of 0.0003vol%. Five-layer composite...

Embodiment 3

[0023] Take the commercially available K 2 CO 3 Powder (Beijing Chemical Reagent Factory, purity 99%), Na 2 CO 3 Powder (Beijing Chemical Reagent Factory, purity 99.8%), Li 2 CO 3 Powder (Beijing Chemical Reagent Factory, purity 99.5%) and Nb 2 o 5 Powder (Jiangxi Yifeng Guizu Tantalum and Niobium Co., Ltd., purity 99.4%) is raw material, adopts atomic percentage according to chemical formula Li 0.06 (K 0.5 Na 0.5 ) 0.94 NbO 3 Perform batching, mixing, and roasting; grind and mix the synthesized lithium-doped potassium sodium niobate (LKNN) powder with Ni powder (Beijing Bailingwei Chemical Technology Co., Ltd., purity >99.9%, particle size ~325 mesh), and mix the powder according to the setting The composition and morphology of the material were laid layer by layer in the mold and molded; LKNN / 10%Ni / 40%Ni / 10%Ni / LKNN was sintered at 1120°C in a nitrogen protective atmosphere with an oxygen content of 0.5vol%. Five-layer composite disc-shaped sample, the thickness of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com