A riveting method and device for novel hybrid composite materials for aviation

A composite material, riveting device technology, applied in applications, household appliances, household components, etc., can solve the problems of lack of interference consideration, inability to control the fatigue life of laminate riveting parts, etc., to reduce the occurrence of riveting defects, high engineering Application value, effect of riveting quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] ①Using CNC milling method to process the 3 / 2 structure glass fiber reinforced aluminum alloy laminate to the target size, implement drilling, and use acetone to ultrasonically clean the impurities in the hole.

[0049] ②Remove the burrs and debris between the fitting surfaces, and clean the fitting surfaces with acetone.

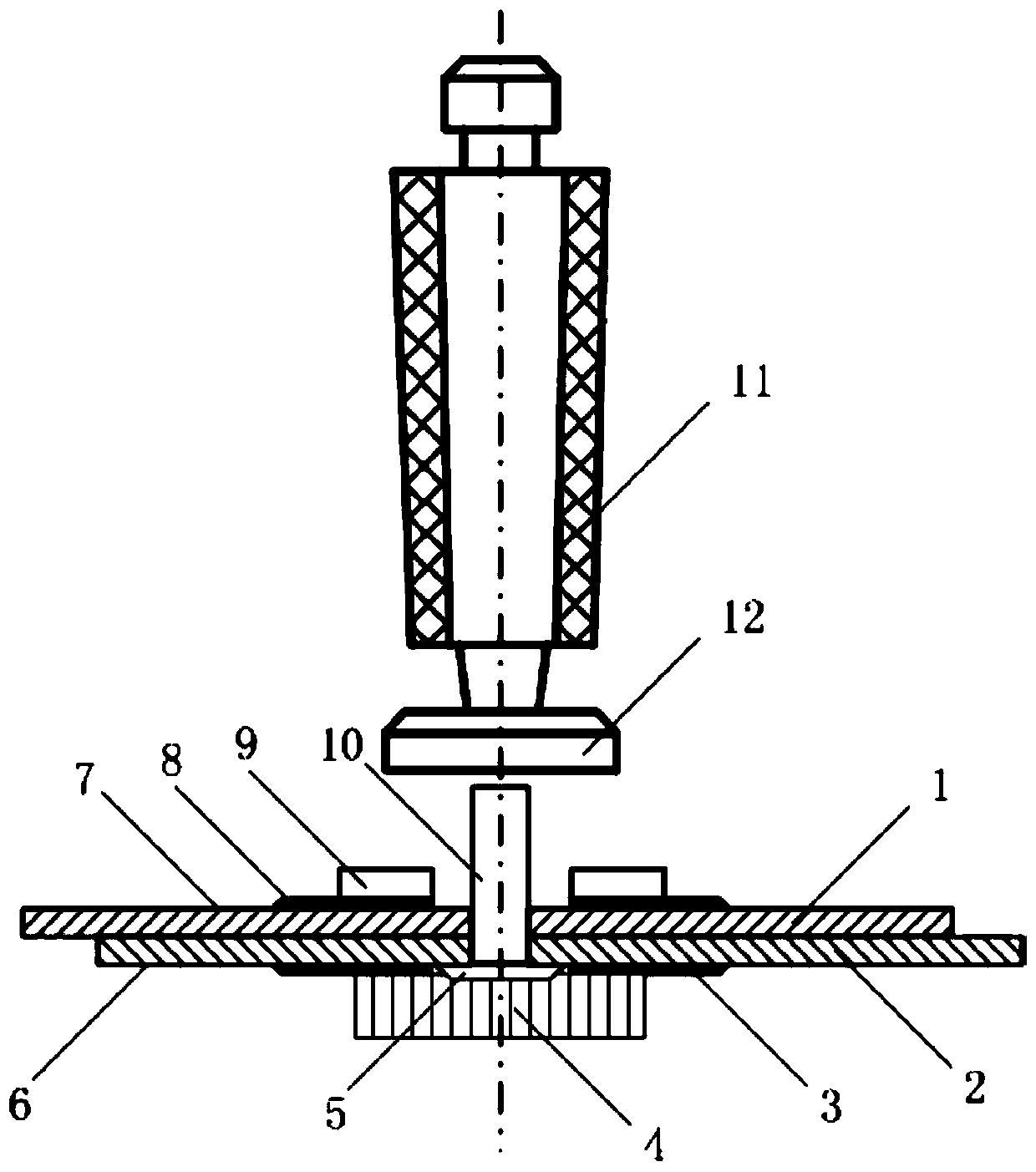

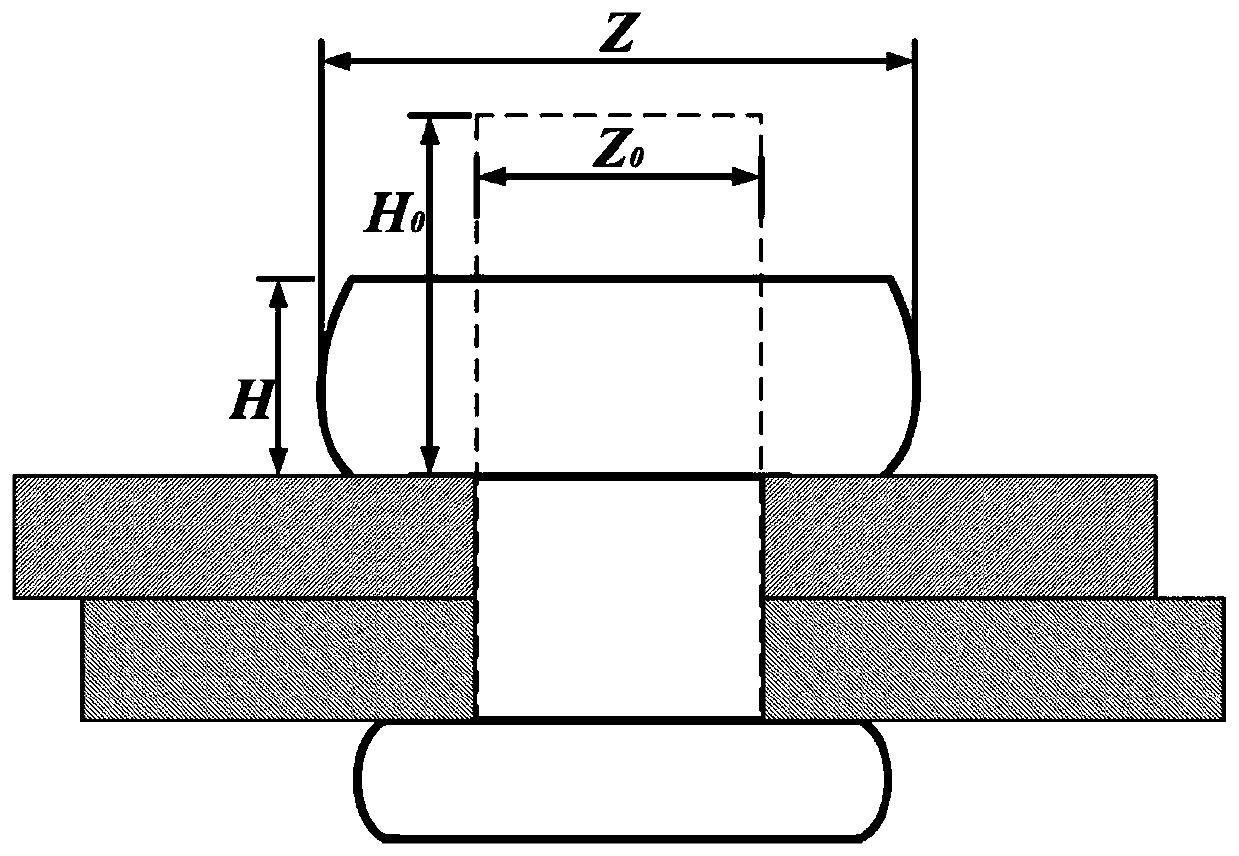

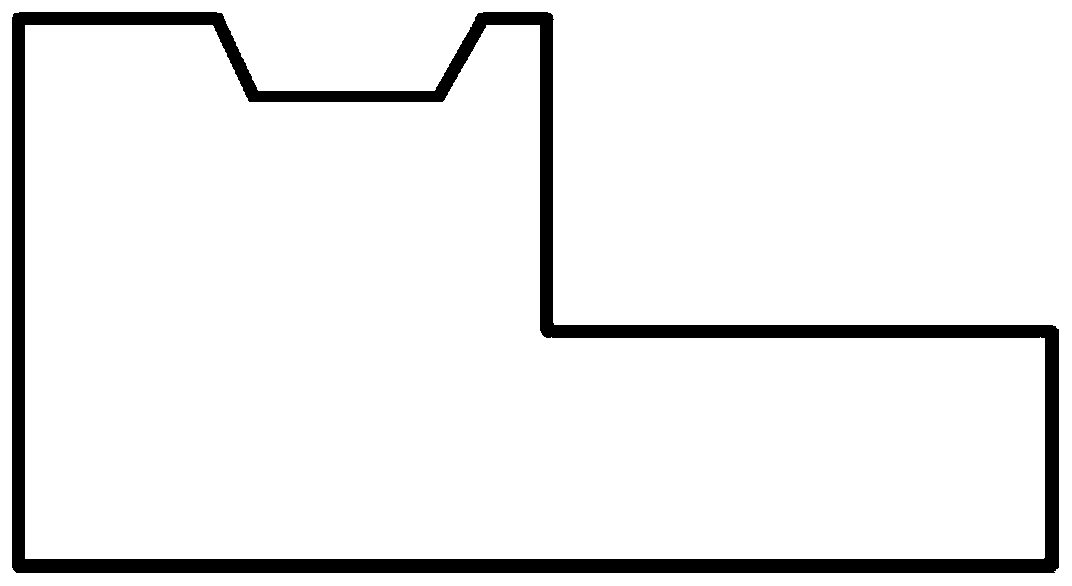

[0050] ③The diameter of the rivet is 4.1mm, the material of the rivet is aluminum alloy, the workpiece is plate, the total thickness of the interlayer is 2.8mm, and the top handle with a weight of 4kg is selected according to the working space of the riveting place and the shape of the workpiece image 3 Top handles, ultrasonic cleaning top handles, metal gaskets and composite material process gaskets.

[0051] ④ The active parts of the riveting device should be lubricated so that there is no tightness. Press the riveted parts tightly, place the nails in the holes according to the riveting requirements, perform riveting on the special riveting device...

Embodiment 2

[0058] ①Using CNC milling method to process the 3 / 2 structure glass fiber reinforced aluminum alloy laminate to the target size, implement drilling, and use acetone to ultrasonically clean the impurities in the hole.

[0059] ②Remove the burrs and debris between the fitting surfaces, and clean the fitting surfaces with acetone.

[0060] ③The rivet diameter is 6.1mm, the rivet material is titanium alloy, the workpiece is a concave curvature part, the total thickness of the interlayer is 2.8mm, and the top handle with a weight of 5kg is selected according to the shape of the riveted part. Figure 4 The convex curvature top handle can realize the riveting of convex curvature laminates. Ultrasonic cleaning of top handles, metal washers and composite process washers.

[0061] ④ The active parts of the riveting device should be lubricated so that there is no tightness. Press the riveted parts tightly, place the nails in the holes according to the riveting requirements, and perform...

Embodiment 3

[0064] ①Using CNC milling method to process the 4 / 3 carbon fiber reinforced titanium alloy laminate to the target size, implement drilling, and use acetone to ultrasonically clean the impurities in the hole.

[0065] ②Remove the burrs and debris between the fitting surfaces, and clean the fitting surfaces with acetone.

[0066] ③The diameter of the rivet is 6.1mm, the material of the rivet is Monel alloy, the workpiece is a concave curvature part, the total thickness of the interlayer is 3.9mm, and the top handle with a weight of 8kg is selected according to the shape of the riveted part Figure 4 The convex curvature top handle can realize the riveting of convex curvature laminates. Ultrasonic cleaning of top handles, metal washers and composite process washers.

[0067] ④ The active parts of the riveting device should be lubricated so that there is no tightness. Press the riveted parts tightly, place the nails in the holes according to the riveting requirements, and perfor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com