Method for manufacturing wind power forging by using 20CrMnMo continuous casting blank

A technology for continuous casting blanks and forgings, applied in the field of forging manufacturing, can solve the problems of reducing the mechanical properties of forgings, affecting the fatigue life of forgings, and having many defects in continuous casting blanks, so as to achieve the effect of ensuring fatigue life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

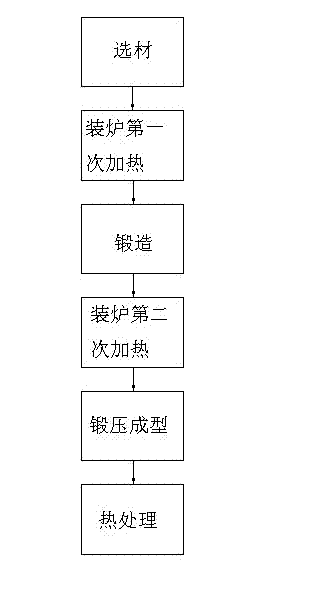

[0021] See figure 1 : the method for making wind power forgings with 20CrMnMo continuous casting slab shown is characterized in that comprising the following steps:

[0022] (1) Material selection, select the continuous casting slab with the grade of 20CrMnMo, the continuous casting slab is a cylindrical continuous casting slab, and the diameter of the continuous casting slab is Φ≥600mm;

[0023] (2) For the first heating of the furnace, the selected continuous casting slabs are loaded into a chamber-type natural gas heating furnace for heating. Ignite until the temperature rises to 1250°C, and the heating rate is ≤200°C / h;

[0024] (3) Forging, on the 8MN hydraulic press, carry out two upsetting and drawing on the heated continuous casting billet to ensure that the first upsetting and drawing ratio is: the upsetting ratio is 2.3, the drawing length ratio is 2.1, and the second upsetting and drawing ratio is : The upsetting ratio is 2.0, the drawing ratio is 1.8, and the ini...

Embodiment 2

[0029] See figure 1 : the method for making wind power forgings with 20CrMnMo continuous casting slab shown is characterized in that comprising the following steps:

[0030] (1) Material selection, select the continuous casting slab with the grade of 20CrMnMo, the continuous casting slab is a cylindrical continuous casting slab, and the diameter of the continuous casting slab is Φ≥600mm;

[0031] (2) For the first heating of the furnace, the selected continuous casting slabs are loaded into a chamber-type natural gas heating furnace for heating. Ignite until the temperature rises to 1265°C, and the heating rate is ≤200°C / h;

[0032] (3) Forging, on the 8MN hydraulic press, perform two upsetting and drawing on the heated continuous casting slab to ensure that the first upsetting and drawing ratio is: the upsetting ratio is 2.4, the drawing length ratio is 2.2, and the second upsetting and drawing ratio is : The upsetting ratio is 2.1, the drawing ratio is 1.9, and the initial...

Embodiment 3

[0037] See figure 1 : the method for making wind power forgings with 20CrMnMo continuous casting slab shown is characterized in that comprising the following steps:

[0038] (1) Material selection, select the continuous casting slab with the grade of 20CrMnMo, the continuous casting slab is a cylindrical continuous casting slab, and the diameter of the continuous casting slab is Φ≥600mm;

[0039] (2) For the first heating of the furnace, the selected continuous casting slabs are loaded into a chamber-type natural gas heating furnace for heating. Ignite until the temperature rises to 1280°C, and the heating rate is ≤200°C / h;

[0040] (3) Forging, the heated continuous casting slab is subjected to two upsetting and drawing on the 8MN hydraulic press to ensure that the first upsetting and drawing ratio is: the upsetting ratio is 2.5, the drawing length ratio is 2.3, and the second upsetting and drawing ratio is : The upsetting ratio is 2.2, the drawing ratio is 2.0, and the ini...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com