Patents

Literature

34results about How to "High speed positioning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

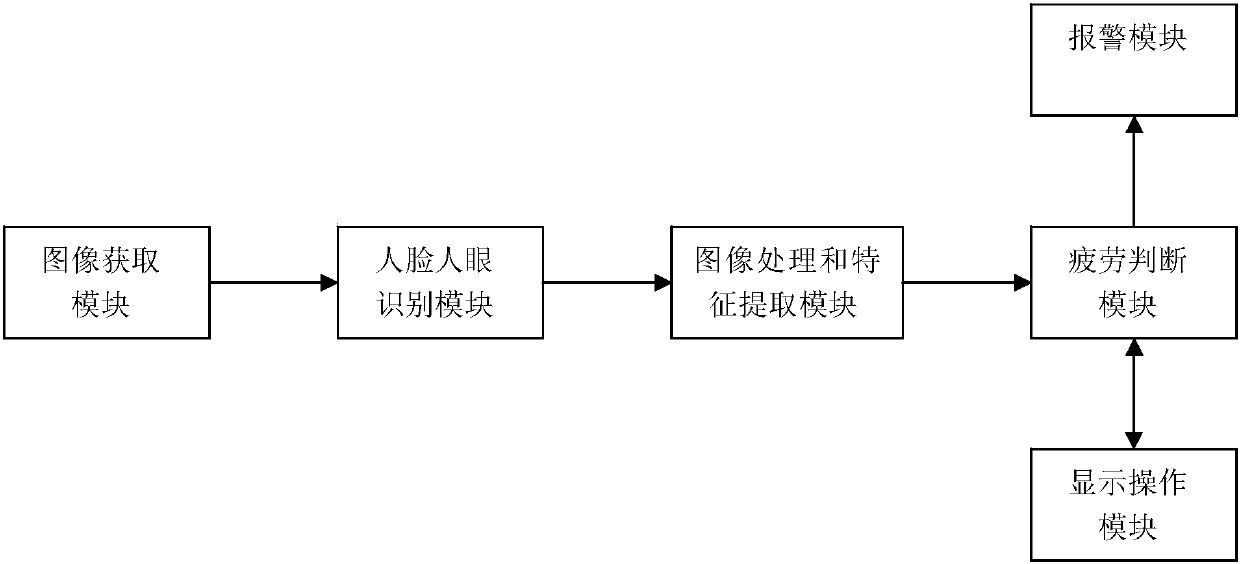

Fatigue driving detection device and detection method based on machine vision human eye recognition

InactiveCN107595307ASolve invisibleSolve the low-light environment imaging problemDiagnostic recording/measuringSensorsBlink frequencyMachine vision

The invention discloses a fatigue driving detection method based on machine vision human eye recognition. The detection method includes the steps: capturing a human face in a captured image, and tracking and positioning human eyes in real time to obtain a human eye image; processing the human eye image; extracting eye characteristics of a human eye area-of-interest; acquiring human eye characteristics in a waking state, fusing the characteristics according to the acquired human eye height characteristics and human eye blinking frequency characteristics, and judging degree of fatigue; giving analarm for the degree of fatigue. The eye characteristics include the human eye height characteristics and the human eye blinking frequency characteristics. By extracting the eye characteristics of auser, PERCLOS in a detection cycle is calculated and then compared with set PERCLOS, different degrees of fatigue are distinguished according to comparison results, and the user is reminded of two different degrees of fatigue including slight fatigue and severe fatigue. The invention further discloses a fatigue driving detection device based on machine vision human eye recognition.

Owner:HUNAN UNIV OF SCI & TECH

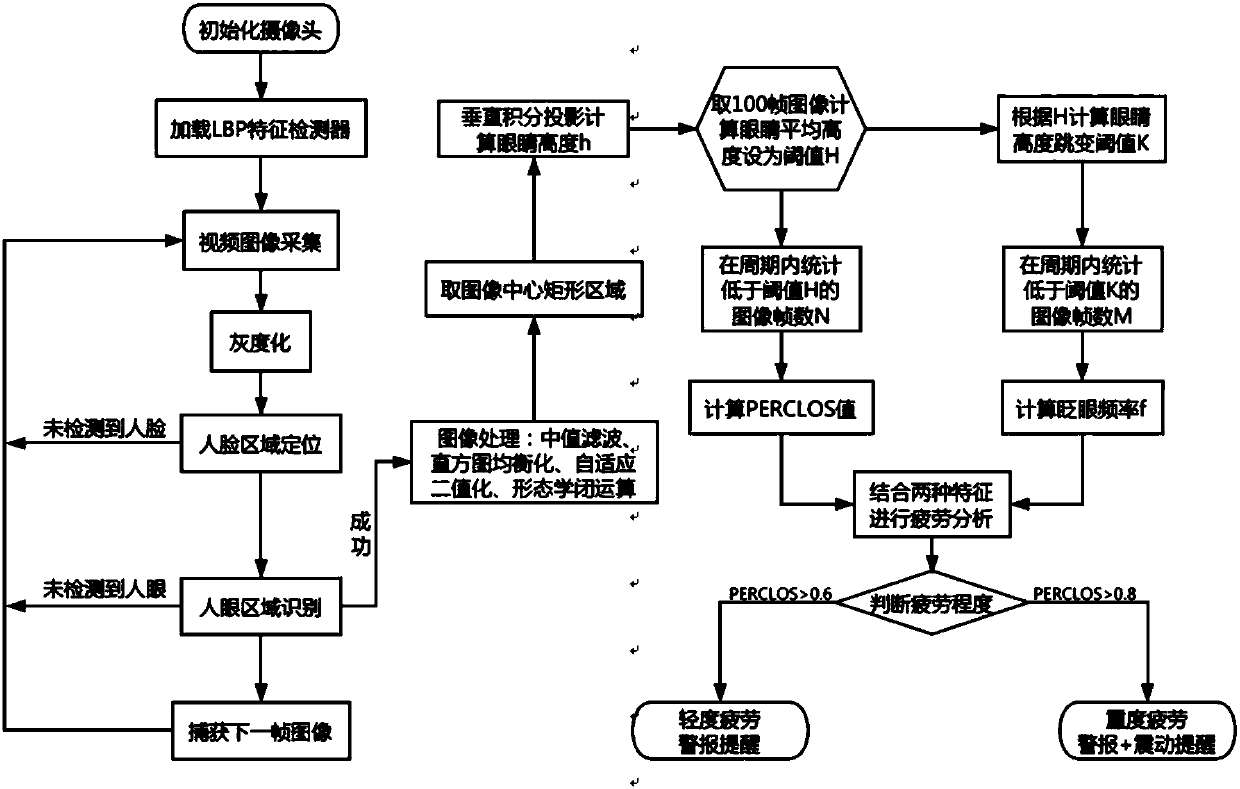

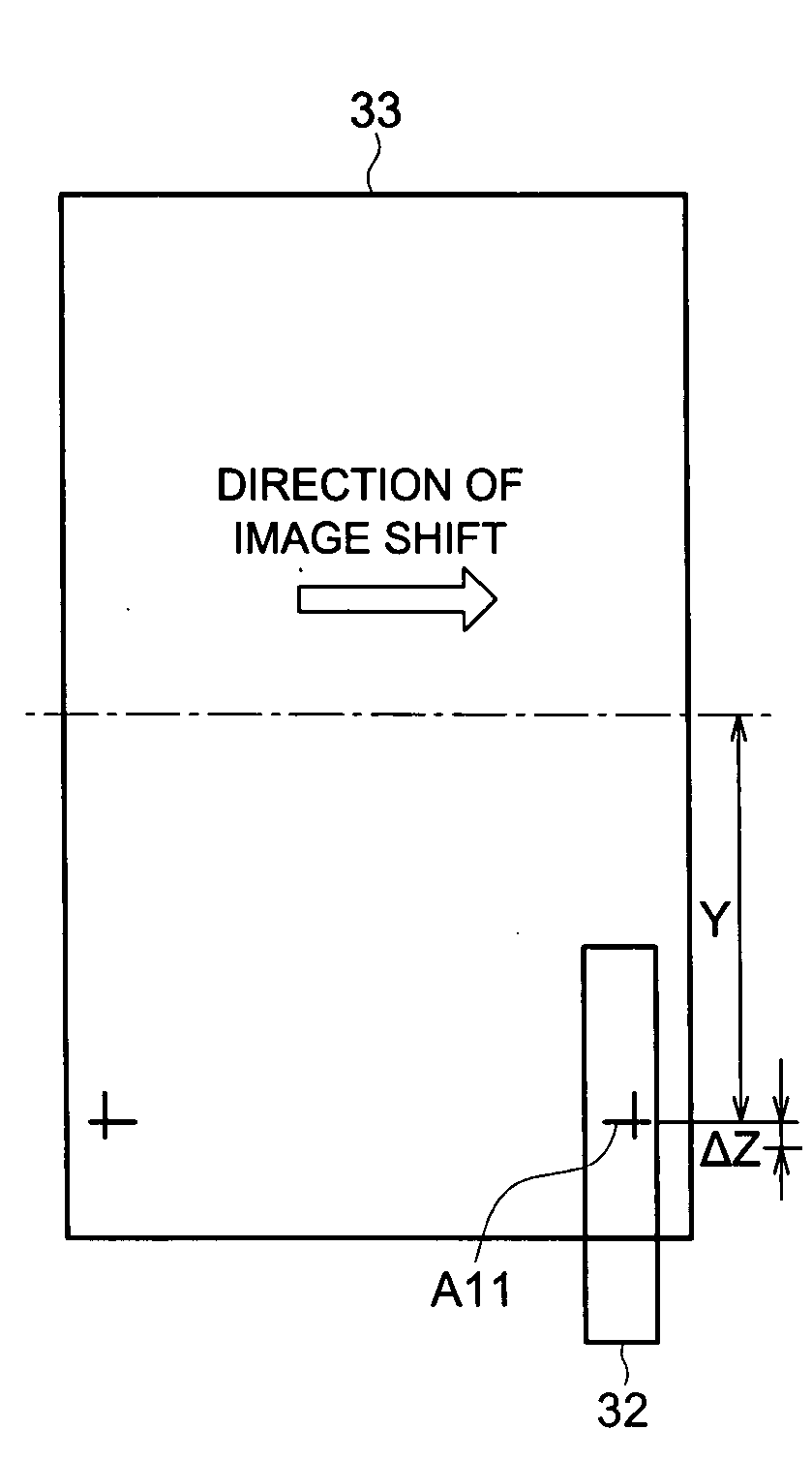

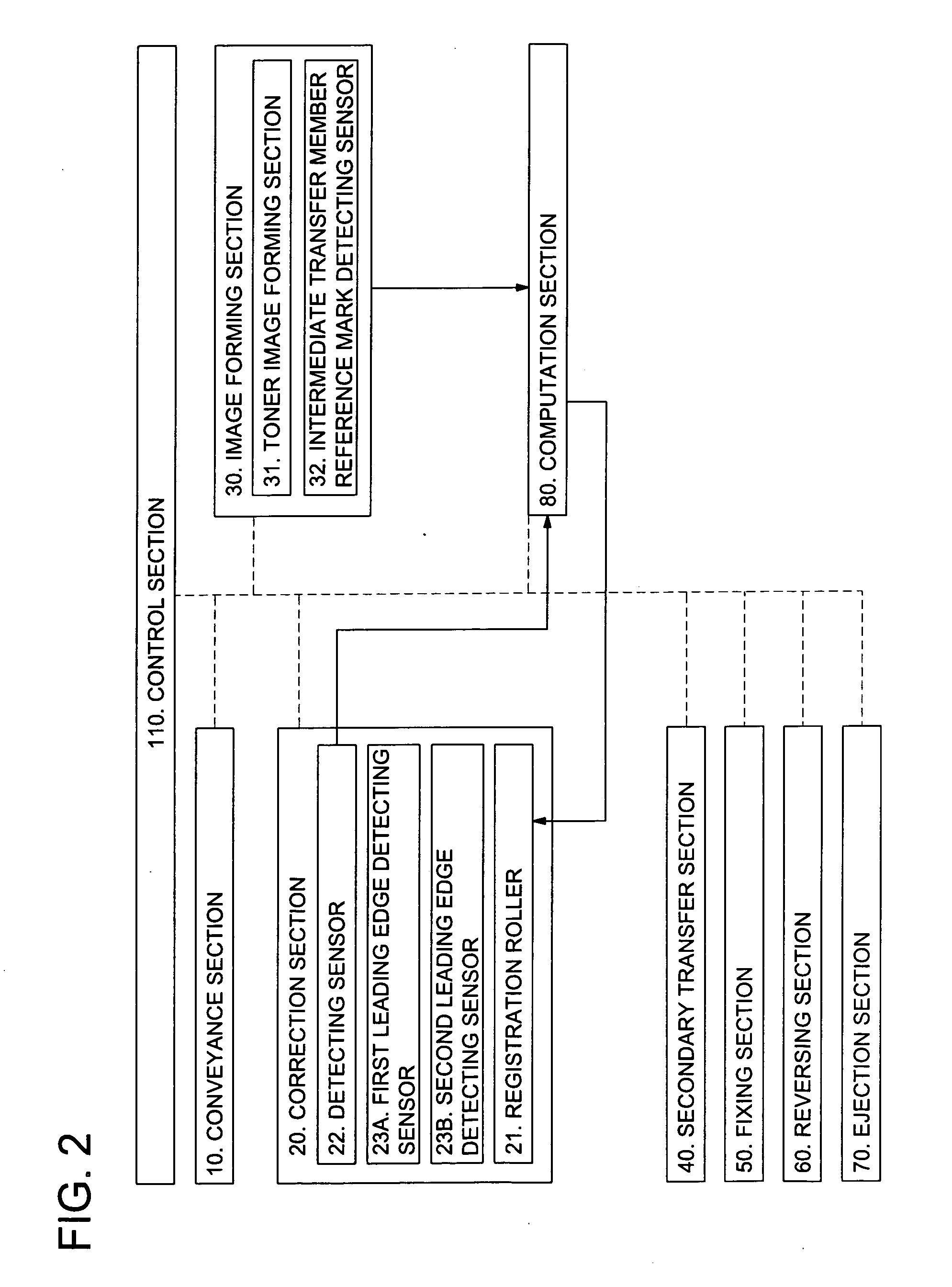

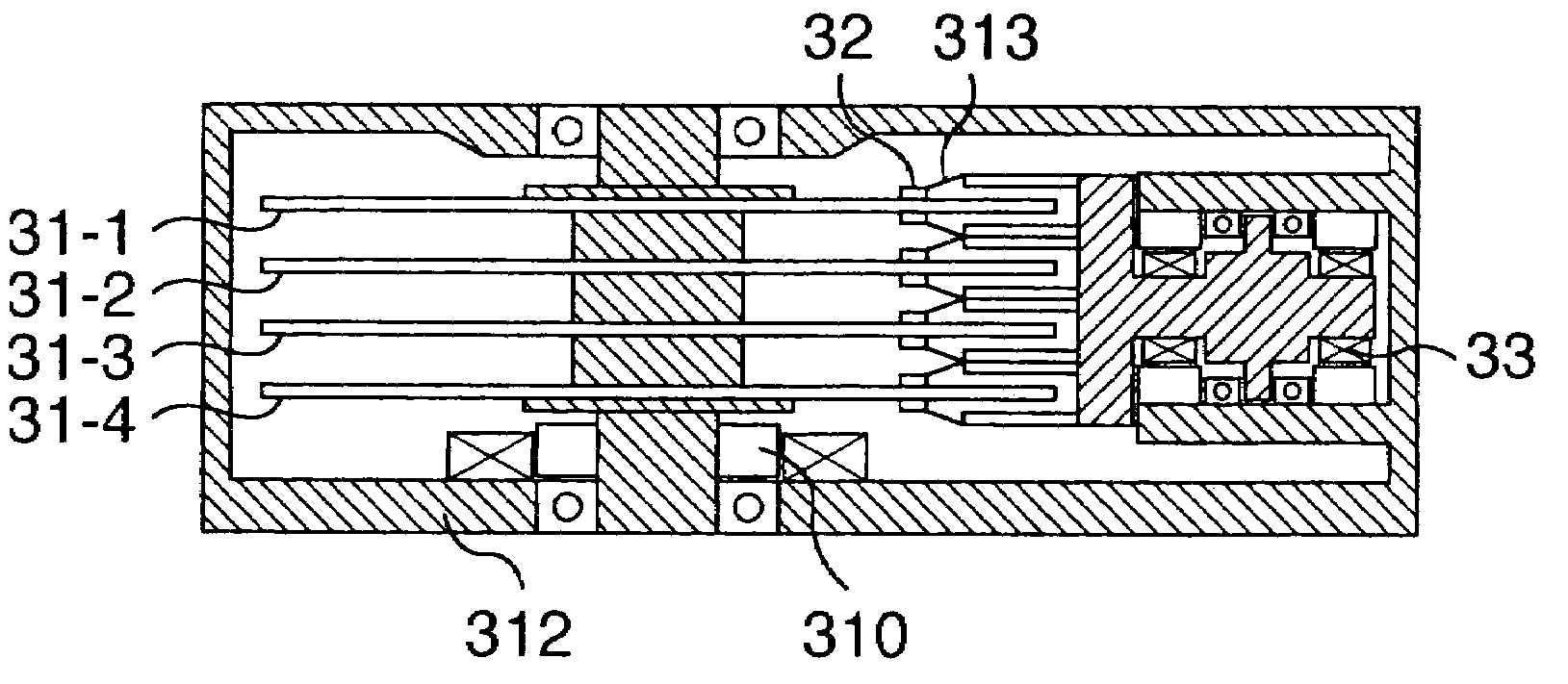

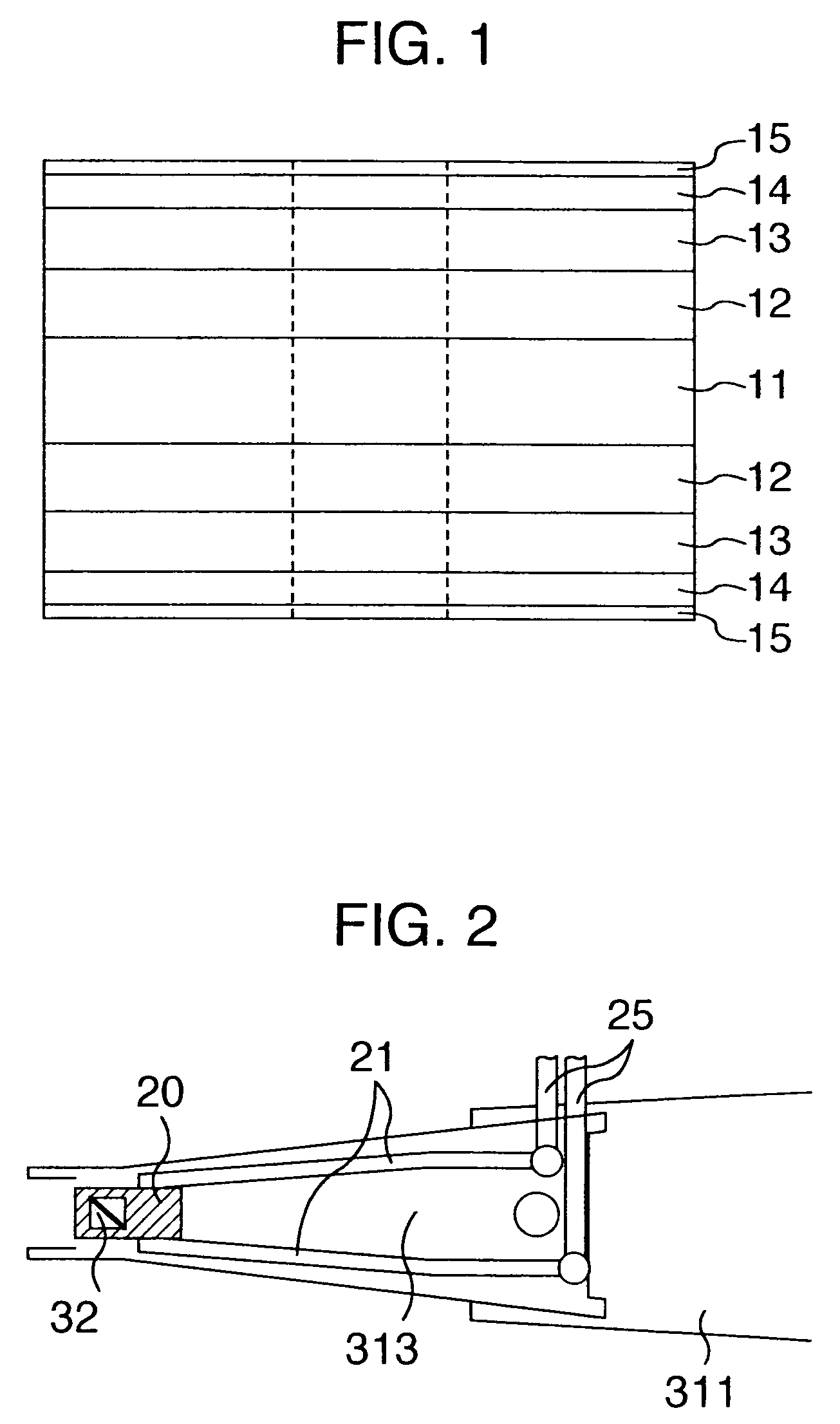

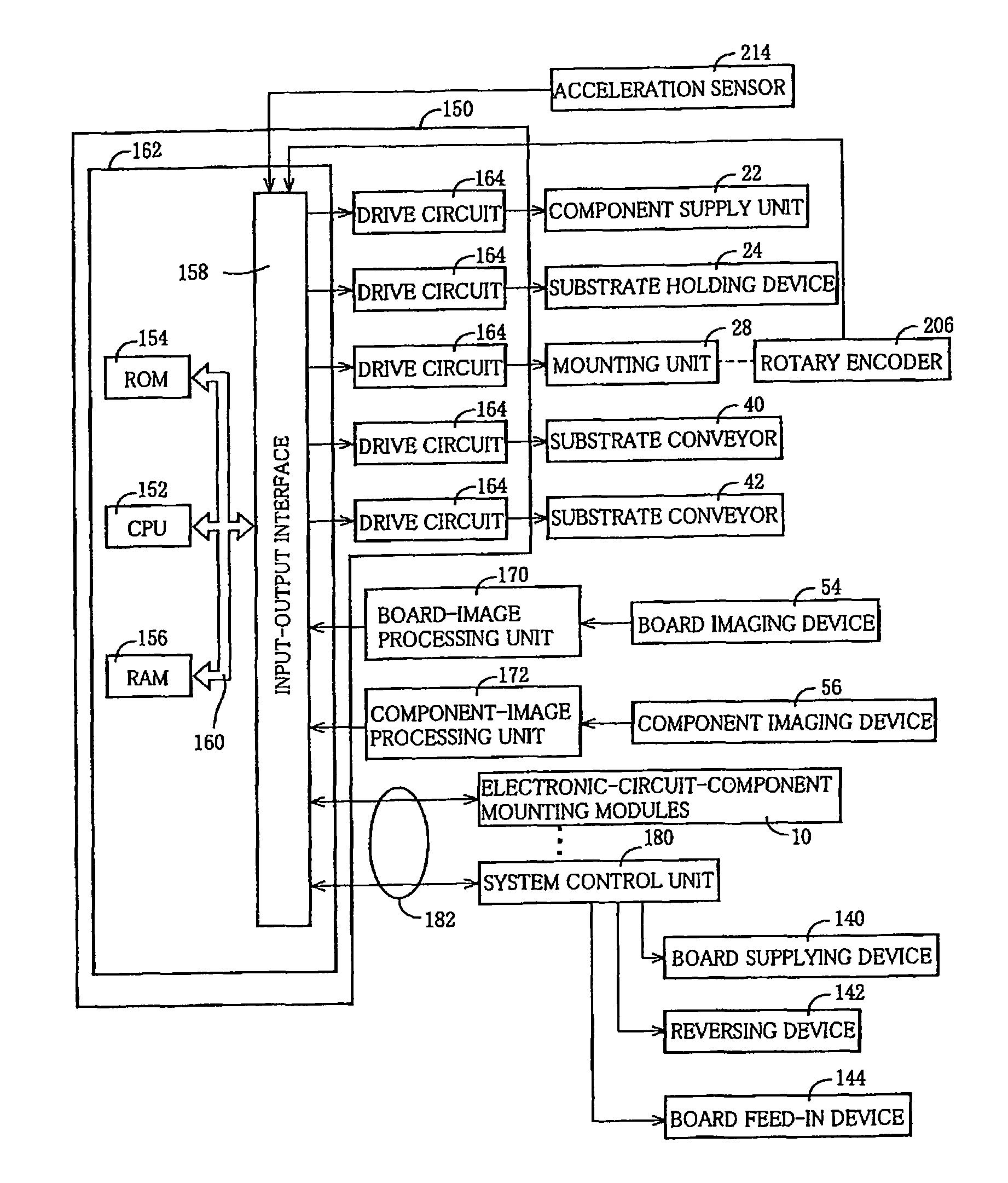

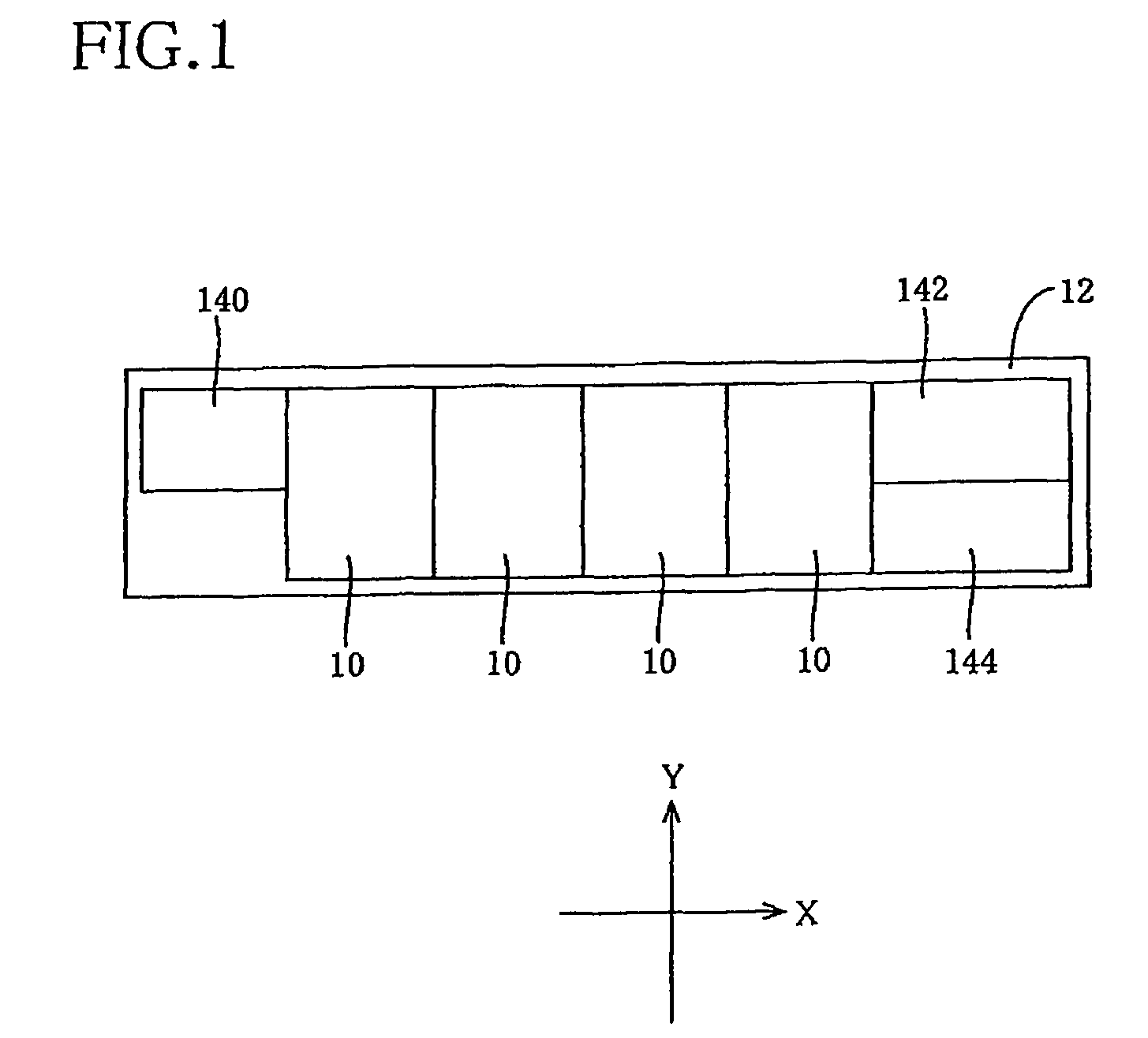

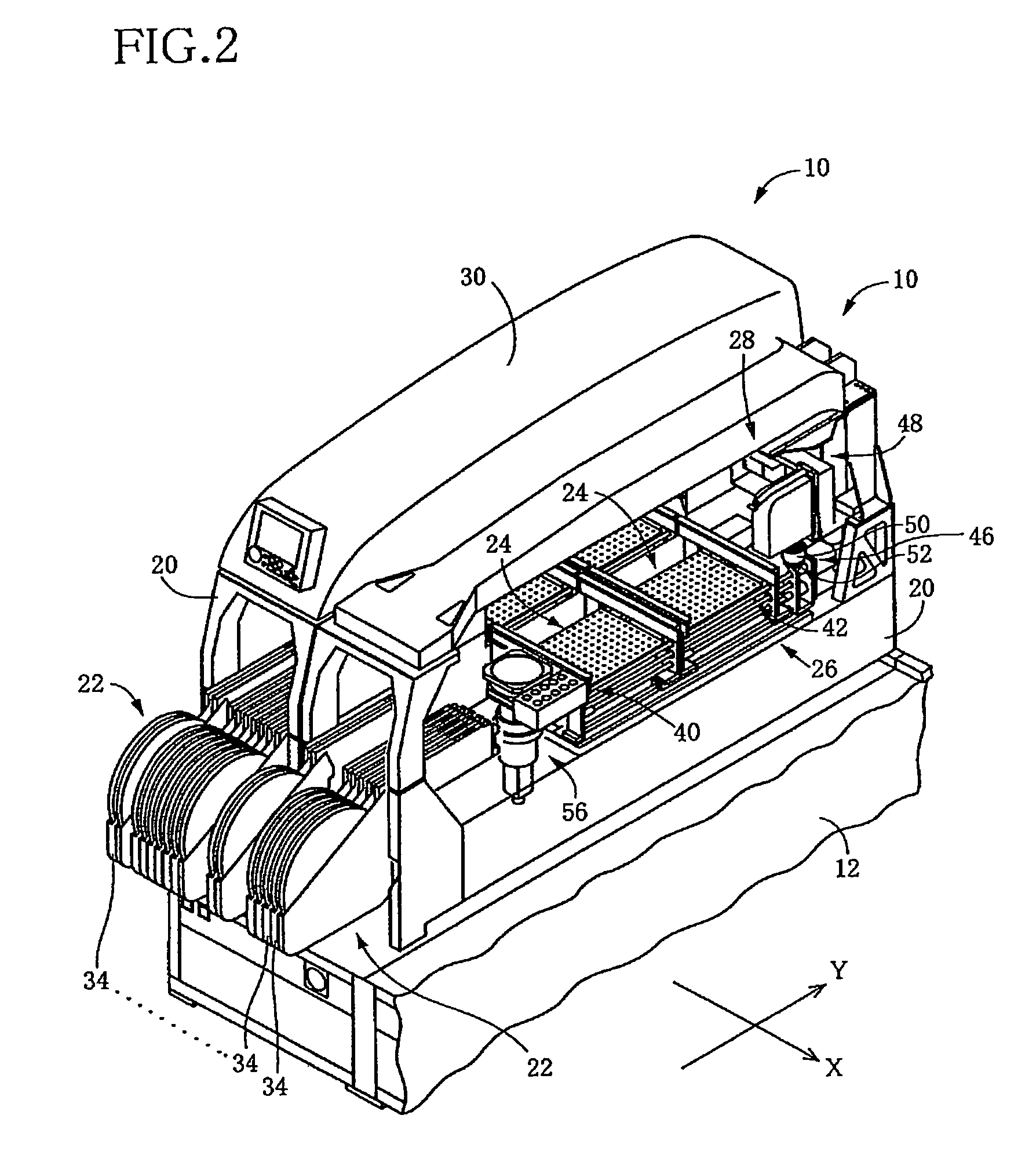

Image forming apparatus

InactiveUS20070264066A1High-speed positioningHigh-speed and high-precision adjustmentRegistering devicesElectrographic process apparatusEngineeringElectrical and Electronics engineering

Owner:KONICA MINOLTA BUSINESS TECH INC

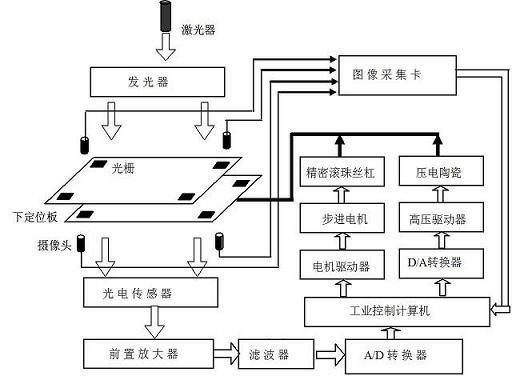

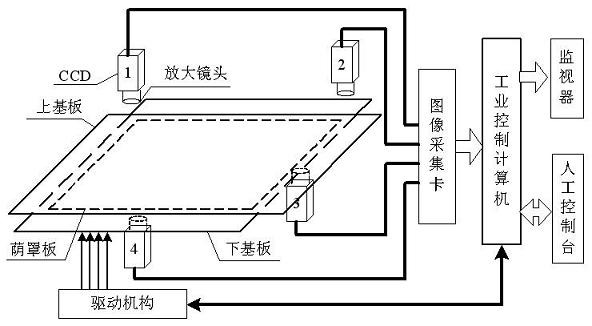

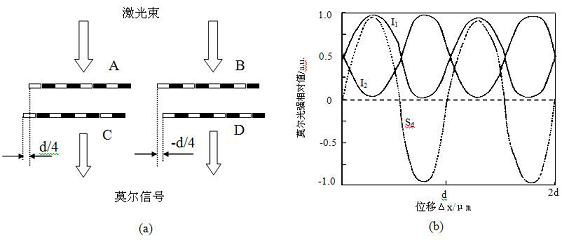

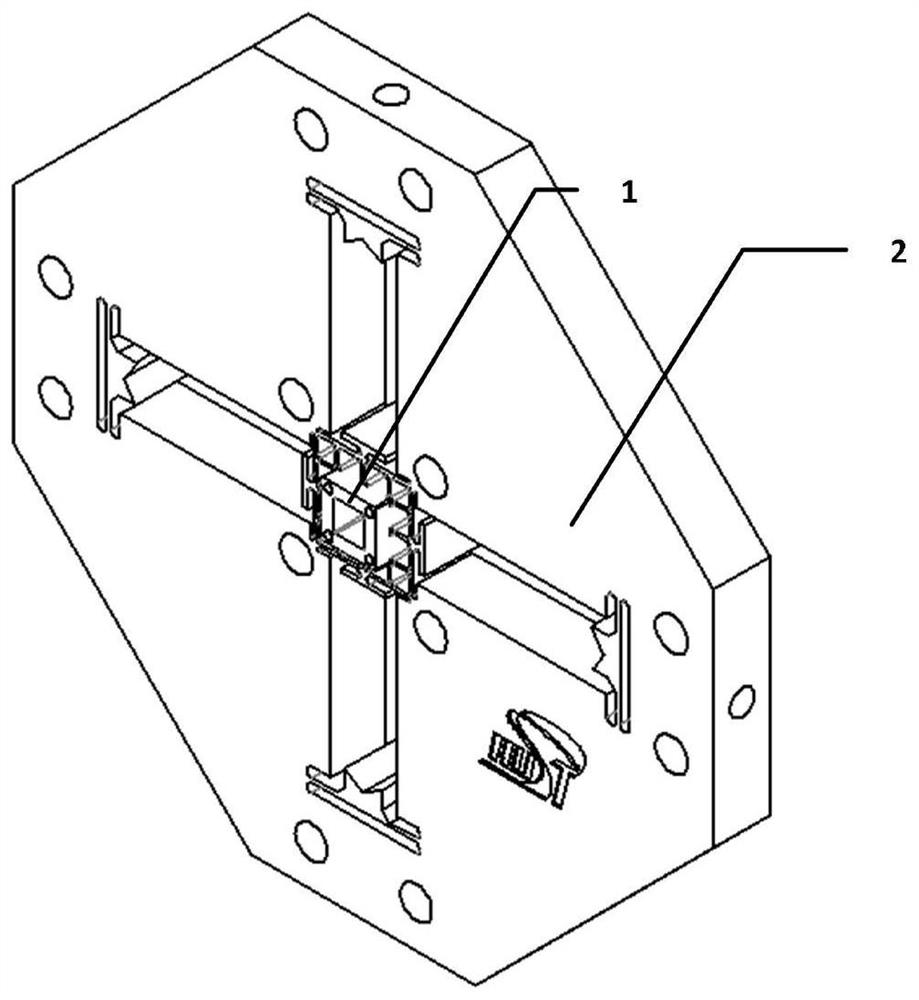

Three-section combined type ultraprecise positioning table and positioning method thereof

The invention relates to the technical field of precision machining, and provides an ultraprecise positioning table and a three-section combined type positioning method which combines coarse positioning, precise positioning and ultraprecise positioning, wherein a computer vision positioning method is adopted for coarse positioning; the positioning table largely drives a coarse positioning mechanism to move in a larger working stroke scope to quickly complete coarse positioning; a coarse grating positioning method is adopted for precise positioning; then a computer judges position deviation according to the size and polarity of mole signals generated by coarse grating and drives the coarse positioning mechanism to move at a quicker speed to complete precise positioning; a fine grating positioning method is adopted for ultraprecise positioning; a piezoceramics micrometric displacement driver is adopted so as to guarantee higher positioning precision. As the three-section combined type positioning method is adopted and positioning combined with large-step quick drive and precise drive is used, the ultraprecise positioning table can realize high-precision positioning in a larger working stroke; meanwhile, the positioning time can be greatly shortened; therefore, high speed positioning is realized.

Owner:NANJING NORMAL UNIVERSITY

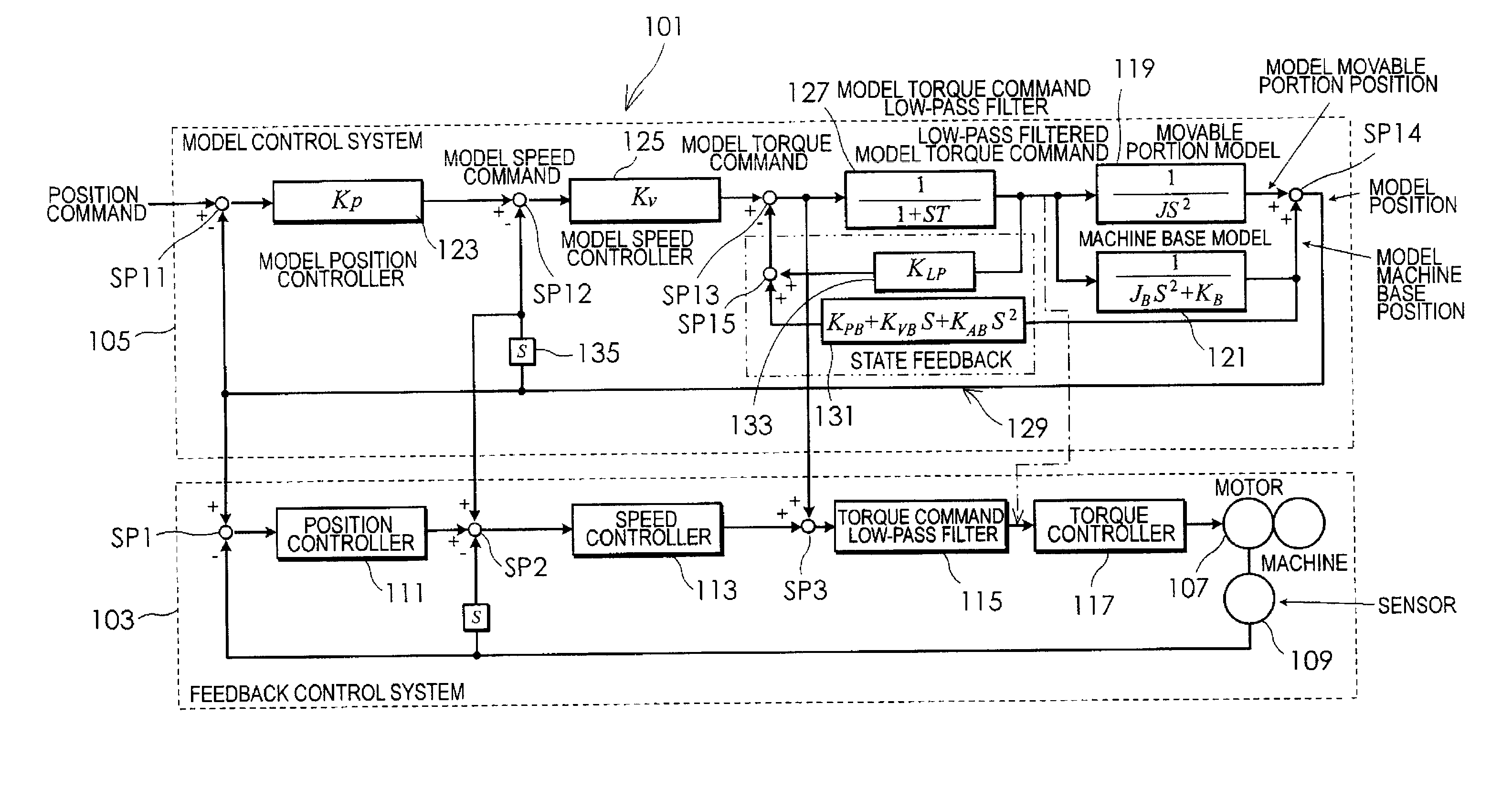

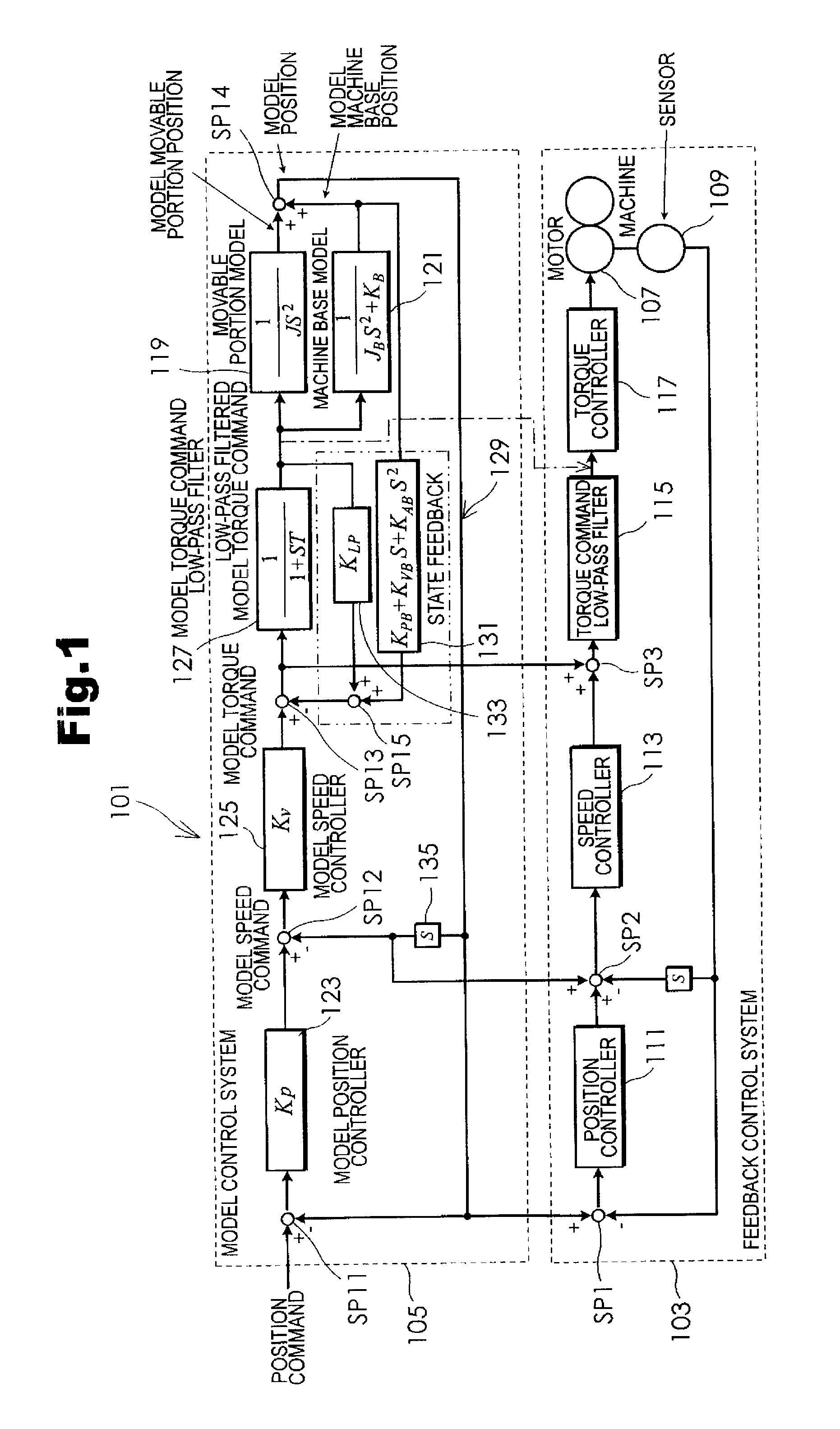

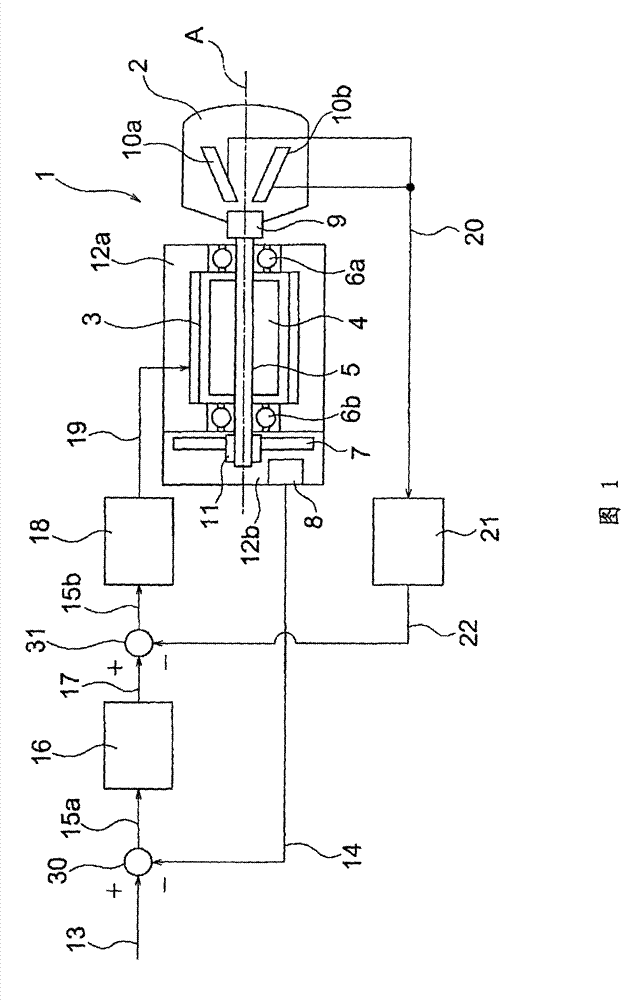

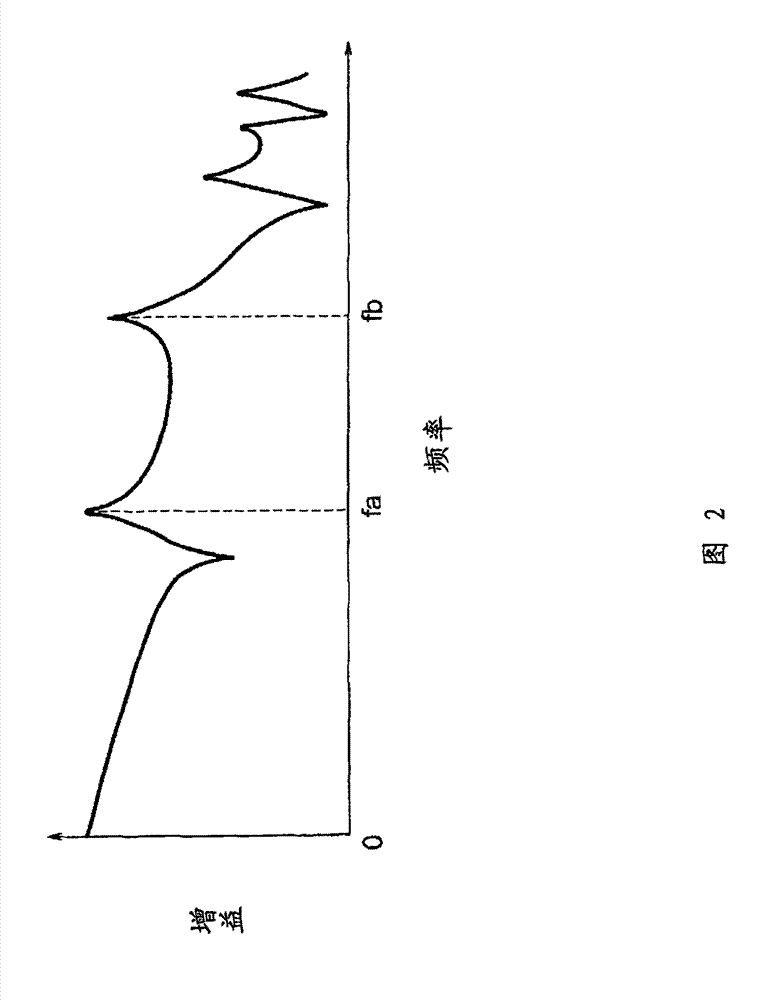

Motor control system

ActiveUS20100060226A1Reduce vibrationEasy to useTorque ripple controlTemperatue controlLow-pass filterControl system

A motor control system suppresses vibration of a machine base and achieves high-speed positioning without using a special sensor but using a model control system. A first feedback section outputs a first feedback command generated based on model machine base position information and containing at least position information on the machine base. A second feedback section outputs a second feedback command containing a filtered model torque command. A differential between the sum of the first feedback command and the second feedback command obtained by a second addition section and the model torque command is calculated to give the differential to an input portion of a model torque command low-pass filter and an input portion of a torque command low-pass filter. The model control system gives a model position command to a position controller as a position command, and model machine base position information generated based on the model position command is added to a speed command input from the position controller to a speed controller.

Owner:SANYO DENKI CO LTD

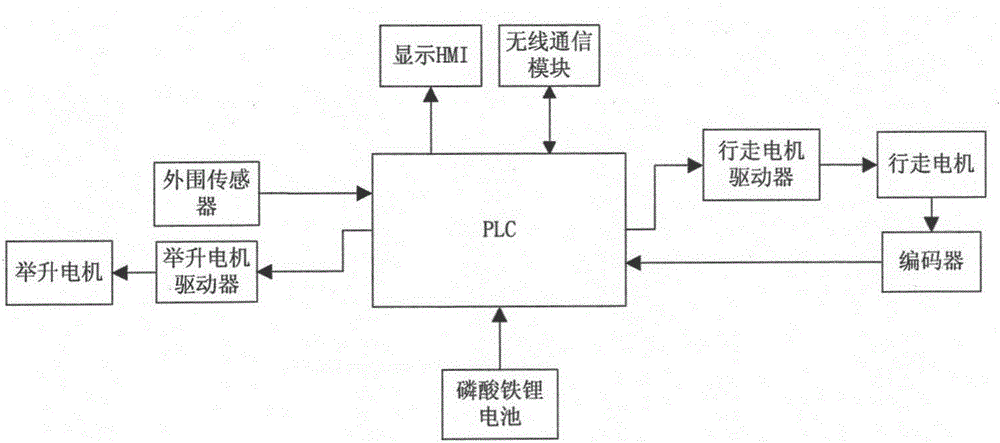

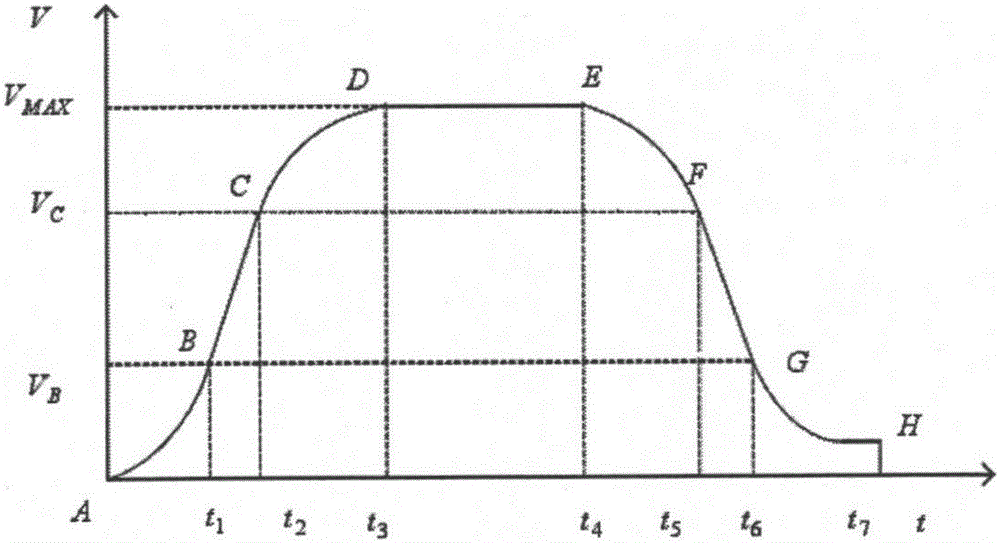

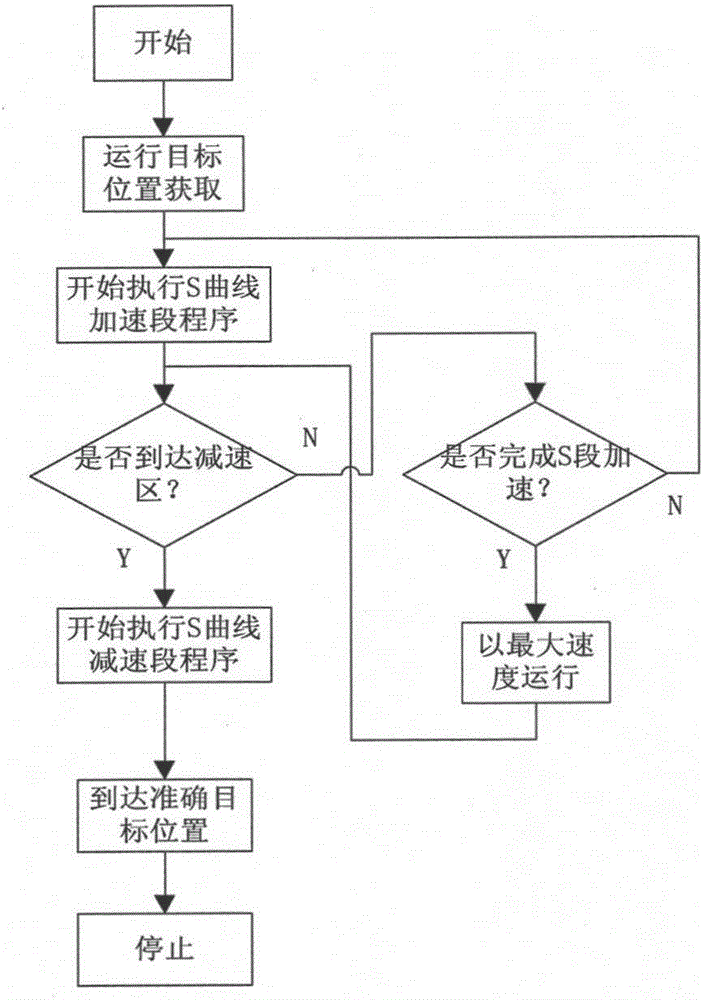

Method for precise positioning of shuttle vehicle moving in dense storage warehouse

InactiveCN106647749APrecise positioningHigh speed positioningPosition/course control in two dimensionsInstabilityEngineering

The invention relates to a method for the precise positioning of a shuttle vehicle moving in a dense storage warehouse. An S-curve acceleration and deceleration algorithm is employed for the adjustment of the real-time speed of the shutter vehicle in a process of precise positioning, thereby achieving the high-speed and precise positioning. The S-curve acceleration and deceleration is indicated by the S-shaped speed curve of a system at the stage of acceleration and deceleration. When the shuttle vehicle carries out the acceleration and deceleration control, the derivative of acceleration is a constant. Through the control of the acceleration value, the method reduces the instability, caused by an inertia load, to maximum degree, and improves the precision.

Owner:上海精星仓储设备工程有限公司 +1

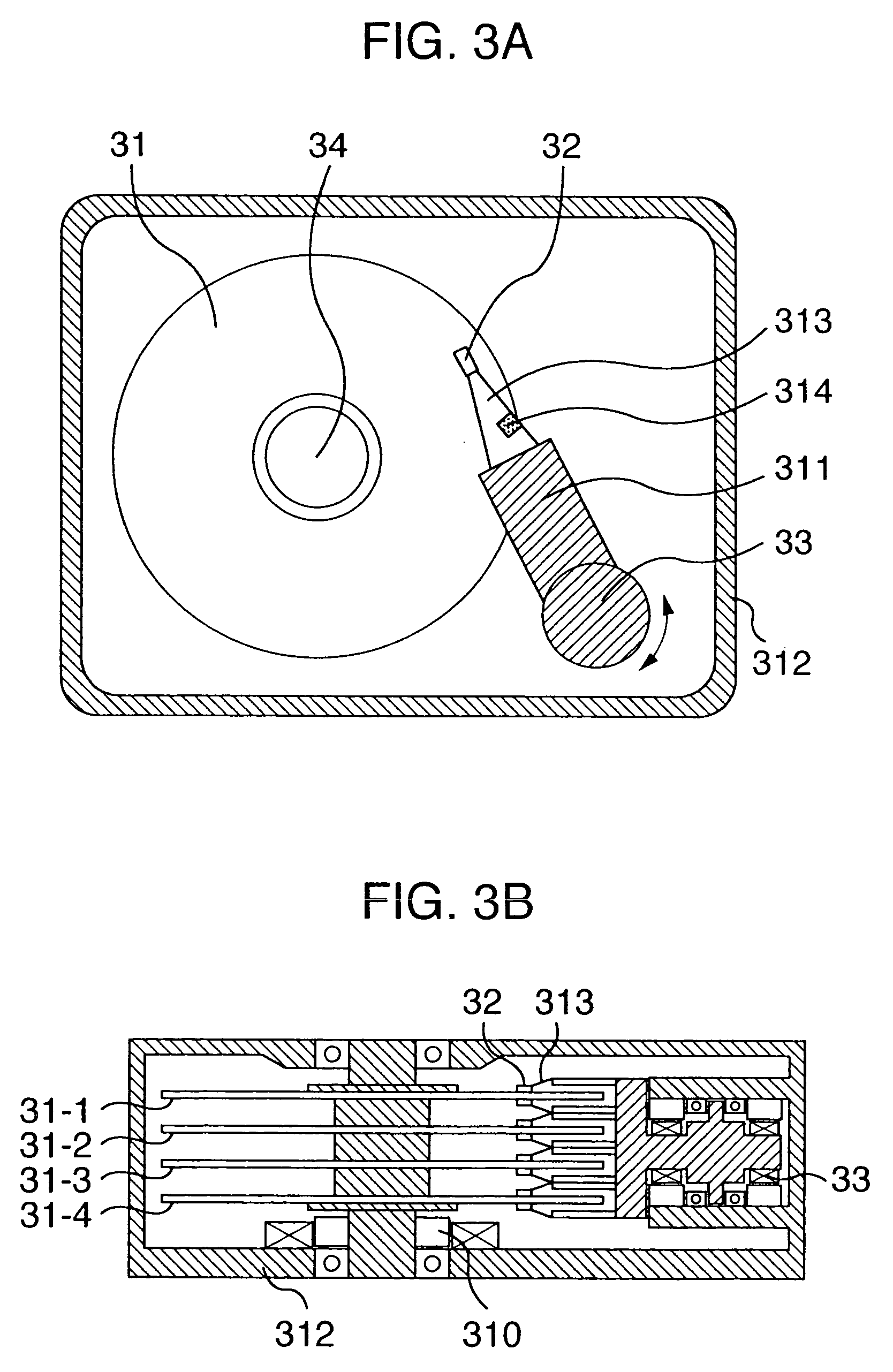

Magnetic recording and reading device

InactiveUS7177115B2Optimizing thermal fluctuationOptimizing damping coefficientNanomagnetismDriving/moving recording headsLine widthRecording density

A magnetic recording and reading device having a transfer rate of not less than 50 MB / s includes a magnetic recording medium having an absolute value of normalized noise coefficient per recording density of not more than 2.5×10−8 (μVrms)(inch) (μm)0.5 / (μVpp), and magnetic head which is mounted on an integrated circuit suspension so that a total inductance is reduced to be not more than 65nH and having a magnetic core which is not more than 35 μm of length, wherein a part of the magnetic core being formed by a magnetic film having a resistivity exceeding at least 50 μΩcm or by a multilayer film consisting of a magnetic film and an insulating film. The device also includes a fast R / W-IC having a line width of not more than 0.35 μm which is installed in a position within 2 cm from a rear end of the magnetic head.

Owner:WESTERN DIGITAL TECH INC

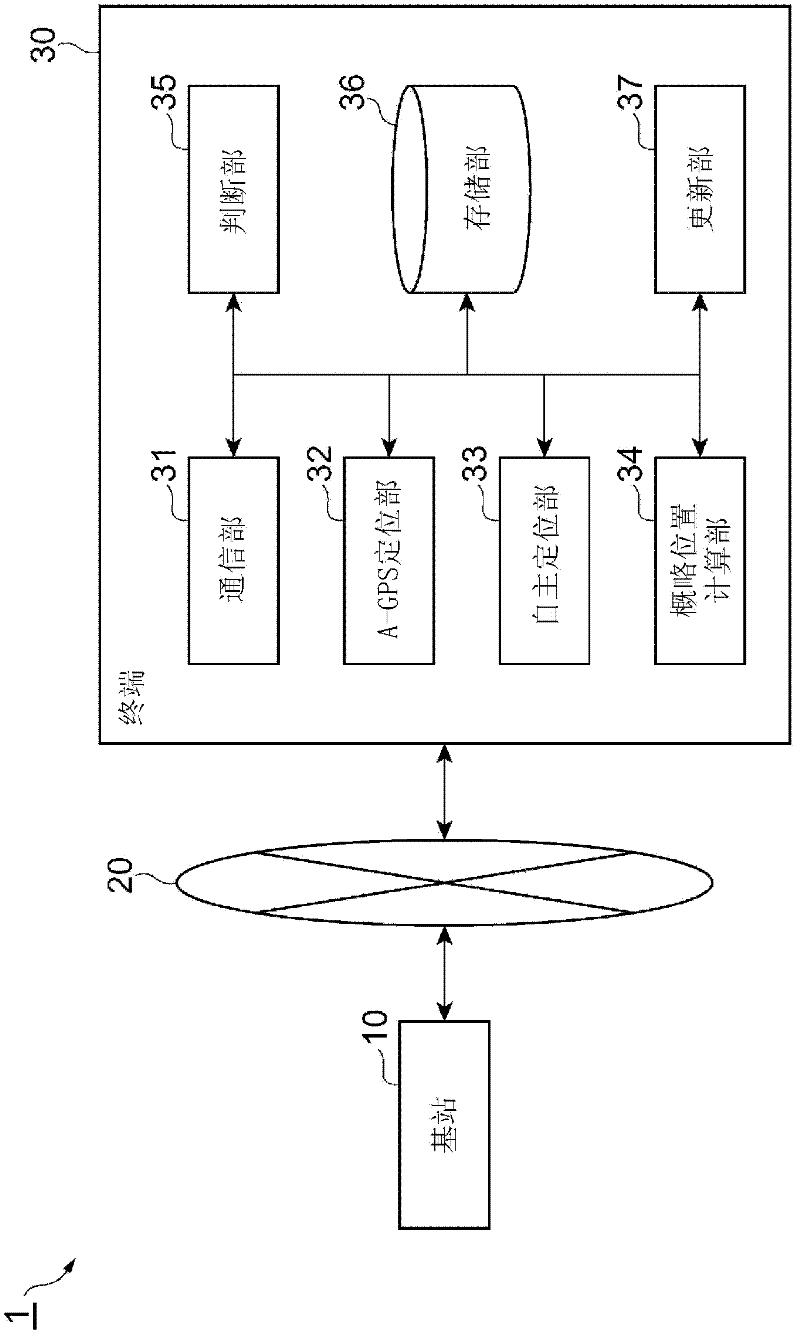

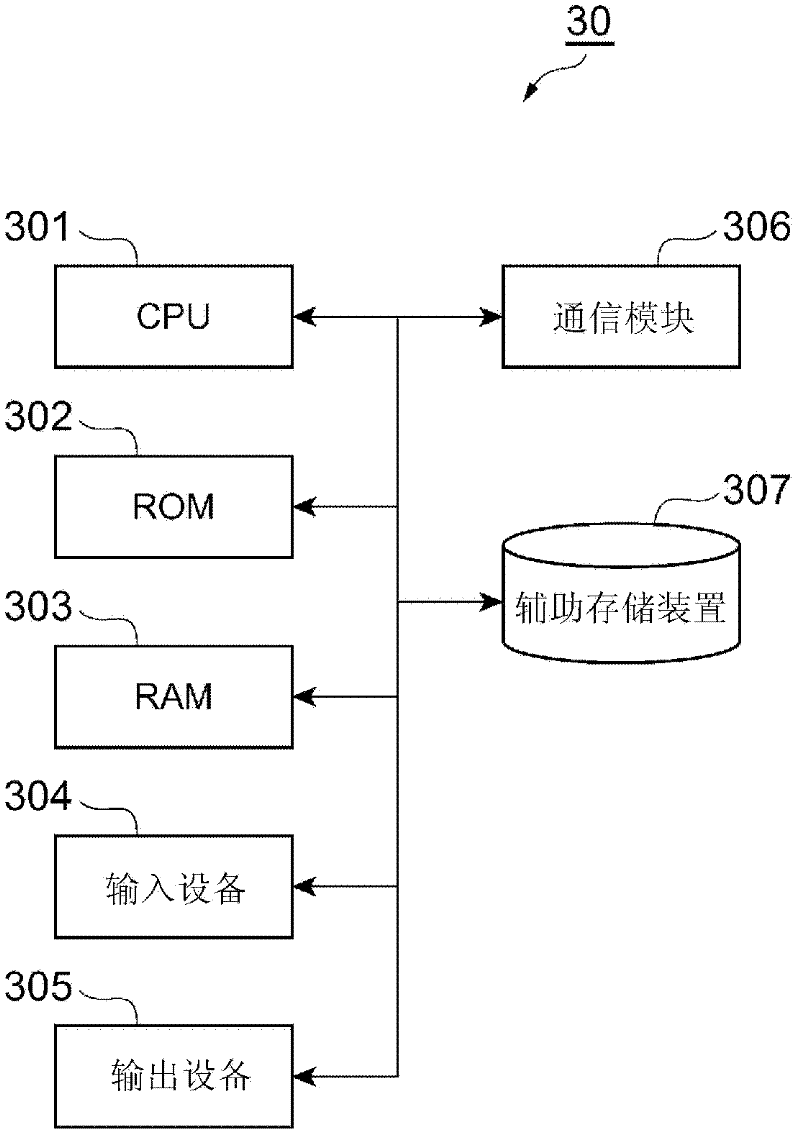

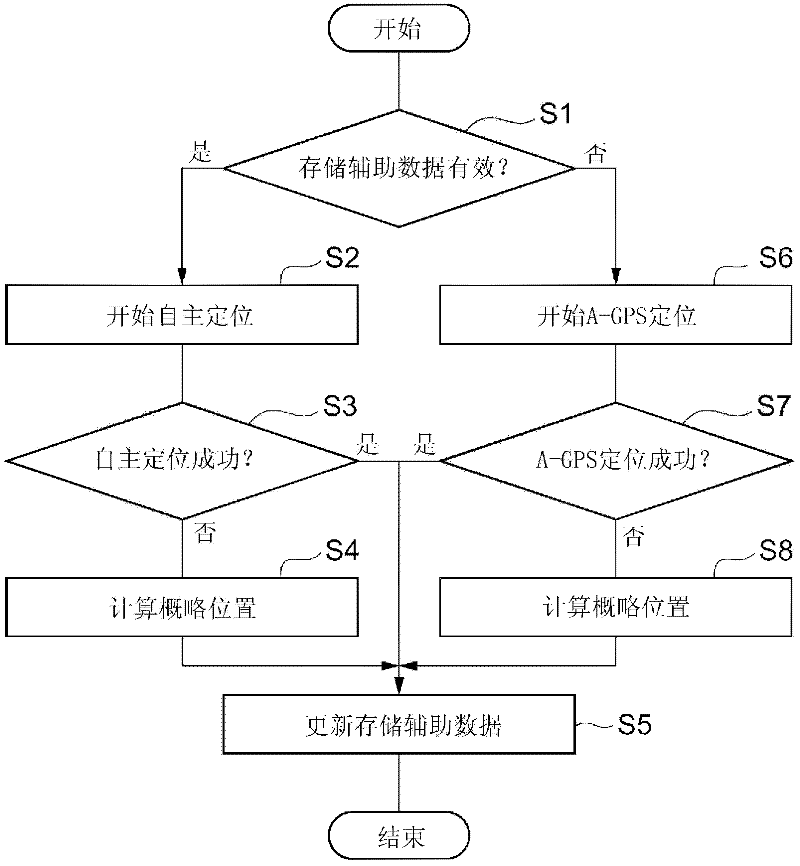

GPS positioning system, GPS positioning method, and GPS positioning terminal

InactiveCN102472819AHigh precisionImprove efficiencySatellite radio beaconingWireless commuication servicesGps positioning systemComputer terminal

A GPS positioning system is provided with a storage unit (36) which stores assist data for GPS positioning therein, a determination unit (35) which determines whether stored assist data that is stored in the storage unit (36) is valid or invalid, an Autonomous positioning unit (33) which, when the stored assist data is determined to be valid, performs the GPS positioning on the basis of the stored assist data determined to be valid, without communication with a base station (10), an A-GPS positioning unit (32) which, when the stored assist data is determined to be invalid, performs the GPS positioning on the basis of assist data acquired by communication with the base station (10), and an updating unit (37) which, when the GPS positioning succeeds, updates the stored assist data on the basis of the result of the positioning, and when the GPS positioning fails, updates the stored assist data on the basis of the assist data acquired by communication with the base station (10).

Owner:NTT DOCOMO INC

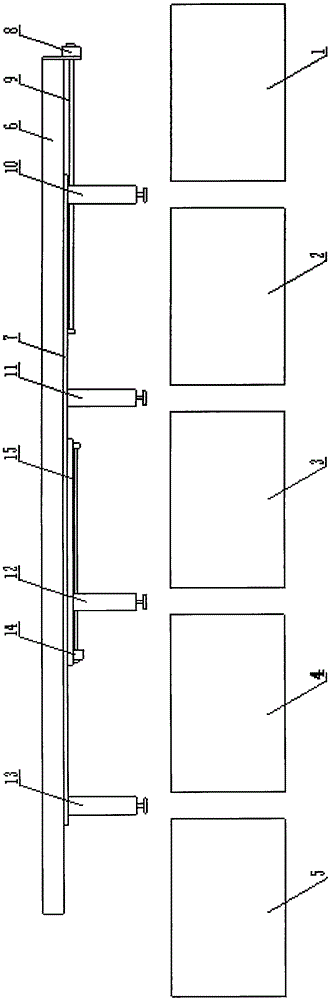

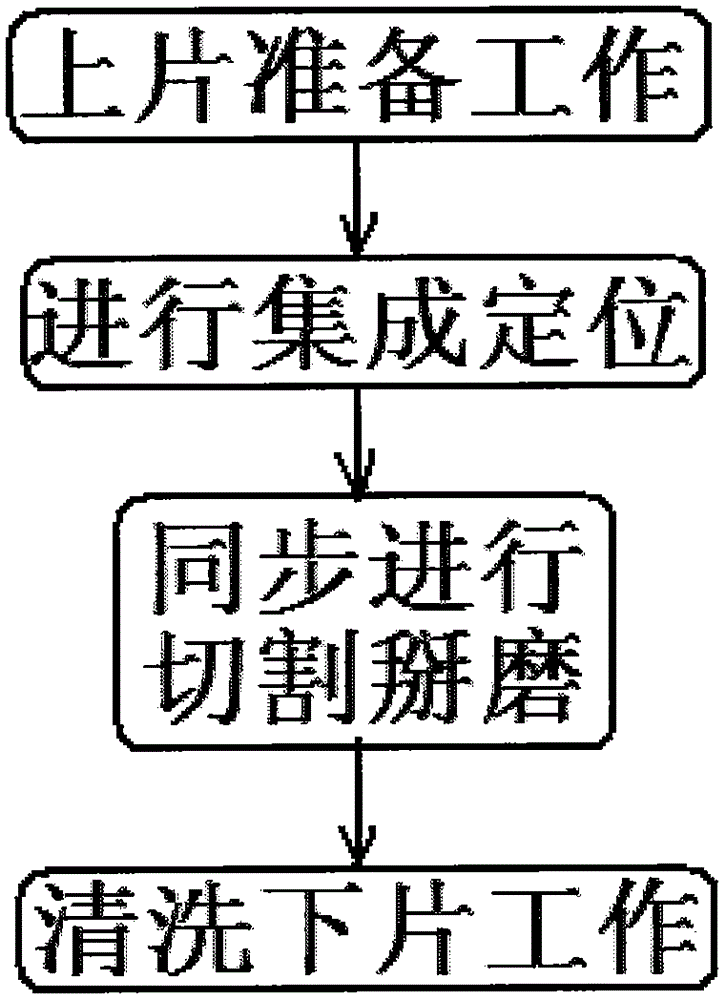

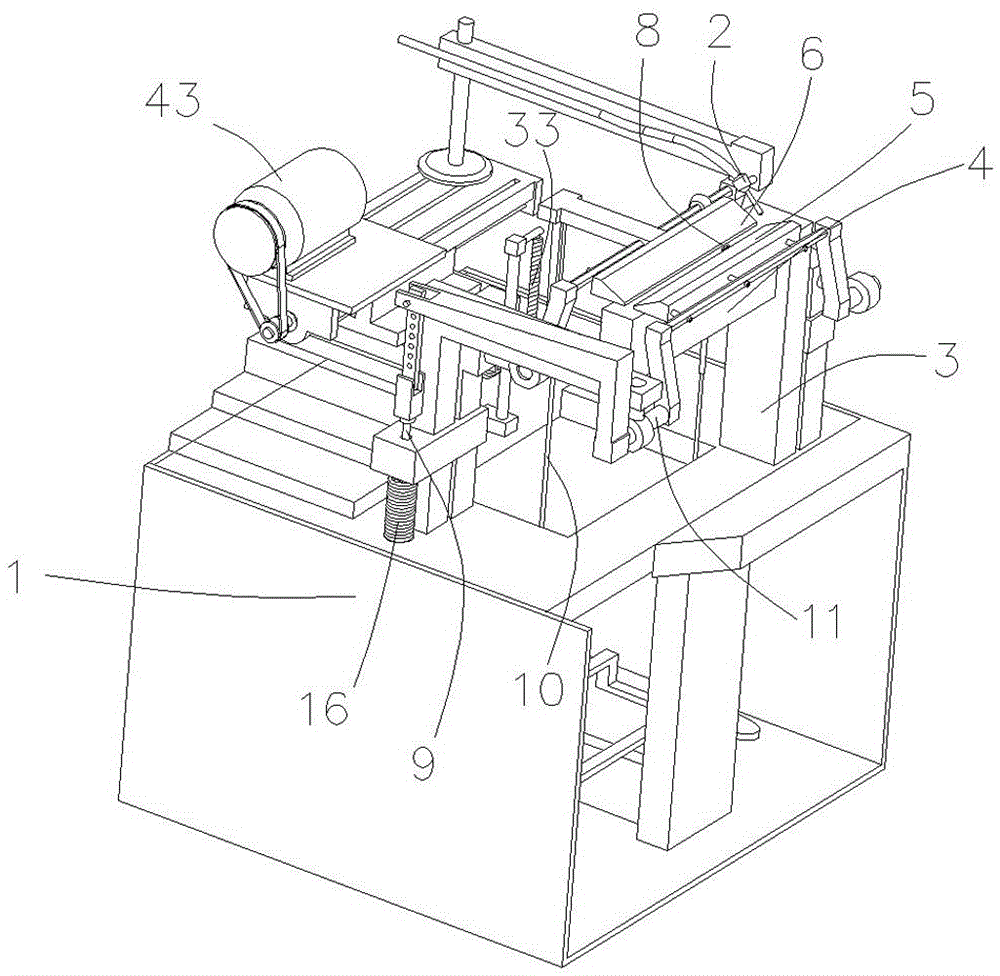

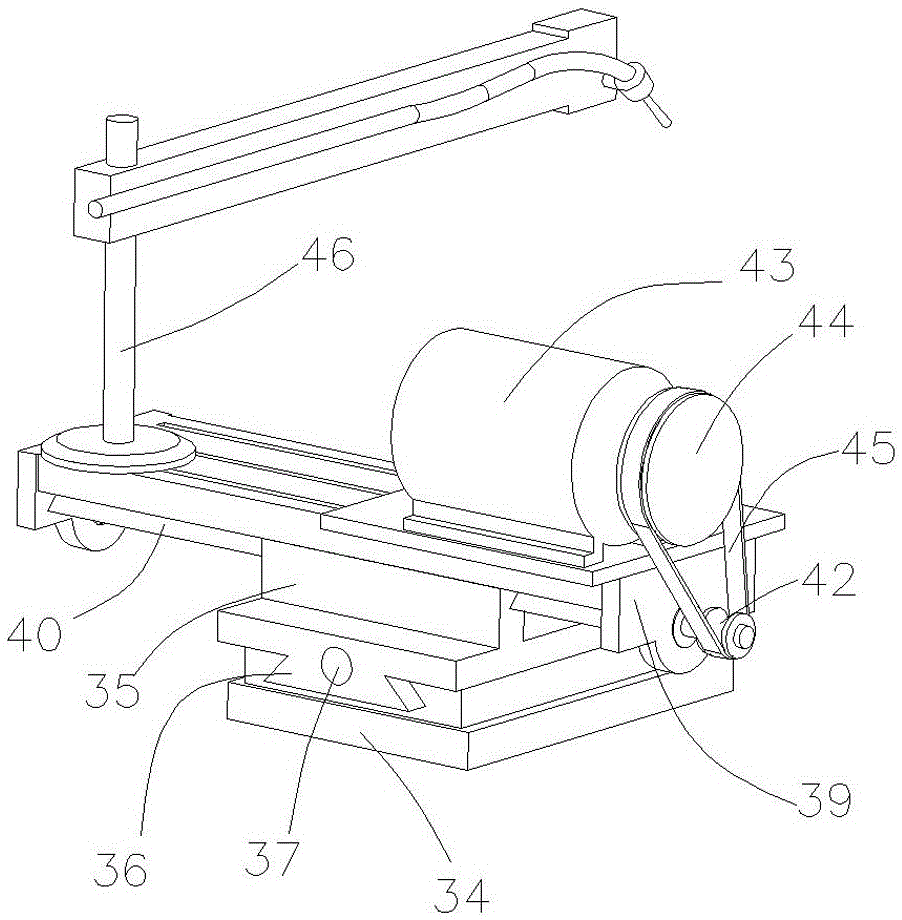

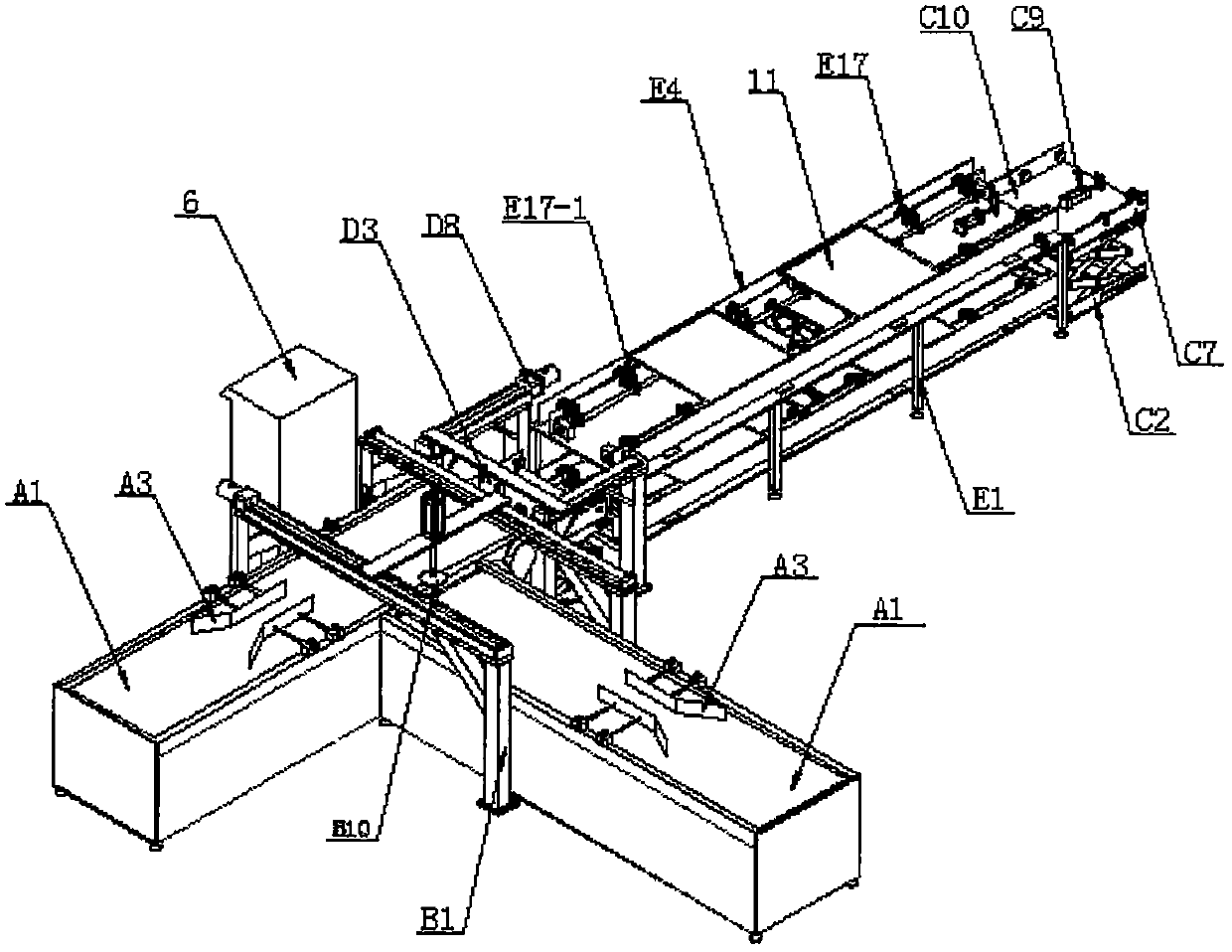

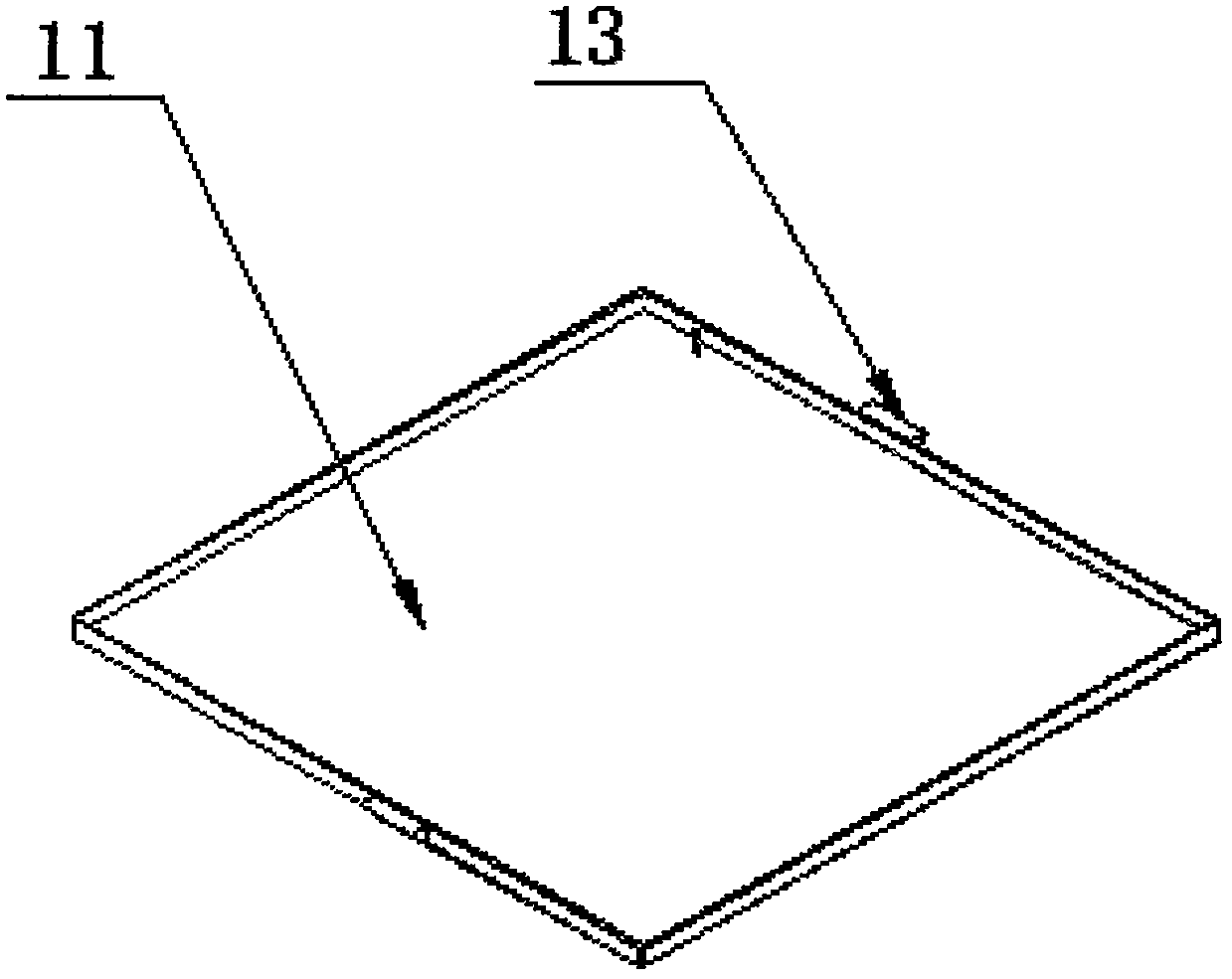

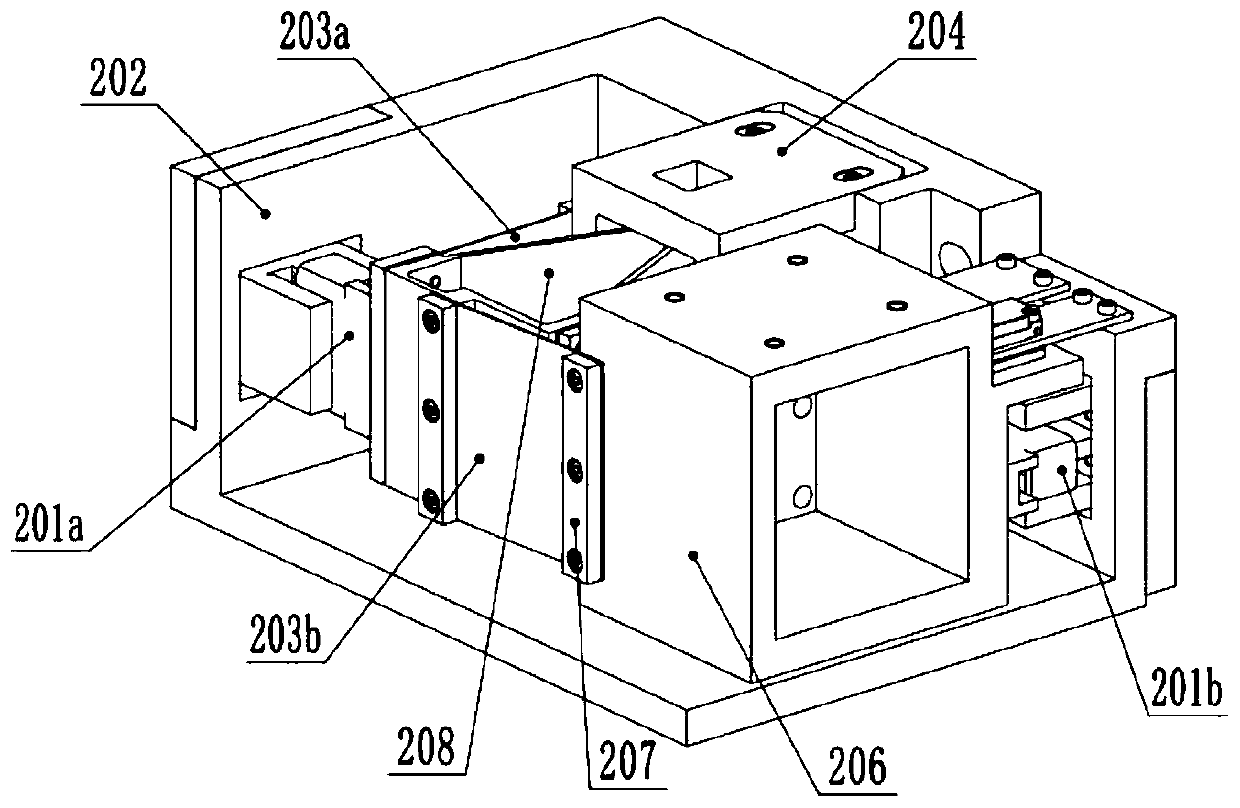

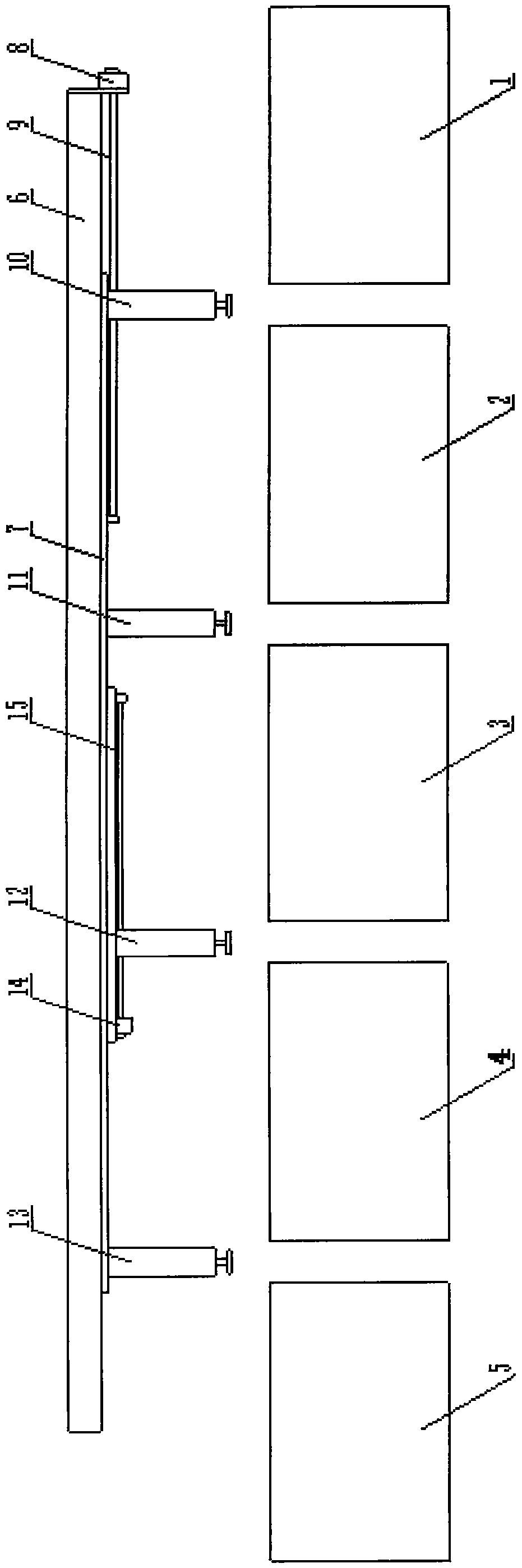

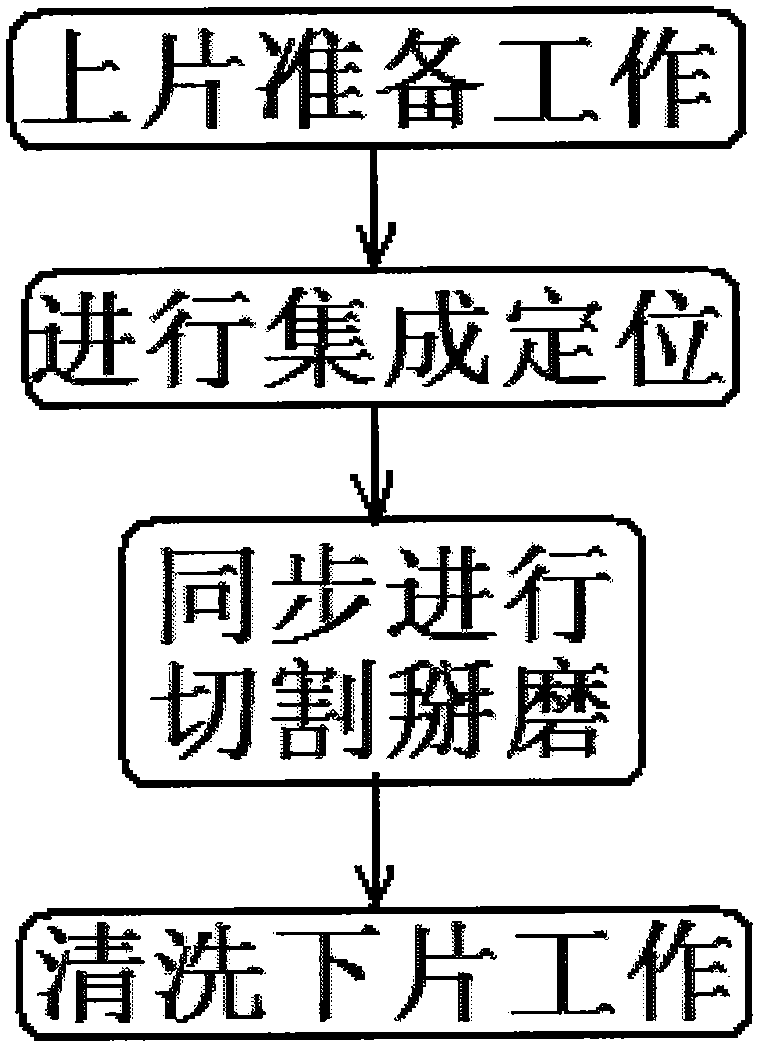

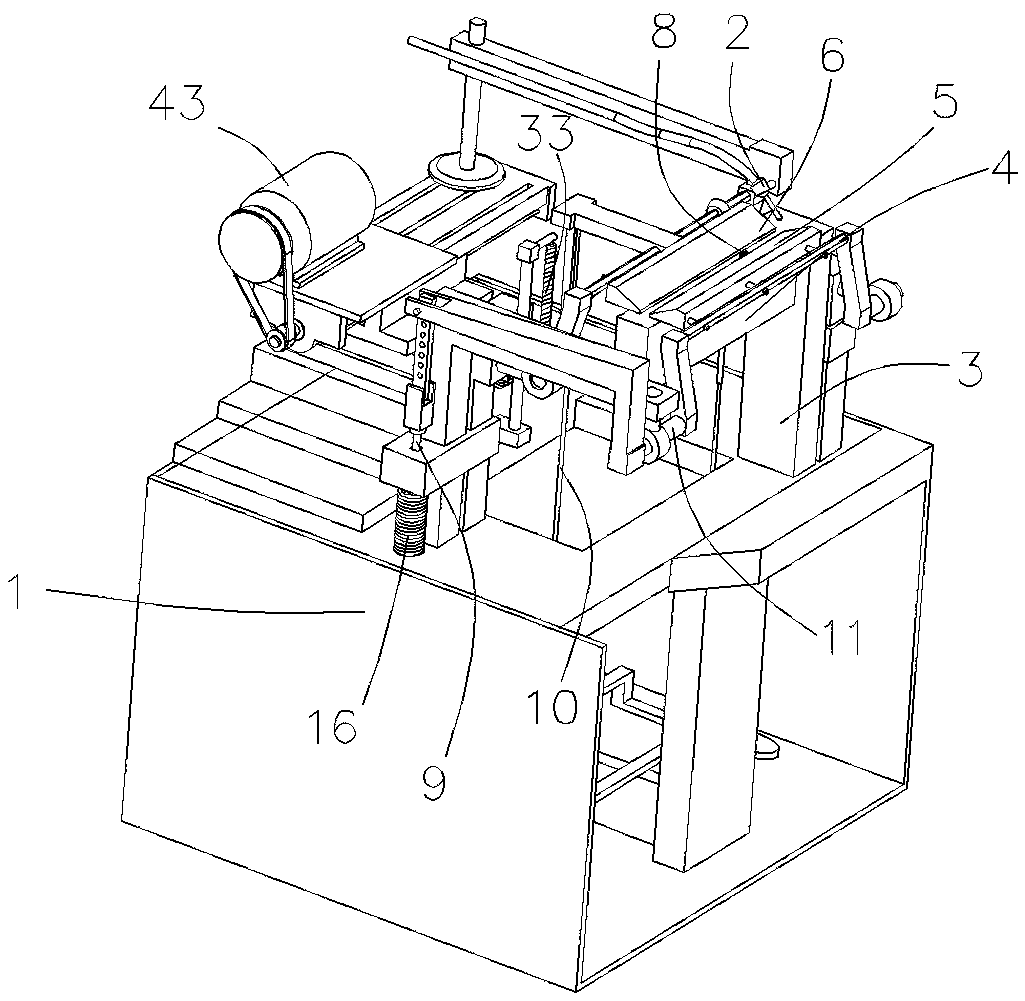

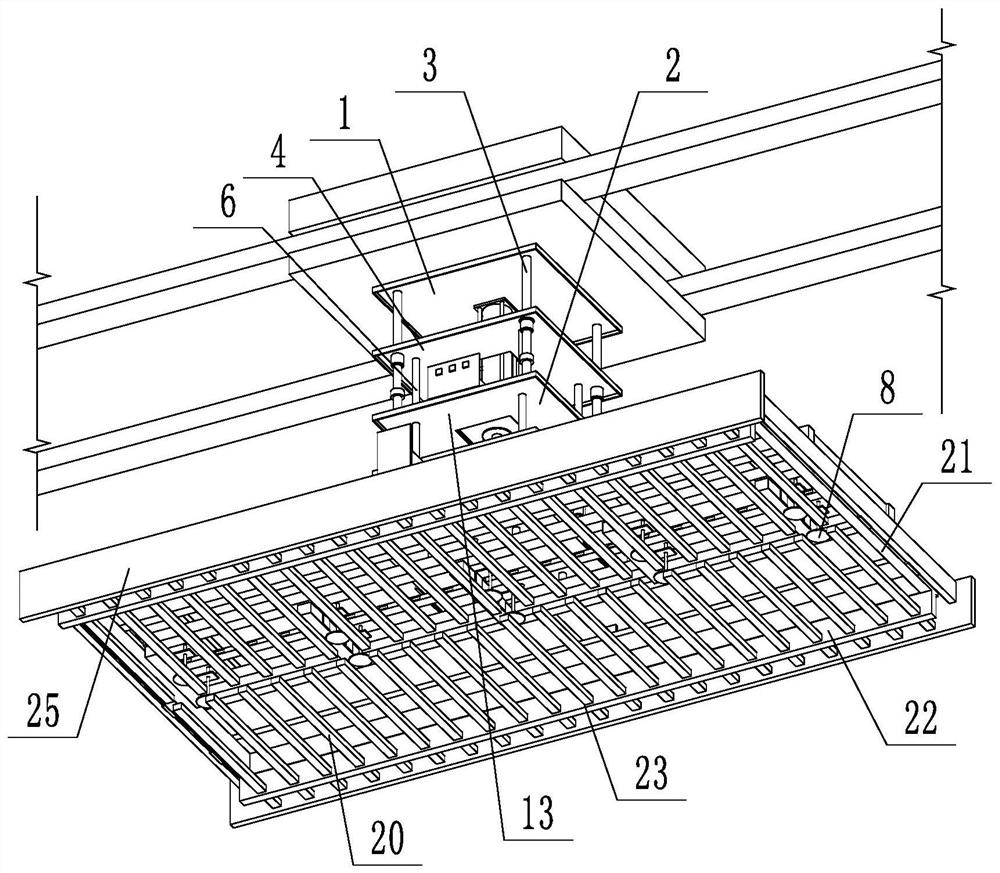

Special-shaped glass remote control cutting, breaking and grinding integrated processing production line and operation method thereof

InactiveCN105598781AHigh precisionImprove edging accuracyEdge grinding machinesGrinding drivesProduction lineRemote control

Provided are a special-shaped glass remote control cutting, breaking and grinding integrated processing production line and an operation method thereof. The processes of cutting, edge breaking, edge grinding and the like are integrated to efficiently process all kinds of special-shaped glass in a fully automatic mode at a time, precision, stability and quickness are achieved, waste is treated by itself, and the performance of the whole machine is excellent. Operation is easy, use is safe and convenient, the rate of finished products reaches up to 99.96%, and production quality and efficiency are greatly improved. Energy saving and environment friendliness are achieved, production cost is reduced by 50%, and the requirements of the production processes and the need of a special-shaped glass deep processing production line for fast development and changes are met. The special-shaped glass remote control cutting, breaking and grinding integrated processing production line is composed of a glass GPS positioning and navigation system, a special-shaped glass remote control cutter, a special-shaped glass remote control edge breaking machine, a special-shaped glass remote control edge grinding machine, a glass remote control cleaning machine, a glass control conveying device, a sensing conveying device, a first servo motor, a first ball screw, a cutting linkage mechanical arm, an edge breaking linkage mechanical arm, an edge grinding linkage mechanical arm and the like.

Owner:LUOYANG BAOHUAN NUMERICAL CONTROL PRECISE EQUIP MFG CO LTD

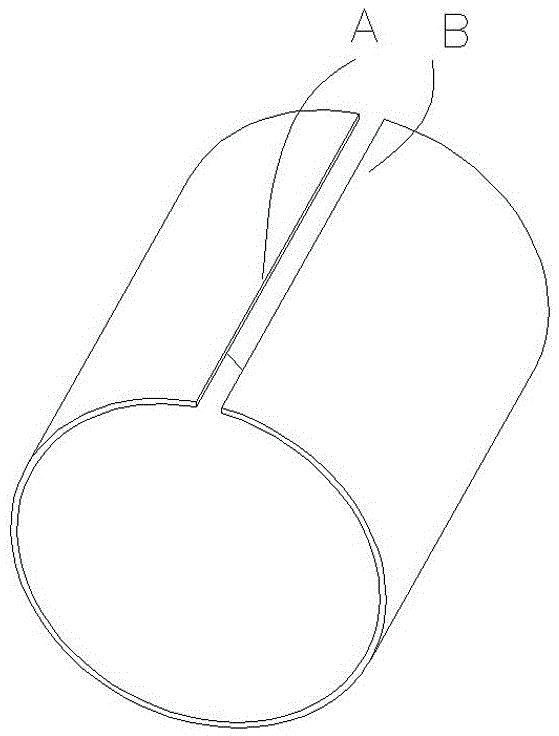

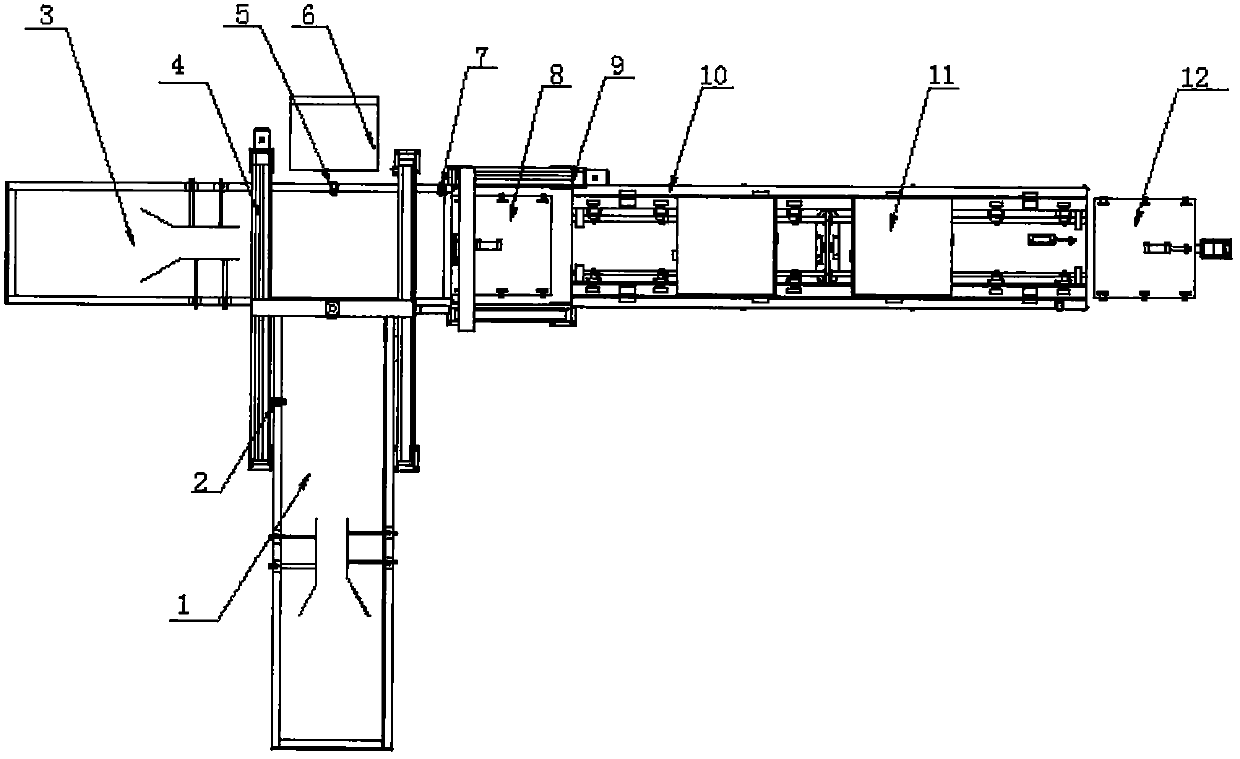

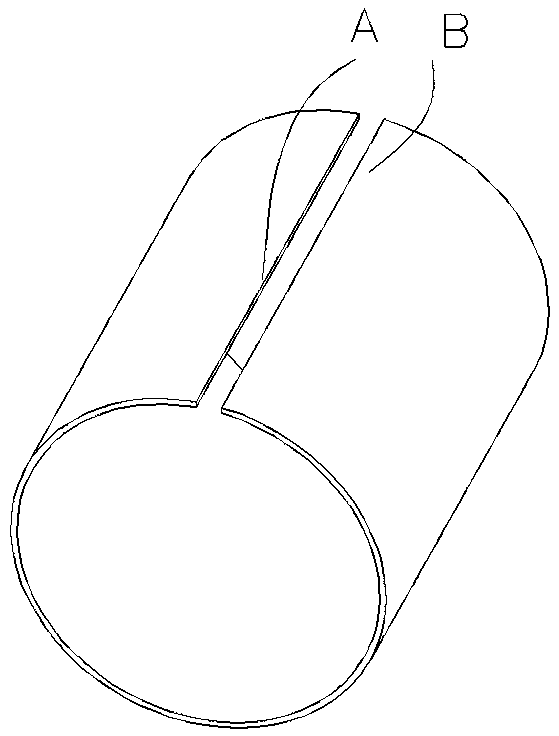

Straight seam welding machine

ActiveCN105965129AHigh speed positioningImprove welding precisionWelding/cutting auxillary devicesArc welding apparatusWater leakageSeam welding

A straight seam welding machine comprises a machine body, wherein a movable welding head and a workpiece fixture are arranged on the machine body; the movable welding head can move horizontally linearly; the workpiece fixture comprises a support; a supporting rod with an upper supporting surface is transversely arranged on the support; and the workpiece fixture further comprises a first press plate and a second press plate which are arranged above the supporting rod. The straight seam welding machine has the beneficial effects as follows: two ends of the first press plate and two ends of the second press plate press a plate, high-speed positioning of a sheet cylinder piece is realized through cooperation with a positioning sheet, and the production efficiency is improved; 2, the press plates with the forward force and the downward force are adopted, so that two ends of the steel plate are combined more precisely, the welding precision of the sheet cylinder piece is improved, and inner containers of water dispensers, kettles and tea cups are not prone to water leakage; 3, a variable frequency motor and a dovetail groove sliding table are adopted, the transmission precision is high, and the welding quality is high.

Owner:鲍人昌

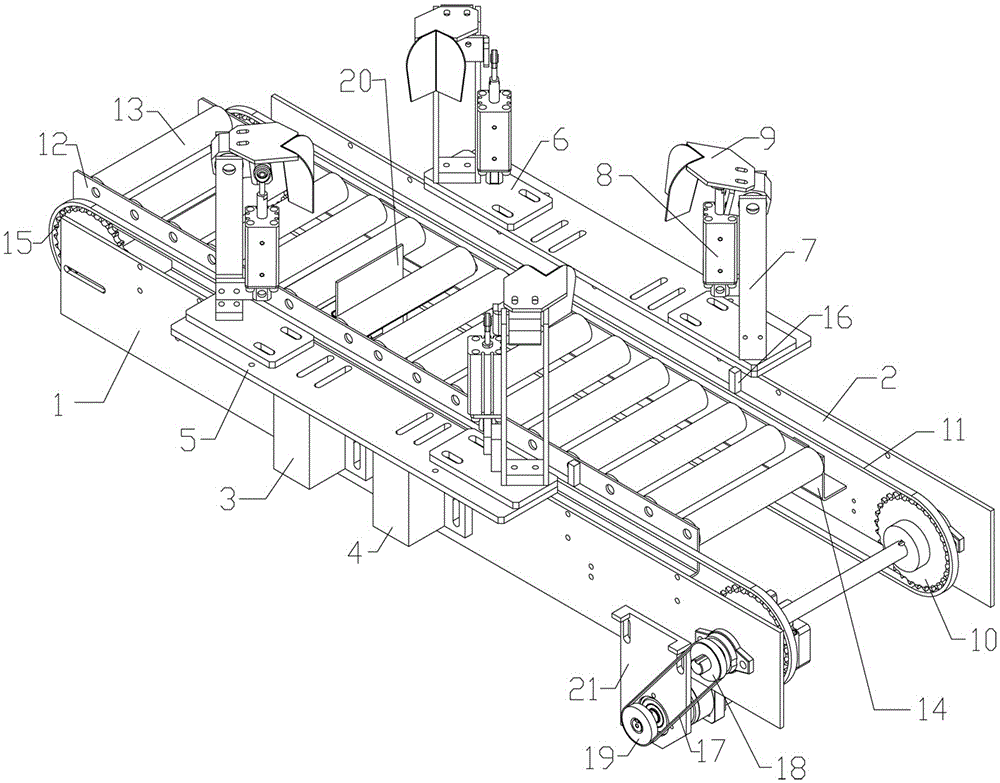

Carton locating device

The invention provides a carton locating device. According to the carton locating device, a servo motor is used for driving a driving wheel to rotate, the driving wheel drives a driven chain wheel to rotate through a synchronous belt, and the driven chain wheel drives a chain to rotate. After the chain drives a carton push plate to take a carton to a predetermined position, cylinders push paperboard clips to move up and down, and locating and opening of the carton are achieved. The carton locating device is simple in structure, convenient to mount, high in stability and capable of achieving high-speed accurate carton locating and opening actions; the production efficiency is improved, the labor intensity is relieved, and the production cost is lowered.

Owner:QINGDAO HAIKEJIA ELECTRONCE EQUIP MFG

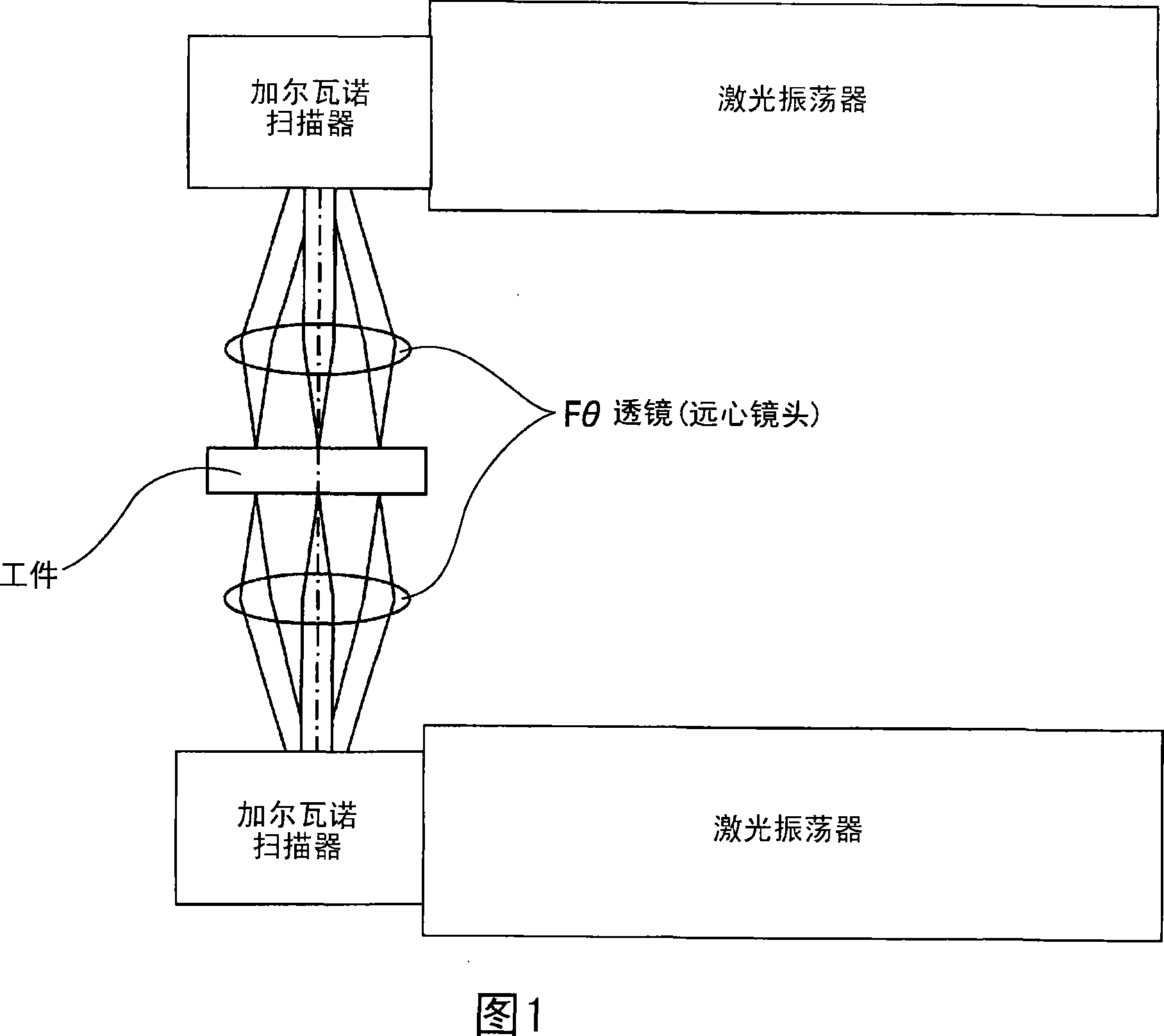

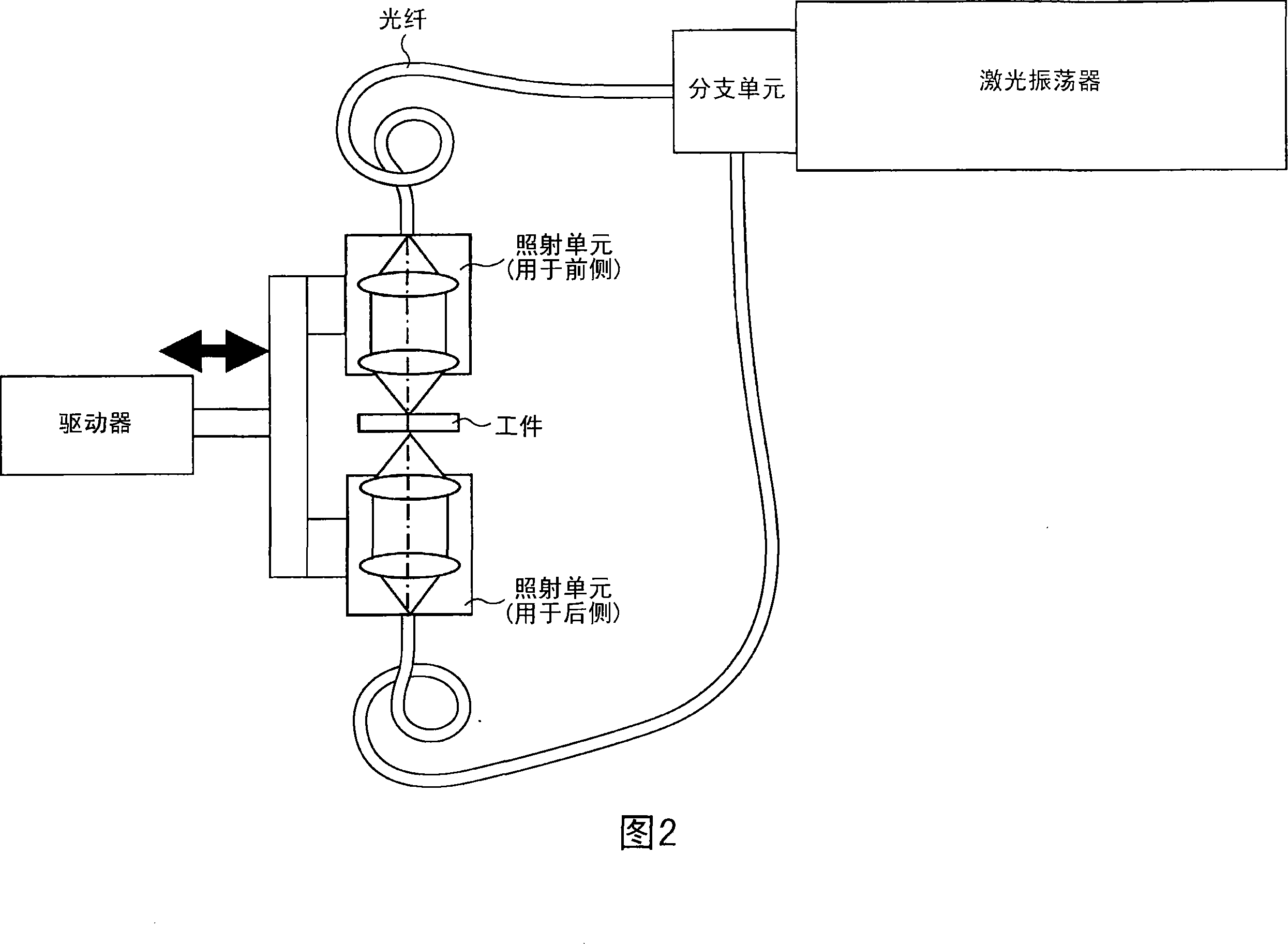

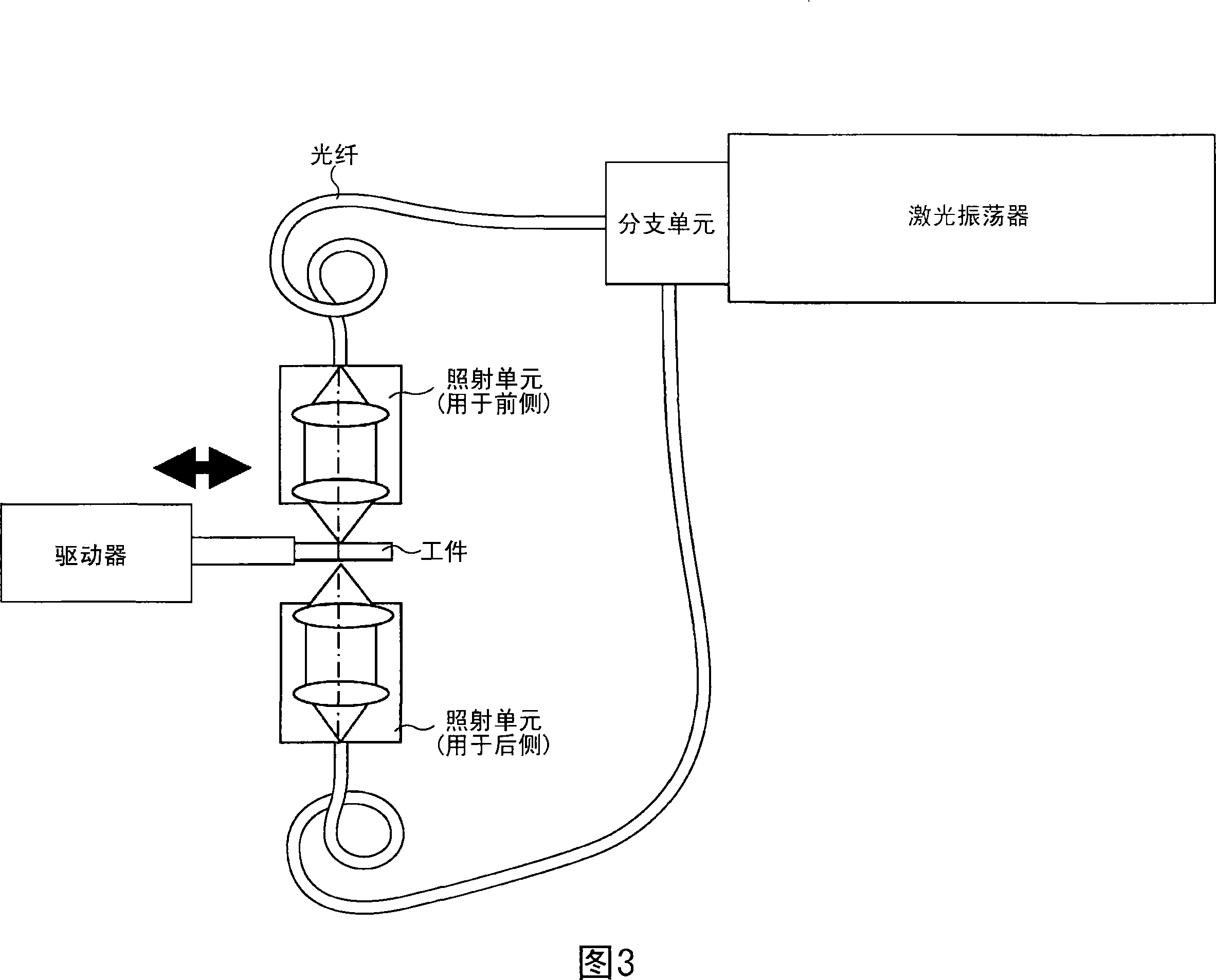

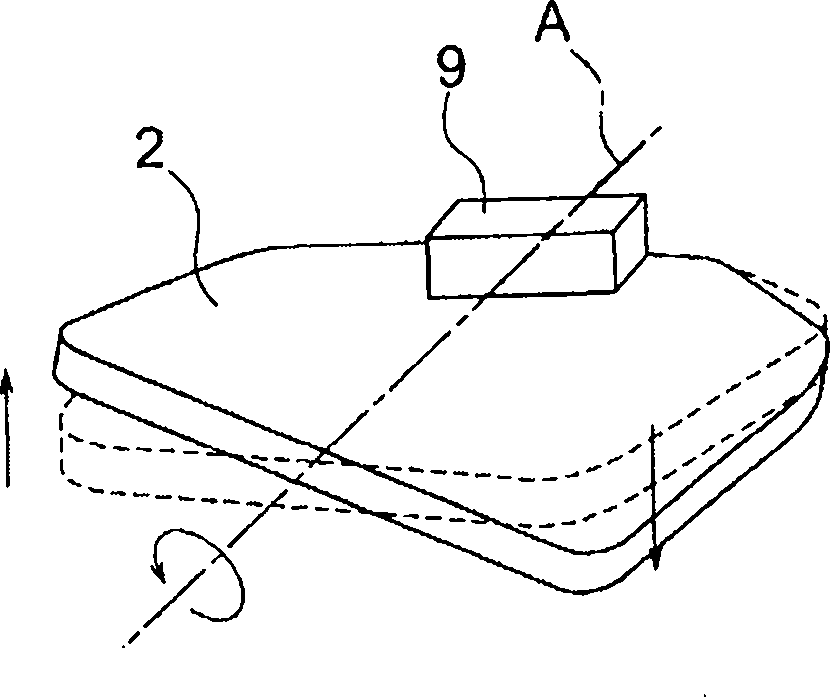

Scanning mechanism, method of machining workpiece, and machine tool

InactiveCN101251647AHigh speed positioningRecord carriers manufactureMetal working apparatusOptical axisLight beam

A scanning mechanism that scans a scanning object with a light beam has light-collecting means for collecting the light beam that is emitted by a light source; driving means for driving the light-collecting means in a direction orthogonal to an optical axis of the light-collecting means; first reflecting means provided near a first aide of the scanning object, for reflecting the light beam collected by the light-collecting means to allow the light beam to be incident on the scanning object; and second reflecting means provided near a second side of the scanning object that is opposite to the first side of the scanning object, for reflecting the light beam collected by the light-collecting means to allow the light beats to be incident on the scanning object.

Owner:FUJITSU LTD

Automatic silicon crystal plate counting and integer packaging device

ActiveCN107792446ACompact structureLong detection distancePackaging automatic controlPackaging machinesInductorMechanical engineering

The invention discloses an automatic silicon crystal plate counting and integer packaging device. The automatic silicon crystal plate counting integer packaging device comprises a first conveyor, a first photoelectric induction switch, a second conveyor, suction cup moving devices, a second photoelectric induction switch, a distribution box, an infrared induction counter, a first lifting machine,a dragging plate moving device, a weight inductor, a packaging conveyor, a second lifting machine and triangular iron blocks. The first conveyor and the second conveyor are vertically connected, the right side of the first conveyor is connected with the first lifting machine, the suction cup moving devices are arranged on the two sides of the first conveyor, the suction cup moving devices stretchacross the second conveyor, the dragging plate moving device is arranged on the first lifting machine, the right side of the first lifting machine is connected with the packaging conveyor, the tail end of the packaging conveyor is connected with the second lifting machine, a material plate is arranged on the packaging conveyor, and the front end and the rear end of the material plate are fixedly provided with the triangular iron blocks. According to the device, cost is saved, and use is convenient.

Owner:福建万春光电科技有限公司

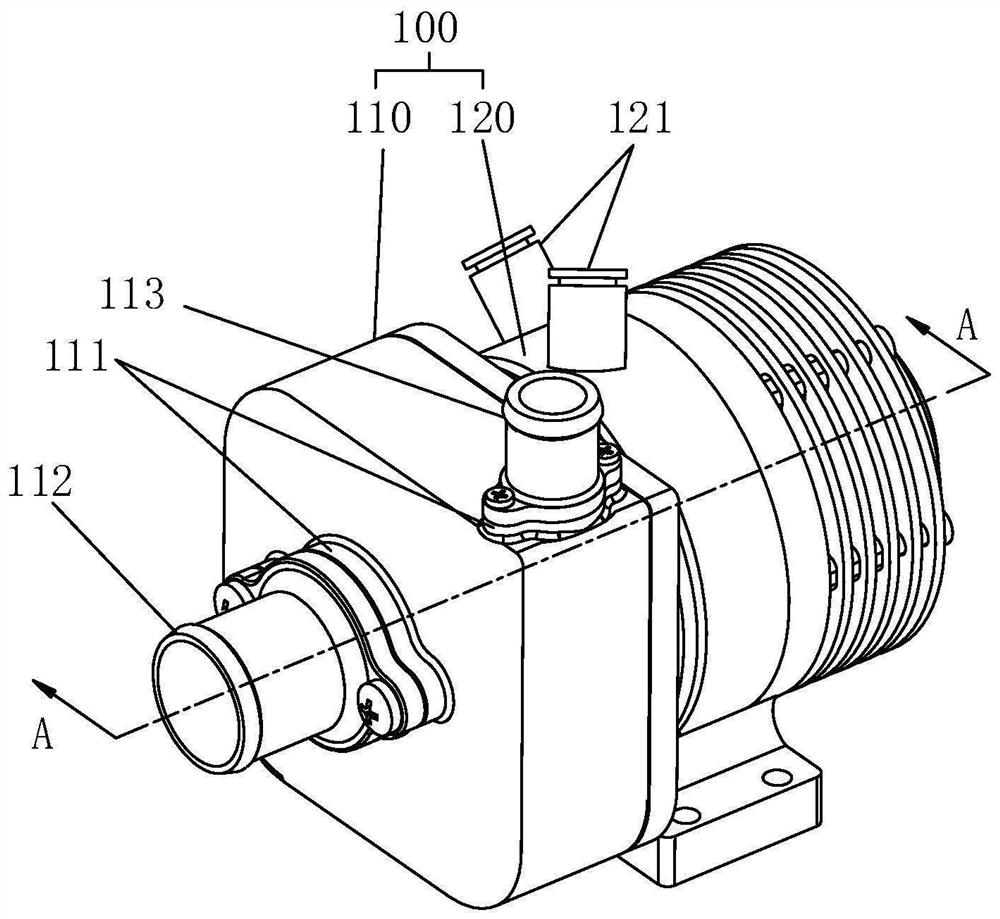

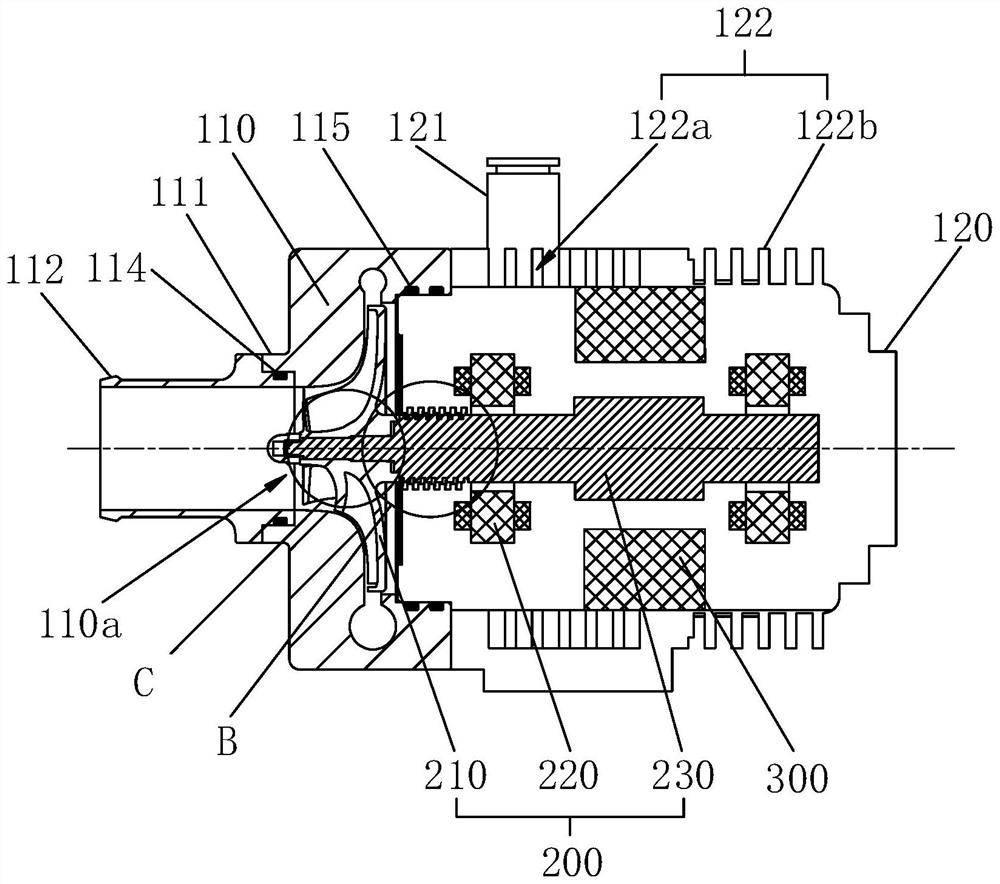

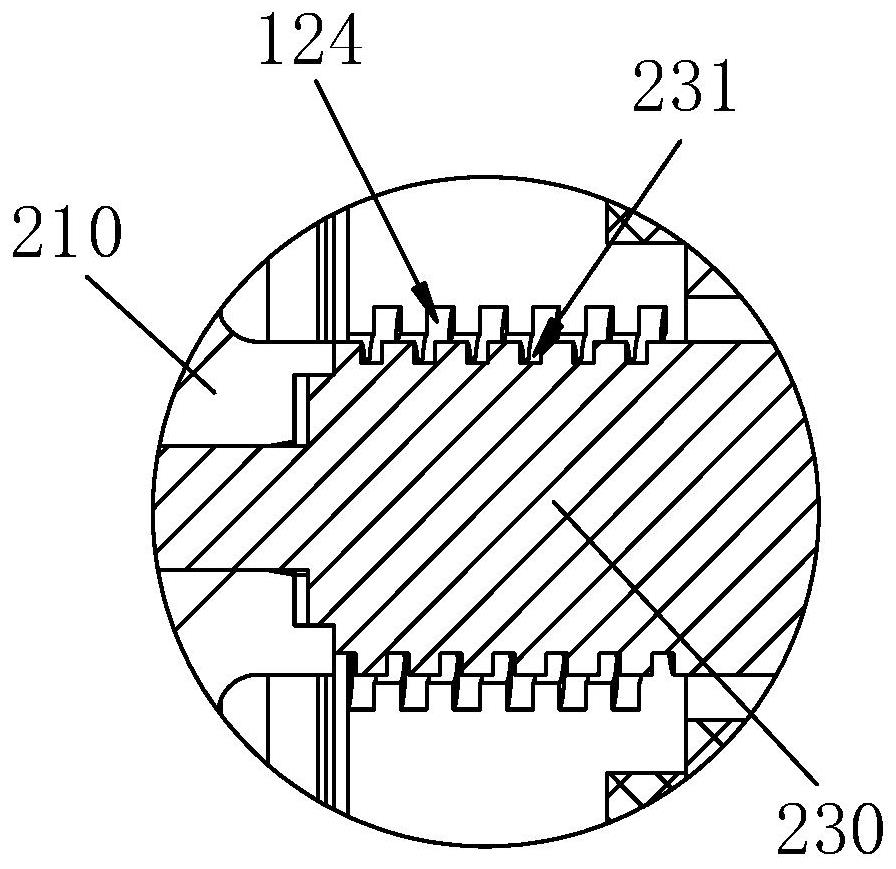

Hydrogen circulating pump

PendingCN113847271AImprove work performanceImprove assembly accuracyPump componentsPumpsImpellerTorque transmission

The invention provides a hydrogen circulating pump, and relates to the technical field of pumps. The hydrogen circulating pump comprises a shell assembly and a shafting assembly arranged in the shell assembly, the shafting assembly comprises an impeller and a rotor shaft, the impeller is provided with an assembly hole along the center line, multiple rotation stopping rotary grooves are formed in the circumferential direction of the assembly hole, rotation stopping rotary teeth corresponding to the rotation stopping rotary grooves are arranged on the outer circumferential face of the rotor shaft, and when the rotor shaft cooperates with the assembly hole, the rotation stopping rotary teeth cooperate with the corresponding rotation stopping rotary grooves, so that the rotor shaft and the impeller rotate synchronously. According to the hydrogen circulating pump, the rotation stopping rotary teeth cooperate with the corresponding rotation stopping rotary grooves, so that the assembly precision of the rotor shaft and the impeller is improved, meanwhile, the hydrogen circulating pump has better torque transmission capability, so that when the rotor shaft drives the impeller to rotate at a high speed, accurate positioning of high-speed rotation is realized, meanwhile, the operation stability is ensured, and then the working performance of the hydrogen circulating pump is improved.

Owner:北京艾尔航空科技有限责任公司

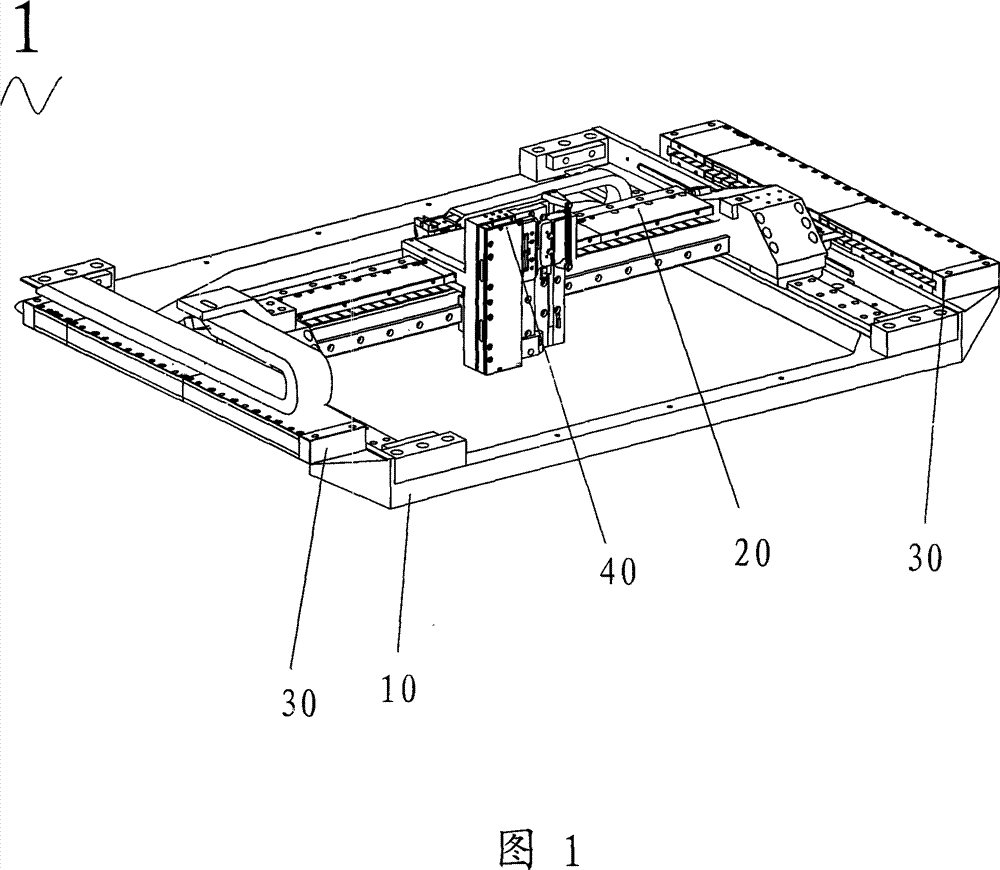

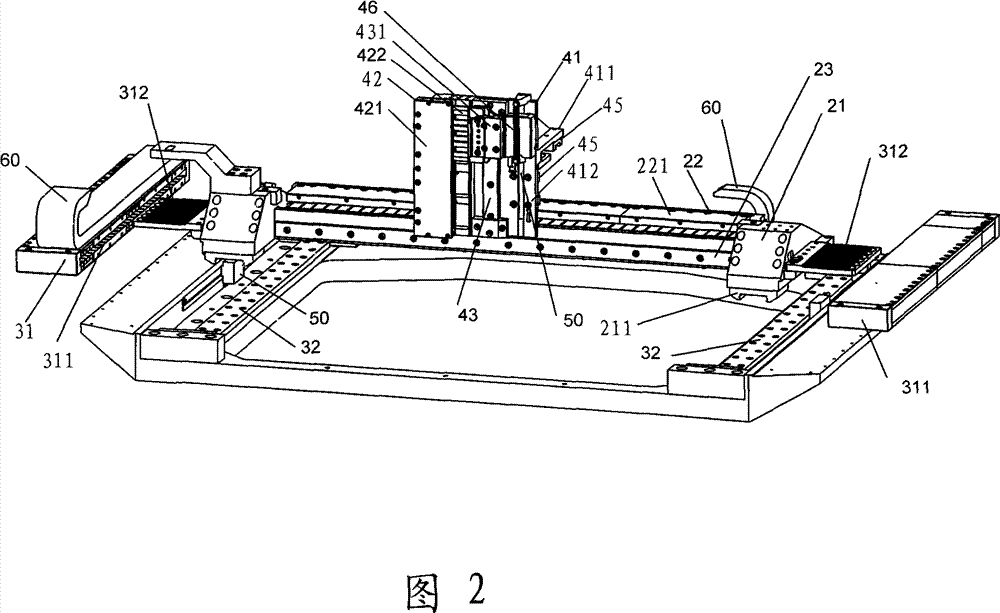

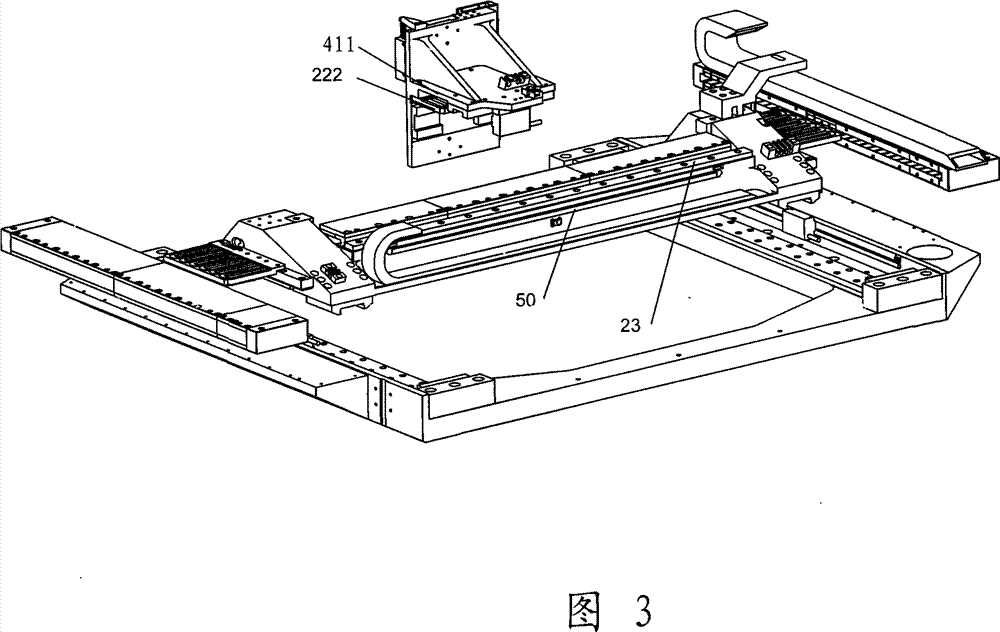

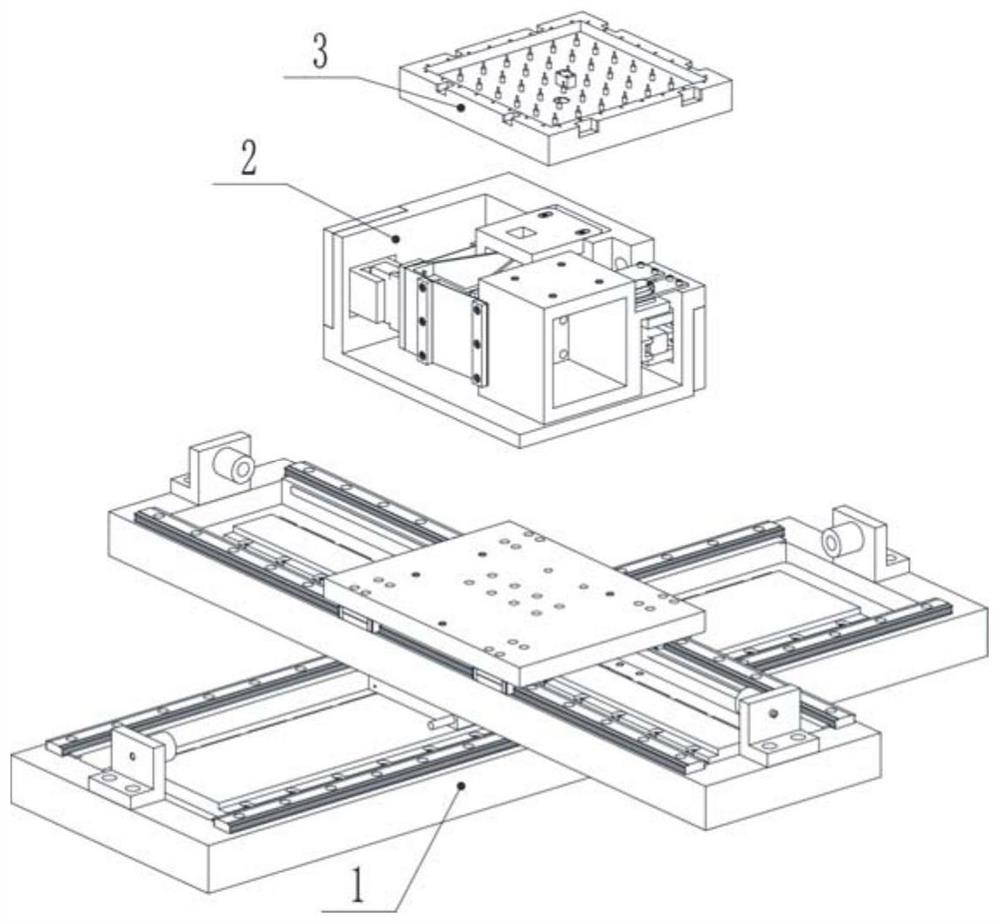

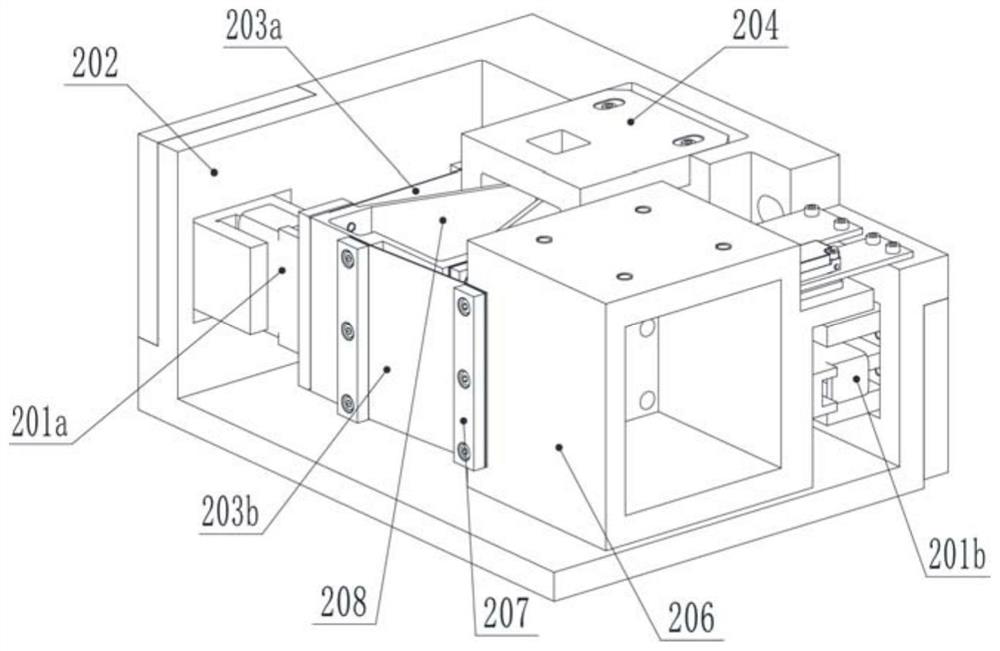

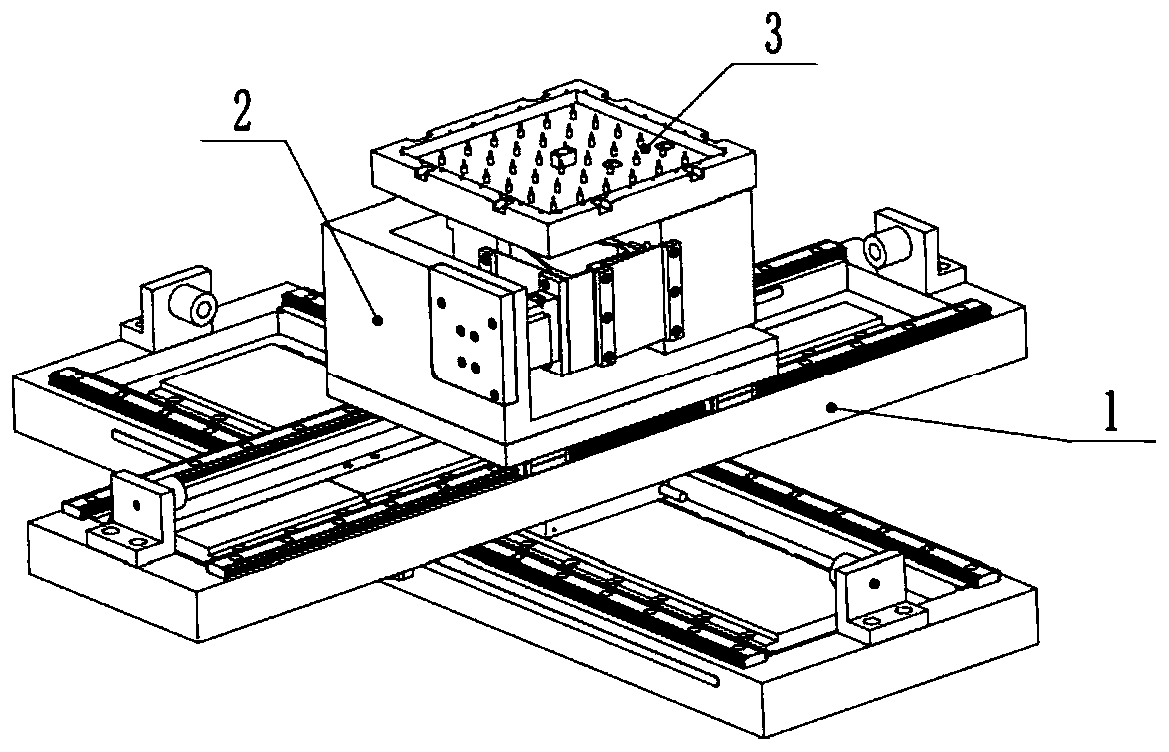

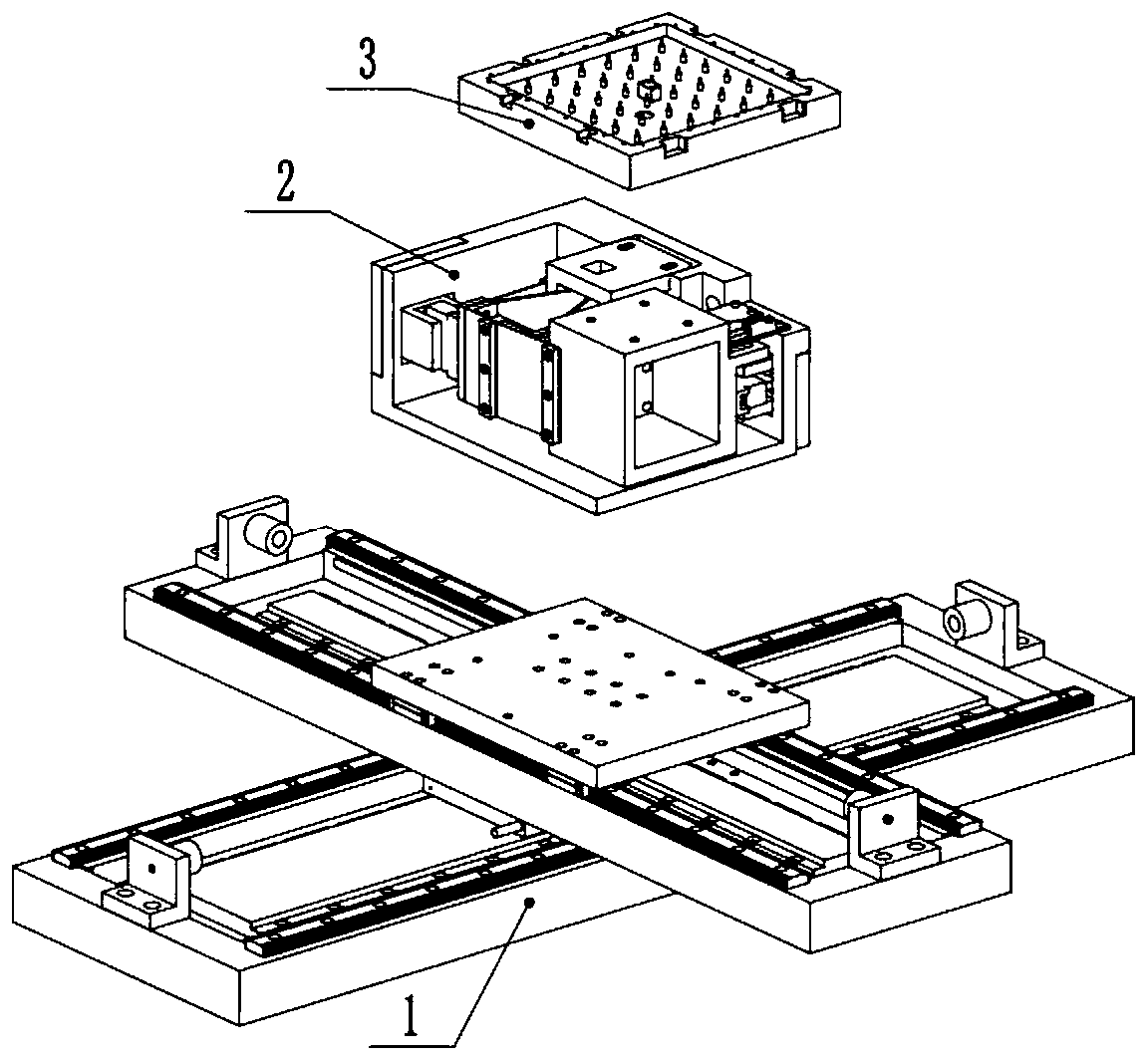

Triaxial movement platform

The invention discloses a triaxial movement platform, comprising a base, a Y axis movement system assembled at two ends of the base, an X axis movement system erected in the middle of the base and a Z axis movement system fixed on the X axis movement system, wherein, the X movement system, the Y movement system and the Z axis movement system respectively comprise a linear motor and a sliding device, which comprises a lead rail and a sliding block; the X axis movement system also comprises a cross beam, on which the linear motor used for driving the X axis movement system and the lead rail arefixed; the Z axis movement system also comprises a fixed bracket, on which the linear motor used for the Z axis movement system and the lead rail are installed. The triaxial movement platform not only can improve the system operation stability and accuracy but also can realize the high speed and accurate positioning of load.

Owner:SHENZHEN HANS MOTOR S&T

Electrical scanner device and laser machining apparatus having electrical scanner device

ActiveCN101576657BSuppression of twisting deformation vibrationHigh speed positioningLaser beam welding apparatusOptical elementsElectricityTransducer

Owner:HITACHI SEIKO LTD +1

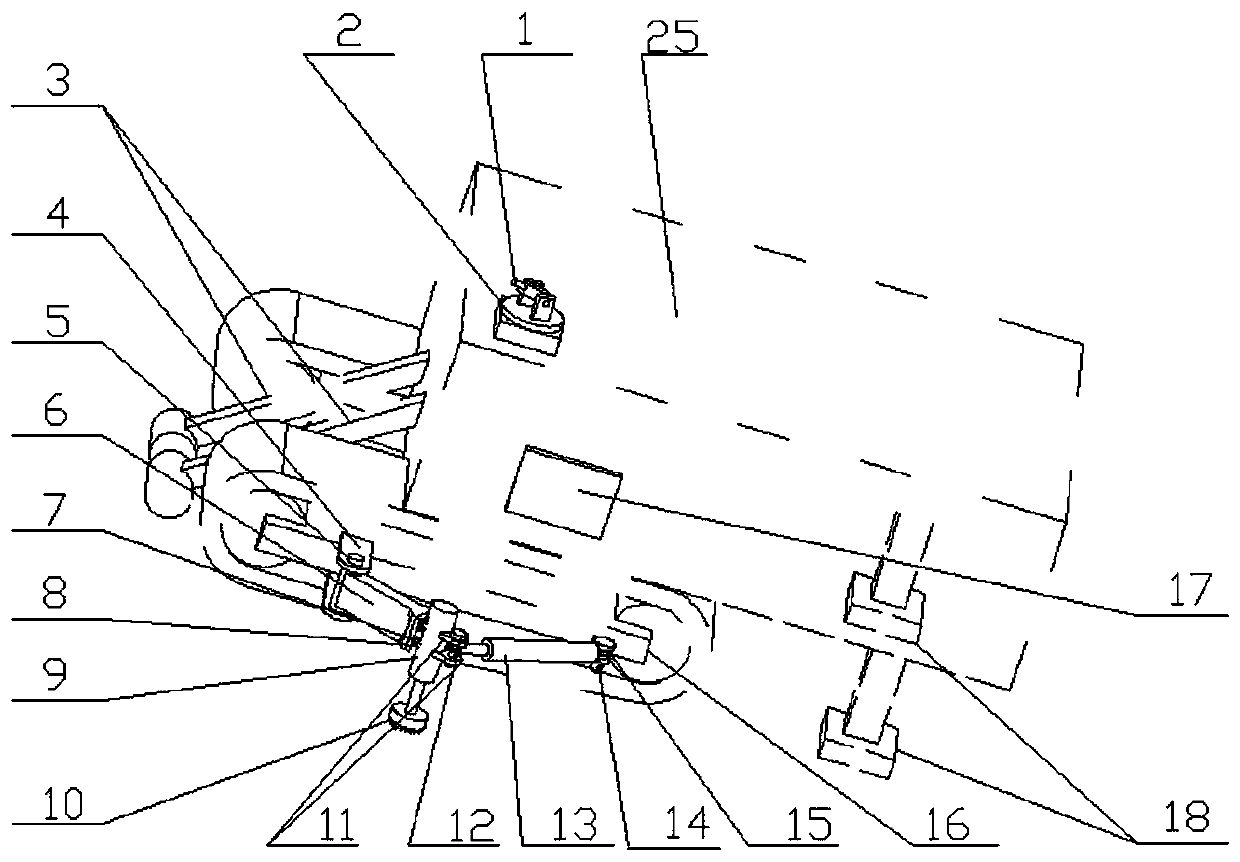

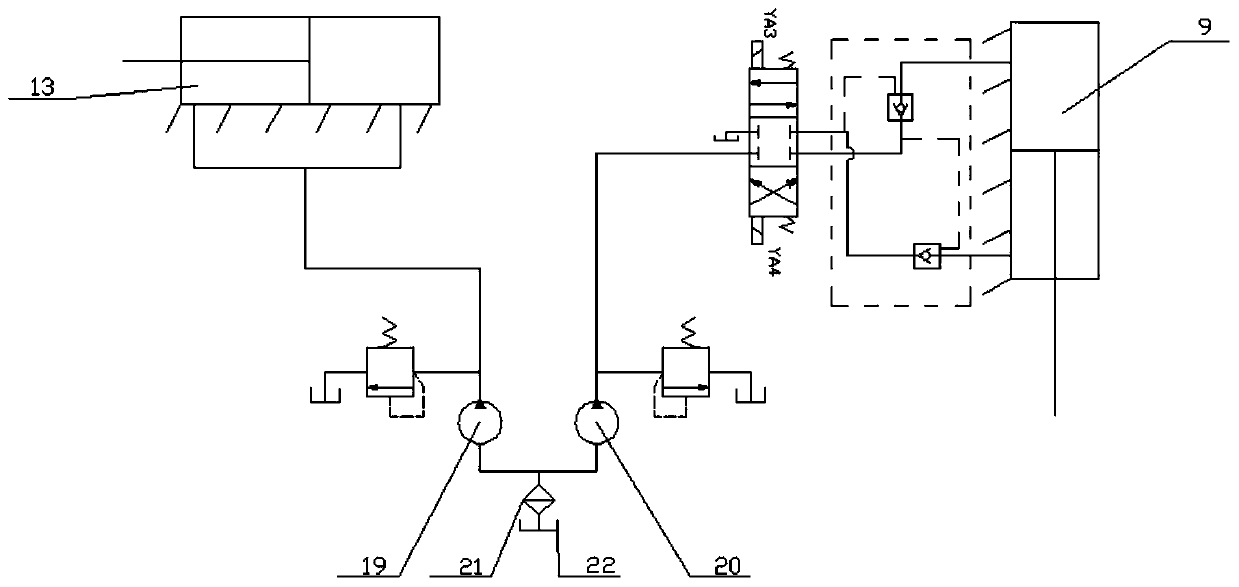

Method and device thereof for shallow type drilling machine self-adaptive balance

ActiveCN110145297AAchieving Adaptive BalanceExpand the range of supportDerricks/mastsAutomatic control for drillingSelf adaptiveAngular displacement

The invention discloses a method and device thereof for shallow type drilling machine self-adaptive balance. The method for shallow type drilling machine self-adaptive balance comprises the steps thata laser rangefinder and an angular displacement sensor are utilized to acquire position information of a tunnel rock wall drilling working face in real time; based on the position information, through calculation of the deflection angle and elongation distance of a drilling arm, deflection of the center of gravity of a drilling machine is determined; and adjustable balance supporting devices on the left side and the right side of the drilling machine are pertinently controlled to rotate correspondingly, the supporting range is increased, and self-adaptive balance of the drilling machine in the working process is achieved. The device comprises the laser rangefinder, the angular displacement sensor, a supporting oil cylinder, a deflection oil cylinder, a supporting transverse beam, a central controller and an oil way control circulating system. The deflection oil cylinder does extending and contracting and rotary motions, and the supporting oil cylinder is driven to rotate correspondingly. According to the method and device thereof for shallow type drilling machine self-adaptive balance, working face signals detected are utilized to control changes of the supporting manner of the drilling machine so that the supporting manner can be adjusted self-adaptively by the supporting devices along with changes of the working face; real-time balanced location of the shallow type drillingmachine in a narrow and long tunnel is achieved; and the working range of the shallow type drilling machine is expanded.

Owner:NANTONG UNIVERSITY

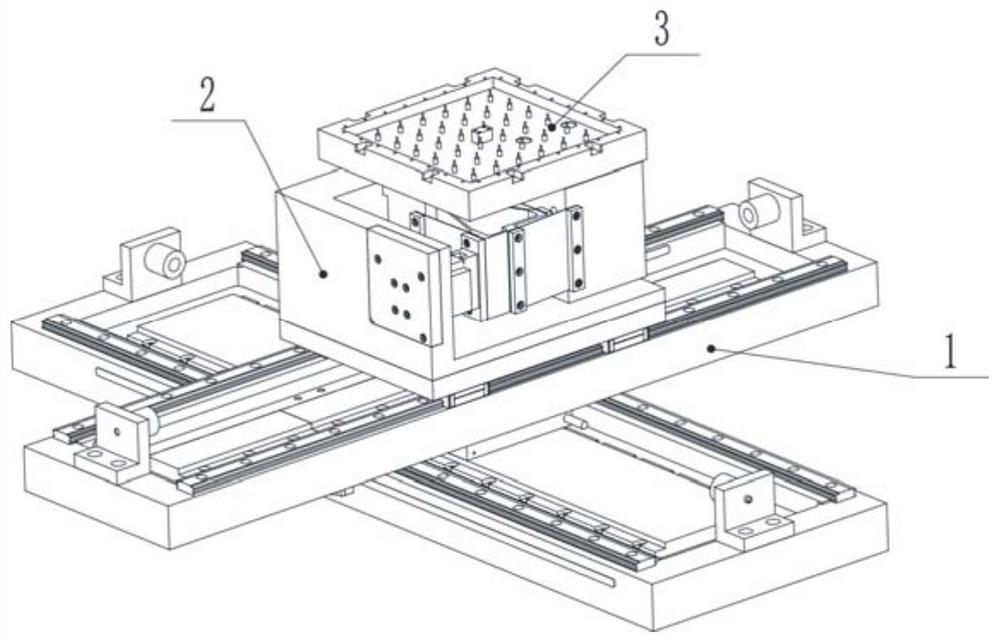

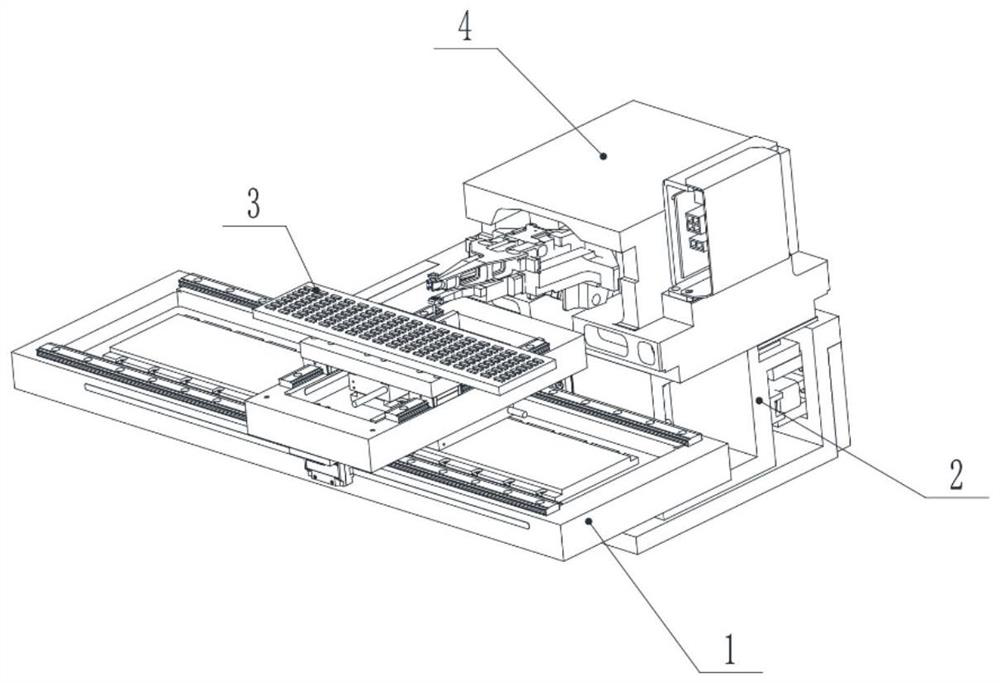

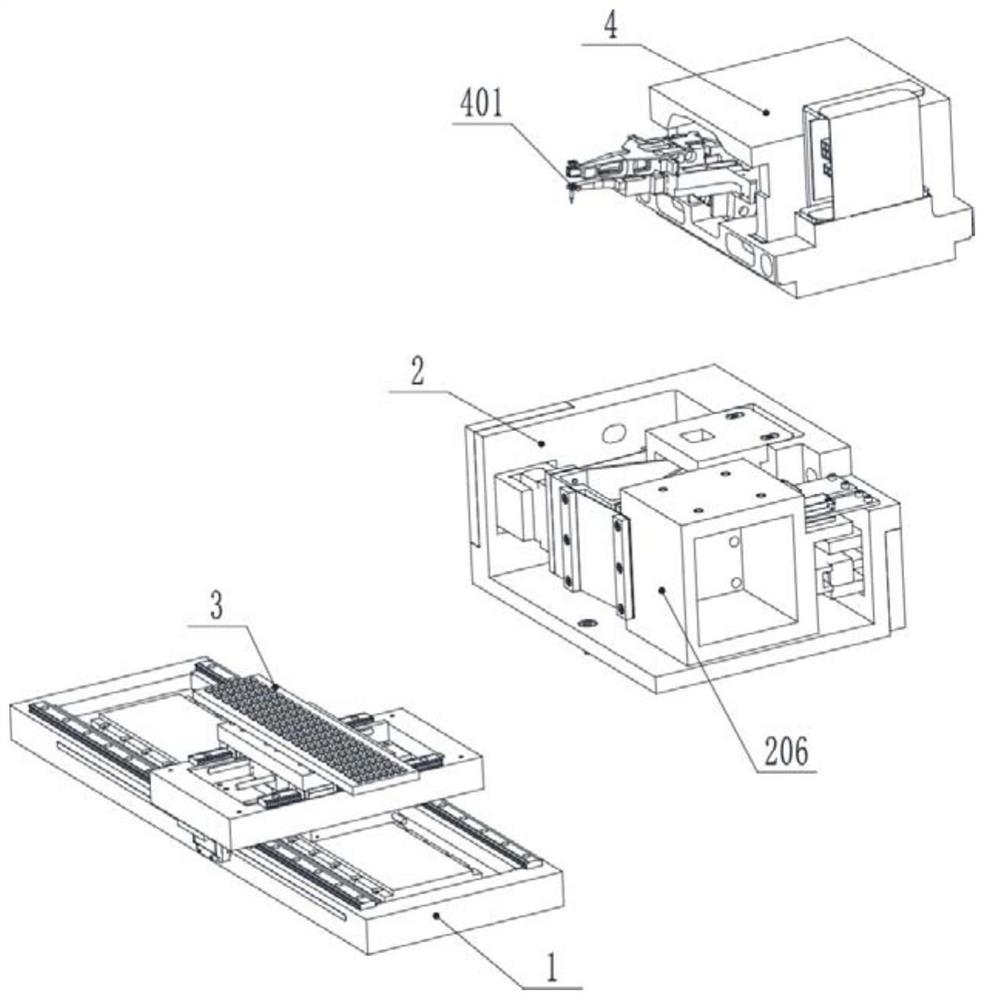

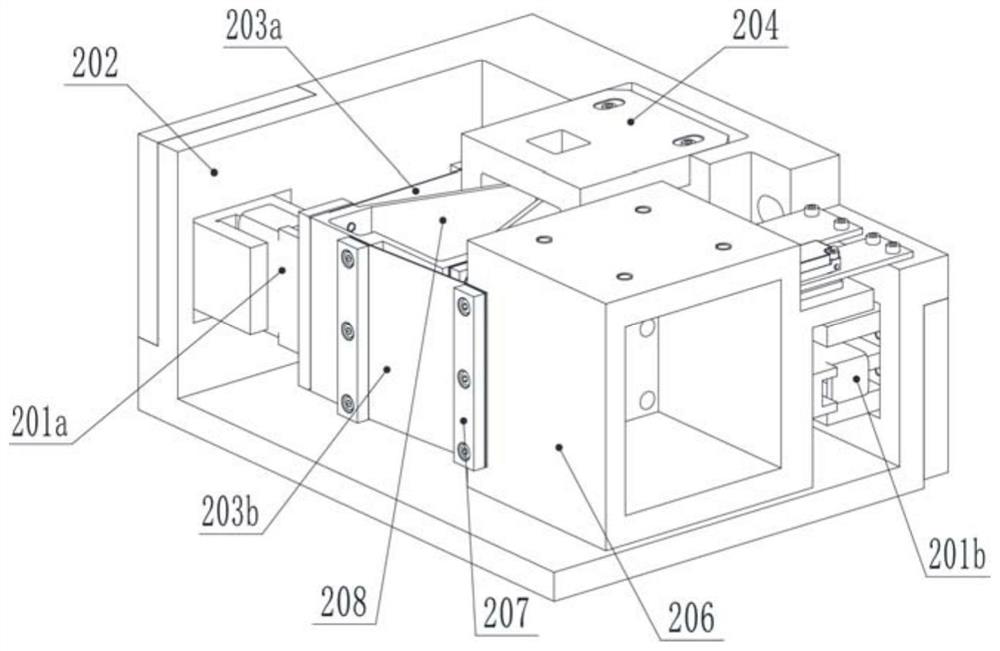

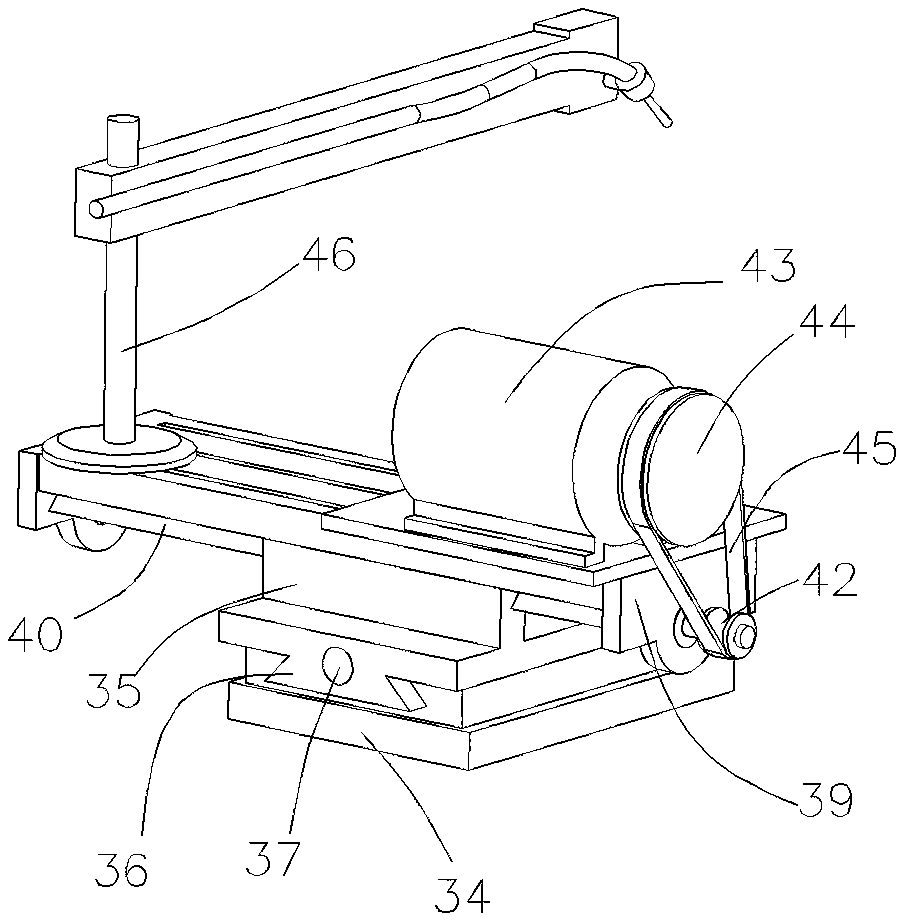

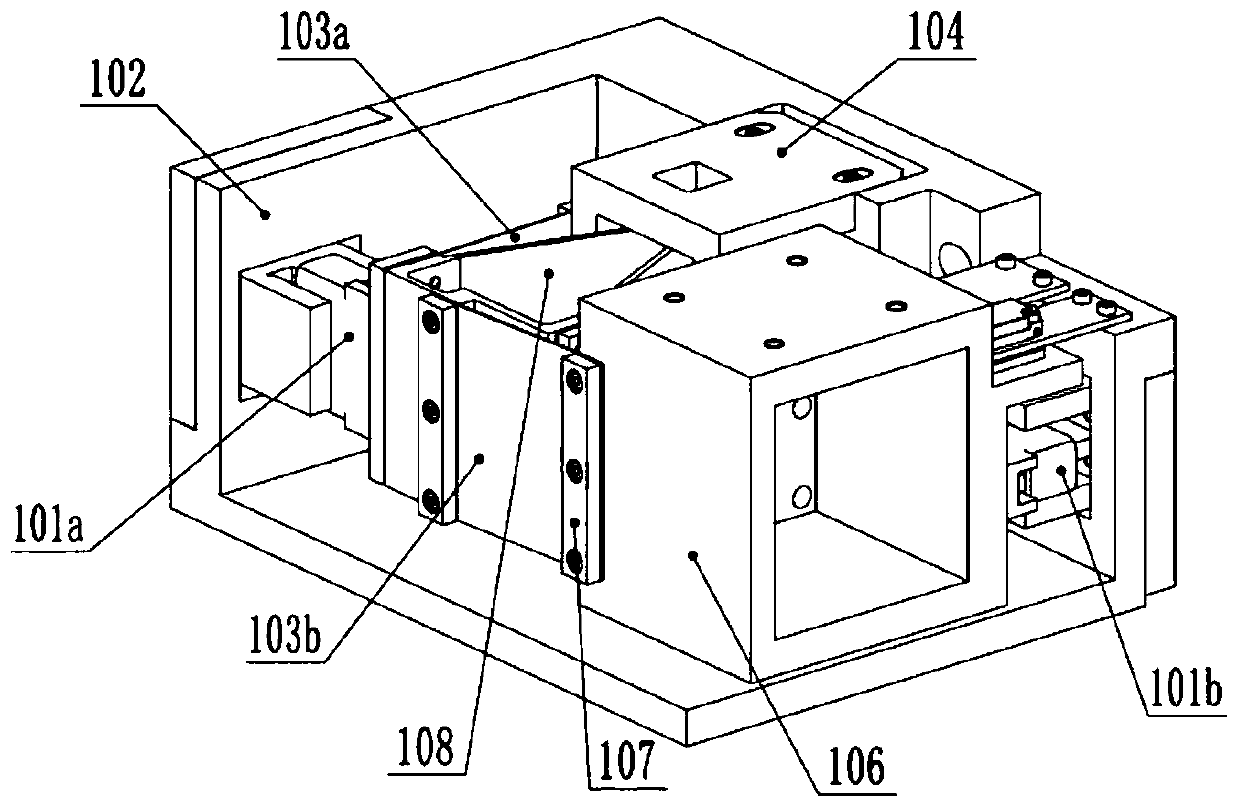

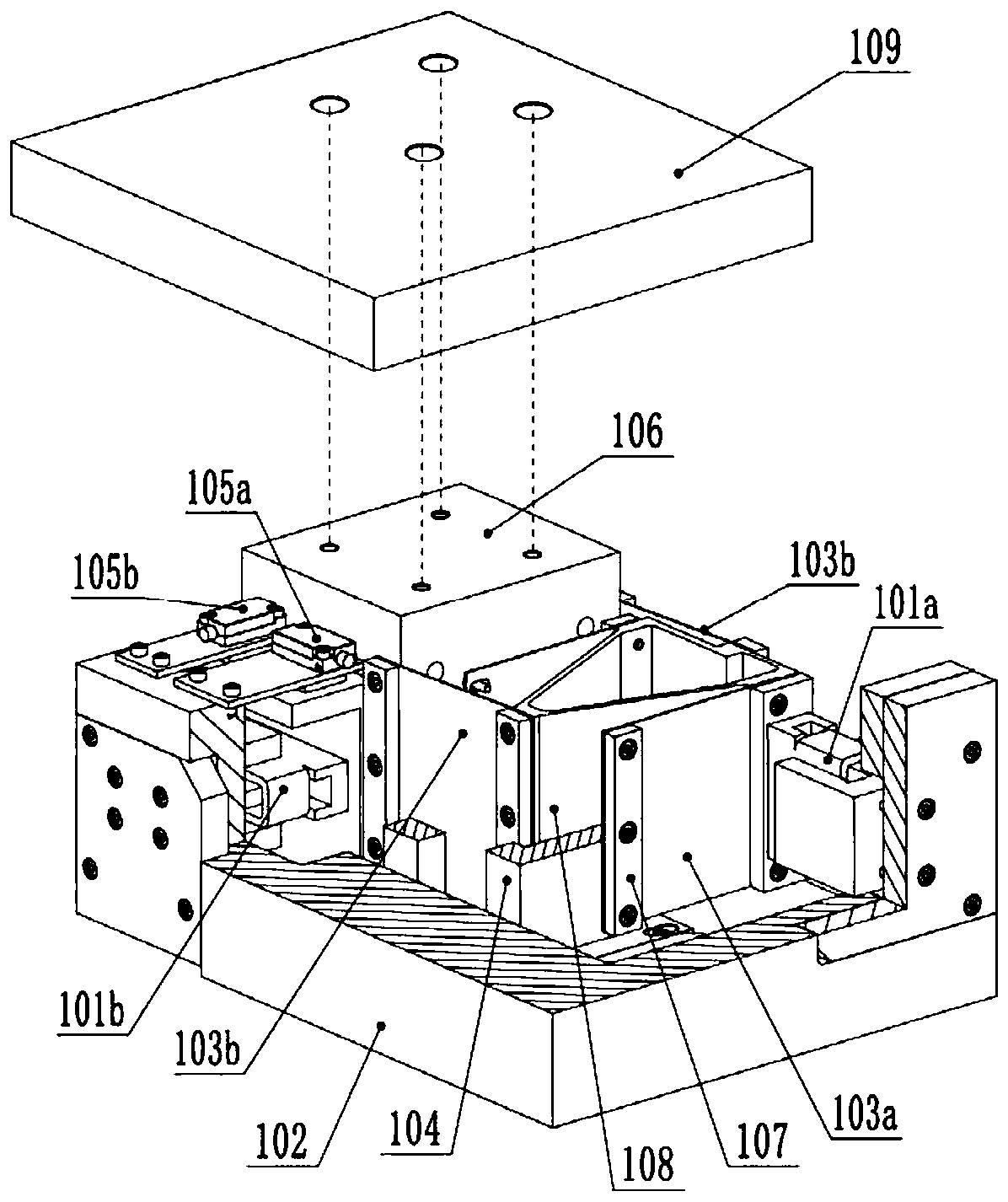

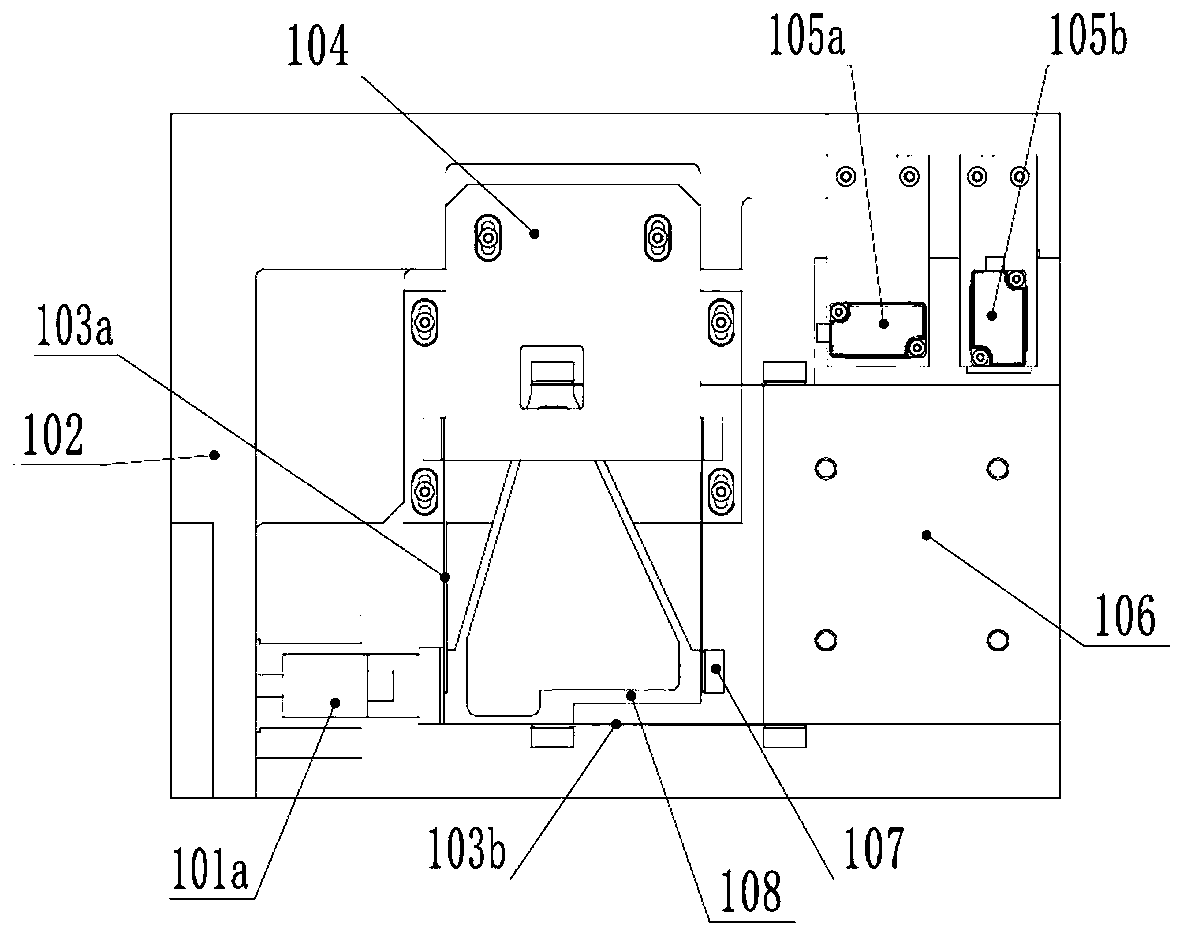

A high-speed precision laser drilling platform and its control method

ActiveCN110253160BHigh speed positioningHigh speed interpolationLaser beam welding apparatusEngineeringMechanical engineering

The invention relates to a high-speed precision laser drilling platform and a control method thereof. The high-speed precision laser drilling platform includes: a macro XY movement platform, a micro XY movement platform, and a working suction cup; the micro XY movement platform is installed on the macro XY movement On the platform; the micro-XY motion platform includes: a support seat, a connecting frame, a micro-bearing platform, an X-axis flexible hinge piece, and a Y-axis flexible hinge piece; the two ends of the X-axis flexible hinge piece are respectively fixed on the connecting frame on the support seat; the two ends of the Y-axis flexible hinge piece are respectively fixed on the connecting frame and the micro-carrying platform; the micro-carrying platform is also provided with a micro-X-axis encoder and a micro-Y-axis The encoders are respectively used to measure the motion information of the X / Y direction of the micro-carrying platform; the working suction cup is installed on the micro-carrying platform of the micro-XY motion platform. The invention utilizes the elastic deformation of the flexible hinge to realize high-speed interpolation and realize high-speed and precise positioning between holes.

Owner:FOSHAN HUADAO SUPER PRECISION TECH CO LTD

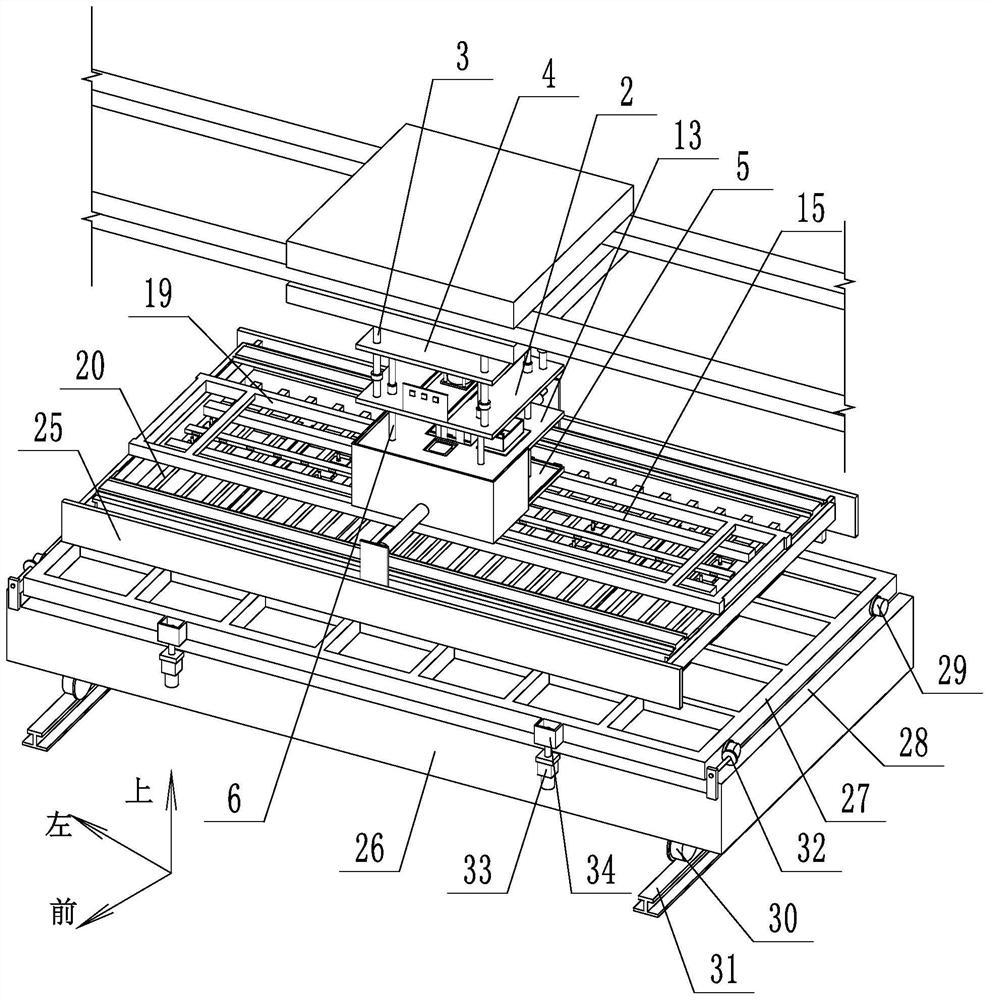

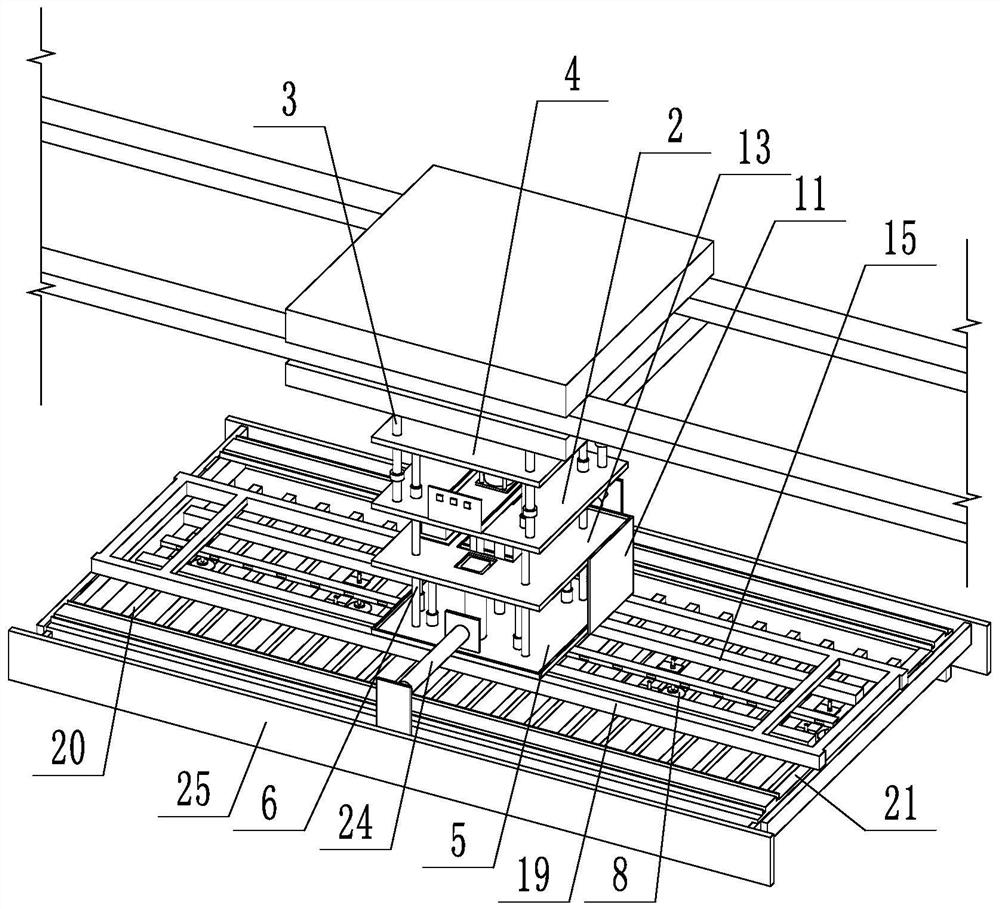

High-speed precise laser drilling platform and control method thereof

ActiveCN110253160AHigh speed positioningHigh speed interpolationLaser beam welding apparatusEngineeringEncoder

The invention relates to a high-speed precise laser drilling platform and a control method thereof. The high-speed precise laser drilling platform comprises a macro XY motion platform, a micro XY motion platform and a working sucker, wherein the micro XY motion platform is arranged on the macro XY motion platform, the micro XY motion platform comprises a supporting base, a connecting frame, a micro-bearing platform, an X-axis flexible hinge piece and a Y-axis flexible hinge piece, the two ends of the X-axis flexible hinge piece are correspondingly fixed on the connecting frame and the supporting base, the two ends of the Y-axis flexible hinge piece are correspondingly fixed on the connecting frame and the micro-bearing platform, the micro-bearing platform is further provided with a micro X-axis encoder and a micro Y-axis encoder which are used for measuring the motion information of the micro-bearing platform in the X / Y direction respectively, and the working sucker is installed on the micro-bearing platform of the micro XY motion platform. According to the high-speed precise laser drilling platform and the control method thereof, high-speed interpolation is realized by means of elastic deformation of flexible hinges, and high-speed precise positioning among holes is realized.

Owner:FOSHAN HUADAO SUPER PRECISION TECH CO LTD

A special-shaped glass remote control cutting, breaking and grinding integrated processing production line and its operation method

InactiveCN105598781BHigh precisionImprove edging accuracyEdge grinding machinesGrinding drivesProduction lineRemote control

Owner:LUOYANG BAOHUAN NUMERICAL CONTROL PRECISE EQUIP MFG CO LTD

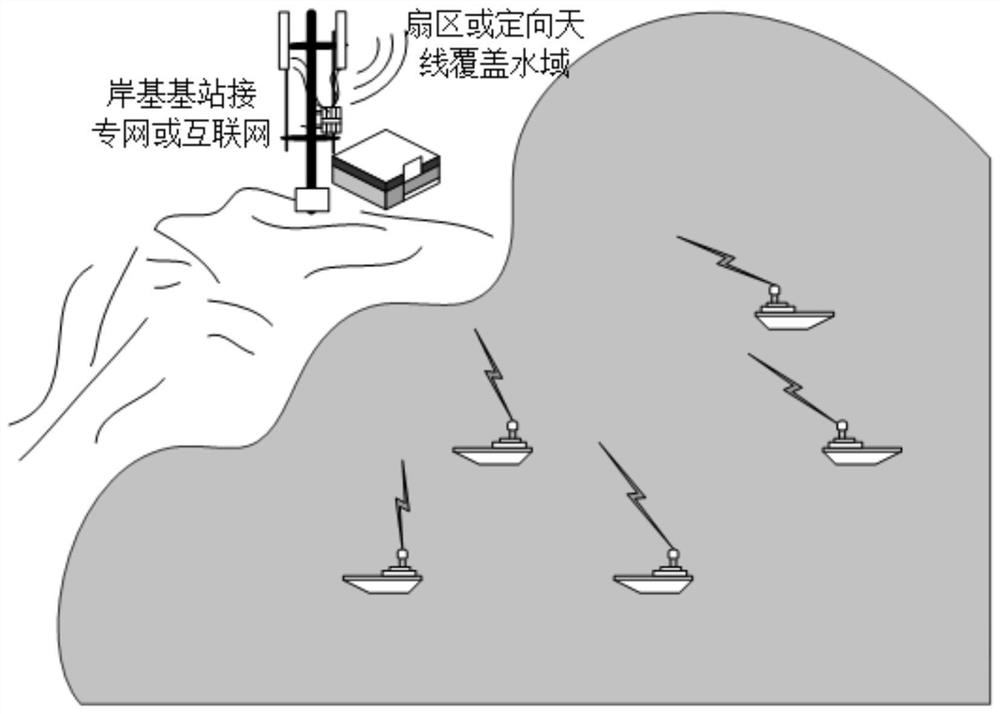

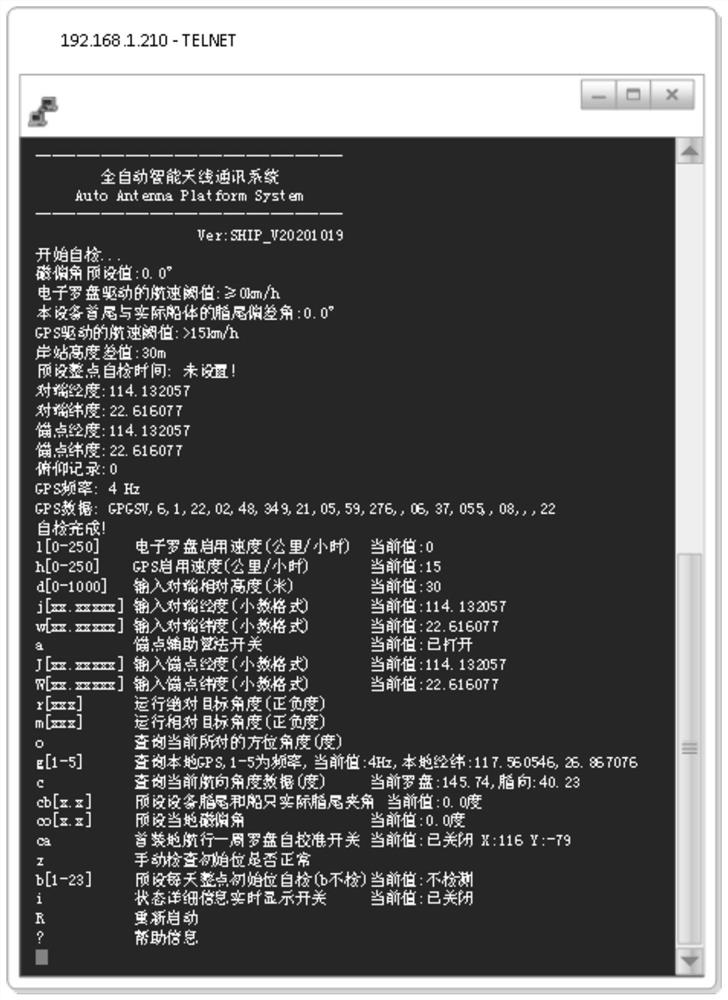

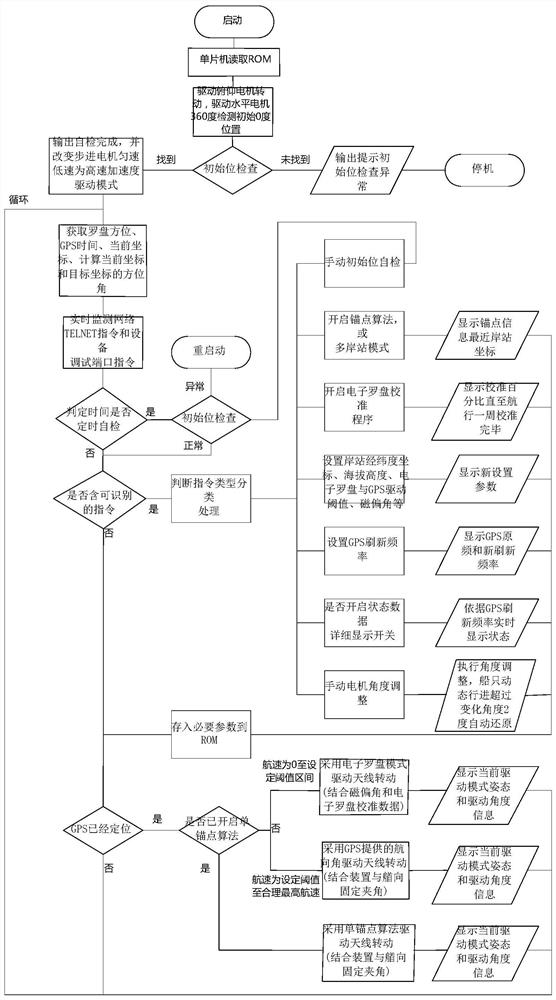

Method for correcting angle of marine directional antenna in real time based on single-chip microcomputer

PendingCN112653524AWith high-speed positioning functionHigh speed positioningTransmitters monitoringReceivers monitoringDirectional antennaShore station

A method for correcting the angle of a marine directional antenna in real time based on a single-chip microcomputer is characterized by comprising the steps: 1, conducting starting, and a single-chip microcomputer reading parameters in an ROM; 2, calculating a direction angle A1 of a current coordinate and a target coordinate, acquiring the current coordinate of the directional antenna by the single-chip microcomputer, and calculating the direction angle A1 according to the current coordinate of the directional antenna and the target coordinate; 3, calculating a current attitude angle A2, and calculating the current attitude angle A2 of the directional antenna by the single-chip microcomputer; 4, correcting the angle of the directional antenna, wherein the single-chip microcomputer corrects the angle of the antenna according to the direction angle A1 and the attitude angle A2; and 5, circulating, and entering the step 2. According to the method, the angle of a marine directional antenna is corrected in real time under the control of a single-chip microcomputer, so that the directional antenna is automatically aligned with a shore station base station antenna in real time.

Owner:深圳市安视源电子科技有限公司

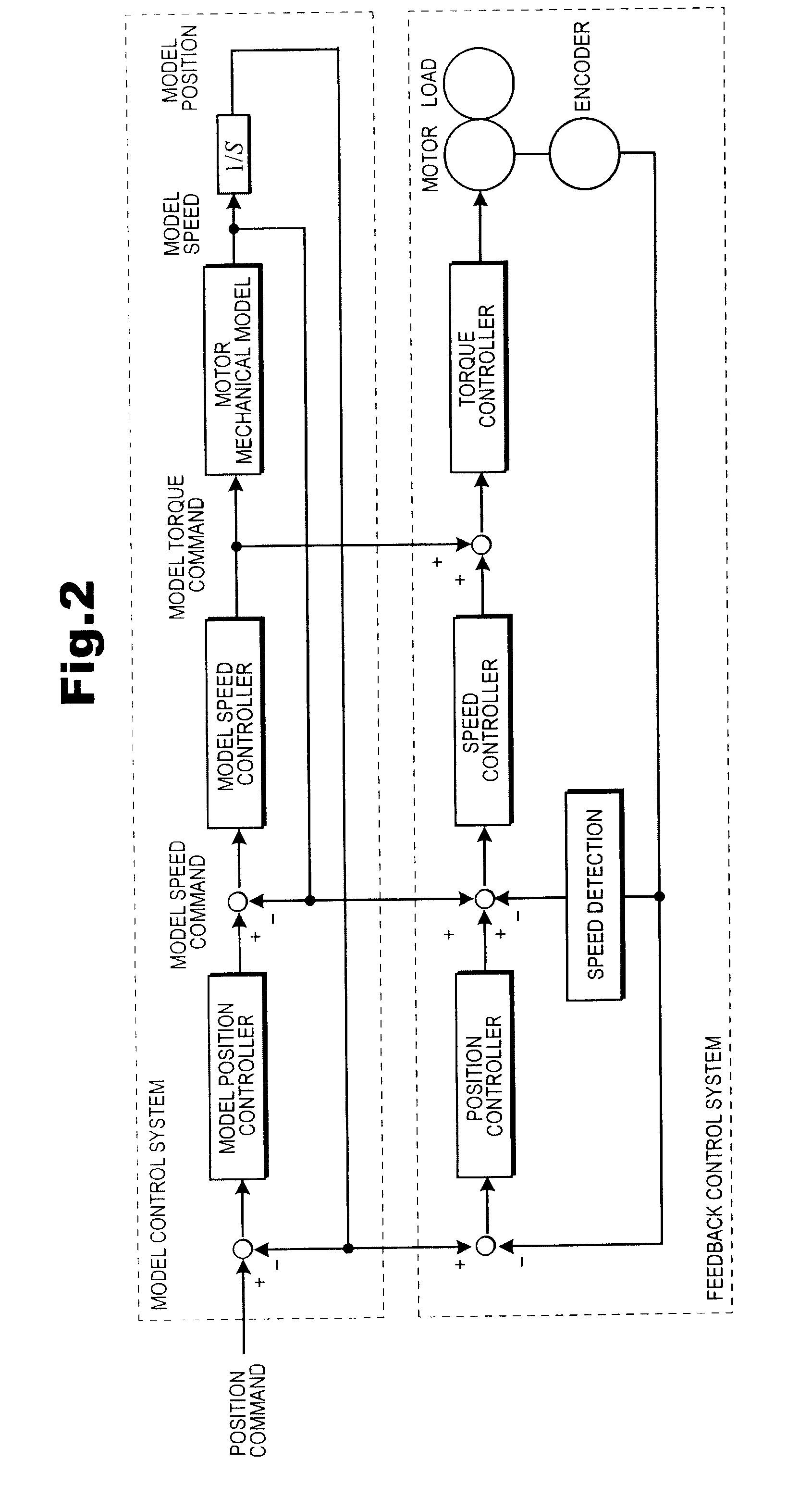

Operating apparatus

ActiveUS8154226B2Reduce vibrationHigh speed positioningMotor/generator/converter stoppersDC motor speed/torque controlControl engineeringControl cell

An operating apparatus including a main body, a movable member, a drive unit having a drive source, and a control unit controlling the drive source to control the position of the movable member relative to the main body. The control unit including a position control system and an acceleration control system. The position control system including a position command portion, a first feedforward compensator outputting a first operation command to the drive source, a second feedforward compensator, a positional-information acquiring device obtaining information related to the position of the movable member, and a first feedback compensator outputting a second operation command to the drive source. The acceleration control system including an acceleration-information acquiring device obtaining information related to an acceleration of the main body, a third feedforward compensator, a second feedback compensator outputting a third operation command to the drive source.

Owner:NAGOYA INSTITUTE OF TECHNOLOGY +1

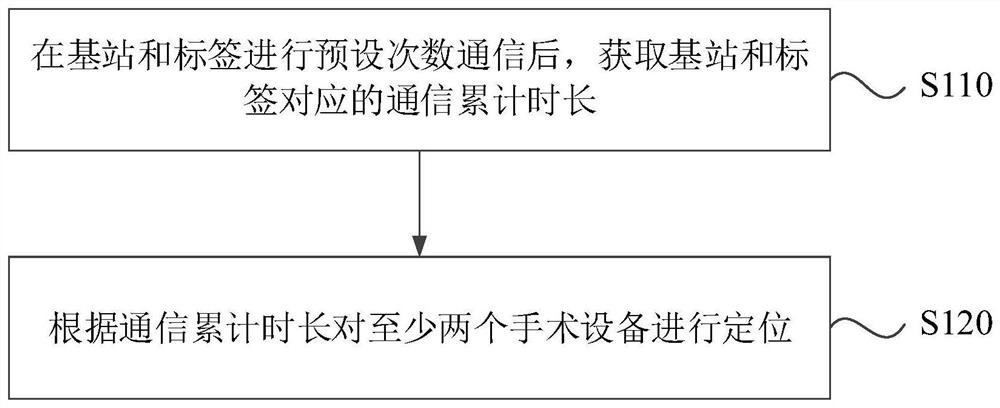

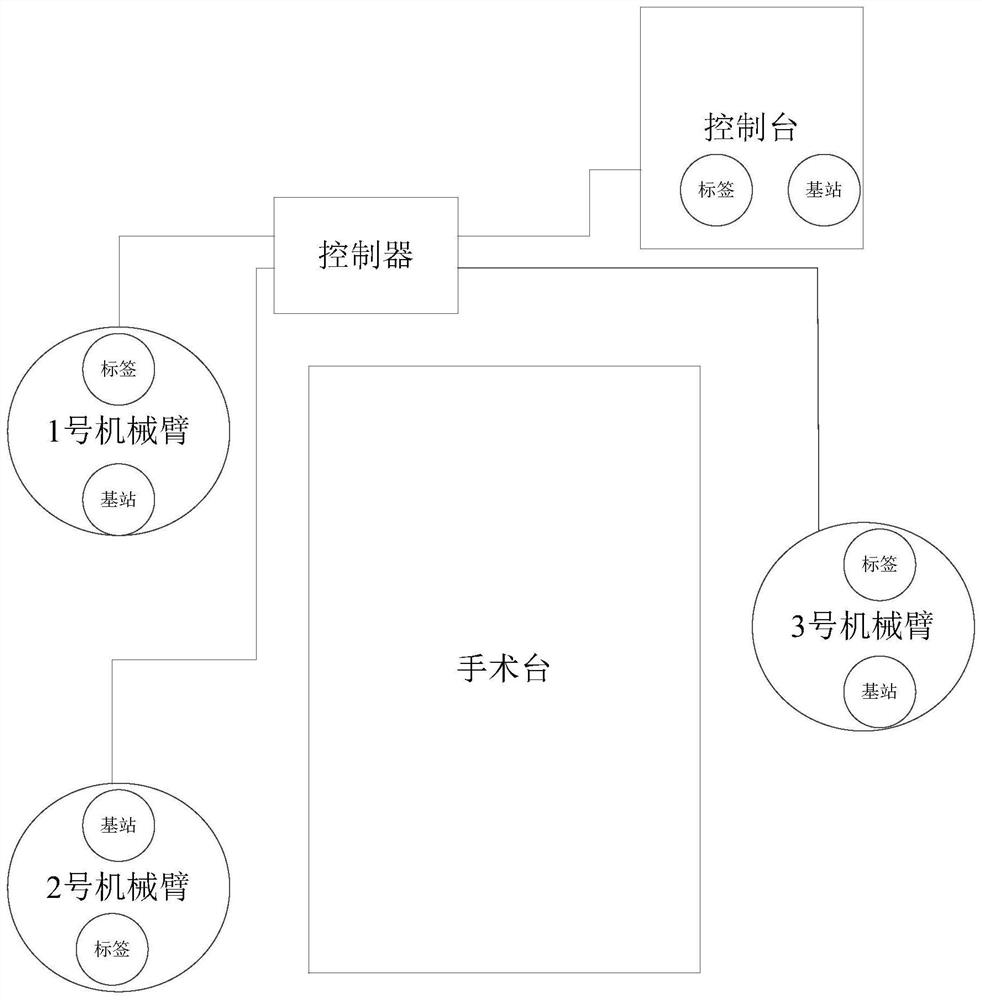

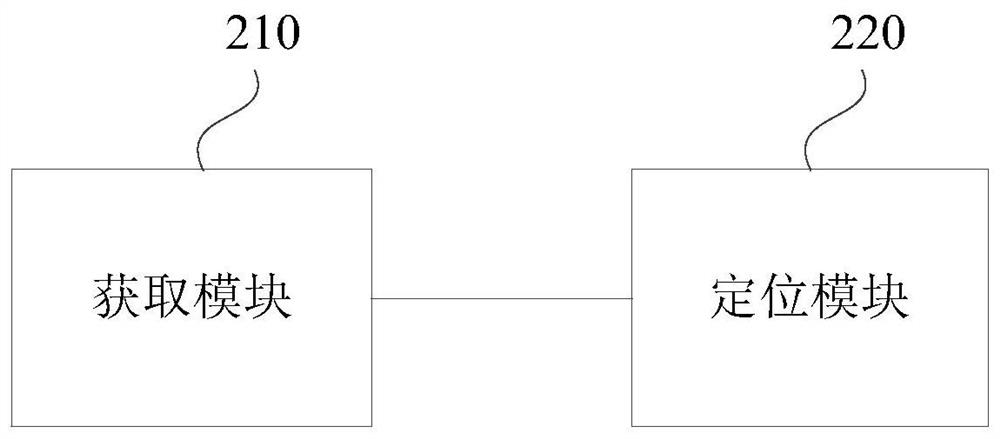

Surgical equipment positioning method and device, equipment and storage medium

PendingCN114640942AHigh cost of solutionHigh speed positioningLocation information based serviceReoperative surgeryVisual perception

The invention discloses a surgical equipment positioning method and device, equipment and a storage medium. The method comprises the following steps: after a base station and a label carry out preset times of communication, acquiring communication accumulated duration corresponding to the base station and the label; according to the technical scheme, the problems that an existing positioning method is high in cost, very sensitive to the illumination environment and large in view field coverage range requirement, a plurality of cameras or movable camera supports capable of detecting the positions need to be installed, and the positioning accuracy is high are solved. In order to solve the problems that at least two surgical devices need to be positioned through base stations and labels configured on the at least two surgical devices, the working process of looking for a visual target through manual or electric motion needs to be executed every time repositioning is carried out, the complexity of user workflow is increased and the like, positioning of the at least two surgical devices can be achieved through the base stations and the labels configured on the at least two surgical devices, and no extra positioning base station system needs to be erected. And a positioning work flow which can be perceived by an operator or requires manual operation does not need to be set, and positioning is automatically carried out in real time at the background.

Owner:RONOVO (SHANGHAI) MEDICAL SCI & TECH LTD

A high-speed precision wire bonding platform and its control method

ActiveCN110270788BHigh speed positioningHigh speed interpolationWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention relates to a high-speed precision bonding wire platform and a control method thereof. The high-speed precision bonding wire platform comprises a macro XY motion platform, a micro XY motion platform, an element bracket and a bonding wire mechanism. The element bracket is mounted on the macro XY motion platform. The micro XY motion platform comprises a support seat, a connecting bracket, a micro bearing platform, an X-axis flexible hinge piece and a Y-axis flexible hinge piece. The two ends of the X-axis flexible hinge piece are fixed to the connecting bracket and the support seat correspondingly. The two ends of the Y-axis flexible hinge piece are fixed to the connecting bracket and the micro bearing platform correspondingly. The micro bearing platform is provided with a micro X-axis encoder and a micro Y-axis encoder, and the micro X-axis encoder and the micro Y-axis encoder are used for measuring motion information, formed in the X direction and the Y direction, of the micro bearing platform. The bonding wire mechanism is mounted on the micro bearing platform of the micro XY motion platform. According to the high-speed precision bonding wire platform and the control method thereof, high-speed interpolation is achieved through elastic deformation of flexible hinges, and inter-hole high-speed precision locating is achieved.

Owner:FOSHAN HUADAO SUPER PRECISION TECH CO LTD

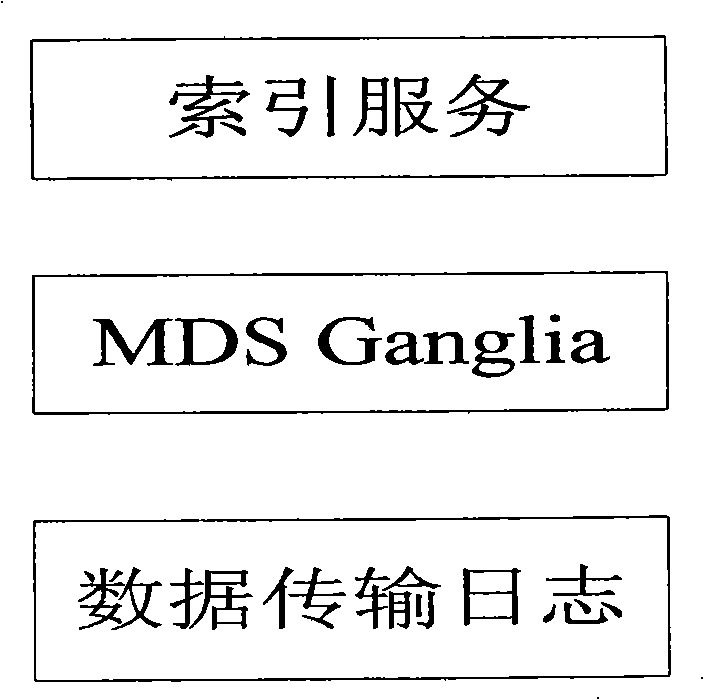

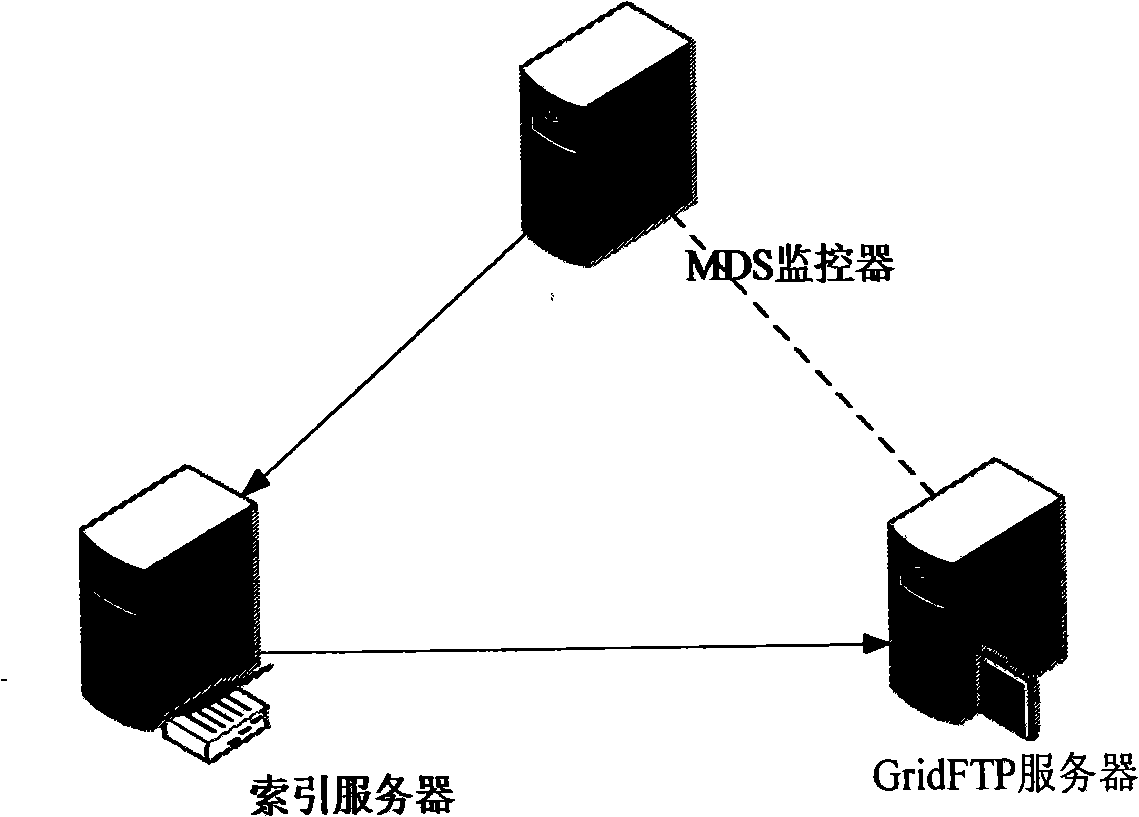

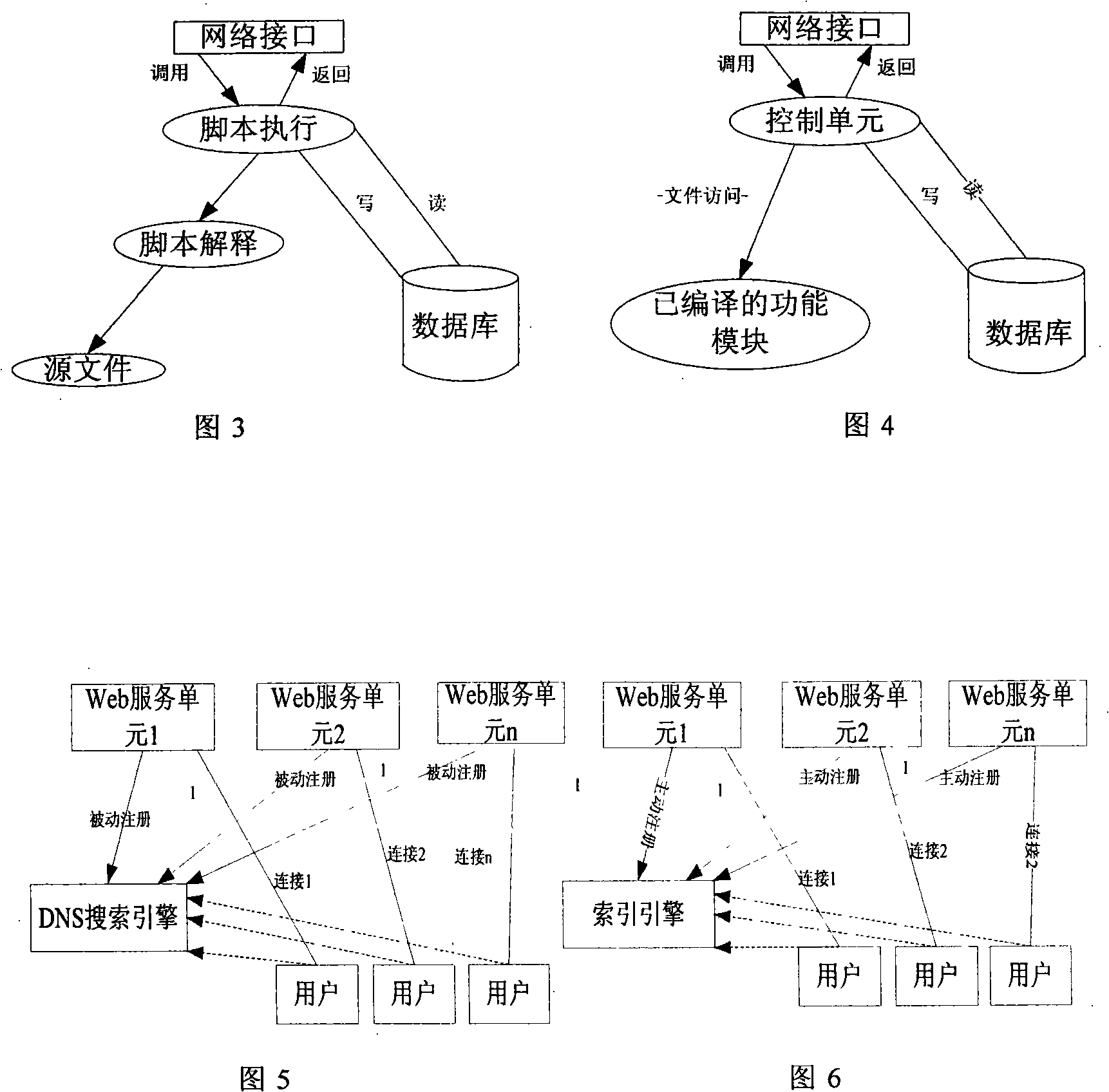

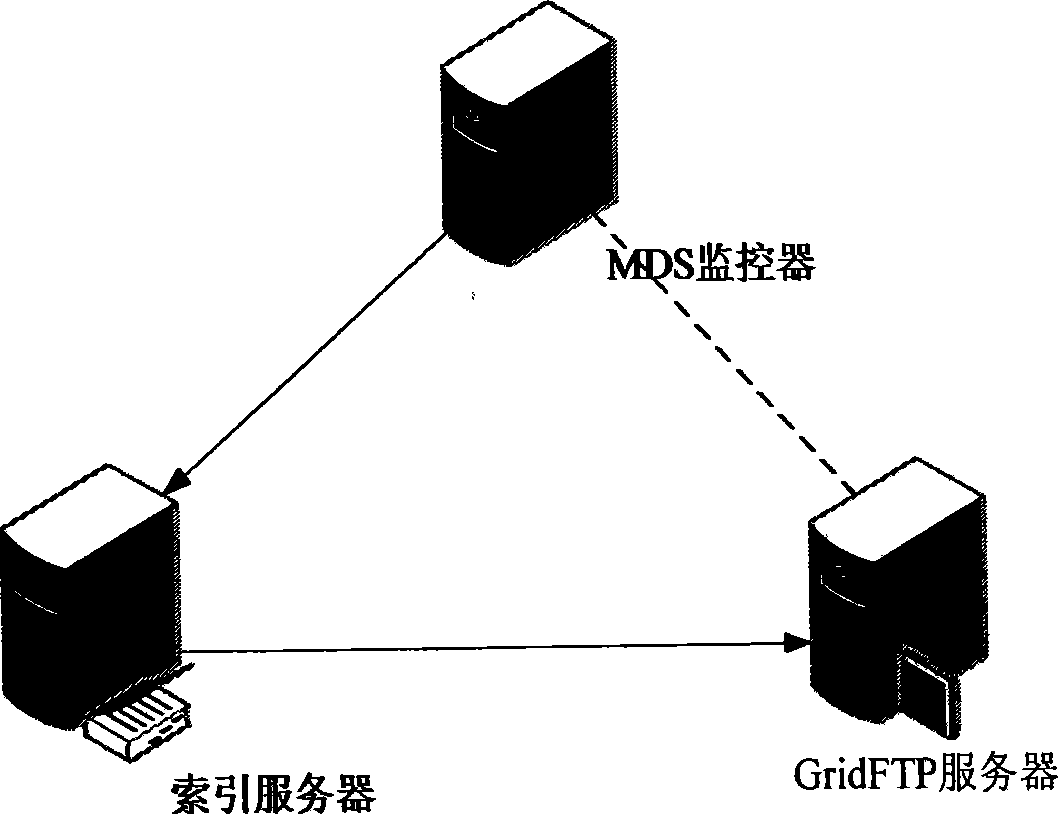

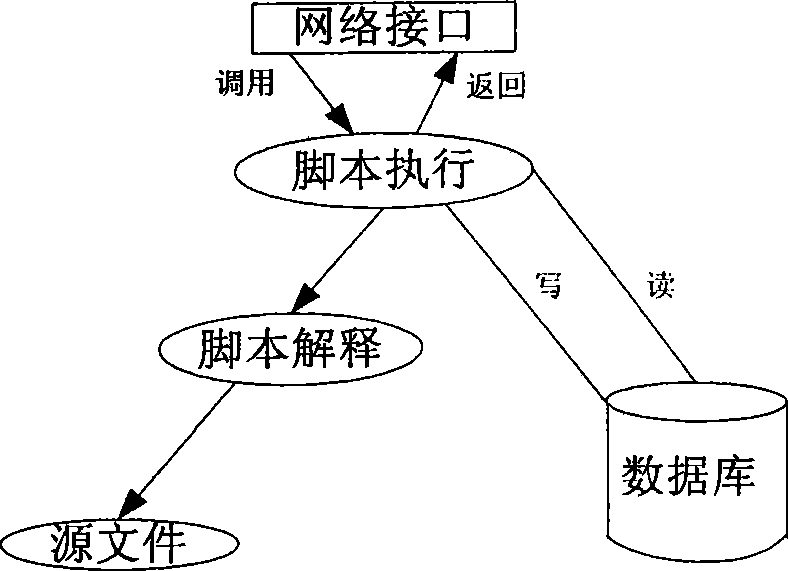

Data index method for schoolyard grid data transmission service

InactiveCN101442496BRapid positioningHigh speed positioningData switching by path configurationIndexing ServiceGridFTP

The invention discloses an index method for data in data transmission service in campus grid, which provides an index mechanism in campus GridFTP under network environment and is convenient for the discovery of resources and the inquiry of the data. A system structure under the mechanism comprises a data transmission log, a monitor and an index server. The key point comprises that the relation among a resource server, the index server and a GridFTP server is established. A data resource list acquired after MDS and ganglia are integrated is shown in figure 5, a GridFTP site is established in the index server, and information of the data resource list is mapped into the GridFTP site to be convenient for the GridFTP server to inquire data resources.

Owner:NANJING UNIV OF POSTS & TELECOMM

Data index method for schoolyard grid data transmission service

InactiveCN101442496ARapid positioningHigh speed positioningData switching by path configurationIndexing ServiceGridFTP

The invention discloses an index method for data in data transmission service in campus grid, which provides an index mechanism in campus GridFTP under network environment and is convenient for the discovery of resources and the inquiry of the data. A system structure under the mechanism comprises a data transmission log, a monitor and an index server. The key point comprises that the relation among a resource server, the index server and a GridFTP server is established. A data resource list acquired after MDS and ganglia are integrated is shown in figure 5, a GridFTP site is established in the index server, and information of the data resource list is mapped into the GridFTP site to be convenient for the GridFTP server to inquire data resources.

Owner:NANJING UNIV OF POSTS & TELECOMM

A straight seam welding machine

ActiveCN105965129BHigh speed positioningImprove welding precisionWelding/cutting auxillary devicesArc welding apparatusEngineeringMechanical engineering

A straight seam welding machine comprises a machine body, wherein a movable welding head and a workpiece fixture are arranged on the machine body; the movable welding head can move horizontally linearly; the workpiece fixture comprises a support; a supporting rod with an upper supporting surface is transversely arranged on the support; and the workpiece fixture further comprises a first press plate and a second press plate which are arranged above the supporting rod. The straight seam welding machine has the beneficial effects as follows: two ends of the first press plate and two ends of the second press plate press a plate, high-speed positioning of a sheet cylinder piece is realized through cooperation with a positioning sheet, and the production efficiency is improved; 2, the press plates with the forward force and the downward force are adopted, so that two ends of the steel plate are combined more precisely, the welding precision of the sheet cylinder piece is improved, and inner containers of water dispensers, kettles and tea cups are not prone to water leakage; 3, a variable frequency motor and a dovetail groove sliding table are adopted, the transmission precision is high, and the welding quality is high.

Owner:鲍人昌

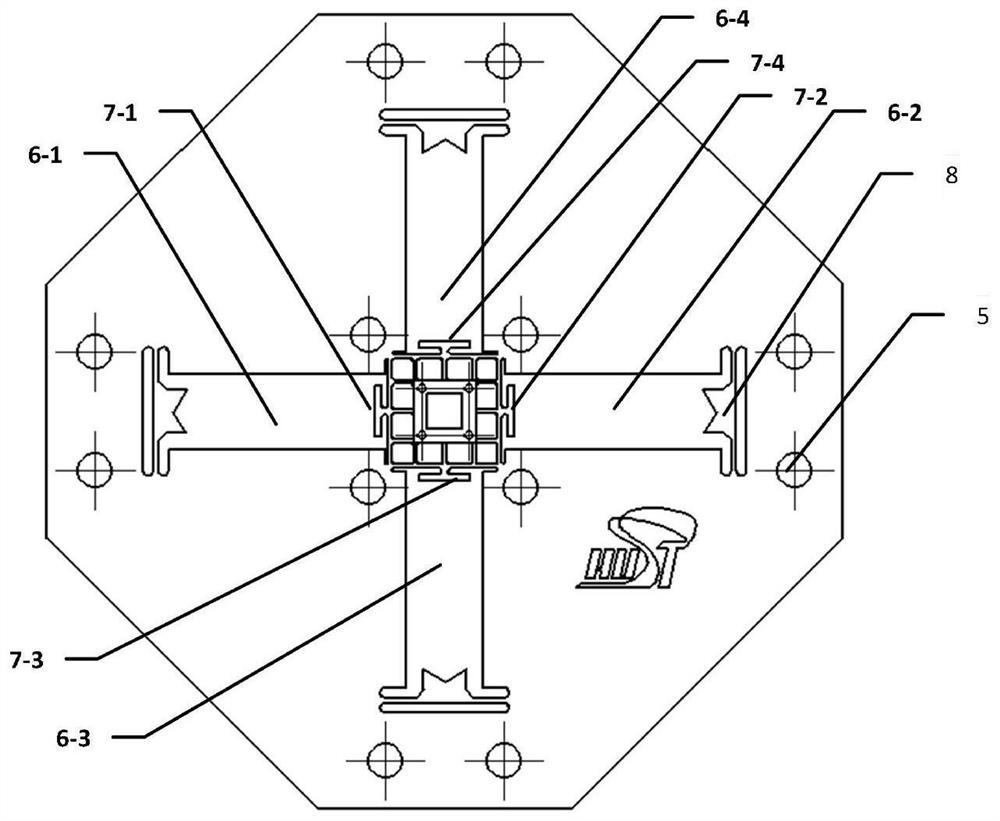

A two-dimensional nanopositioning platform

ActiveCN112067850BHigh strengthHigh precisionScanning probe microscopyCompliant mechanismControl engineering

The invention discloses a two-dimensional nano-positioning platform, belonging to the field of image-level atomic force microscope positioning control, comprising: a platform base, a motion platform and a driving device, the motion platform is set at the center of the platform base, and is used for driving signals Under the action, the displacement movement is carried out on the platform base; the driving device is respectively connected with the platform base and the motion platform, and there are correspondingly connected four-direction drive slots, four-direction drive branch chains, and four-direction connection branch chains. And the transmission branch chain group of four directions. The driving signal output by the driver in the driver slot is output to the transmission branch chain group through the driving branch chain and the connecting branch chain, and drives the motion platform to perform two-dimensional translational motion. The platform of this application is distributed symmetrically around the motion platform, and the transmission branch chains in each direction adopt a three-parallel axis symmetrical branch chain layout, which can effectively reduce coupling errors; the integrated compliant mechanism design has the characteristics of high rigidity and no friction, which can improve the performance of the platform. the natural frequency.

Owner:HUAZHONG UNIV OF SCI & TECH

A sheet metal automatic loading and unloading machine

ActiveCN111717660BHigh mechanical strengthImprove flexibilityConveyorsStacking articlesControl engineeringMachine

The invention discloses an automatic plate loading and unloading machine, comprising a flexible lifting device, a grabbing mechanism and a supporting mechanism, the grabbing mechanism is located at the lower end of the flexible lifting device, and the upper end of the flexible lifting device is provided with a driving mechanism for driving the flexible lifting device to move , the driving mechanism is driven by a servo motor and a synchronous belt. There is a track above the flexible lifting device. The servo motor and the synchronous belt drive the flexible lifting device to move forward. The walking torque is large, the positioning is accurate, the operation is stable, and it can be positioned at a high speed. It can be used without finishing general profiles, and is suitable for long-distance transportation of sheets. The supporting mechanism is located below the grabbing mechanism, the sheet is installed on the supporting mechanism, the sheet is grabbed by the grabbing mechanism, and then the driving mechanism drives the flexible lifting device to move to realize automatic feeding of the sheet.

Owner:济南瑞开电气有限公司

Large-stroke flexible hinge platform

ActiveCN110370228AShort tripSingle frequencyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMulti axis

The invention relates to the technical field of high-precision motion, in particular to a large-stroke flexible hinge platform. The large-stroke flexible hinge platform comprises a supporting base, aconnecting frame, a micro bearing platform, an X-axis flexible hinge sheet and a Y-axis flexible hinge sheet, wherein the two ends of the X-axis flexible hinge sheet are separately fixed onto the connecting frame and the supporting base; the two ends of the Y-axis flexible hinge sheet are separately fixed onto the connecting frame and the micro bearing platform; and rigidity of the flexible hingesheet can be regulated by regulating a clamping position, so that matching of variable working conditions is realized. The large-stroke flexible hinge platform utilizes a rigidity-adjustable flexiblehinge to realize multi-axis dynamic characteristic coordination, and utilizes nonlinear elastic deformation of the flexible hinge to realize large-stroke high-speed interpolation, so that efficient processing is realized.

Owner:FOSHAN HUADAO SUPER PRECISION TECH CO LTD

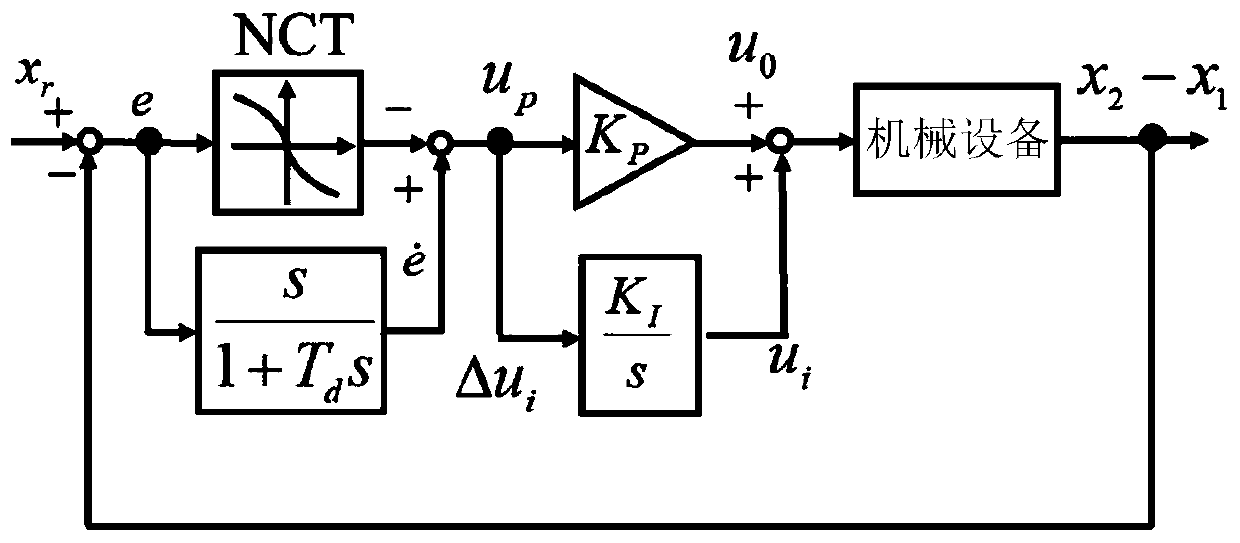

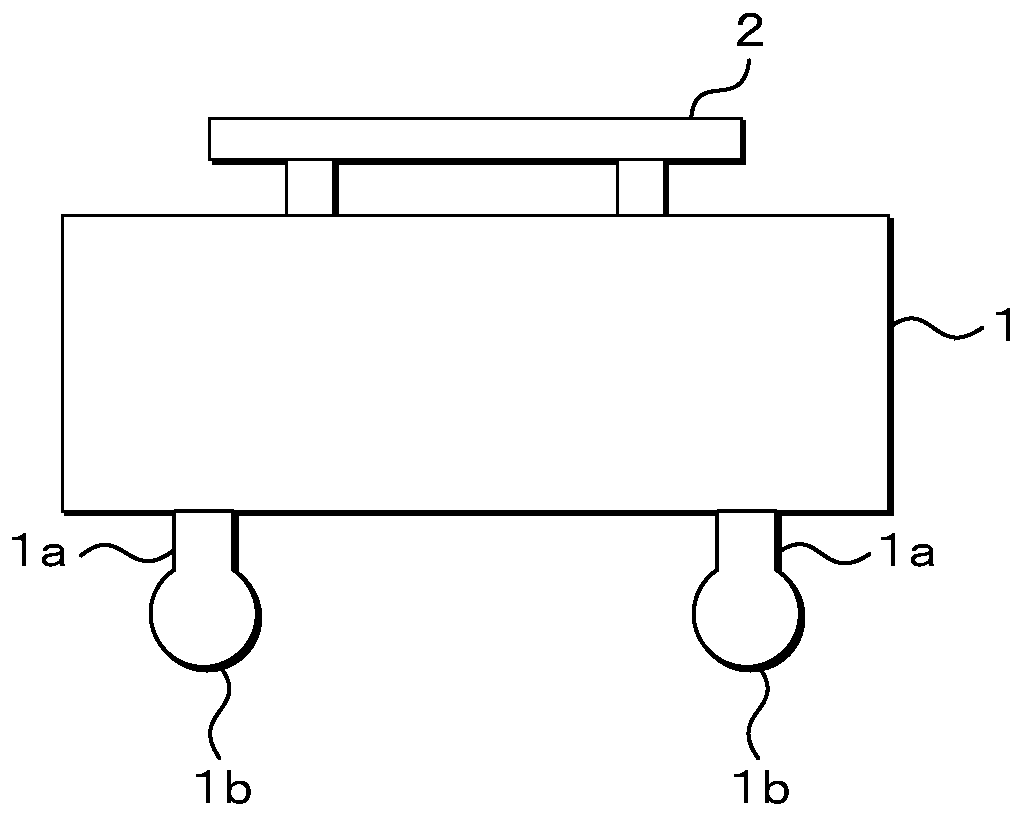

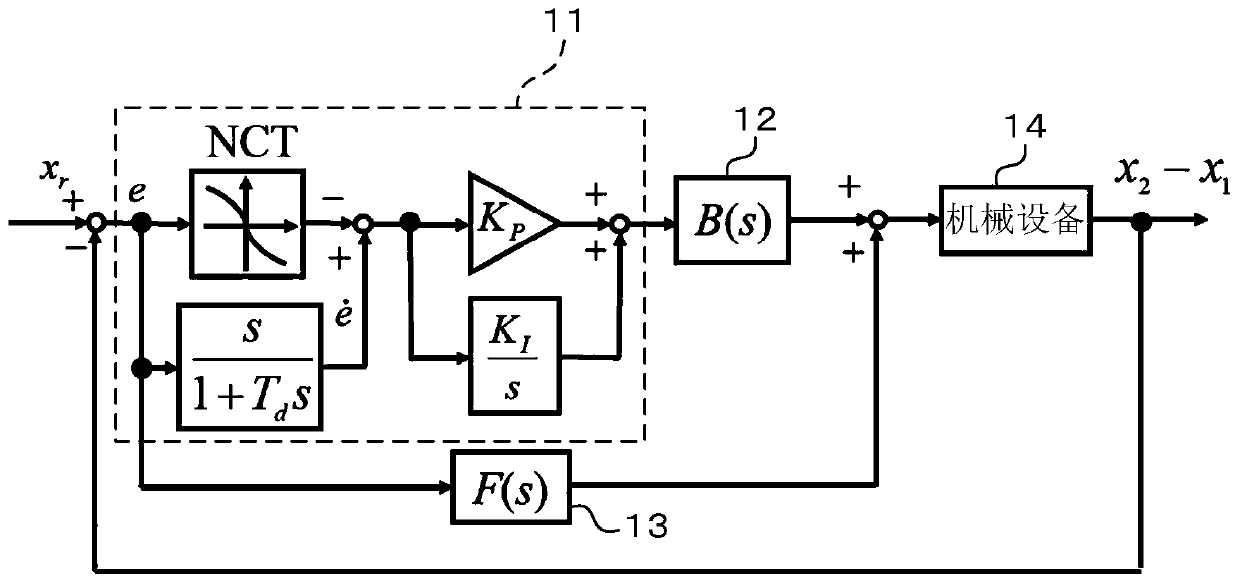

Control method and control apparatus of linear motor stage

PendingCN111324033ASuppress high frequency vibrationHigh speed positioningAC motor controlControllers with particular characteristicsControl theoryElectric machinery

The invention provides a control method and a control device for a linear motor stage based on the NCTF control method, which are easy in process and controller adjustment without special knowledge about control theory, and can be positioned with high precision and high speed. When positioning on a linear motor stage with a movable worktable on the plate, the NCTF control using the nominal characteristic trajectory allows the worktable to follow the vibration from the plate and suppresses high-frequency vibration generated in a process of allowing the worktable to follow the vibration of the plate. The nominal characteristic trajectory is obtained from an open-loop experiment using the input signal to the linear motor stage. Feedforward control is added to NCTF control. The target is control that suppresses the influence of the stage on relative movement of the plate with respect to the worktable due to the vibration of the plate.

Owner:株式会社博迈立铖

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com