Scanning mechanism, method of machining workpiece, and machine tool

A technology of scanning mechanism and concentrating device, applied in the field of scanning mechanism, can solve the problems of high-speed positioning or high-precision positioning difficulties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

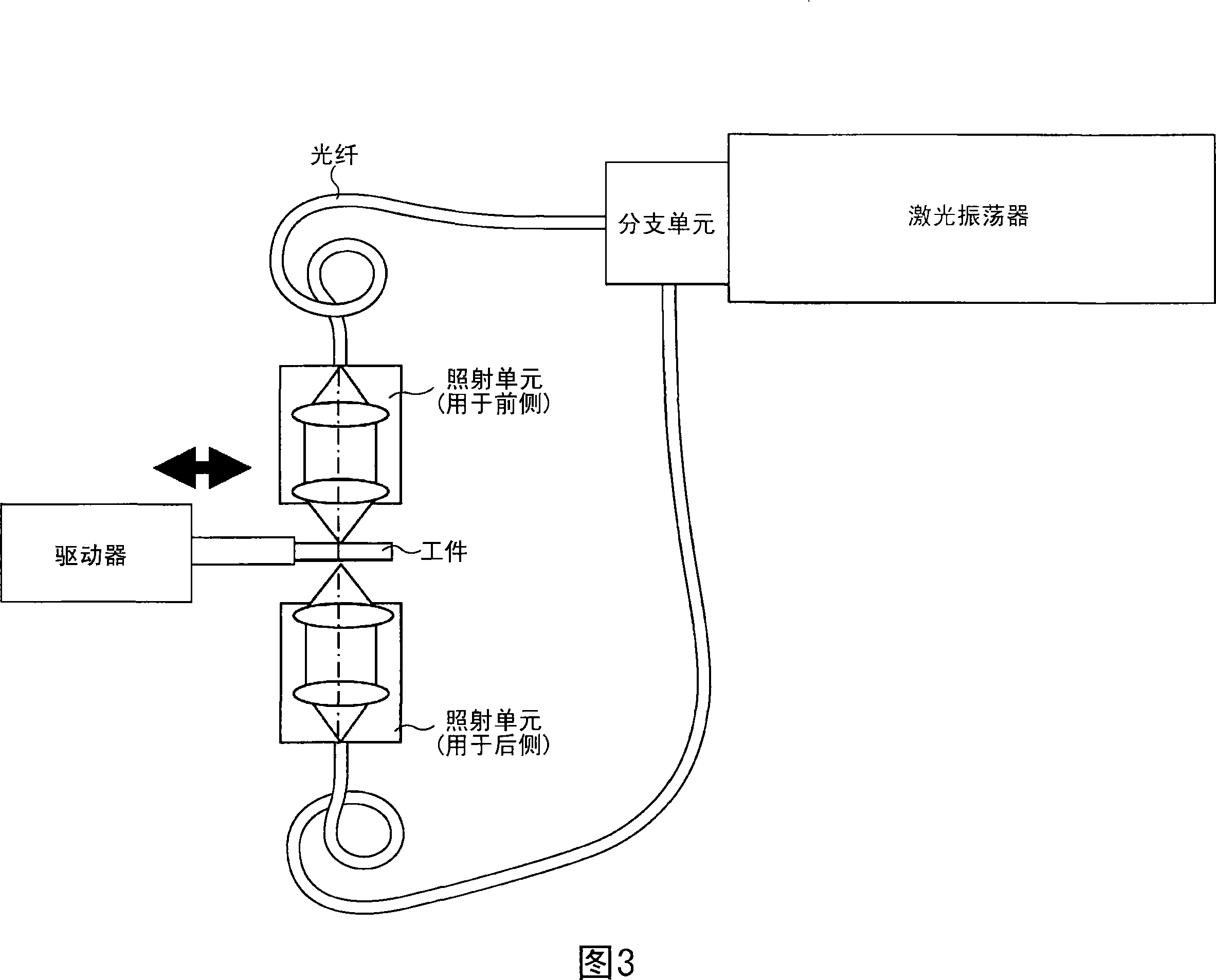

[0042] An embodiment of the laser scanner will be described below with reference to the accompanying drawings.

[0043] FIG. 4 is a schematic diagram showing a brief structure of a laser scanner according to an embodiment of the present invention.

[0044] The laser scanner of this embodiment includes a condensing lens that condenses a laser beam emitted by a laser source (not shown), and a condensing lens holder with a focusing mechanism as light condensing means, the condensing lens A lens holder supports the condenser lens. Adjusting screws are arranged around the periphery of the condenser lens holder. These adjustment screws are screwed into the condenser lens mounting plate. Correspondingly, by rotating the condenser lens holder, the condenser lens holder can move along the Y-axis direction in the figure, that is, move along the direction indicated by the horizontal arrow in Figure 4, and the focus position of the laser beam can be moved Adjusted to lie on the surface...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com