Triaxial movement platform

A motion platform and motion system technology, applied in the field of motion platforms, can solve problems such as low efficiency, poor stiffness, and slow response, and achieve the effects of accurate positioning, reducing dynamic errors, and improving stability and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

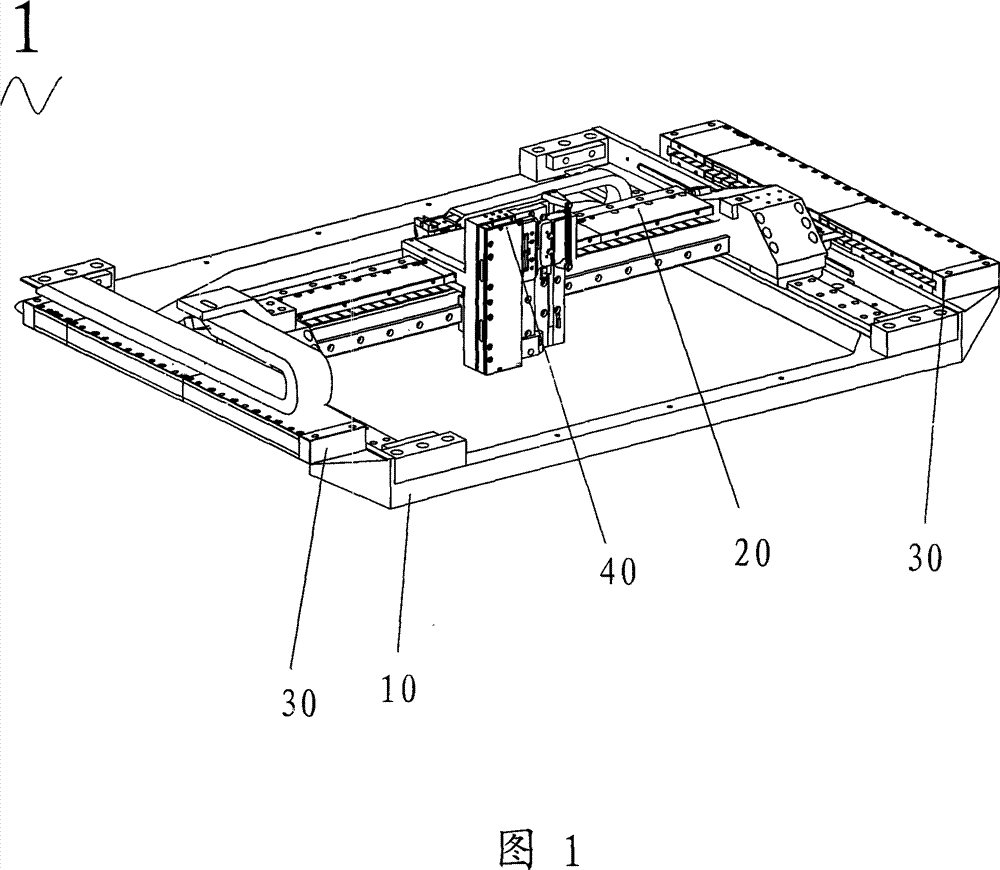

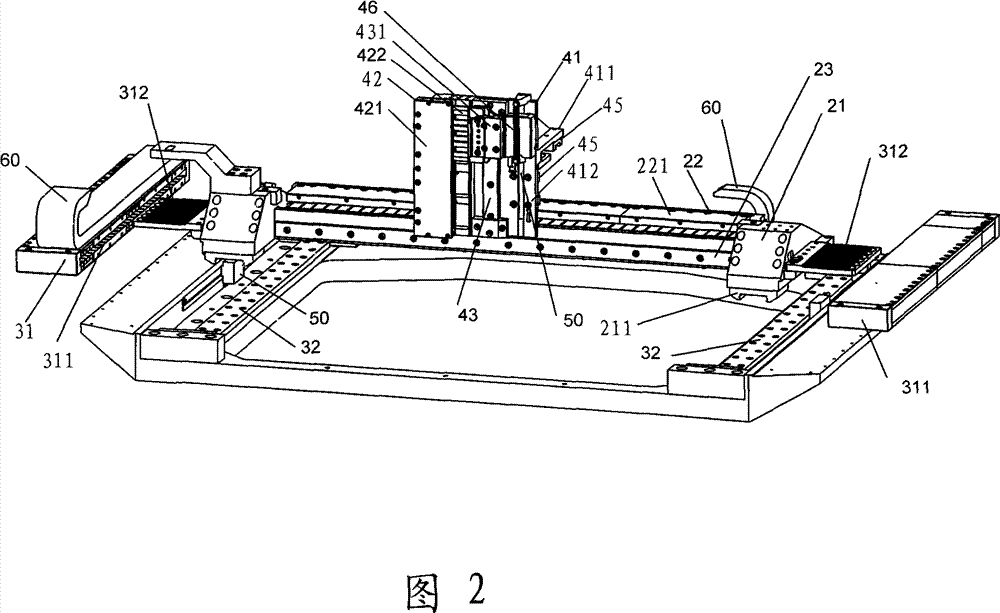

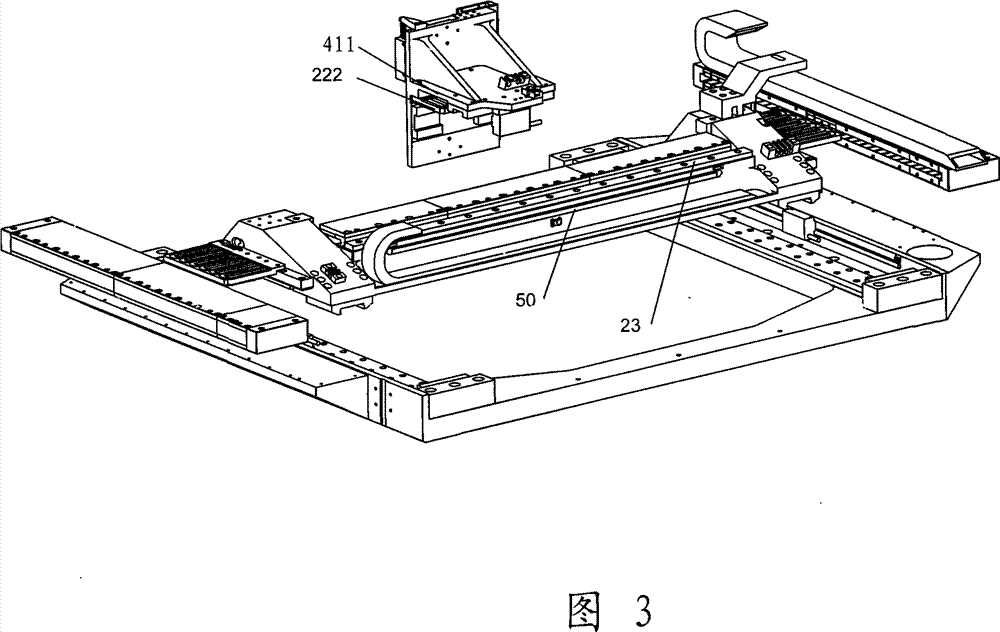

[0019] see figure 1 and figure 2 , the three-axis motion platform 1 of the present invention includes a base 10 , an X-axis motion system 20 , a Y-axis motion system 30 and a Z-axis motion system 40 .

[0020] The base 10 is roughly in the shape of a cuboid. The Y-axis motion system 30 is assembled at both ends of the base 10 respectively. The X-axis motion system 20 is erected in the middle of the base 10 . The Z-axis motion system 40 is assembled on the X-axis motion system 20 .

[0021] The X-axis motion system 20 includes a beam 21 , a linear motor A22 and a guide rail A23 . The linear motor A22 includes a stator A221 and a mover A222. The stator A221 is installed on the beam 21 . Magnets are housed in the stator A221. The guide rails A23 are mounted on the front and rear sides of the stator A221 respectively.

[0022] The Y-axis motion system 30 includes a linear motor B31 and a guide rail B32. The linear motor B31 also includes a stator B311 and a mover B312. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com