Roller bearing

A technology of roller bearings and bearings, applied in the direction of roller bearings, bearing components, shafts and bearings, to achieve the effects of low friction, avoiding temperature rise, and high service stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

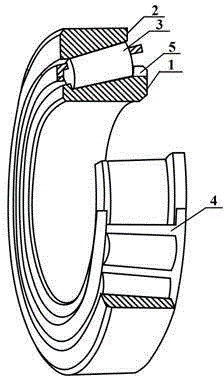

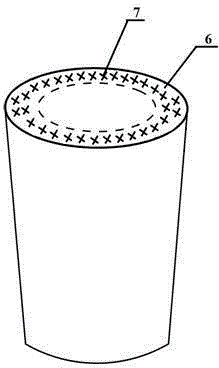

[0022] Such as figure 1 , 2 As shown, the roller bearing includes an inner ring 1 with a raceway on the outer circumference, an outer ring 2 with a raceway on the inner circumference, a roller 3 between the raceway of the inner ring 1 and the raceway of the outer ring 2, a cage 4 and The thrust structure 5, the thrust contact area 6 on the end surface of the roller 3 is a compound lubricating structure, the compound lubricating structure is composed of a solid lubricating coating and a surface micro-texture 7, wherein the surface micro-texture 7 is uniformly distributed micro pits array.

[0023] The thrust structure 5 is a rib or a retaining ring.

[0024] The shape of the pits in the micro pit array is one of circle, ellipse, triangle and quadrangle or a combination thereof.

[0025] The area density of micro-pits is less than 65%, and the depth is greater than 5 μm.

[0026] The solid lubricating coating includes an amorphous carbon layer and a transition layer, the tot...

Embodiment 2

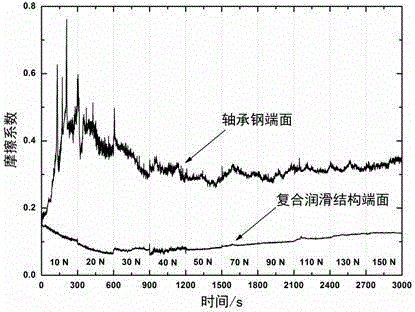

[0030] image 3 It is the change diagram of the friction coefficient between the tapered roller end face and the bearing steel roller end face of the present invention. The base material of the roller is GCr15 bearing steel, the diameter of the large end of the roller is 10 mm, and the micro-texture in the compound lubrication structure is a circular micro-pits array, the diameter of the pits: 200 μm, the density Dt : 25%, pit depth 5~7 μm. The solid lubricating coating is a Cr-doped amorphous carbon layer, the transition layer is Cr, and the total thickness of the coating is 2.5 μm. The SRV friction testing machine was used to test the friction coefficient change of the GCr15 bearing steel roller end face and the roller end face with compound lubrication structure. The test conditions were: amplitude 1 mm, frequency 25 Hz, load 10-150 N, lubricant PAO-10, friction The dual is a bearing steel disc to simulate the contact between the roller end face and the raceway rib.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com