An engine and a vehicle using the engine

A technology for engines and gaskets, applied in the direction of gear lubrication/cooling, etc., can solve the problems of high labor cost, reduce the lubrication effect of gaskets, shorten the service life of gaskets, etc., and achieve the advantages of convenient processing, good lubrication effect and long service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

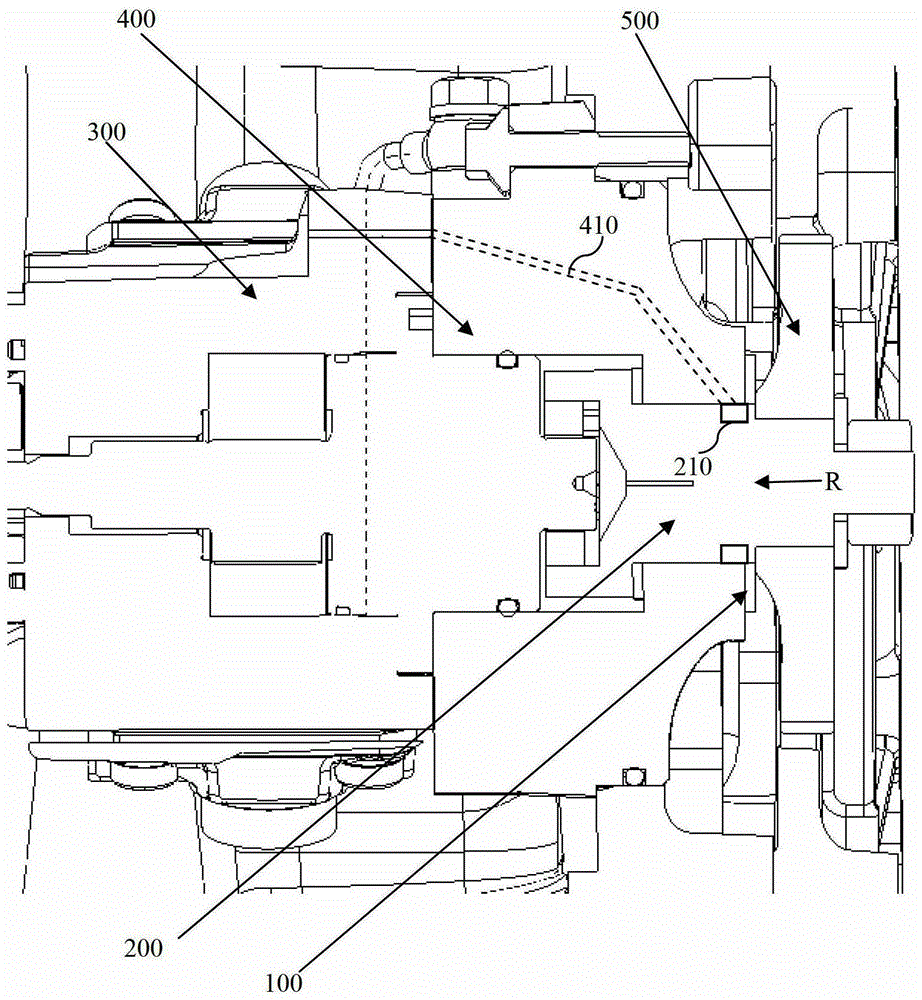

[0027] figure 1 A fuel pump drive mechanism in an engine timing train employing a spacer 100 is shown by way of example. Of course, those of ordinary skill in the art should understand that the gasket 100 can also be used in other timing trains such as generator drive mechanisms, or in other positions of the engine with shaft parts and gear parts, or in other parts of the automobile. Location. The gear 500 is driven by power from the crankshaft to drive the shaft 200 to rotate in the shaft hole of the flange 400 , and the flange 400 is fixedly installed on the cylinder body 300 . The washer 100 is sleeved on the shaft 200 and located between the gear 500 and the flange 400 . An oil passage 410 for supplying oil to the annular oil groove 210 on the shaft 200 is processed on the flange 400 , and the annular oil groove 210 serves as an oil passage for supplying oil to the gasket 100 .

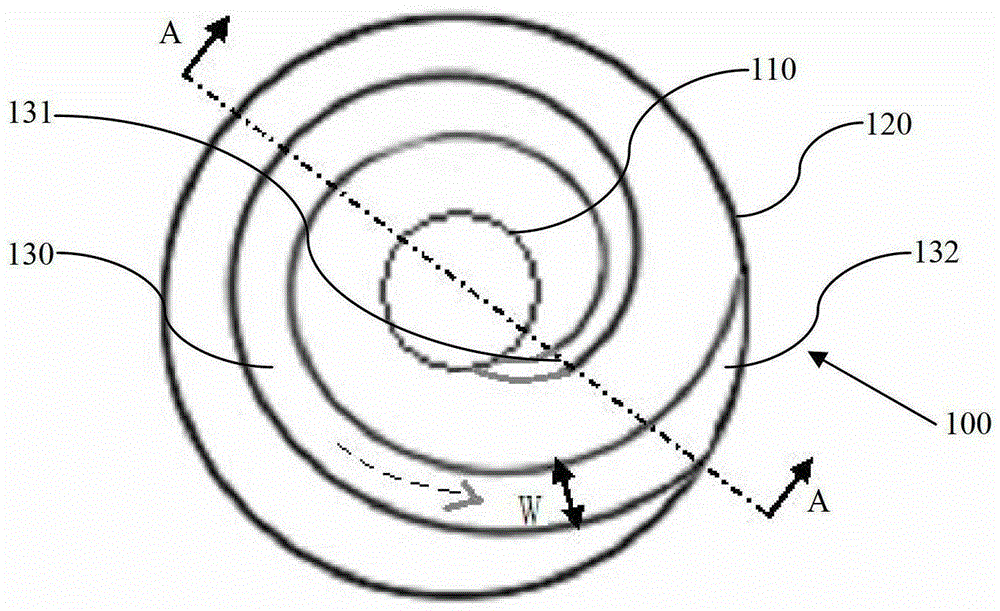

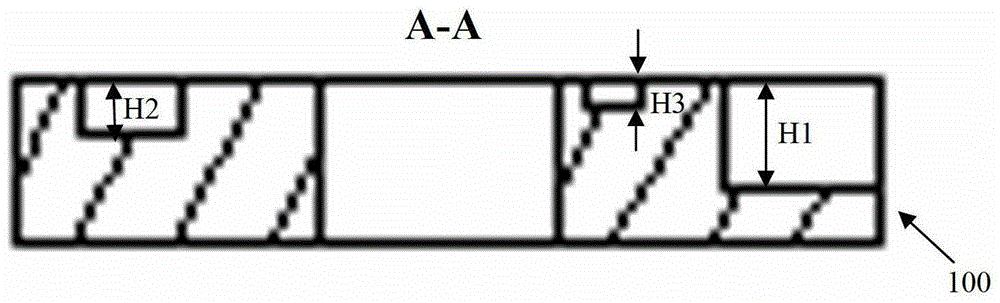

[0028] refer to figure 2 , the gasket 100 is annular, with an inner circle 110 and an out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com