High-speed lubrication engineering plastic ball

A technology of engineering plastics and spheres, used in sliding contact bearings, bearings, combined bearings, etc., can solve the problems of high manufacturing cost and complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below by means of drawings and specific embodiments.

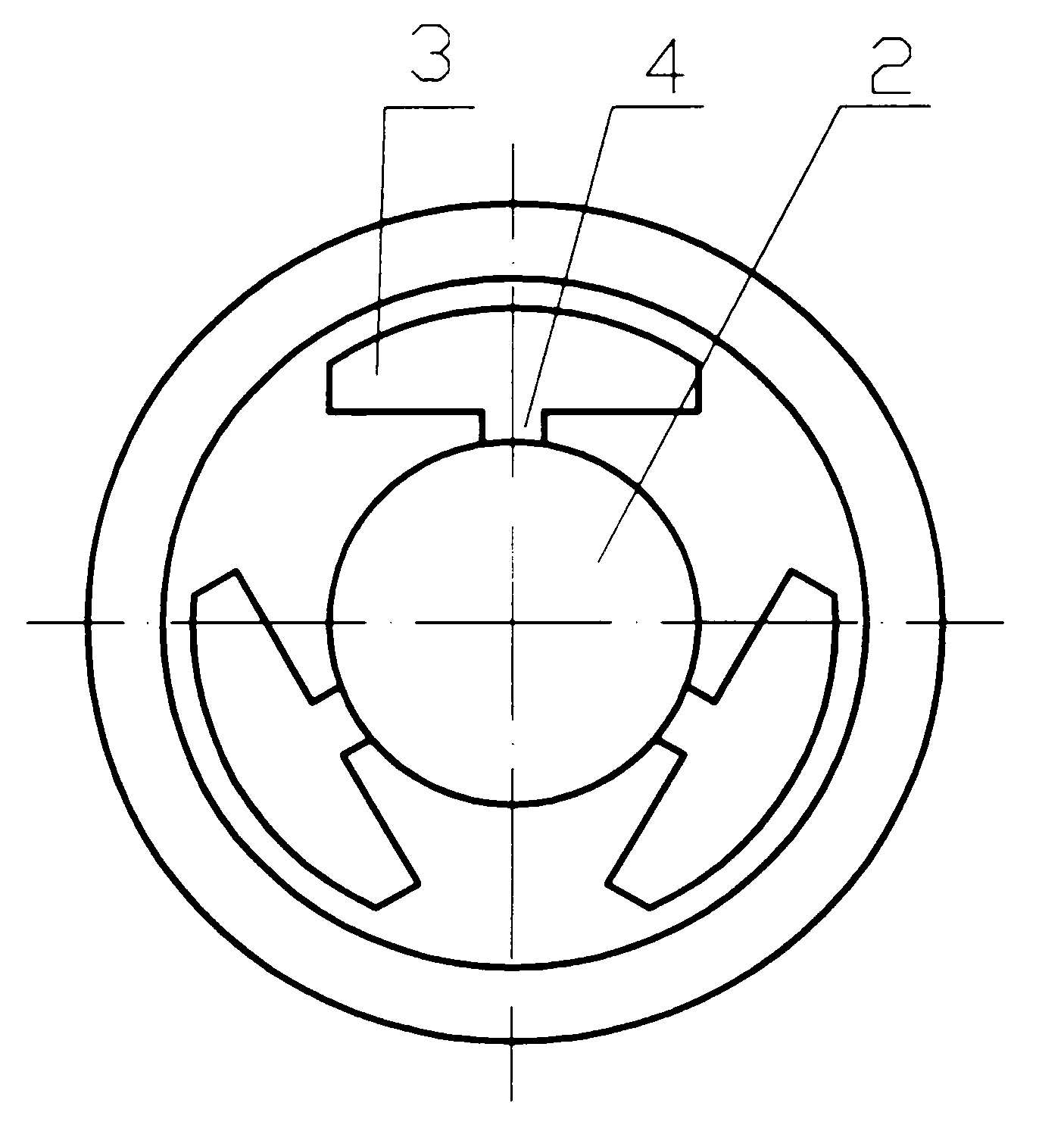

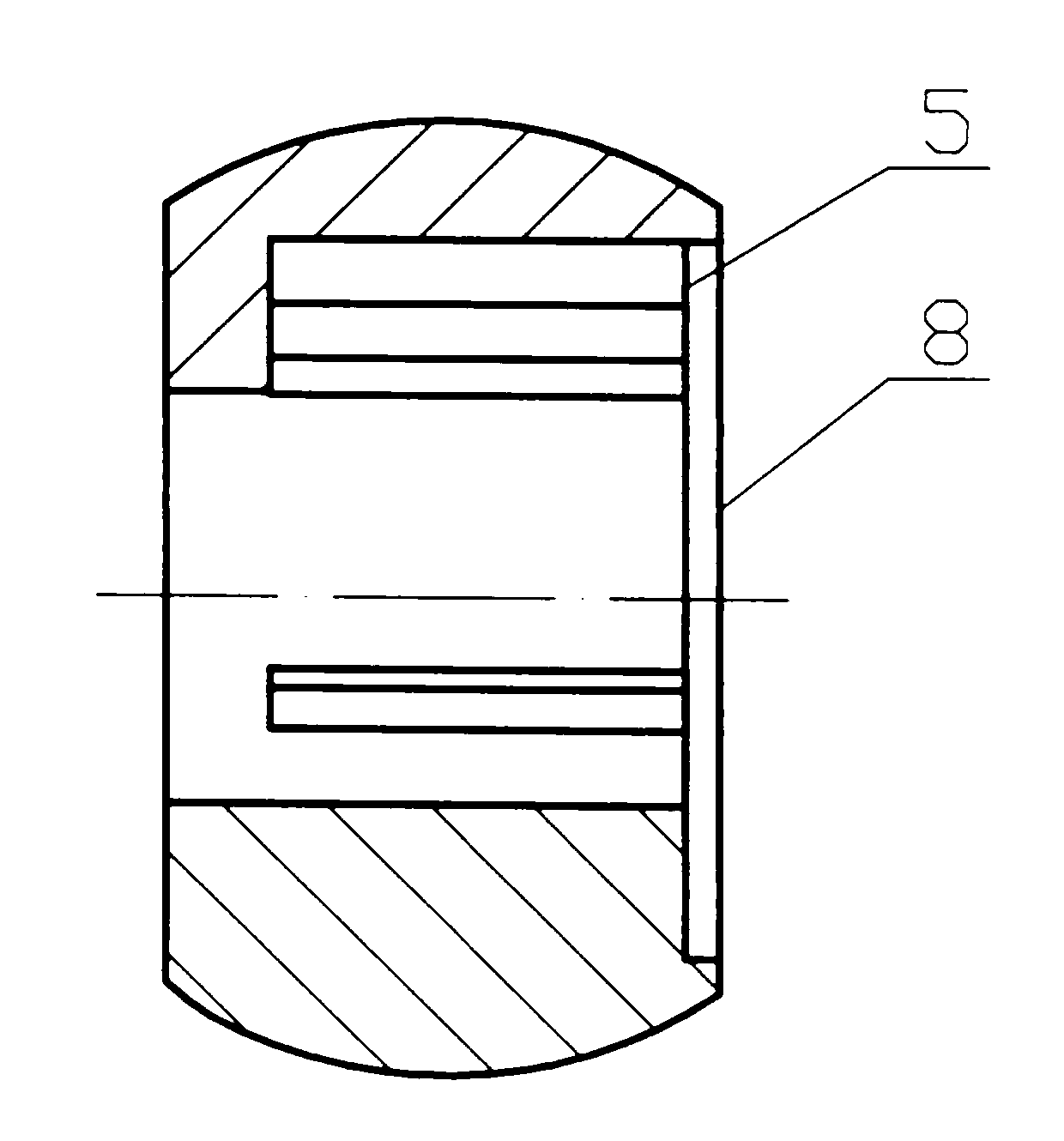

[0018] Figure 1 to Figure 4 It is a schematic diagram of the structure of a high-speed lubricating engineering plastic sphere. It can be seen from the figure that it is a sphere 1 made of engineering plastics. There is a shaft hole 2 through the center of the sphere 1. In the sphere 1 on the outer circle of the shaft hole 2, there are 3 groups evenly distributed in the shaft hole. The surroundings of 2 are cavities 3 for storing lubricating grease, and each cavity 3 communicates with the shaft hole 2 through an oil guide groove 4 . The cavity 3 is only in communication with the end surface of one end of the shaft hole 2, but not connected with the end surface of the other end of the shaft hole 2. A cover with a hole 6 in the middle is installed on the communication end surface 5 and covers the opening of the cavity 3. plate 7. The communicating end face 5 is slight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com