A kind of preparation method and application of powder core wire material for nickel-based coating, coating

A powder core wire material and coating technology, which is applied in the direction of coating, metal material coating process, fusion spraying, etc., to achieve the effect of improving service stability, high hardness and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

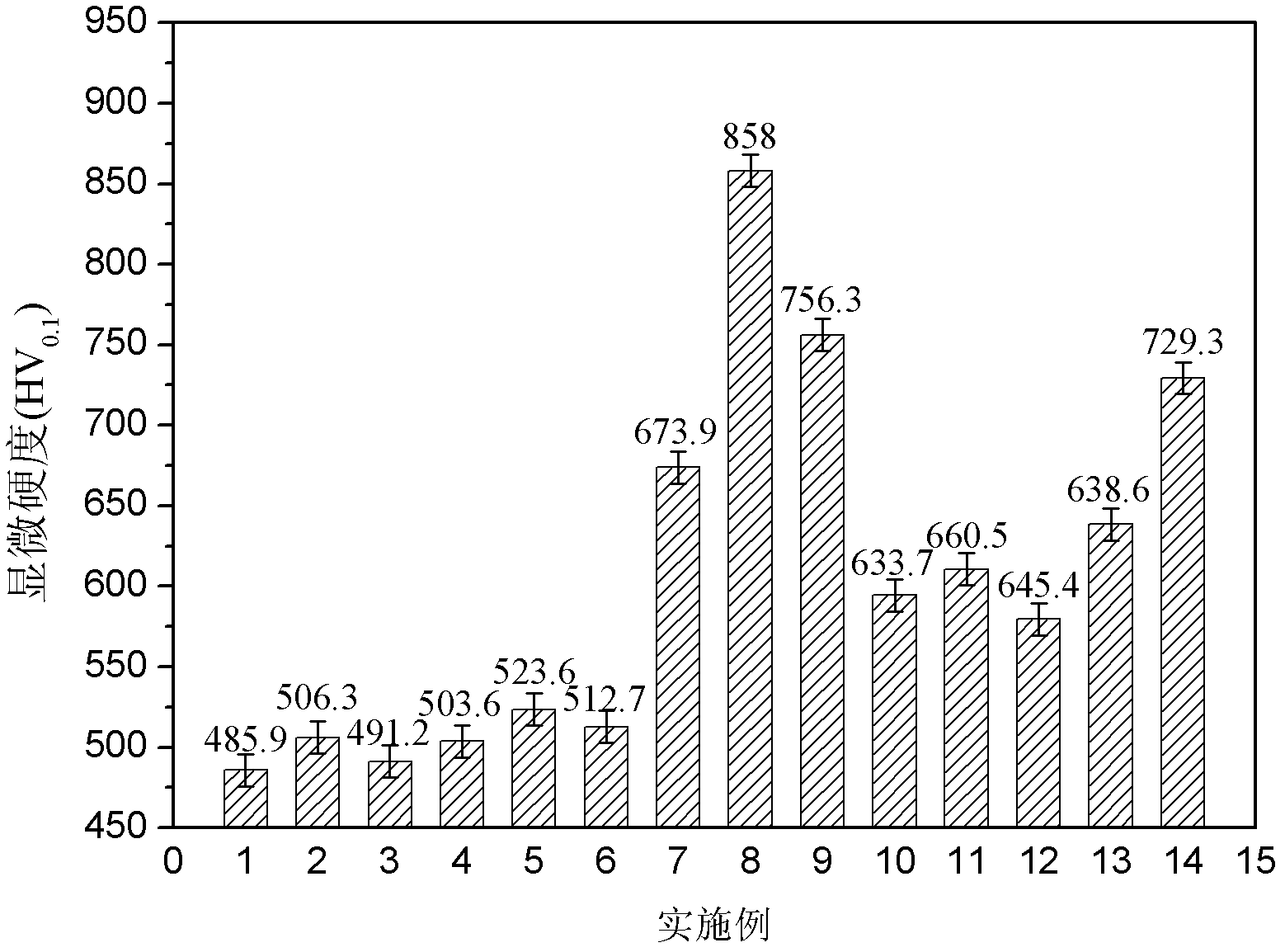

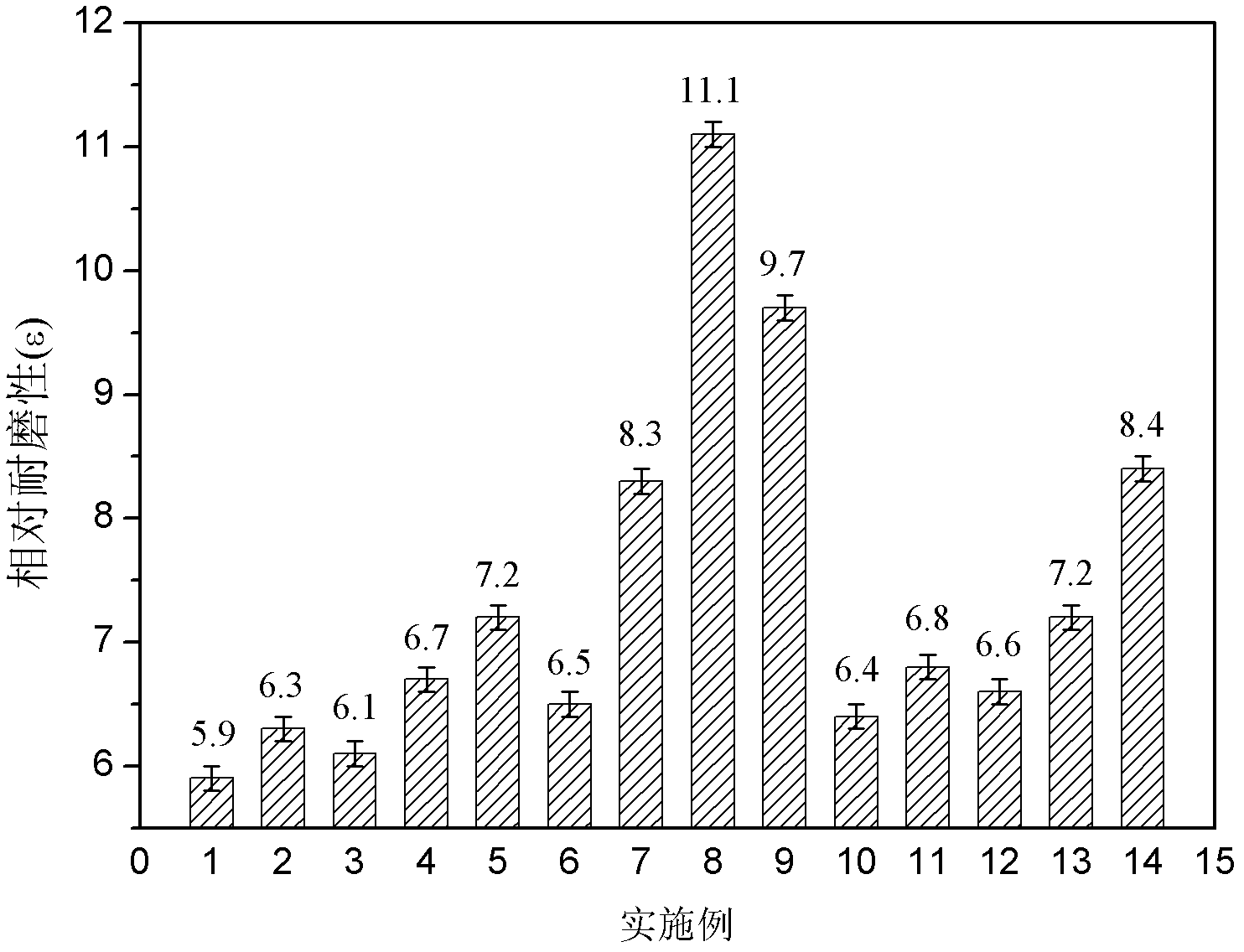

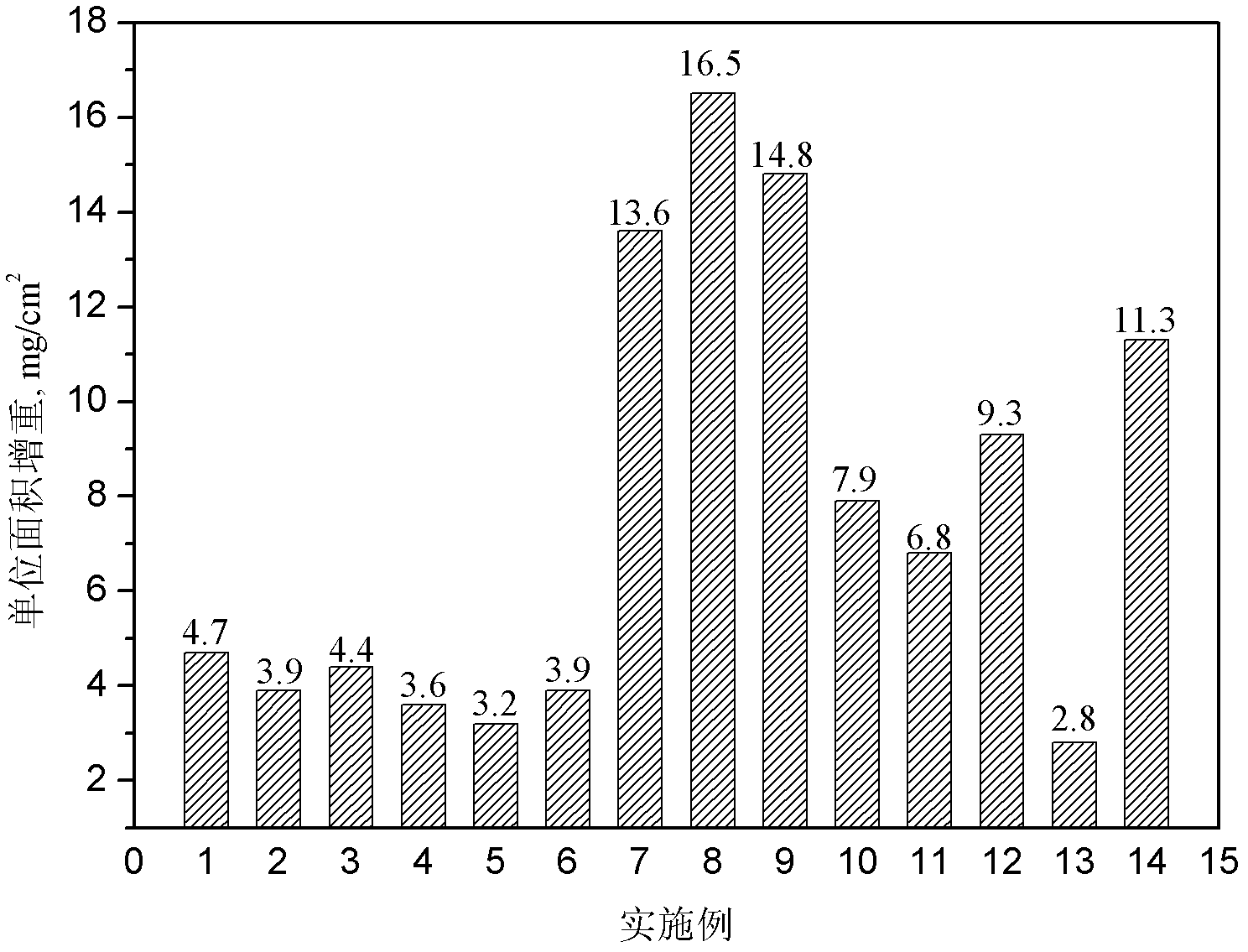

Examples

Embodiment 1

[0035] According to the atomic percentage of the drug core composition of the powder core silk material: Cr: 20at.%; B: 30at.%; C: 2.5at.%; Ni: the balance. Filling rate: 32%, rolled powder core wire. Spraying parameters used for coating preparation: voltage 28-30V; current 160-180A; spraying distance 190mm; compressed air pressure 0.5-0.6MPa.

Embodiment 2

[0037] According to the atomic percentage of the drug core composition of the powder core silk material: Cr: 20at.%; B: 30at.%; C: 2.5at.%; Ni: the balance. Filling rate: 32%, rolled powder core wire. Spraying parameters used for coating preparation: voltage 30-32V; current 180-200A; spraying distance 200mm; compressed air pressure 0.5-0.6MPa.

Embodiment 3

[0039] According to the atomic percentage of the drug core composition of the powder core silk material: Cr: 20at.%; B: 30at.%; C: 2.5at.%; Ni: the balance. Filling rate: 32%, rolled powder core wire. Spraying parameters used for coating preparation: voltage 32-34V; current 200-220A; spraying distance 210mm; compressed air pressure 0.5-0.6MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com