Precious metal single-atom dispersion type cleaning catalyst and preparation method thereof

A technology for purifying catalyst and atomic dispersion, applied in catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc., can solve the problems of harsh reaction conditions, high cost, disadvantage, etc. Achieve the effect of reducing production cost, reducing usage, and improving dehydrogenation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

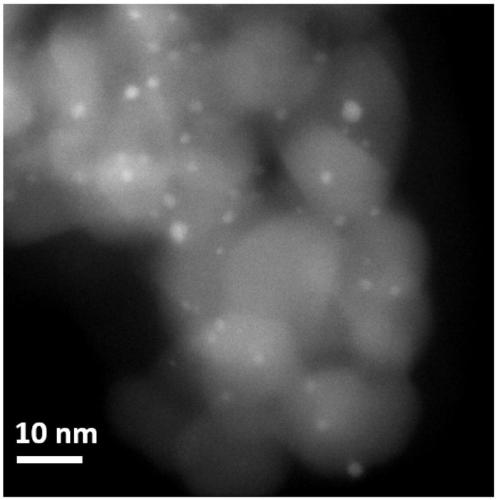

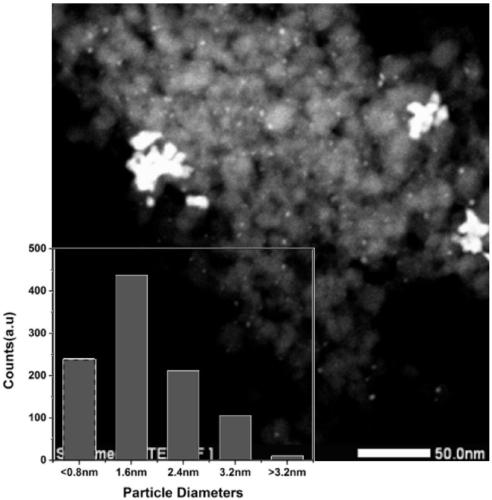

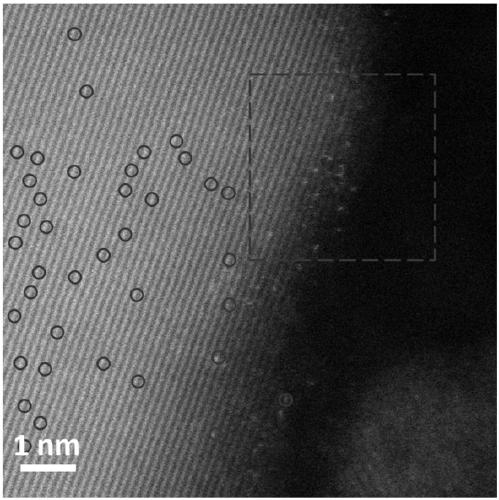

[0053] A noble metal single-atom dispersed purification catalyst, including components and mass percentage: 99.9% TiO 2 Support with 0.1% Pt for H removal in high concentration CO gas 2 , where TiO 2 The particle size of the carrier is 20-30nm. In this catalyst, Pt is in TiO 2 The carrier presents a monoatomic dispersion state.

[0054] The preparation method of the noble metal single-atom dispersed purification catalyst comprises the following steps:

[0055] In a vacuum glove box, 136.12 g of tetrabutyl titanate was weighed and diluted to 200 mL with absolute ethanol. Weigh 0.2g of chloroplatinic acid (molecular formula is H 2 PtCl 6 ·6H 2 O), magnetic stirring was dissolved in the ethanol solution (hereinafter referred to as the solution A0 solution). Another 200 mL of 0.1 M ammonium carbonate solution was prepared, and the pH was adjusted to 8 using a small amount of hydrochloric acid (hereinafter this solution is referred to as B0 solution). The A0 solution was pl...

Embodiment 2

[0057] A noble metal single-atom dispersed purification catalyst, including components and mass percentages: 99.5% TiO 2 Support with 0.5% Pt for H removal in high concentration CO gas 2 , where TiO 2 The particle size of the carrier is 20-30nm. In this catalyst, Pt is in TiO 2 The carrier presents a monoatomic dispersion state.

[0058] The preparation method of the noble metal single-atom dispersed purification catalyst comprises the following steps:

[0059] In a vacuum glove box, 136.12 g of tetrabutyl titanate was weighed and diluted to 200 mL with absolute ethanol. Weigh 1g of chloroplatinic acid (molecular formula is H 2 PtCl 6 ·6H 2 O), magnetic stirring is dissolved in this ethanol solution (hereinafter referred to as this solution is A solution). Another 200 mL of 0.1 M ammonium carbonate solution was prepared, and the pH was adjusted to 8 with a small amount of hydrochloric acid (hereinafter this solution is referred to as solution B). Place A solution in a ...

Embodiment 3

[0073] A noble metal single-atom dispersed purification catalyst, including components and mass percentage: 98.2% TiO 2 Support with 1.8% Pd for removal of H in high concentration CO gas 2 , where TiO 2 The particle size of the carrier is 20-30nm. In this catalyst, Pd is in TiO 2 The carrier presents a monoatomic dispersion state.

[0074] The preparation method of the noble metal single-atom dispersed purification catalyst comprises the following steps:

[0075] In a vacuum glove box, weigh 85.08g of tetrabutyl titanate, and use absolute ethanol to dilute to 200mL, weigh 1g of palladium tetrachloride (molecular formula is PdCl 4 ), magnetically stirred and dissolved in the ethanol solution (hereinafter referred to as the solution A2 solution).

[0076] Another 200 mL of 0.1 M ammonium carbonate solution was prepared, and the pH was adjusted to 8 with a small amount of hydrochloric acid (hereinafter this solution is referred to as B2 solution). The A2 solution was placed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com