A high-energy solid propellant

A solid propellant, high-energy technology, applied in the direction of offensive equipment, compressed gas generation, non-explosive/non-thermal agent components, etc., can solve the problems of limited application, low elongation, high glass transition temperature, etc., and achieve low-temperature mechanical properties Improvement, lower glass transition temperature, widen the effect of application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

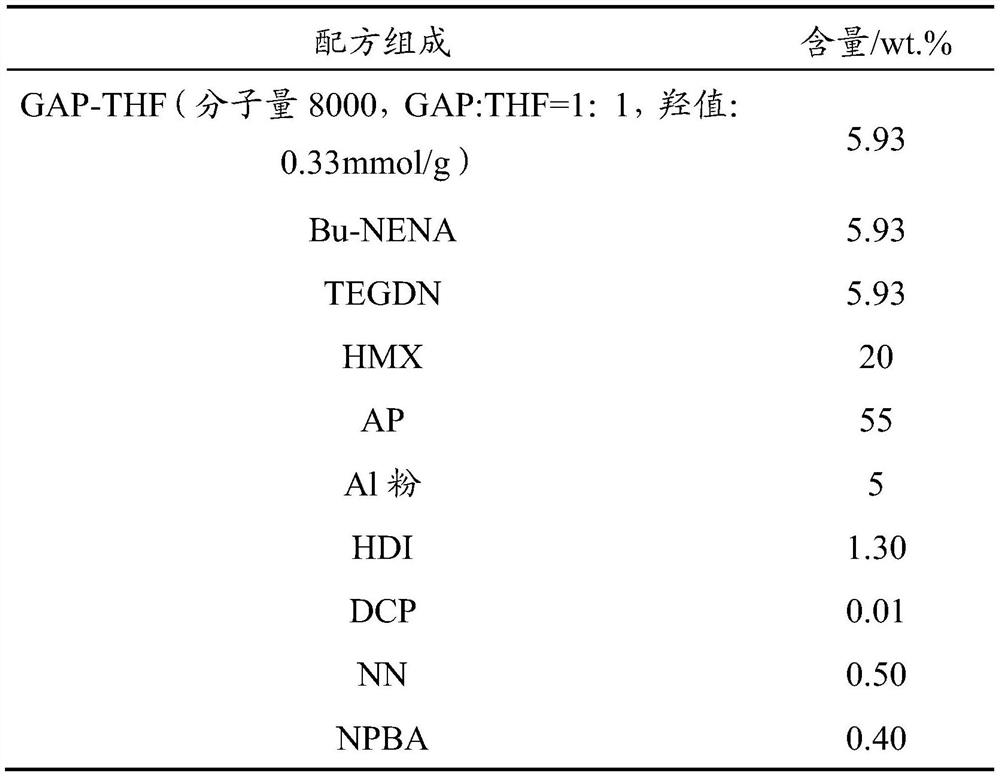

[0032] (1) The propellant formula composition (mass percentage) is shown in Table 1-1:

[0033] Table 1-1 Propellant formulation

[0034]

[0035] According to the above formula, the raw materials are weighed and mixed by a vertical mixer. The mixture of binder and plasticizer is pre-mixed to form a homogeneous liquid, referred to as glue. In the mixer, first add Al powder, neutral polymer bonding agent, stabilizer, curing catalyst and 70% glue mixture and mix for 10 minutes, then add HMX or FOX-7 and mix for 15 minutes, then add AP and mix for 30 minutes, and finally add curing The mixture of propellant and 30% glue is mixed for 20 minutes at a mixing temperature of 55°C±2°C. After the propellant slurry is discharged, it is poured into the mold through a vacuum pouring tank, and finally placed in an oil bath oven at 50°C for 7 days to be propelled. The preparation method of each subsequent embodiment is the same as that of this embodiment.

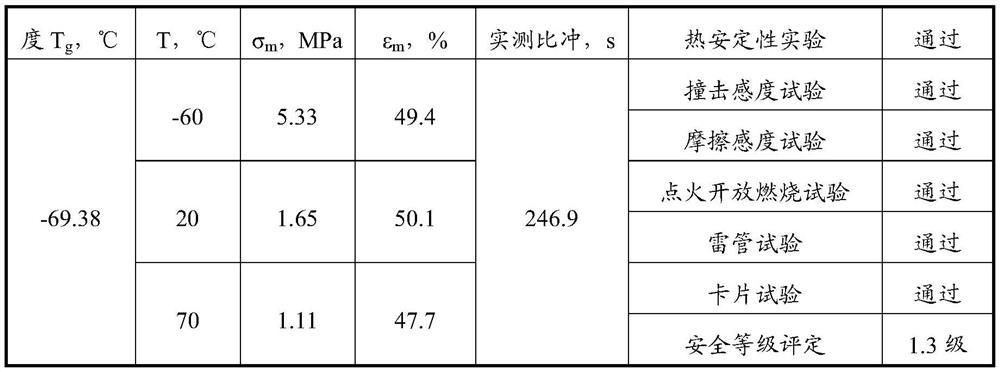

[0036] (2) The comprehensive...

Embodiment 2

[0042] (1) The propellant formula composition (mass percentage) is shown in Table 1-2:

[0043] Table 1-2 Propellant formulation

[0044]

[0045] (2) The overall performance of the propellant is shown in Table 2-2:

[0046] Table 2-2 Propellant Performance Parameters

[0047]

[0048] Signal characteristics: visible light transmittance of propellant plume is 65.6%, laser transmittance is 73.9%, near-infrared transmittance is 82.4%, mid-infrared transmittance is 84.9%, far-infrared transmittance is 90.4%, microwave attenuation is 0.34dB, The middle and far infrared radiation intensity of plume flame is 70% and 90% lower than that of 18.5% Al butylated hydroxyl propellant.

Embodiment 3

[0050] (1) The propellant formula composition (mass percentage) is as shown in Table 1-3:

[0051] Table 1-3 Propellant formulation

[0052]

[0053] (2) The combustion performance of the propellant is shown in Table 2-3:

[0054] Table 2-3 Propellant Performance Parameters

[0055]

[0056] Signal characteristics: Propellant plume visible light transmittance 75.5%, laser transmittance 87.1%, near-infrared transmittance 87.6%, mid-infrared transmittance 94.2%, far-infrared transmittance 98.6%, microwave attenuation 0.27dB, The middle and far infrared radiation intensity of the plume flame is 73% and 95% lower than that of the 18.5% Al butylated hydroxyl propellant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| laser radiation transmission | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com