A method for improving the performance of high-entropy alloys by staged cryogenic treatment

A high-entropy alloy and cryogenic treatment technology is applied in the field of metal materials to achieve the effects of improving low-temperature mechanical properties, increasing processing time, and refining alloy structures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] 1) Alloy preparation: According to the ratio of Al, Cr, Fe, Ni atomic ratio of 1: 1: 2: 2, using a single purity of 99.9%, and determined according to the mass percentage The quality of the metal (Al, Cr, Fe, Ni is 5.26 g, 10.13 g, 21.75 g, 22.86g, according to each alloy ingot 60g) and weighing, ingredient, and then put a good metal raw material In the vacuum arc smelting furnace, non-consumable arc smelting method under argon is protected, repeatedly turning the sample smelting 4 to 5 times, resulting in a uniform Al-Cr-Fe-Ni mother alloy ingot;

[0043] 2) Alloy material is constitutive processing: a block-shaped AlCrfe, an Al-Cr-Fe-Ni alloy ingot obtained in the step 1), using an electric discharge line cutting technique, a block AlCrFe of 8 mm × 8 mm × 6 mm 2 Ni 2 Alloy materials;

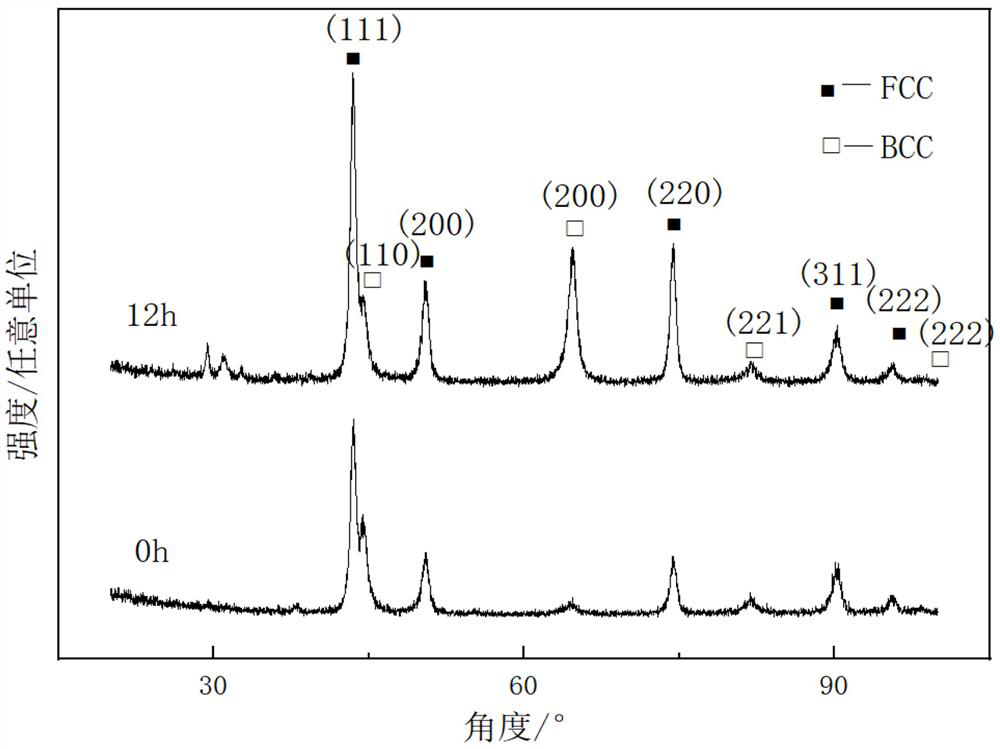

[0044] 3) Deep cold treatment: A liquid carbon dioxide environment is subjected to liquid carbon dioxide in a liquid carbon dioxide environment at a temperature of -75 to -85 ° C, AlCrfe is...

Embodiment 2

[0046] This embodiment is substantially the same as the examples, in particular

[0047] 1) preparing an alloy: This step is the same as first embodiment;

[0048] 2) setting treatment alloy material: This step is the same as first embodiment;

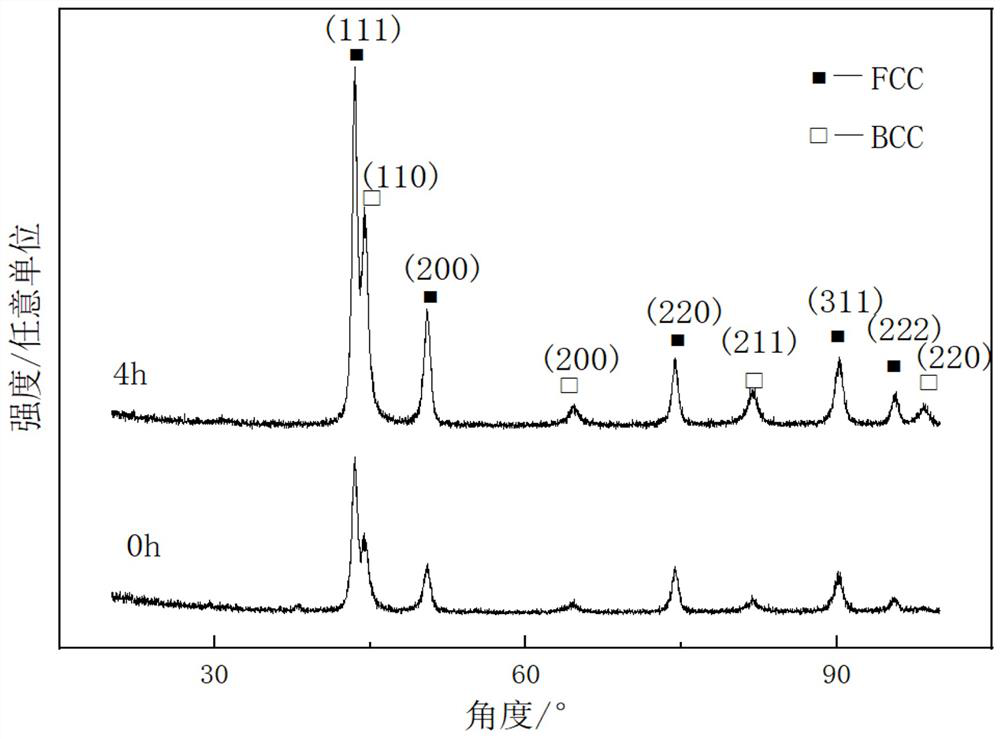

[0049] 3) cryogenic treatment: its liquid nitrogen cryogenic treatment, the prepared liquid nitrogen ambient at a temperature of -190 ~ -196 ℃ in) in the step 2 AlCrFe 2 Ni 2 The alloy was placed in 4 hours in which it was deeply cold, and then the sample was returned to room temperature, that is, the AlCrfe 2 Ni 2 The deep cooling process of high entropy alloy.

Embodiment 3

[0051] This embodiment is substantially the same as the examples, in particular

[0052] 1) preparing an alloy: This step is the same as first embodiment;

[0053] 2) setting treatment alloy material: This step is the same as first embodiment;

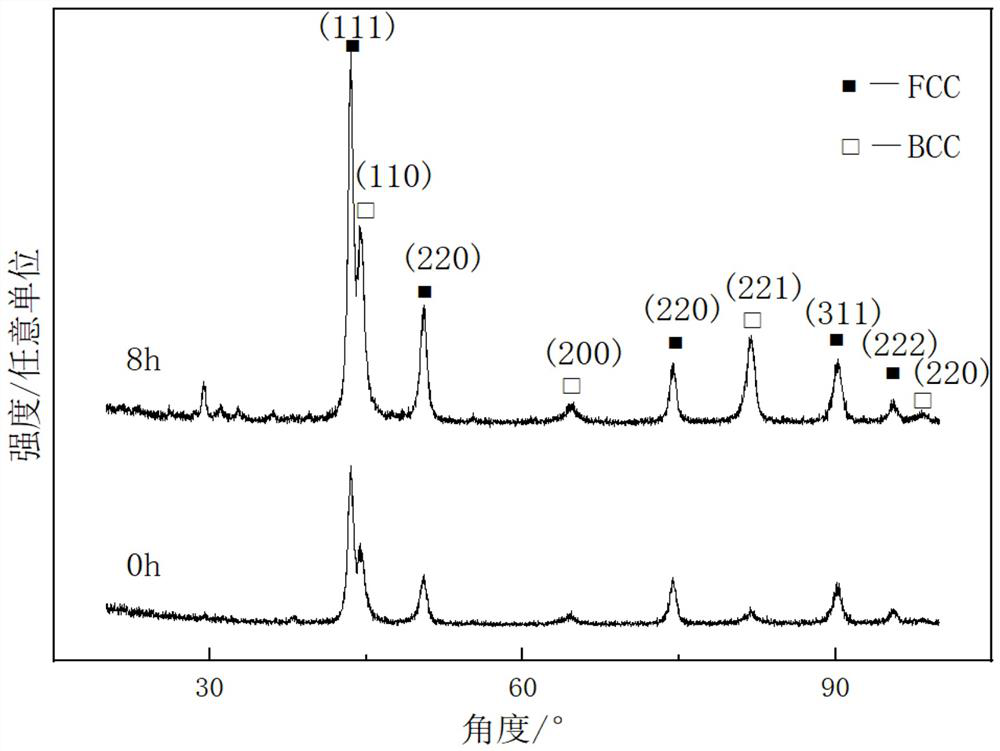

[0054] 3) cryogenic fractionation process: use of liquid carbon dioxide subjected to fractionation + nitrogen cryogenic process, the preparation of liquid carbon dioxide at ambient temperature in a -75 ~ -85 ℃) in step 2 AlCrFe 2 Ni 2 Wherein the alloy is placed for 2 hours, a cryogenic treatment, and then remove the sample placed directly in liquid nitrogen ambient at a temperature of -190 ~ -196 ℃ for 2 hours, remove the sample was returned to room temperature in air, i.e. complete AlCrFe 2 Ni 2 The classification process of high entropy alloy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com