A kind of protective topcoat for bridge steel structure in plateau cold and drought area and preparation method thereof

A technology for steel structures in cold and arid regions, applied in the field of protective topcoats for bridge steel structures in plateau cold and arid regions and its preparation, can solve problems such as poor mechanical properties, reduced weather resistance, and blistering of coating films, and achieve high hardness and Effects of reactivity, improvement of chemical resistance, and reduction of the amount of additives used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

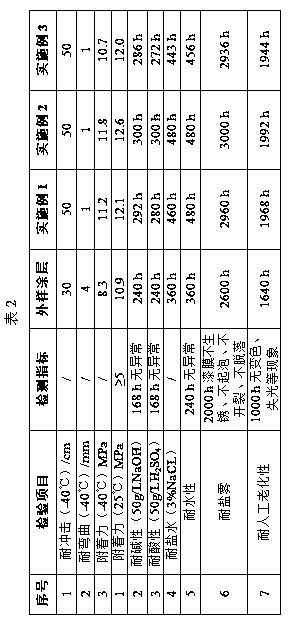

Examples

Embodiment 1

[0035] Preparation of protective topcoat for steel structures of bridges in cold and arid plateau areas:

[0036] Component 1 Prepare raw materials according to the following dosage: ACR6730 high-hydroxy acrylic resin 60kg, CA6000 dispersant 0.8kg, pigment (rutile titanium dioxide) 22 kg, polytetrafluoroethylene powder SJF381 / SJF2037 kg, BYK-052 defoamer 0.06 kg, BYK-306 leveling agent 0.12 kg, vinyl tris(2,2,2-trifluoro)ethoxysilane 0.4 kg, dibutyltin dilaurate catalyst 0.01 kg, mixed solvent (100# solvent naphtha 7.61 kg and xylene 2 kg).

[0037] Component 2 Prepare raw materials according to the following dosage: HDI biuret 22A-75PX curing agent 30 kg, HDI trimer HT-75B curing agent 25 kg, IPDI trimer Desmodur Z4470MPA / X curing agent 8 kg, polyester resin 8 kg, propylene glycol methyl ether acetate 16 kg, sec-butyl acetate 13 kg.

[0038] The preparation method comprises the following steps:

[0039] The preparation method of component one:

[0040] A. Add two-thirds o...

Embodiment 2

[0049] Preparation of protective topcoat for steel structures of bridges in cold and arid plateau areas:

[0050] Component 1 Prepare raw materials according to the following dosage: Setalux1161 high-hydroxy acrylic resin 59 kg, BYK-2025 dispersant 1.5 kg, pigments (rutile titanium dioxide, carbon black and iron oxide red) 21 kg, polytetrafluoroethylene powder 8 kg , BYK-052 defoamer 0.05 kg, 837 leveling agent 0.1 kg, vinyl tris(2,2,2-trifluoro)ethoxysilane 0.5 kg, dibutyltin dilaurate catalyst 0.02 kg, mixed solvent (100 # solvent oil 7 kg and xylene 3 kg).

[0051] Component 2 prepare raw materials according to the following dosage: HDI biuret 22A-75PX curing agent 35 kg, HDI trimer HT-75B curing agent 22 kg, IPDI trimer Desmodur Z4470MPA / X curing agent 7 kg, polyester resin 10 kg, propylene glycol methyl ether acetate 15 kg, sec-butyl acetate 11 kg.

[0052] The preparation method comprises the following steps:

[0053] The preparation method of component one:

[0054]...

Embodiment 3

[0063] Preparation of protective topcoat for steel structures of bridges in cold and arid plateau areas:

[0064] Component 1 Prepare raw materials according to the following dosage: 58 kg of BS962 high-hydroxyl acrylic resin, 1.2 kg of BYK-2025 dispersant, 24 kg of pigments (rutile titanium dioxide, carbon black and medium chrome yellow), 5 kg of polytetrafluoroethylene micropowder , 6800 defoamer 0.1kg, BYK-306 leveling agent 0.2 kg, vinyl tris(2,2,2-trifluoro)ethoxysilane 0.3 kg, dibutyltin dilaurate catalyst 0.02 kg, mixed solvent (100 # solvent oil 9 kg and xylene 2.18 kg).

[0065] Component 2 prepare raw materials according to the following amount: HDI biuret 22A-75PX curing agent 33 kg, HDI trimer HT-75B curing agent 26 kg, IPDI trimer Desmodur Z4470MPA / X curing agent 5 kg, polyester resin 9 kg, propylene glycol methyl ether acetate 12 kg, sec-butyl acetate 15 kg.

[0066] The preparation method comprises the following steps:

[0067] The preparation method of compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com