A kind of organic rectorite modified silicone fluororubber seal and preparation method thereof

A technology of organic rectorite and silicon fluorine rubber, applied in the direction of engine seals, mechanical equipment, engine components, etc., can solve the problems of poor aging resistance, loss of function, inability to meet and other problems, achieve high mechanical strength, improve mechanical performance, resistance to environmental erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

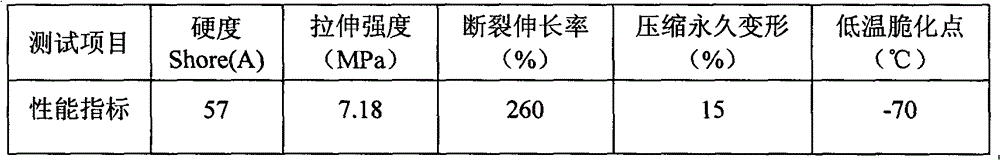

specific Embodiment approach 1

[0016] Specific embodiment 1: The organized rectorite-modified fluorosilicone rubber prepared in this embodiment consists of 80 to 90 parts of fluorosilicone rubber, 10 to 20 parts of silicone rubber, 40 parts of meteorological white carbon black, and hydroxyl 2 parts of silicone fluorine oil, 1.5 parts of vinyl silicone fluoride oil, 0.5 parts of 2,5-dimethyl-2,5-bis(tert-butyl peroxide)hexane (double 25), 3 parts of iron trioxide to make.

specific Embodiment approach 2

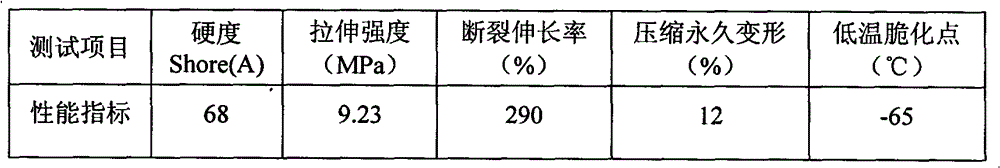

[0017] Specific embodiment 2: The rectorite-modified fluorosilicone rubber prepared in this embodiment consists of 80-90 parts of fluorosilicone rubber, 10-20 parts of silicone rubber, and 5-6 parts of organic rectorite according to the mass fraction ratio. 30-35 parts of French silica, 2-2.5 parts of hydroxyl silicone fluorine oil, 1-1.5 parts of vinyl silicone fluorine oil, 2,5-dimethyl-2,5-bis(tert-butyl peroxide)hexane Prepared from 0.5-0.8 parts (double 25), 3-5 parts of iron trioxide.

specific Embodiment approach 3

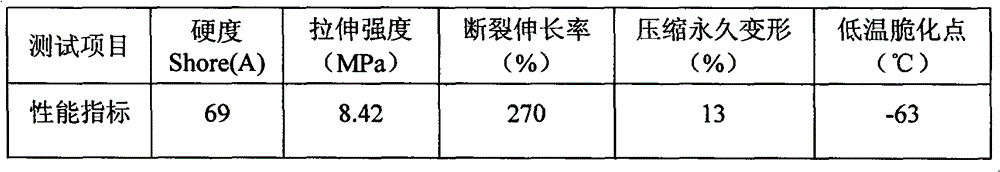

[0018] Specific embodiment 3: the silicone fluororubber modified by the organic rectorite prepared in this embodiment is composed of 80 parts of silicon fluororubber, 20 parts of silicone rubber, 3 parts of organic rectorite, and meteorological white carbon black according to the mass fraction ratio 30 parts, 2 parts of hydroxy silicone fluorine oil, 0.5 parts of vinyl silicone fluorine oil, 0.5 parts of 2,5-dimethyl-2,5-bis(t-butylperoxy)hexane (double 25), trioxide 5 servings of iron. Mix the weighed fluorosilicone rubber, silicone rubber and organic rectorite into the mixing chamber of the internal mixer for melting and intercalation to obtain a mixture (the intercalation temperature is 100 degrees, the rotating speed is 35r / Min, and the intercalation time is 10Min). Put the mixture on the roller with a temperature of 30-40 degrees and a roller distance of 2 mm, then add the weighed white carbon black after the rollers are wrapped, add hydroxyl silicone fluorine oil, vinyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com