Assembly method of ultrafast laser reflector for miniature laser gyroscope

A laser gyroscope and ultrafast laser technology, applied in laser welding equipment, chemical instruments and methods, Sagnac effect gyroscopes, etc., can solve the problem that glass powder sintering technology is difficult to break through, and optical glue technology is difficult to meet strong impact requirements, etc. problems, to achieve the effect of quality protection, high connection strength, and good roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

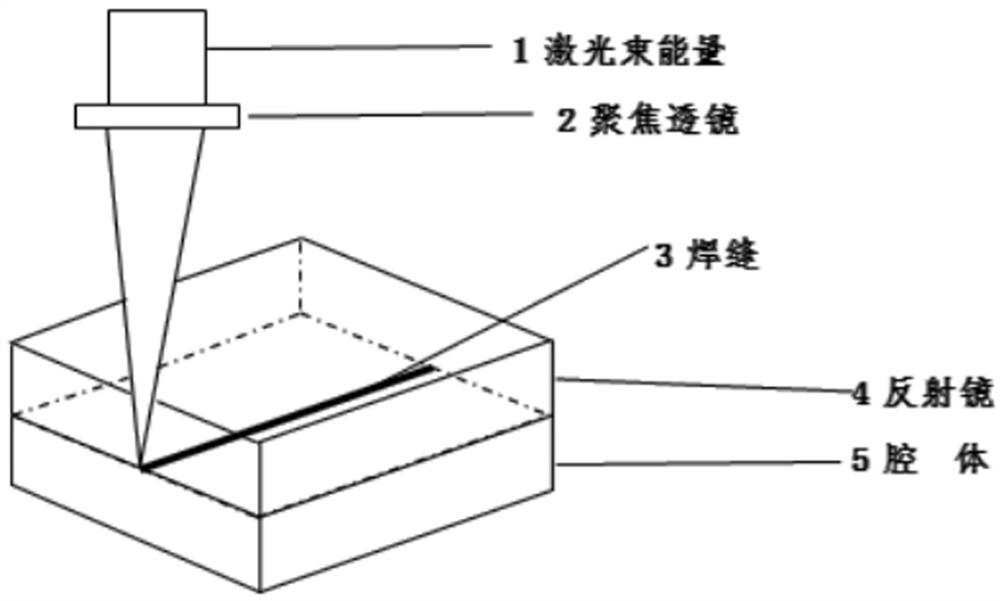

[0027] This example provides an assembly method of an ultrafast laser mirror for a micro-laser gyroscope. The assembly schematic diagram is as follows figure 1 shown, including the following steps:

[0028] Step (1): Use a cleaning agent to clean the laser gyro cavity-0-level glass-ceramic cavity and the mirror-0-level glass-ceramic mirror, and then fix the optical adjustment tooling with the aid of precision tooling and optical equipment; , the cleaning agent was prepared by the following method: 12 parts of choline hydroxide, 4 parts of tetrabutylammonium hydroxide, 20 parts of N-methylpyrrolidone, 0.3 parts of sorbitol-based polyether polyol and 30 parts of ultrapure water Mix separately, and stir at room temperature for 45 min to prepare;

[0029] Step (2): Transfer the laser gyro cavity and mirror fixed in step (1) to the welding area of the laser welding machine for laser welding; among them, the laser welding process parameters are: laser power 980w, welding speed 15...

Embodiment 2

[0035] This example provides a method for assembling an ultrafast laser reflector for a micro-laser gyro. The only difference from Example 1 is that the reflector is a quartz glass reflector, and the cleaning agent consists of the following components by mass: choline hydroxide 15 parts, 5 parts of tetrabutylammonium hydroxide, 25 parts of N-methylpyrrolidone, 0.1 part of sorbitol-based polyether polyol and 35 parts of ultrapure water; the rest of the steps and parameters are the same.

[0036] The impact test was carried out. The laser micro-welded resonator in this example passed the 10,000 g unprotected impact test. After the impact, the performance of the test resonator met the design index requirements; and a further 35,000 g impact test was carried out, and the performance of the resonant cavity also met the design index after the impact test. Require.

[0037] In this example, the average roughness of the cleaned laser gyro cavity and reflector surface was also measured...

Embodiment 3

[0039] This example provides an assembly method of an ultrafast laser reflector for a micro-laser gyroscope. The difference from Example 1 is that the reflector is a K9 optical glass reflector, and the laser welding process parameters are: laser power 1080w, welding speed 160mm / s, the welding path is a hyperbola, and the defocus is +2 mm; the rest of the steps and parameters are the same.

[0040] The impact test was carried out. The laser micro-welded resonator in this example passed the 10,000 g unprotected impact test. After the impact, the performance of the test resonator met the design index requirements; and a further 35,000 g impact test was carried out, and the performance of the resonant cavity also met the design index after the impact test. Require.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com