Tubular facesheet-linked fabric with ribs additionally arranged in circumferential/axial direction and preparation method thereof

A technology of circular tubular and circumferential ribs, which is applied in fabrics, textiles, textiles and papermaking, etc., can solve the problems of inability to realize vertical and horizontal bidirectional simultaneous reinforcement, and inability to form circular tube fabrics, etc., to achieve improved mechanical properties and good connectivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

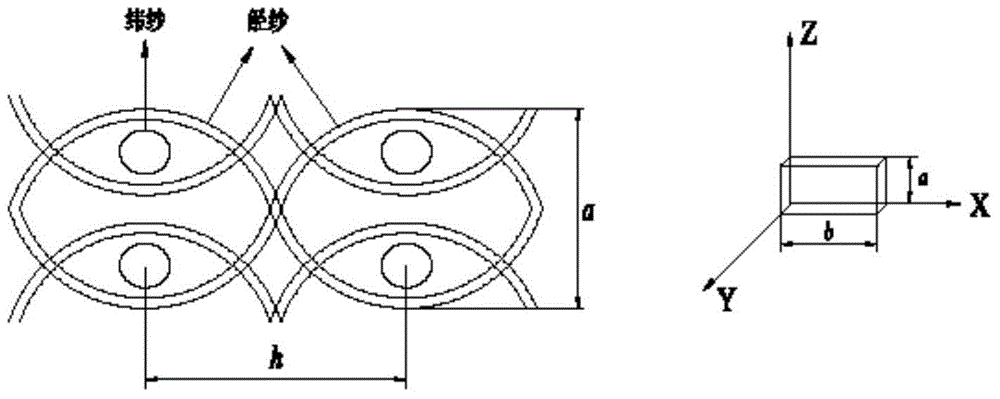

[0030] Adopt 2.5D structure, the warp yarn is 195tex quartz fiber × 4 strands, the weft yarn is 195tex quartz fiber × 6 strands, and the wall thickness of the circular tubular layered fabric is 20mm. The design warp yarn density is 8 yarns / cm, and the weft yarn density is 4 yarns / cm. The specific weaving steps are as follows:

[0031] (1) Yarn arrangement: according to the design requirements of the fabric, arrange 10 layers and 70 rows of warp yarns on the multi-eye heddles in the front and rear heald frames of the loom;

[0032] ⑵Shedding movement: the heald lifting device controls the relative movement of the front and rear heald frames up and down, driving the warp yarns to form 11 layers of sheds;

[0033] (3) Introducing the weft yarn: introducing the weft yarn at the opening of the warp yarn in the formed 11-layer shed;

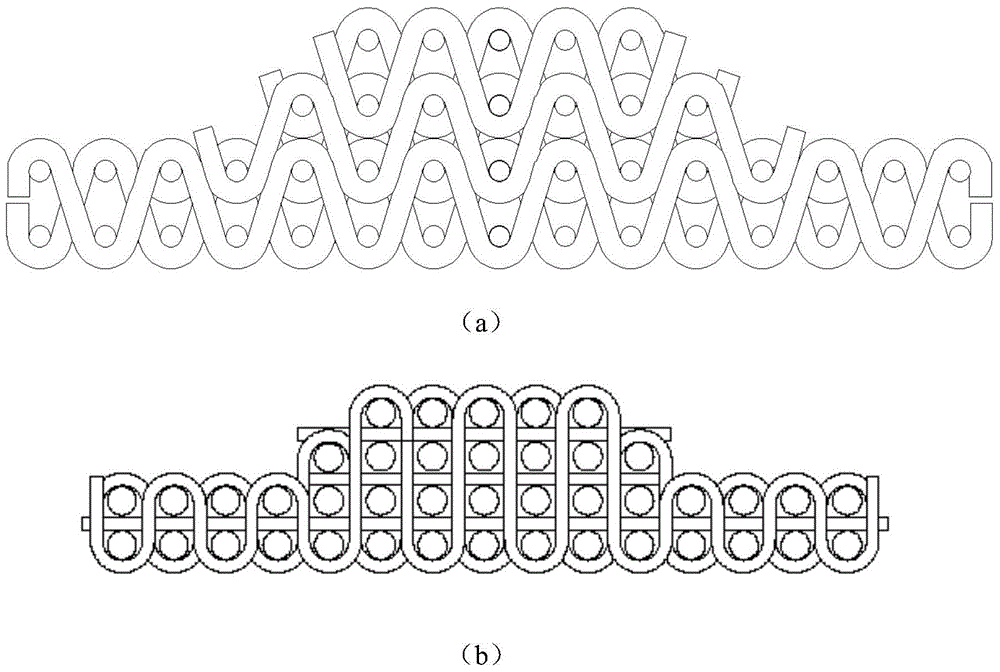

[0034] (4) Circumferential reinforcement: the warp yarn density of the circumferential ribbed layer is 6 threads / cm, and the weft thread density is ...

Embodiment 2

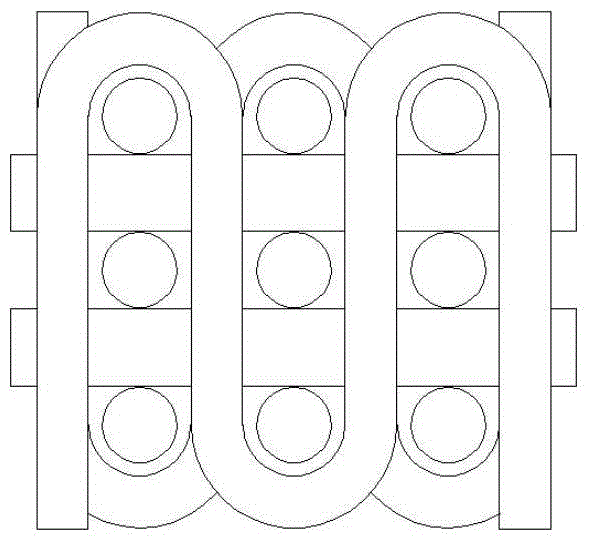

[0040] Orthogonal three-way structure is adopted, the warp yarn is 190tex quartz fiber × 6 strands, the weft yarn is 190tex quartz fiber × 8 strands, the wall thickness of the circular tubular layered fabric is 14mm; the design warp yarn density is 6 yarns / cm, and the weft yarn density is 4 yarns / cm cm. The specific weaving steps are as follows:

[0041] (1) Yarn arrangement: According to the design requirements of the fabric, arrange 6 layers of 50 rows of warp yarns on the multi-eye heddles in the front and rear heald frames of the loom;

[0042] ⑵Shedding movement: the heald lifting device controls the relative movement of the front and rear heald frames up and down, driving the warp yarns to form a 7-layer shed;

[0043] (3) Introducing the weft yarn: introducing the weft yarn at the opening of the warp yarn in the formed 7-layer shed;

[0044] (4) Circumferential reinforcement: the warp yarn density of the circumferential rib layer is 6 threads / cm, and the weft thread den...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com