Method for construction of sprayed steel fiber reinforced concrete in sandy surrounding rock

A technology of steel fiber reinforced concrete and construction method, which is used in earth-moving drilling, wellbore lining, tunnel lining, etc., can solve the problems of loose nature and can not meet the quality requirements of shotcrete for the initial lining of the tunnel, and achieves reduction of rebound rate, saving of raw materials, Guarantee the effect of construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in detail below with reference to accompanying drawing and embodiment:

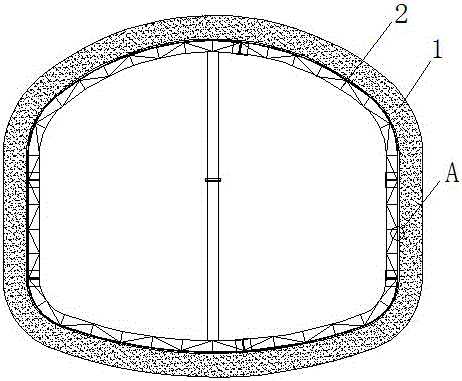

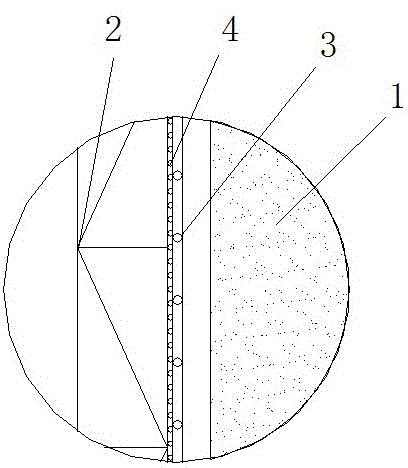

[0023] attached Figure 1-2 It can be seen that a construction method of sprayed steel fiber concrete in a sandy soil surrounding rock comprises the following steps:

[0024] Step 1: Pre-support the small conduit for advance grouting on the excavation surface; the size of the small conduit is: Φ32*3.5, L=2.0m, and inject water glass slurry into the small conduit;

[0025] The second step: manual excavation of tunnel sandy soil 1;

[0026] Step 3: Tunnel grid steel frame 2 assembly; adjacent grid steel frame 2 spacing: 0.5m;

[0027] Step 4: Extend the outer arc of the steel frame between the grille steel frame and apply the main steel mesh 3 according to the design requirements; the diameter of the steel bar of the main steel mesh 3 is Φ6.5, and the mesh size of the main steel mesh is: 120*120mm;

[0028] Step 5: Make auxiliary steel mesh 4 on the inner side ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap