Tool for heat treatment of solid rocket engine shell

An engine casing and solid rocket technology, which is applied in heat treatment furnaces, heat treatment equipment, quenching devices, etc., can solve the problems of unsuitable heat treatment of large solid rocket motor casings, low strength, and increased tooling size control requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] This embodiment is a heat treatment tool for the casing of a solid rocket motor with a diameter ≥ 2500 mm.

[0023] This embodiment is a tool for the heat treatment of the solid rocket motor casing, which is made of heat-resistant stainless steel 1Cr18Ni9Ti.

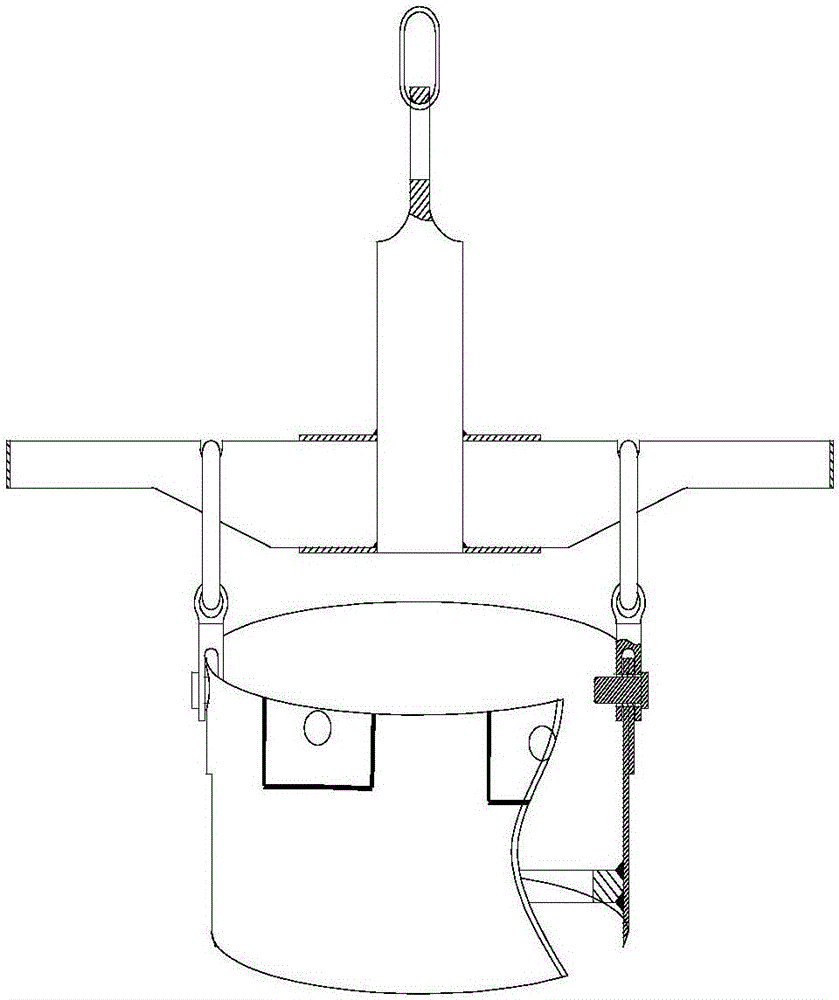

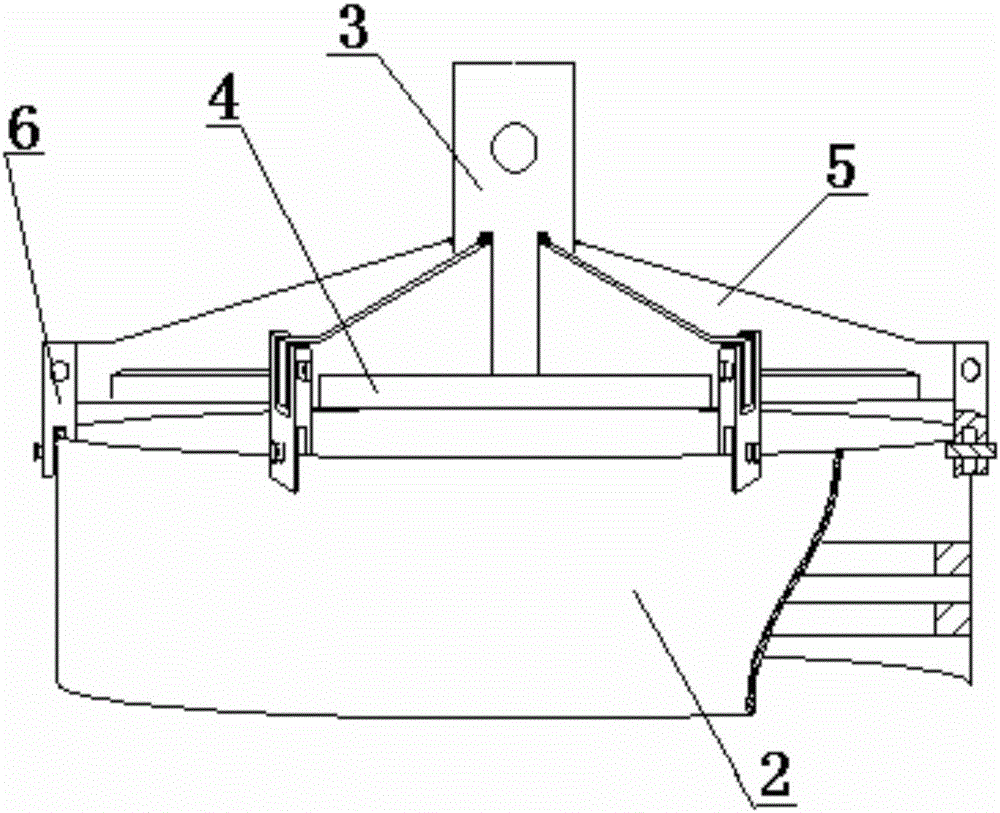

[0024] This embodiment includes a quenching hanger and a process hanger 2, and the quenching hanger and the process hanger are used in conjunction to achieve the purpose of the present invention.

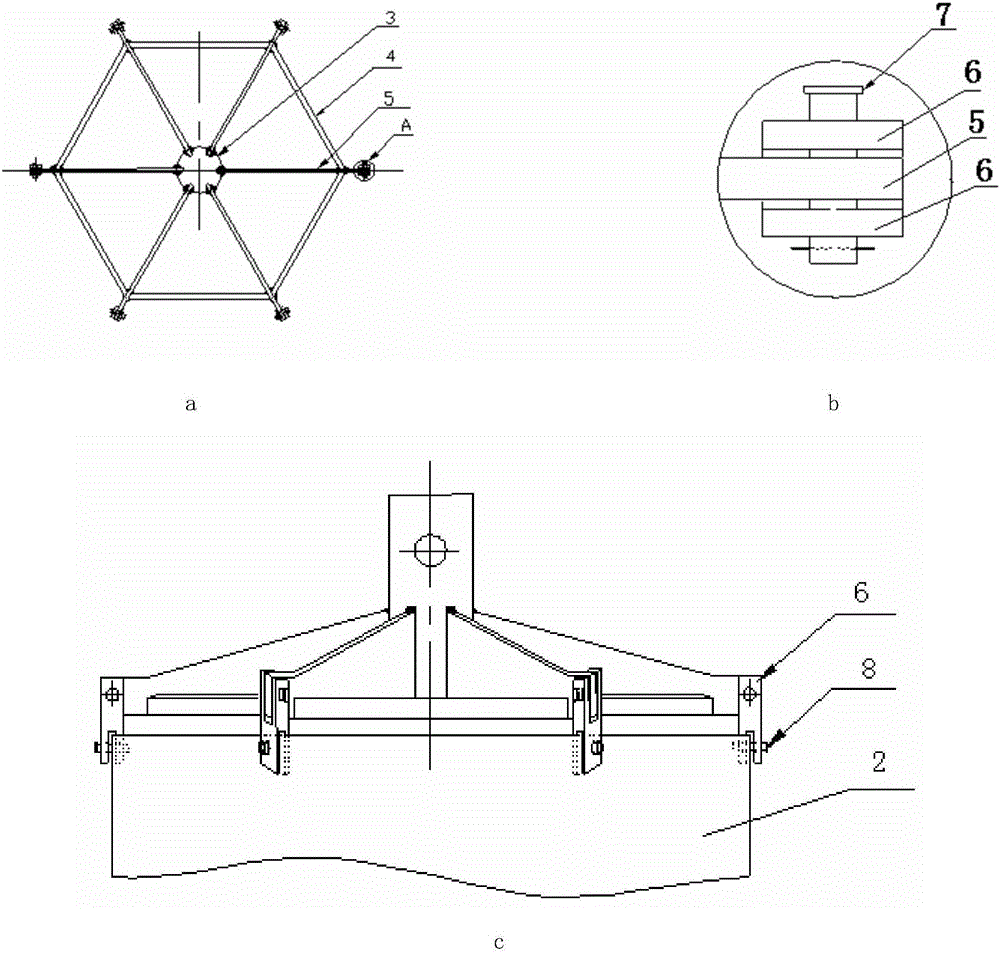

[0025] The quenching hanger is hexagonal. It includes upright columns 3, six frame panels 4 and six support panels 5. One end of the six support plates is a fixed support end, and the fixed support ends are evenly distributed and fixed on the circumferential surface of the column 3; A frame plate 4 is respectively fixed between the side surfaces. The ends of the cantilever ends of each support plate have lifting lugs 6 respectively, and each lifting lug has a pin hole cooperating with the hoisting hole of the process...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com