Backflow combustor case head structure and manufacturing method thereof and engine combustor

A technology of backflow combustion chamber and combustion chamber, which is applied in the direction of combustion method, combustion chamber, continuous combustion chamber, etc. It can solve the problems of easy local deformation, stress, large load, and affecting engine safety, etc., so as to increase the weight of the casing and avoid Stress concentration, avoiding the effect of scratching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] It should be noted that the embodiments in the present application and the features of the embodiments may be combined with each other in the case of no conflict. The present invention will be described in detail below with reference to the accompanying drawings and in conjunction with the embodiments.

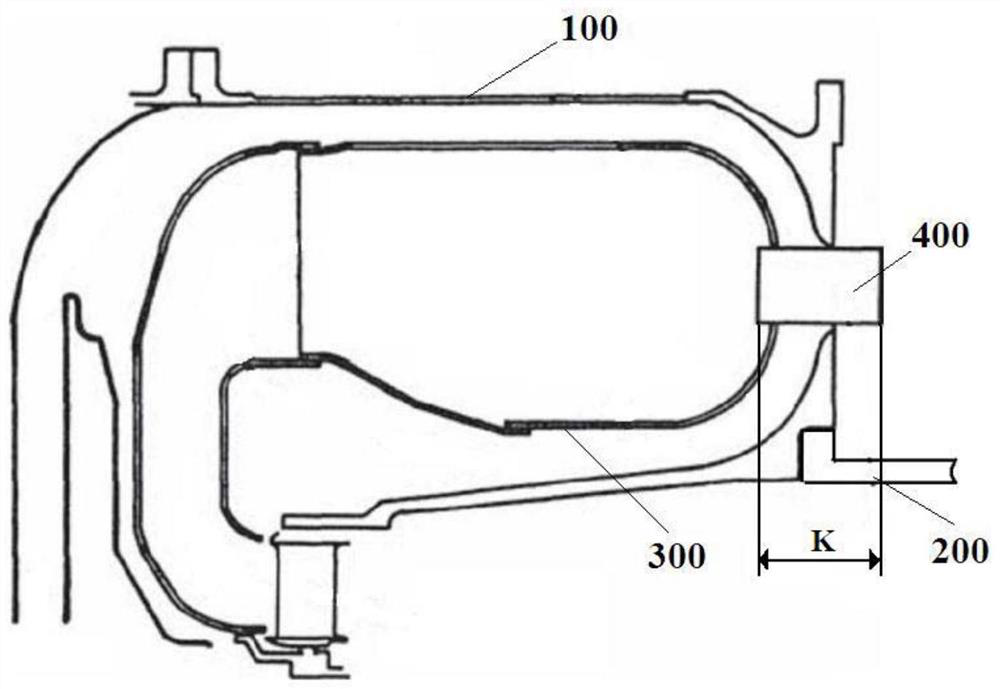

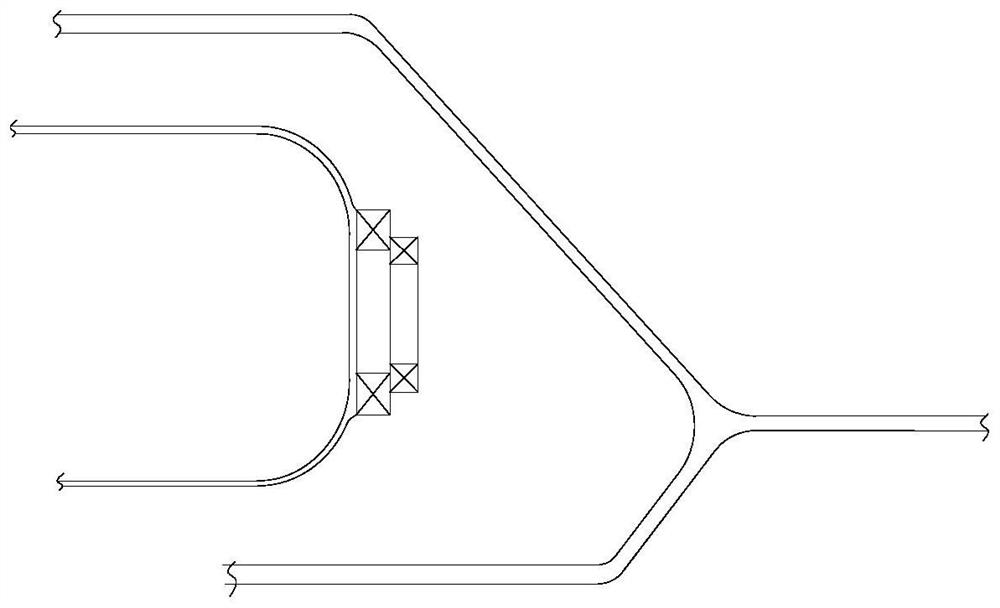

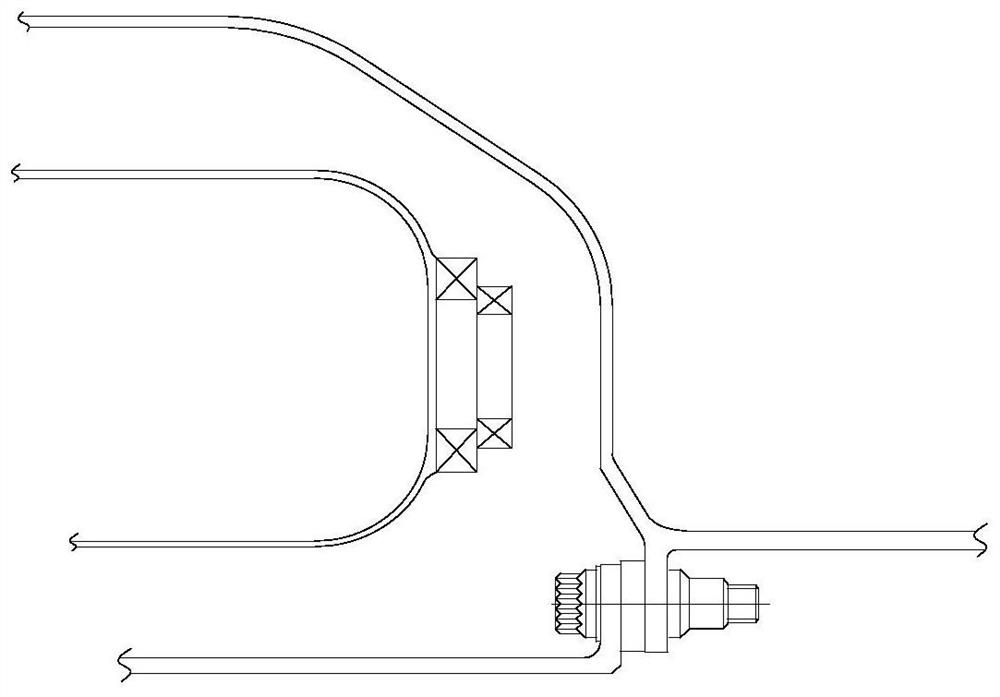

[0033] figure 1 is the schematic diagram of the recirculation combustion chamber; figure 2 It is a schematic diagram of the head structure of the inclined combustion chamber casing; image 3 It is a schematic diagram of the head structure of the stepped combustion chamber casing; Figure 4 is the structure diagram of the casing head of the recirculation combustion chamber according to the preferred embodiment of the present invention; Figure 5 is the A-A sectional view of the preferred embodiment of the present invention; Image 6 is the B-B sectional view of the preferred embodiment of the present invention; Figure 7 It is a C-C sectional view of the preferred ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap