Welding method for longitudinal butt joint of thin-wall aluminum alloy non-profile long pipes

A welding method and technology of aluminum alloy, applied in welding equipment, arc welding equipment, metal processing equipment, etc., can solve the problems of welding joint failure, lack of fusion, lack of penetration, etc., to ensure product quality, avoid poor forming, improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

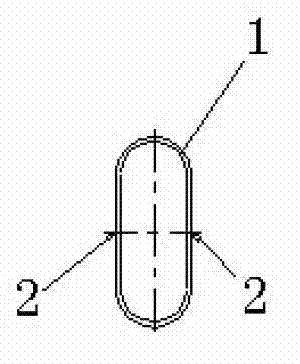

[0019] The welding method of the longitudinal butt joint of thin-walled aluminum alloy non-profile long pipe fittings of the present invention, its preferred specific implementation mode is:

[0020] Including groove preparation process, cleaning process, welding process;

[0021] In the groove preparation process, a groove is made on the part to be welded;

[0022] In the cleaning process, first use a stainless steel wire brush to clean up oxides and other impurities within 25mm on both sides of the part to be welded, and then perform chemical cleaning;

[0023] Described chemical cleaning comprises steps:

[0024] Prepare HNO with a mass concentration of 40-50% respectively 3 solution and 50-60°C mass concentration of 8-10% NaOH solution;

[0025] First, immerse the parts to be welded in NaOH solution, take out the parts and rinse with cold water to remove NaOH residues on the surface of the workpiece;

[0026] Then, put the cleaned parts into HNO 3 Soak in the solution...

specific Embodiment

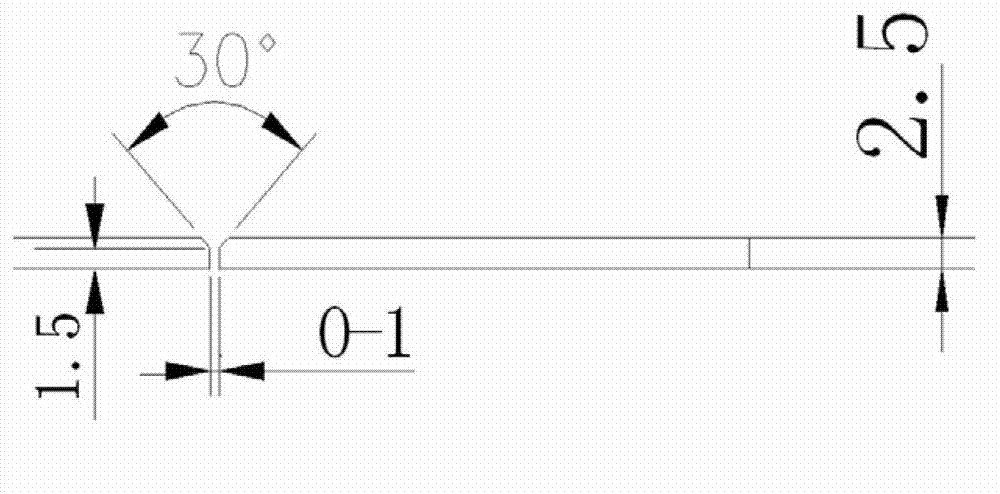

[0042] 1. Make a bevel on the part to be welded. The bevel type is a single-sided chamfer of 15° and a blunt edge of 1.5mm.

[0043] 2. Use a stainless steel wire brush to clean the oxides and other impurities within 25mm on both sides of the part to be welded until the metallic luster is exposed.

[0044] 3. Prepare 50-60°C containing 8-10% NaOH (caustic soda) solution and HNO respectively 3 (nitric acid) 40-50% solution; soak the parts to be welded in NaOH (fire alkali) for 6-8 minutes. Between -14, when the PH value is less than the specified value, an appropriate amount of NaOH can be added at any time to make the PH value reach the specified value; after taking out the parts from the alkaline solution, rinse them with cold water. Remove NaOH (fire alkali) residues on the surface of the workpiece, and soak the cleaned parts in nitric acid solution for 30 seconds - 1 minute, but not more than 1 minute. Use pH test paper to test the concentration of nitric acid before each...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com