Patents

Literature

55results about How to "Solve production cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A low-cost precision casting method for titanium alloy and titanium-aluminum alloy

InactiveCN102294436AIncrease contentControl quality costFoundry mouldsFoundry coresPolyvinyl alcoholTitanium alloy

The invention relates to a method for precisely casting a titanium alloy and a titanium aluminum alloy with low cost, which relates to a method for precisely casting the titanium alloy and the titanium aluminum alloy, and solves the technical problem that cast pieces have low surface quality and internal quality in the conventional method for lowering the cost of precisely casting the titanium alloy and the titanium aluminum alloy by using electrically-fused alumina and silica sol. The method comprises the following steps of: preparing a surface layer binder from zirconium sol, silica sol, a wetting agent JFC, n-octyl alcohol, polyvinyl alcohol and latex; adding calcium carbonate, alumina, titanium dioxide and zirconia to prepare a surface layer coating; preparing a shell surface layer; preparing a shell back layer by a universal method for precisely casting the titanium alloy; dewaxing and sintering to obtain a shell; and casting the titanium alloy or the titanium aluminum alloy by using the shell so as to obtain a titanium alloy cast piece or a titanium aluminum alloy cast piece. Compared with a precise casting method by purely using a zirconium-based binder and a zirconia fireproof material, the method has the advantage that raw material cost is lowered by 30 to 70 percent and the method can be used for civil titanium alloy cast pieces and titanium aluminum alloy cast pieces for common aviation.

Owner:HARBIN SHITAI NEW MATERIAL TECH & DEV

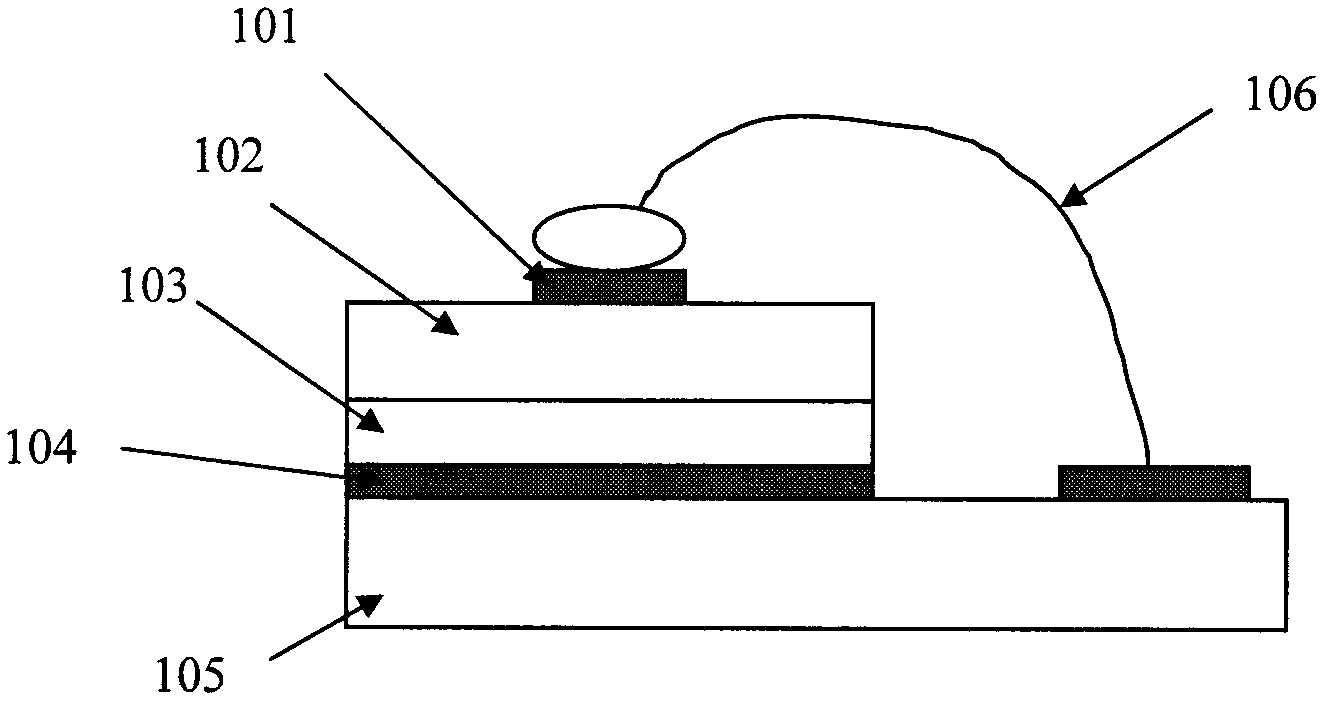

High voltage LED (light-emitting diode) chip and manufacturing methods thereof

InactiveCN102881799ASmooth connectionReduce manufacturing costSolid-state devicesSemiconductor devicesInterconnectionEngineering

The invention relates to a high voltage LED (light-emitting diode) chip and manufacturing method of the high voltage LED chip. The chip is in the following structure: a circuit comprising a plurality of LED unit chips in interconnection is distributed on one surface of a bearing base plate, and the LED unit chips are welded on the surface in an inversion way, wherein at least two of the LED unit chips are in series connection through electrodes on the first surface of the bearing base plate; two or more than two connecting electrodes are arranged on another surface of an insulating substrate; and circuits on the two surfaces of the insulating substrates are connected by filling through holes / metal. The invention also discloses multiple processes for manufacturing the chip.

Owner:郭文平

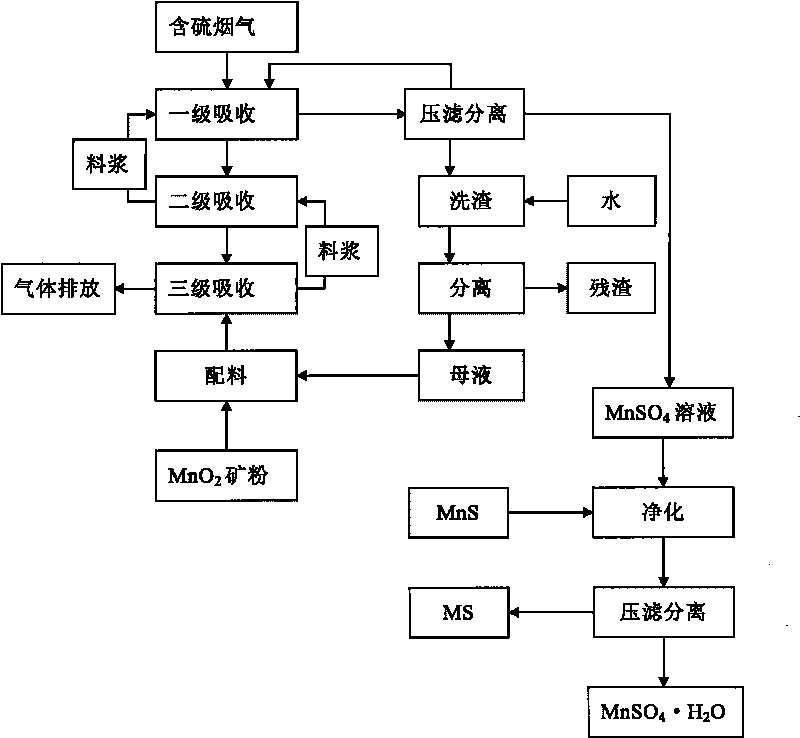

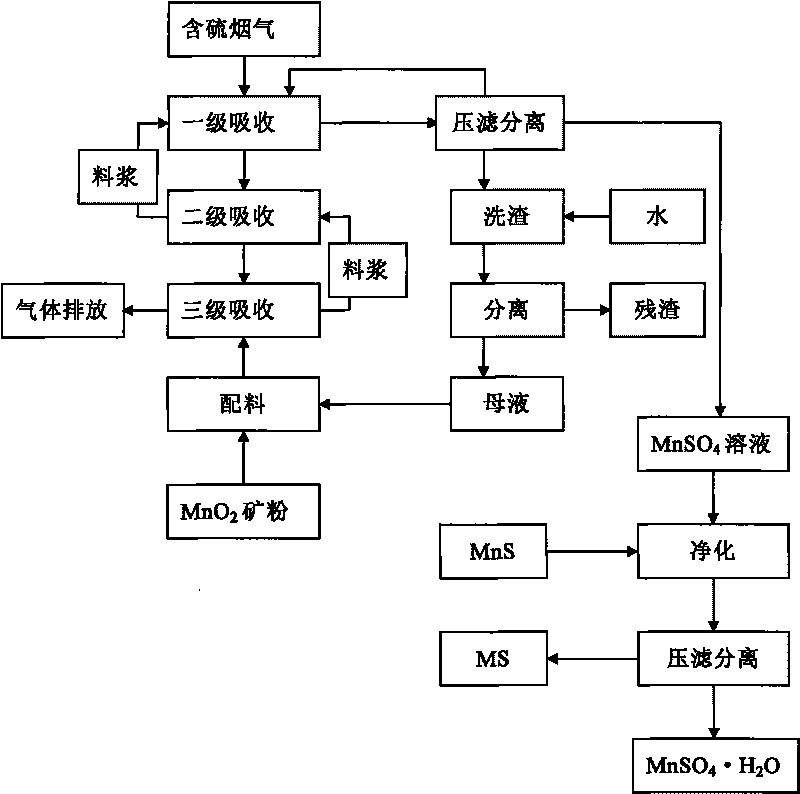

Method for preparing MnSO4.H2O by performing flue gas desulphurization on medium-and-low-grade MnO2 ore

ActiveCN101723466ASolve production costHigh recovery rateDispersed particle separationManganese sulfatesManganese sulphateFlue gas

Owner:GUIZHOU REDSTAR DEVING

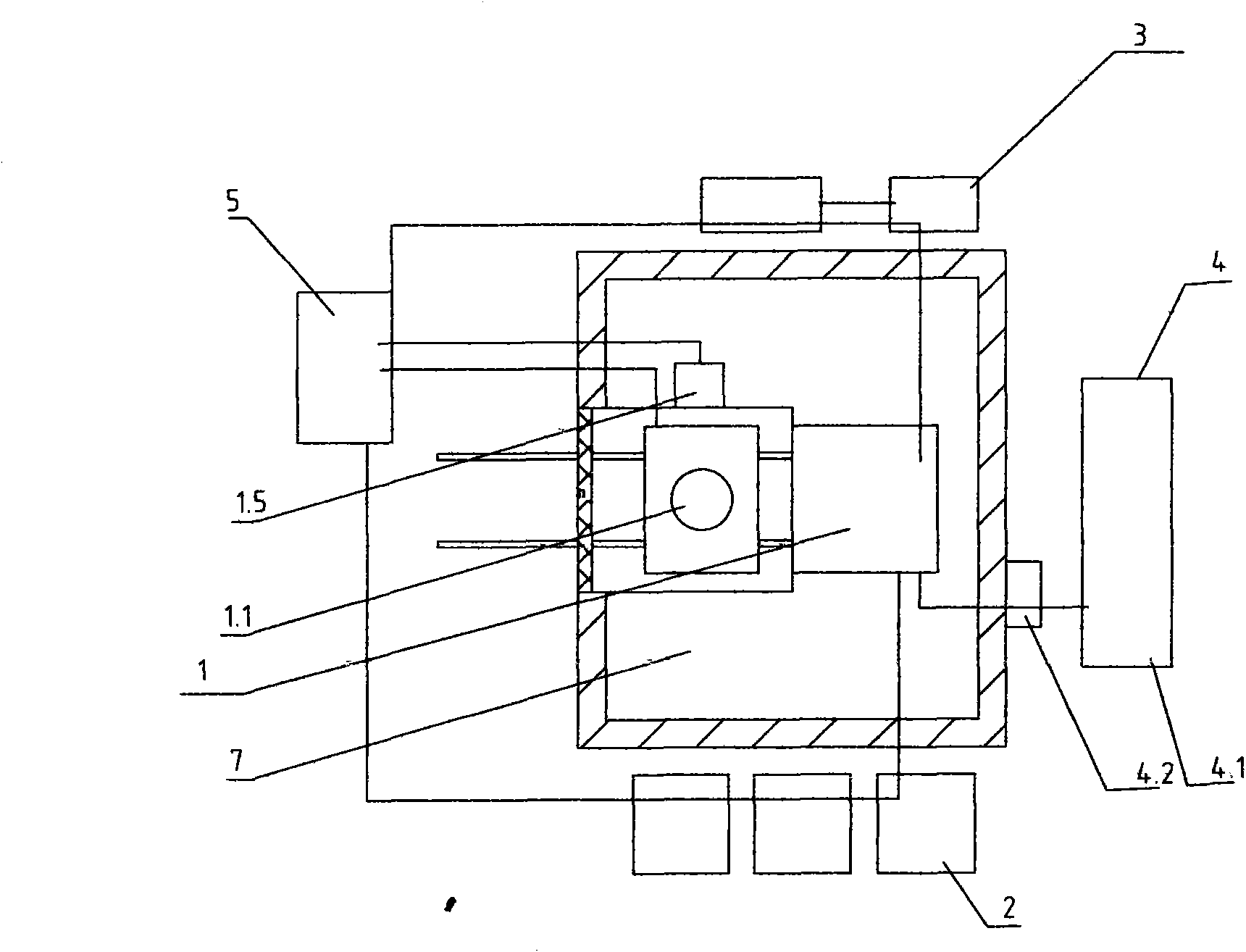

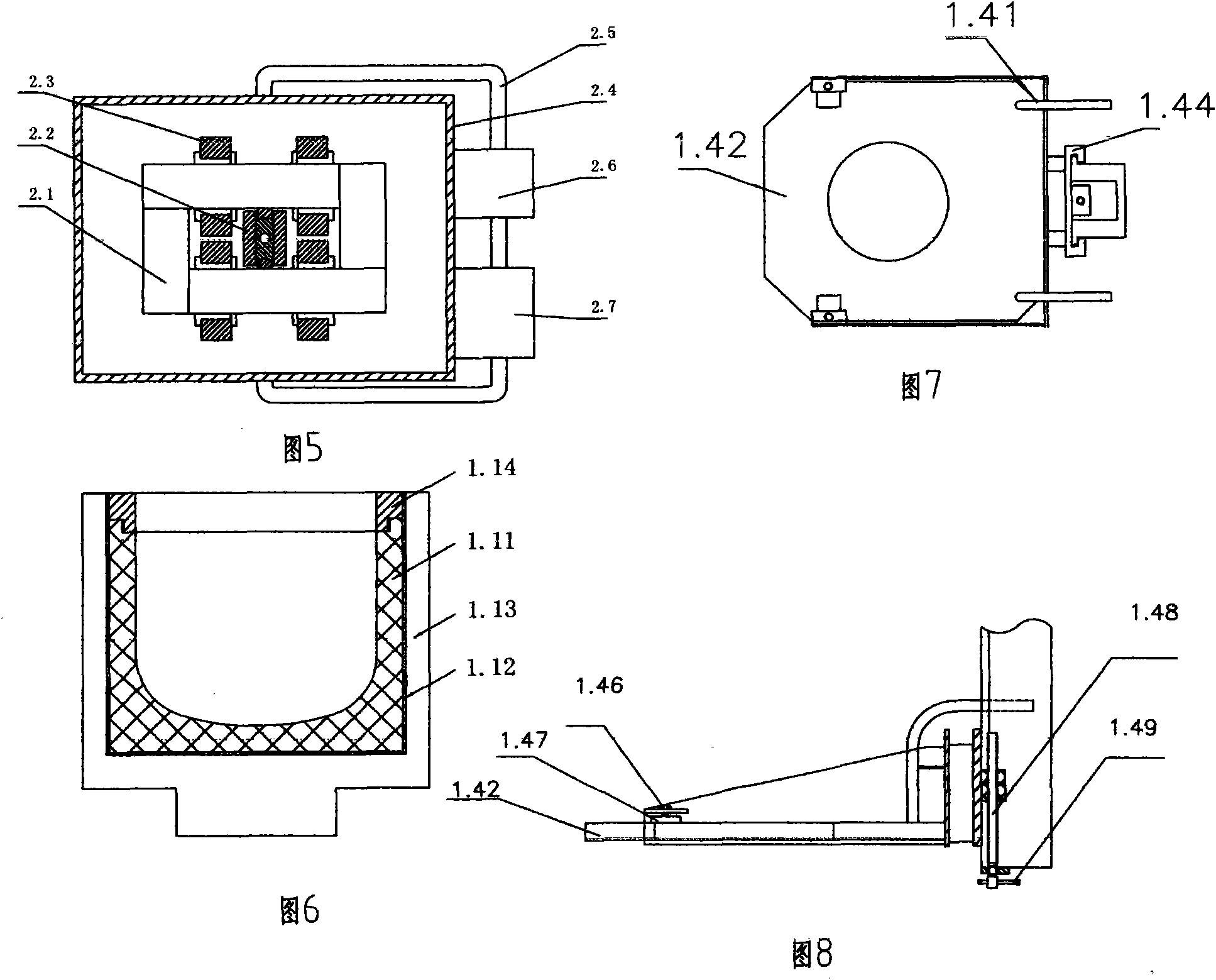

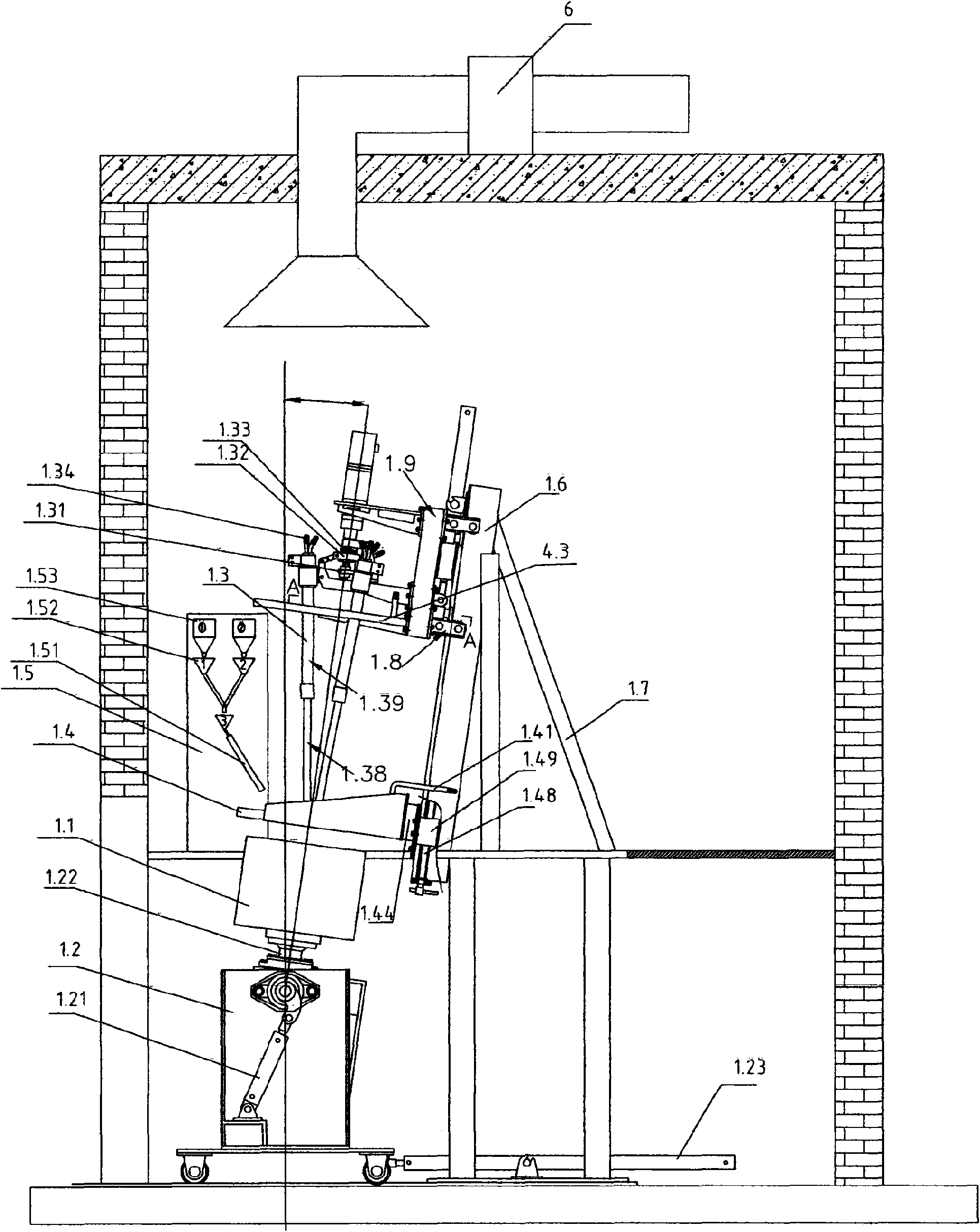

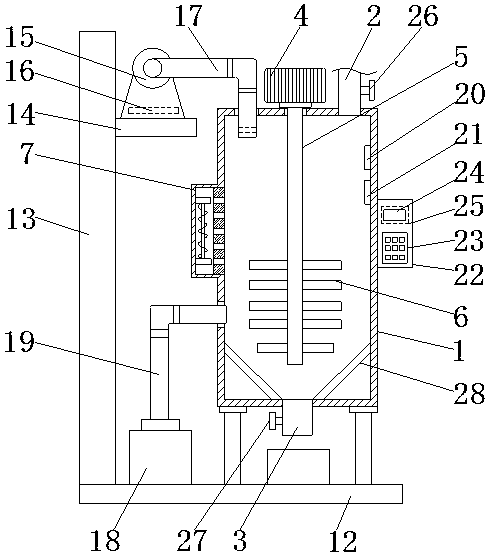

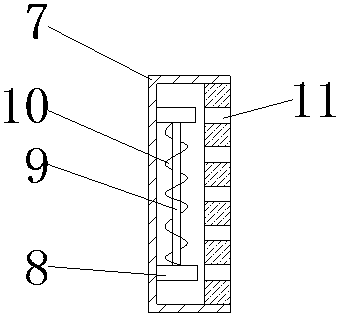

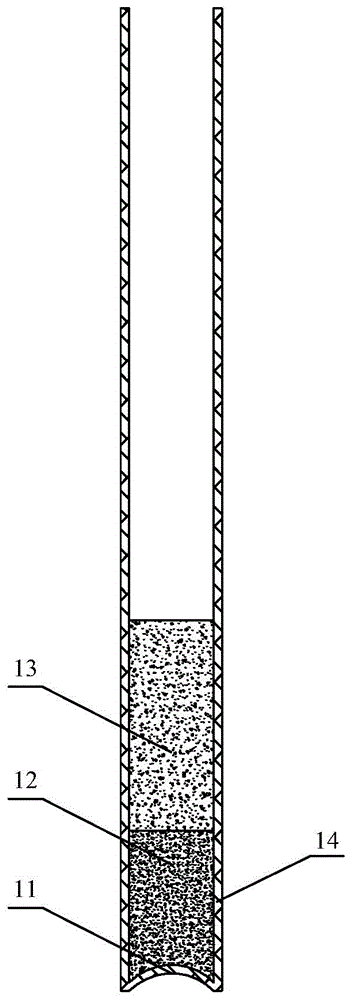

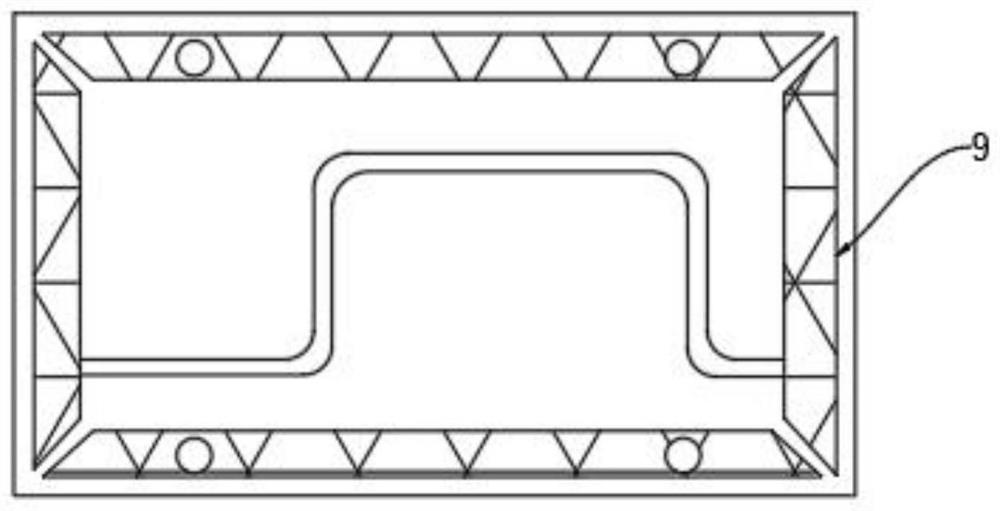

Deep cavity quartz crucible with the thick wall of 26 inches, production method and equipment thereof

InactiveCN101570389AMeet the requirementsMeet production needsPot furnacesChemical industryControl system

The invention relates to the crucible product field, in particular to a quartz crucible with the thick wall of 26 inches, a production method and equipment thereof. The invention solves the problem that a crucible with thick wall does not exist in the prior art, the existing crucible can not meet the requirements of large volume, thick crucible wall, long service life during melting materials in glass, chemical industries, and the existing processing technique and equipment can not manufacture the crucible with the thick wall; therefore, the quartz crucible with the thick wall of 26 inches is provided; a quartz crucible hot forming system including a crucible founded host computer, an oil-filled transformer, a hydraulic power transmission system, a cooling system, a control system and an exhaust air system is also provided; the oil-filled transformer, the hydraulic power transmission system, the cooling system and the control system are respectively connected with the crucible founded host computer by electrical signals or pipelines. The design of the invention and the daring and scientific technical reform fill up the manufacture gas of the quartz crucible with the thick wall.

Owner:余姚市晶英电弧坩埚有限公司

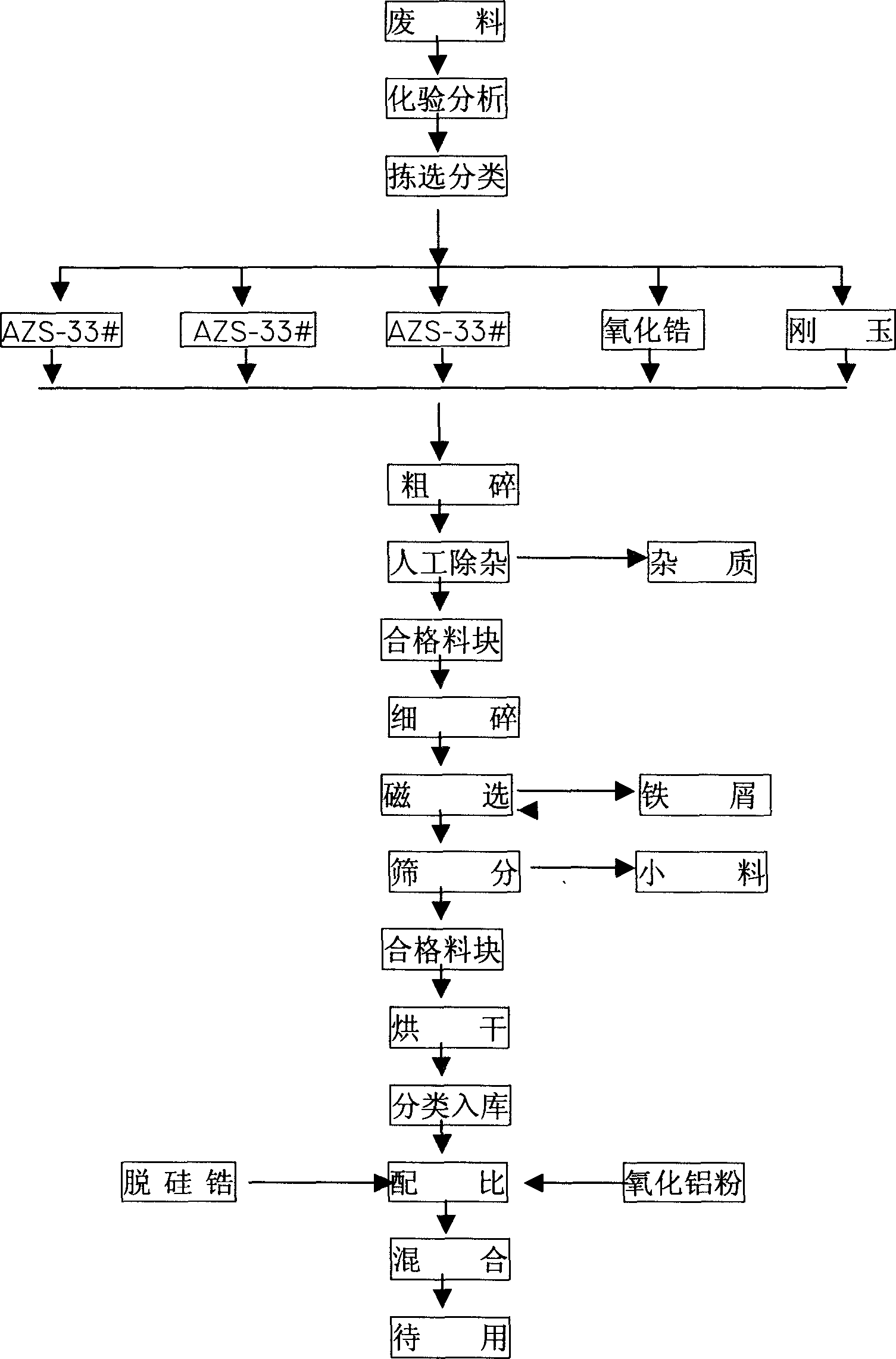

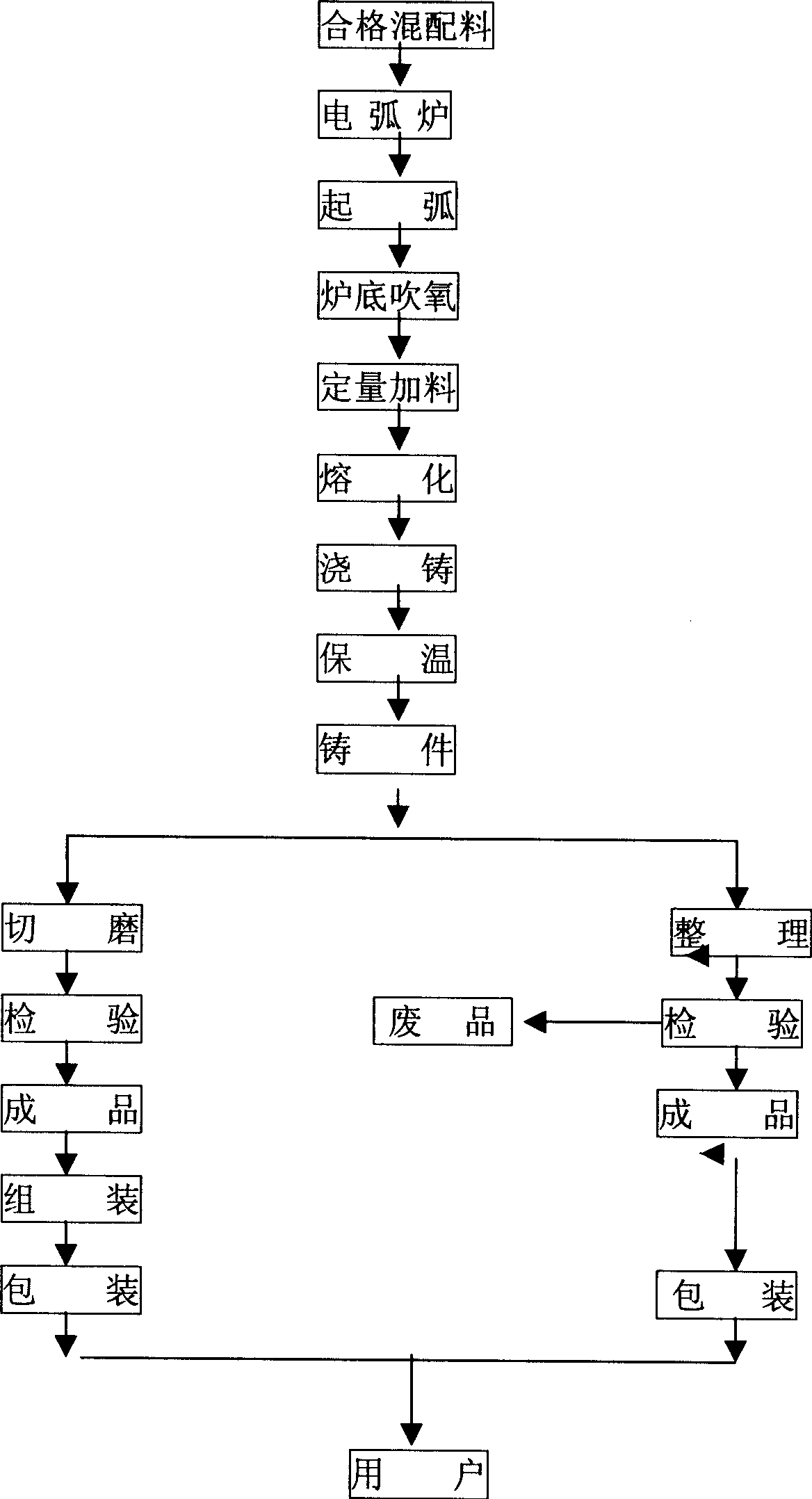

Process for producing electric smelting zirconium corundum 33#, 36#, 41# products by secondary casting

A process for preparing the electrocast zirconium corundum No.33, 36 and 41 includes such steps as pretreating the leftover of cast zirconium corundum, zirconium oxide and corundum, proportional mixing, smelting by blowing oxygen from furnace bottom for removing impurities, casting and holding the temp for a certain time.

Owner:侯松发

Potassium chlorate drying device

PendingCN107677072AImprove work efficiencyGood drying effectDrying gas arrangementsDrying machines with non-progressive movementsElectric machineryHot blast

The invention discloses a potassium chlorate drying device comprising a drying box. The right side of the top of the drying box is movably connected with a feeding pipe. The bottom of the drying box is movably connected with a discharging pipe. The top of the drying box is movably connected with a motor. The bottom of a rotating shaft penetrates through the drying box and extends to an inner cavity of the drying box. Through matching of the drying box, the feeding pipe, the discharging pipe, the motor, the rotating shaft, stirring blades, a heating box, heating bases, a heating pipe, an electric heating wire, heat conducting sheets, a bottom plate, a connecting plate, a supporting plate, a hot air blower, a power frequency modulator, a hot air guide pipe, a vacuum pipe, an exhaust pipe, atemperature sensor, a humidity sensor, a control panel and a single chip microcomputer, the problems that a traditional potassium chlorate drying device is slow in drying process and does not have a smashing function, potassium chlorate needs to be smashed through a smashing machine after being dried, and consequently production cost is increased for enterprises are solved.

Owner:LEIYANG JINYUE SCI & TECH DEV

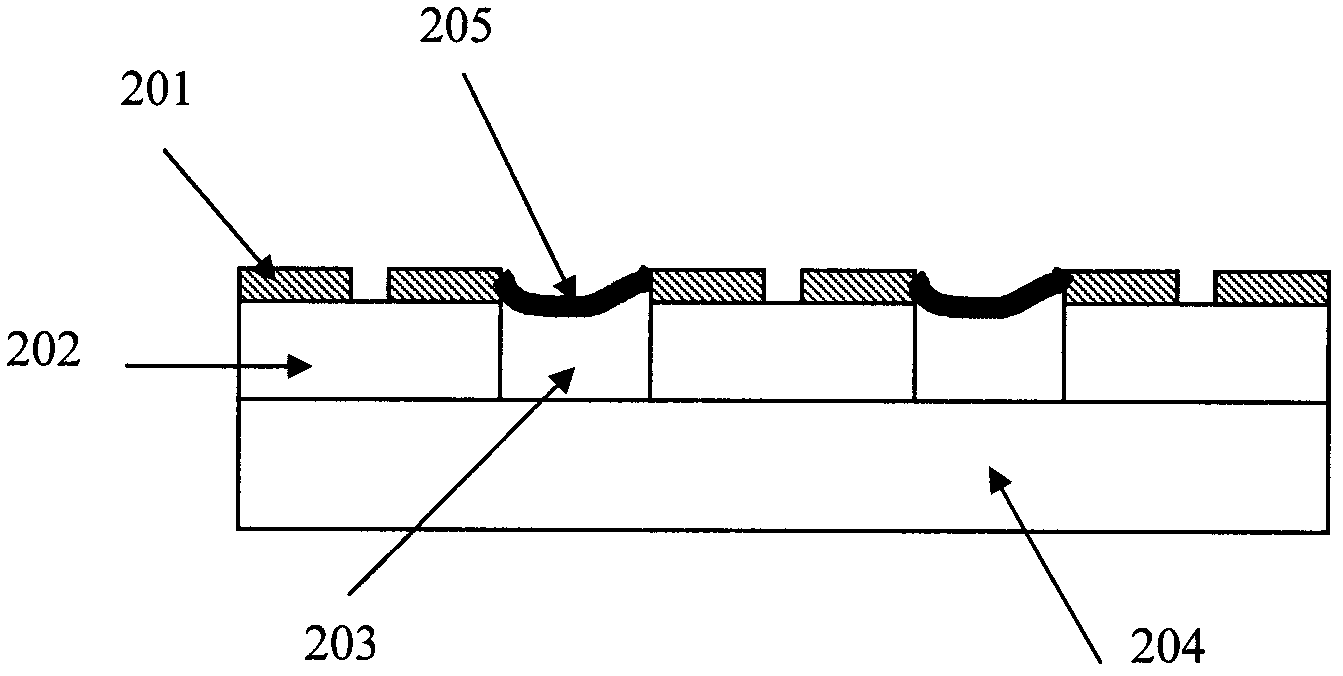

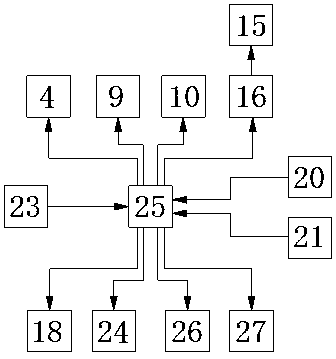

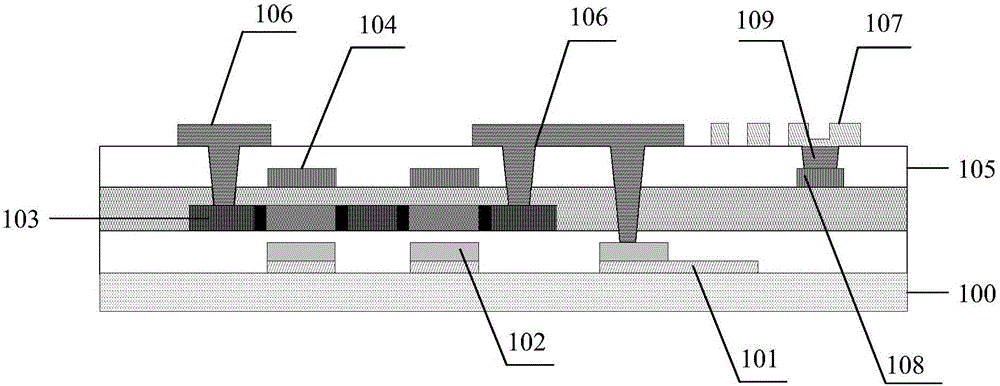

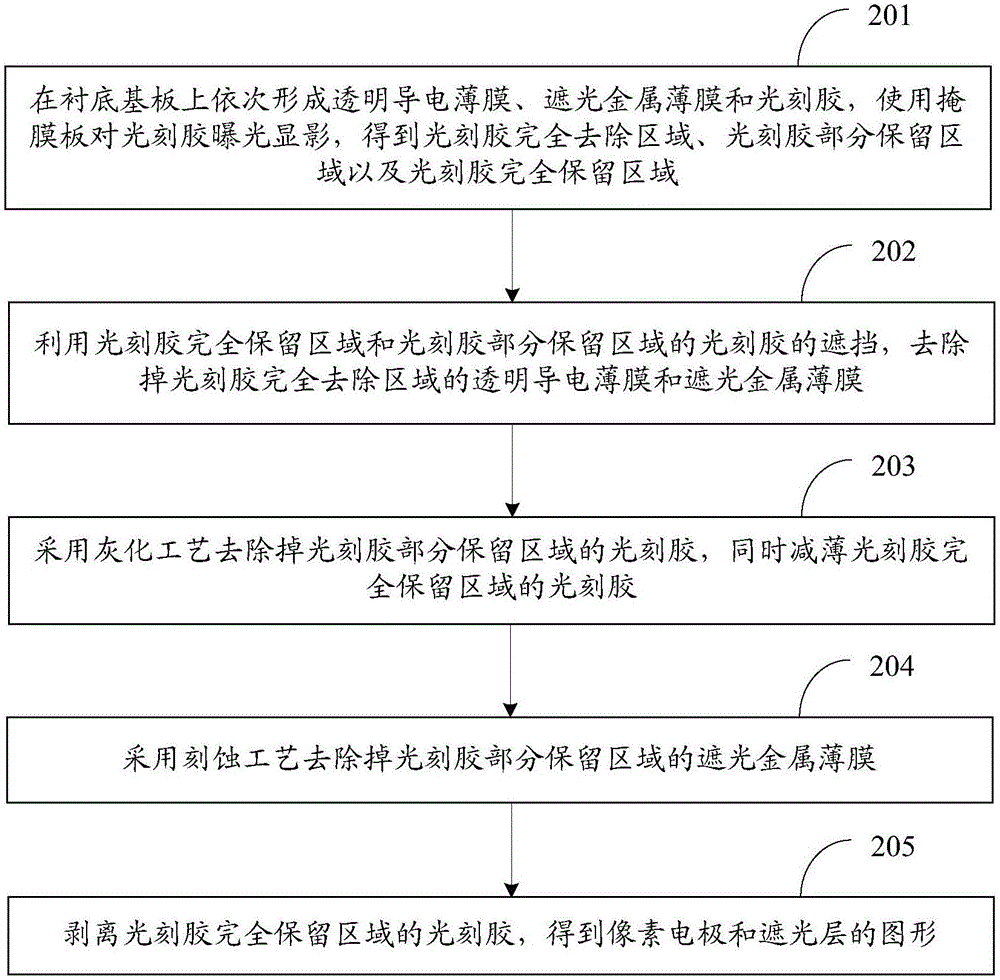

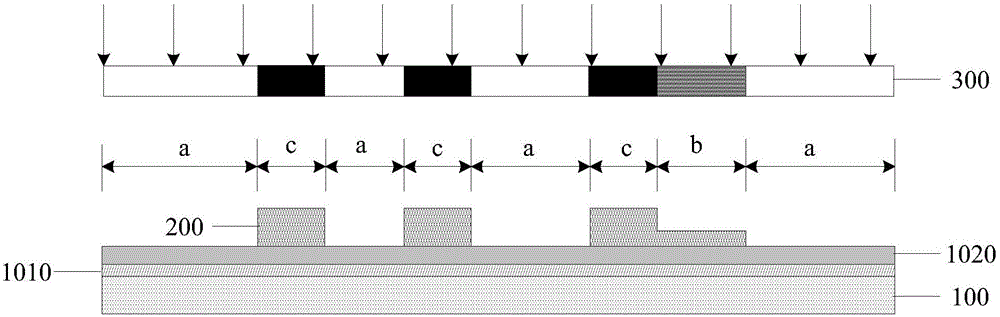

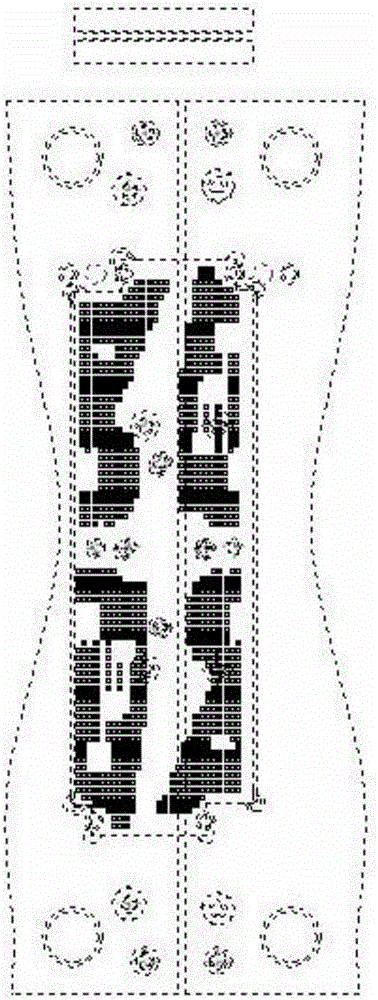

Method for manufacturing low-temperature polycrystalline silicon TFT array substrate and corresponding device

ActiveCN106024813AReduce in quantitySimple processSolid-state devicesSemiconductor/solid-state device manufacturingState of artInsulation layer

The invention relates to a method for manufacturing a low-temperature polycrystalline silicon TFT array substrate and a corresponding device. The method for manufacturing the low-temperature polycrystalline silicon TFT array substrate and the corresponding device are used for solving the problems that a current common LTPS process is complex in manufacturing process, 10-11 photolithography techniques need to be carried out generally, and consequently the production cost of low-temperature polycrystalline silicon display equipment is increased. The method comprises the steps that the graph of a pixel electrode, the graph of a shading layer, the graph of a low-temperature polycrystalline silicon active layer, the graph of a grid, the graph of an interlayer insulation layer, the graph of a source and drain and the graph of a common electrode are sequentially formed on an underlayer substrate; the graph of the pixel electrode and the graph of the shading layer are formed through one composition process. In the method for manufacturing the low-temperature polycrystalline silicon TFT array substrate, the graph of a pixel electrode layer and the graph of the shading layer can be formed through one composition process, the manufacturing process of the whole array substrate is achieved only through six composition processes, and compared with the mode that 10-11 photolithography techniques need to be carried out in the prior art, the number of mask plates used in the LTPS process is reduced, the manufacturing process is simplified, and the production cost is reduced.

Owner:BOE TECH GRP CO LTD

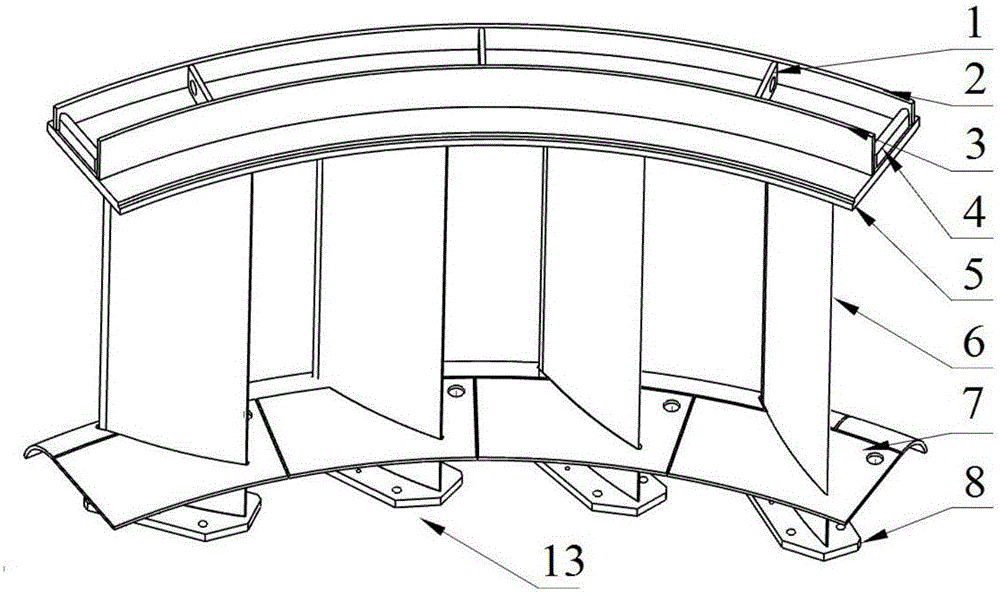

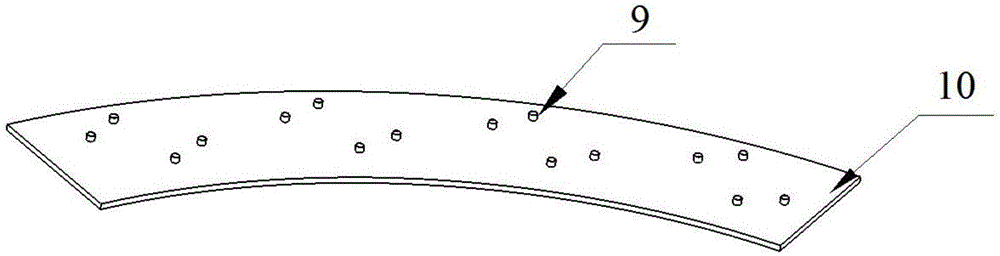

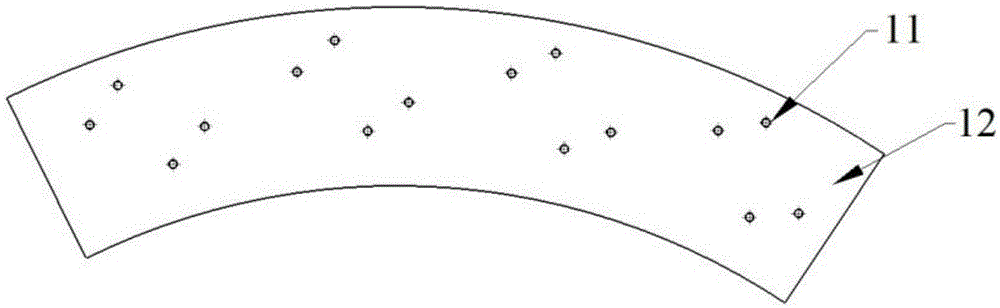

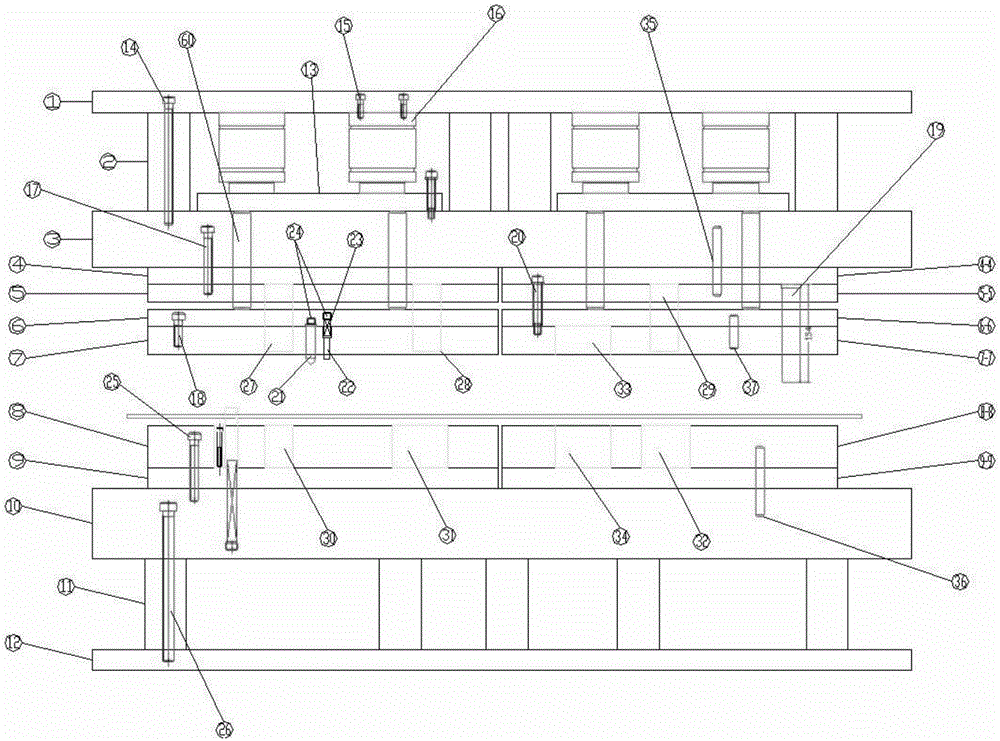

Erecting welding technological method for single-upper-ring type large segmented stand ring with sole plates

ActiveCN105057855AReduce weightReduce difficultyArc welding apparatusProcessing costWelding deformation

The invention relates to an erecting welding technological method for a single-upper-ring type large segmented stand ring with sole plates. A sole plate positioning template and positioning pipes are used for precise positioning; and after splice welding of a lower guide plate, fixed guide vane mounting holes are perforated in a matched mode, and then fixed guide vanes are inserted. The key process problems of stand ring welding deformation, sole plate assembly positioning, sole plate combining through hole processing cost, the production cycle and the like are solved through an auxiliary lower ring, the sole plate positioning templates and the positioning pipes, and the production cost and the production cycle are reduced. According to the stand ring manufactured through the technological method, the problems of assembly positioning, the production cost, welding deformation and the like are effectively solved, and construction site installation requirements are met; the subsequent production cycle and processing cost are greatly reduced, economy and practicability are both considered, and the purposes of lowering cost and improving effects are achieved.

Owner:HARBIN ELECTRIC MASCH CO LTD

High-yield-ratio air-conditioner foil base material and preparation method thereof

The invention discloses a high-yield-ratio air-conditioner foil base material and a preparation method thereof in the technical field of calendaring manufacturing for aluminum foils, and aims at solving the technical problem that an aluminum foil for an air conditioner is incapable of being high in both extensibility and yield ratio, and not beneficial to reducing the production cost for fins forthe air conditioner, and increasing the production efficiency for the fins in the prior art. The base material comprises the following components in percentage by mass: Al, 0.57%-0.63% of Si, 0.77%-0.83% of Fe, not greater than 0.05% of Cu, not greater than 0.01% of Mn, not greater than 0.03% of Zn and not greater than 0.04% of Ti. The method comprises the following step: a cold-rolling phase of carrying out rough rolling on a finished cast-rolled coil to reach a preset thickness, and then carrying out intermediate homogenization annealing treatment.

Owner:JIANGSU DINGSHENG NEW MATERIAL JOINT STOCK CO LTD

Manufacturing method of radiation-resistant anti-shrinking hydraulic gel material

ActiveCN104402259ALower firing temperatureTo achieve the purpose of saving energy and reducing consumptionCement productionStrontianiteMaterials science

The invention discloses a manufacturing method of a radiation-resistant anti-shrinking hydraulic gel material. Barite, strontianite, and camsellite tailings are taken as the raw material, and mixed into a conventional silicate raw material according to the barium-strontium-boron synergistic principle. Then the mixture is sintered, after the sinter cools down, a proper amount of gypsum is added into the sinter, and the mixture is pulverized to produce the radiation-resistant anti-shrinking hydraulic gel material. The material is widely applied to hospital / nuclear plant buildings with a radioactive source or civil buildings with high requirements, and the problems of shrinking and cracking of conventional silicate cement are solved. The problem that the expansion of a large amount of clinker hydrate causes the structural destruction or destructions on decoration is solved. The comprehensive utilization of barite, strontianite, and camsellite tailings is achieved. The sintering temperature is reduced by 100 to 150 DEG C. The goals of energy saving and energy consumption reduction can be achieved. At the same time the material has an anti-radiation performance. The long-term problems of short service life of conventional silicate cement and shrinkage caused by dryness are solved.

Owner:深圳市凌烁家具工艺有限公司

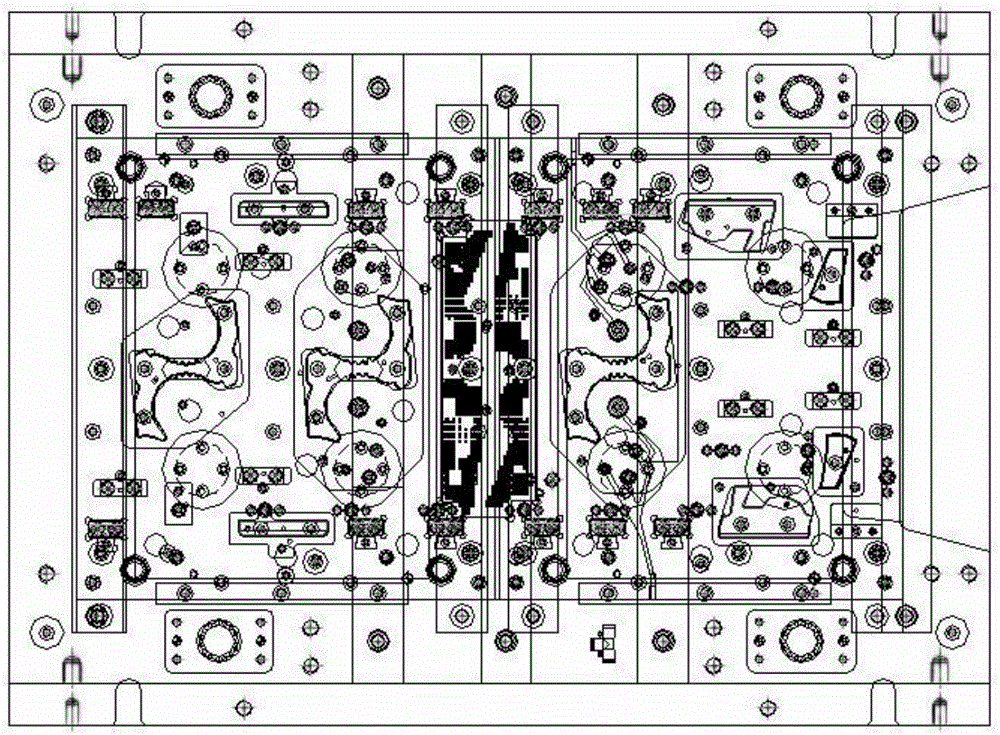

Stamping continuous die for thick steel plate local fine stamping tooth-shaped product

The invention discloses a stamping continuous die for a thick steel plate local fine stamping tooth-shaped product. The stamping continuous die comprises an upper supporting plate, upper cushion blocks, an upper die base, upper cushion plates, upper clamping plates, stop plates, stripping plates, lower die plates, lower cushion blocks, a lower die base, lower cushion blocks, lower supporting plates, a nitrogen spring ejector column knocking-out plate, upper die screws, screws, nitrogen springs, upper die inner guide columns, an equal-height sleeve, a guide pin, an upper die ejector cylinder, a spring, a set screw, lower die screws, punches, a lower die insert DB1, lower die inserts, plane inserts, an upper die dowel pin, a lower die dowel pin and a dowel bar top. Providing the continuous die through which two kinds of products are produced in the first section, and multiple procedures of punching, protrusion beating, cutting off, flanging and forming are combined into a whole is the purpose.

Owner:JIANGSU LILE AUTOMOBILE COMPONENTS

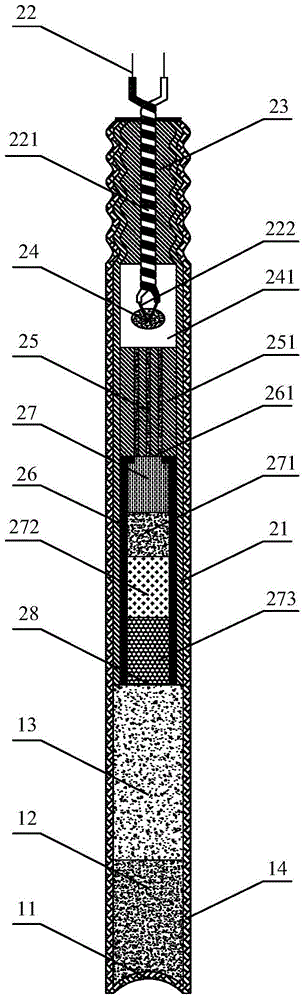

Split assembled type primary explosive-free electric detonator

The invention discloses a split assembled type primary explosive-free electric detonator, which comprises a detonator outer pipe, main charge explosive and a detonator inner pipe, wherein the main charge explosive and the detonator inner pipe are embedded in the detonator outer pipe; the detonator inner pipe comprises a detonator inner pipe shell, a leg wire, a leg wire skin, a bridge wire, a bayonet plug, an explosive head, a gas chamber, a fire transmission hole, an explosion propagation element and a detonator outer pipe base; and the explosion propagation element comprises a reinforcing cap and a plurality of layers of auxiliary charge explosive which are embedded in the reinforcing cap in sequence. A split design is adopted for the primary explosive-free electric detonator; and primary explosive with higher sensitivity is replaced by explosive with lower sensitivity, and the design of a charge structure of a plurality of auxiliary charge explosive is adopted, so that the problems that the initiating ability of the existing primary explosive-free electric detonator is poor, the safety is still low, the production cost and the use cost are high and the like are solved.

Owner:HONGDA MINING IND

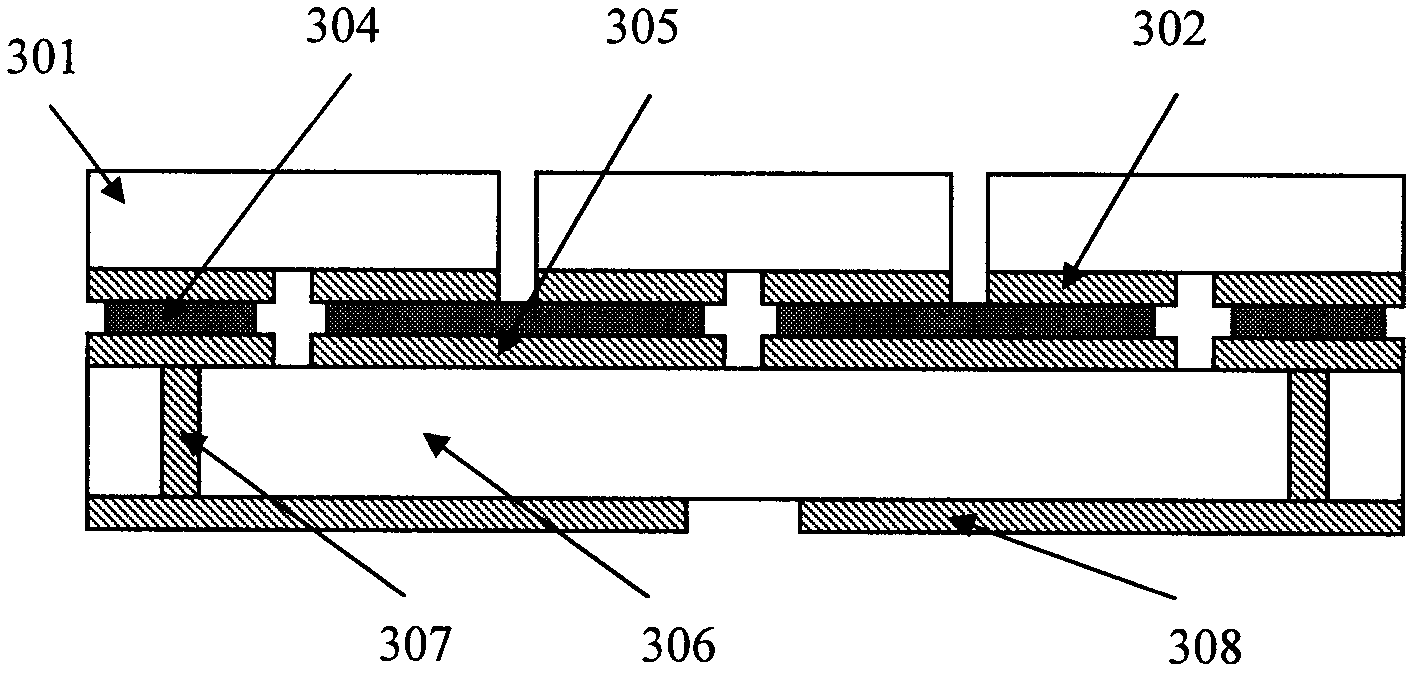

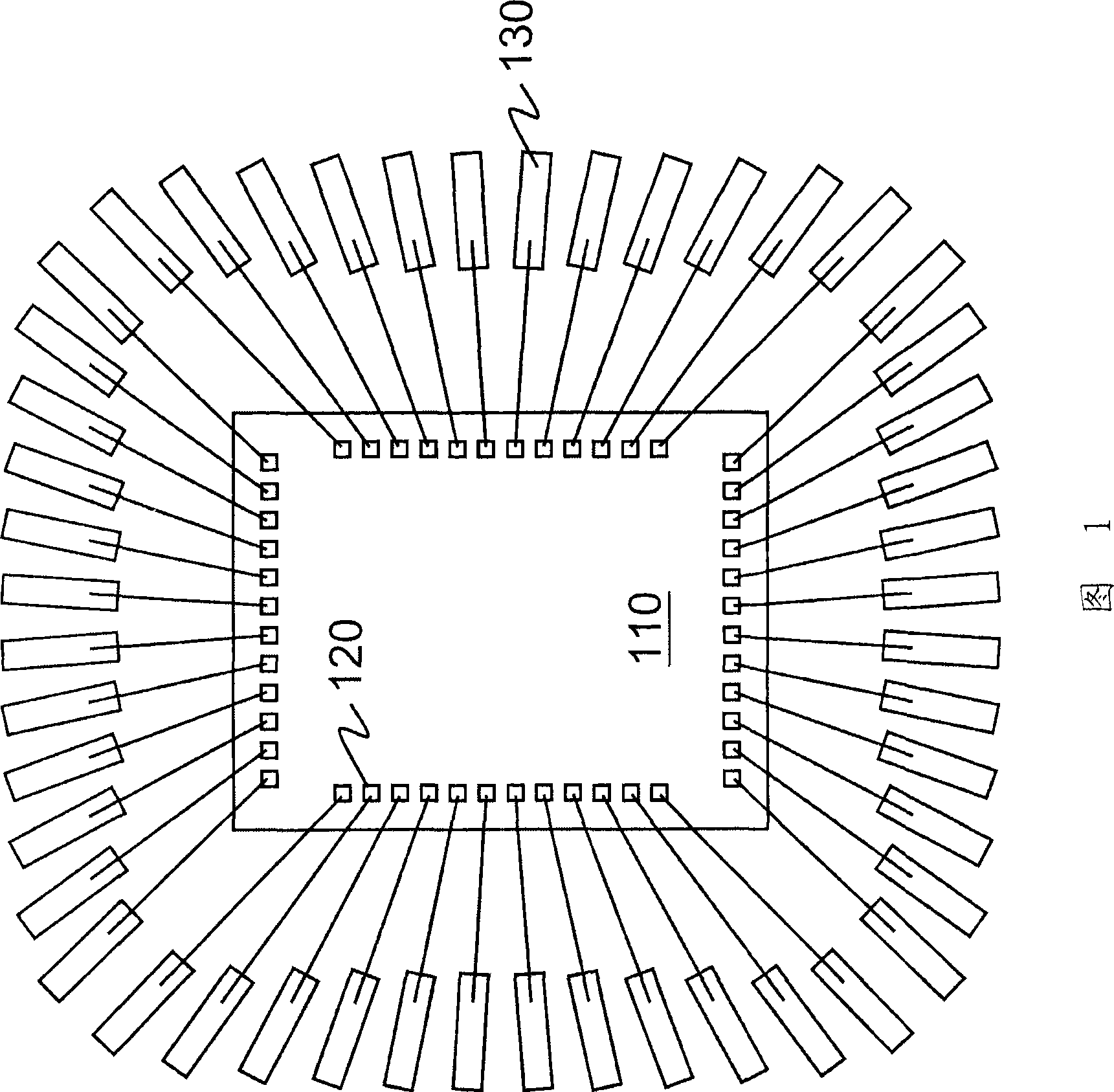

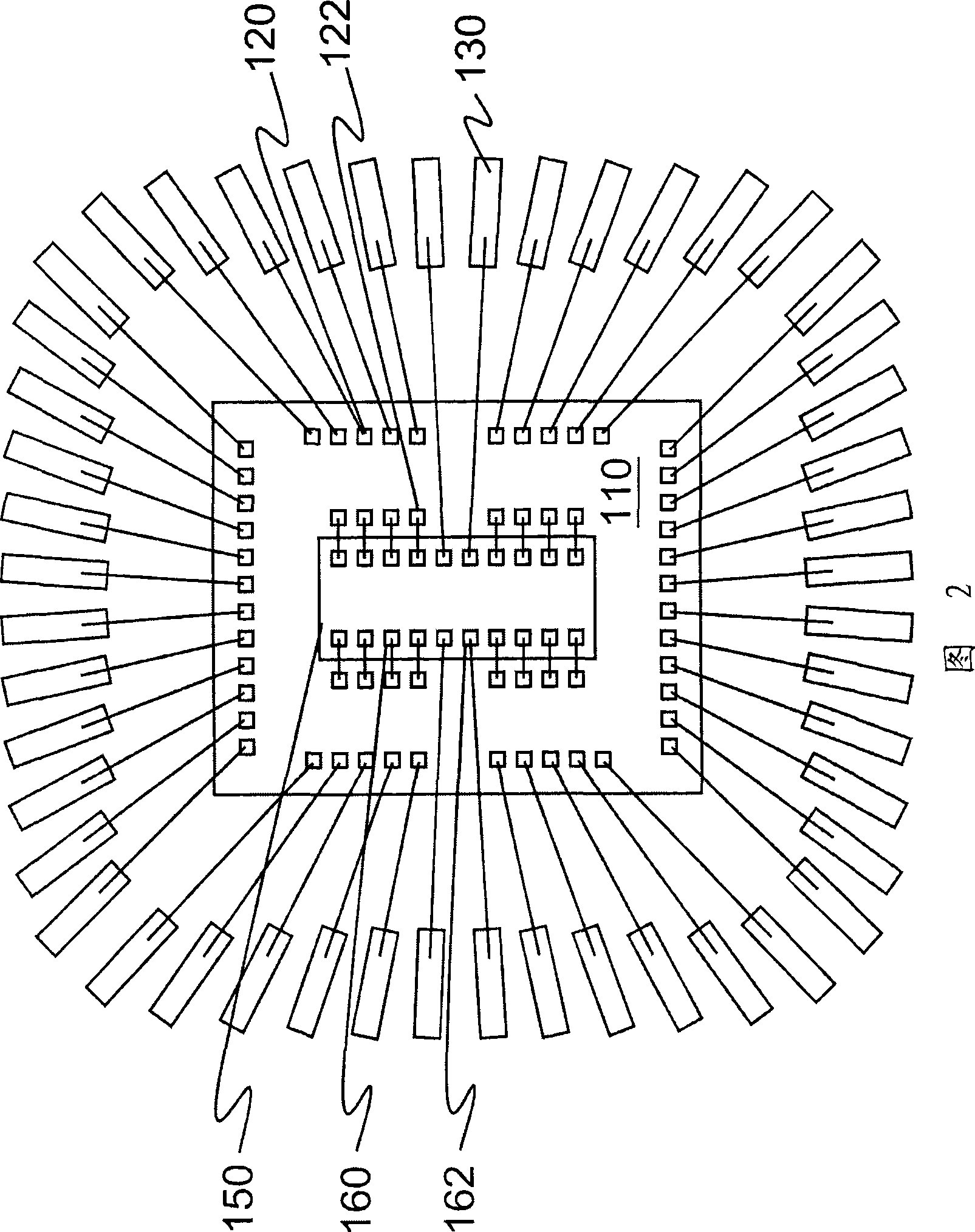

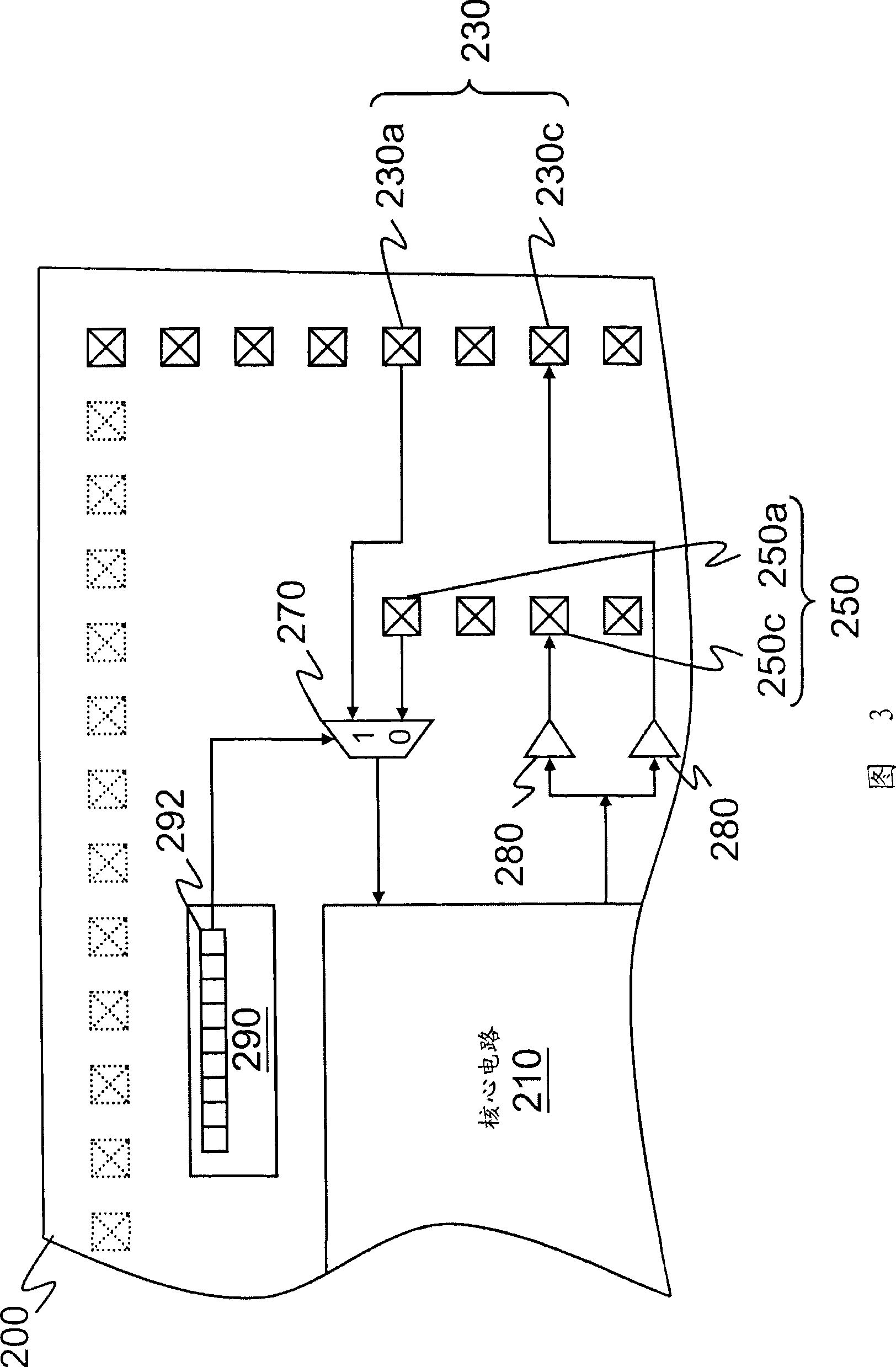

Integrated circuit suitable for various encapsulation modes

ActiveCN101442050ASolve production costImprove application flexibilitySemiconductor/solid-state device detailsSolid-state devicesIntegrated circuitEngineering

The invention provides an integrated circuit applicable to a plurality of encapsulation modes. The integrated circuit comprises a core circuit, a plurality of joint sheets and a selection module, wherein the selection module is coupled among the core circuit and the plurality of the joint sheets, and comprises a plurality of option circuits for determining a conduction state of the core circuit with the plurality of the joint sheets through the selection module according to a control signal. When the control signal is of a first numerical value, the core circuit and the plurality of the joint sheets are in a first conduction state, the integrated circuit is used in encapsulating of a mono-microchip, while the control signal is of a second numerical value, the core circuit and the plurality of the joint sheets are in a second conduction state, and the integrated circuit is used in encapsulating of multi-microchip.

Owner:REALTEK SEMICON CORP

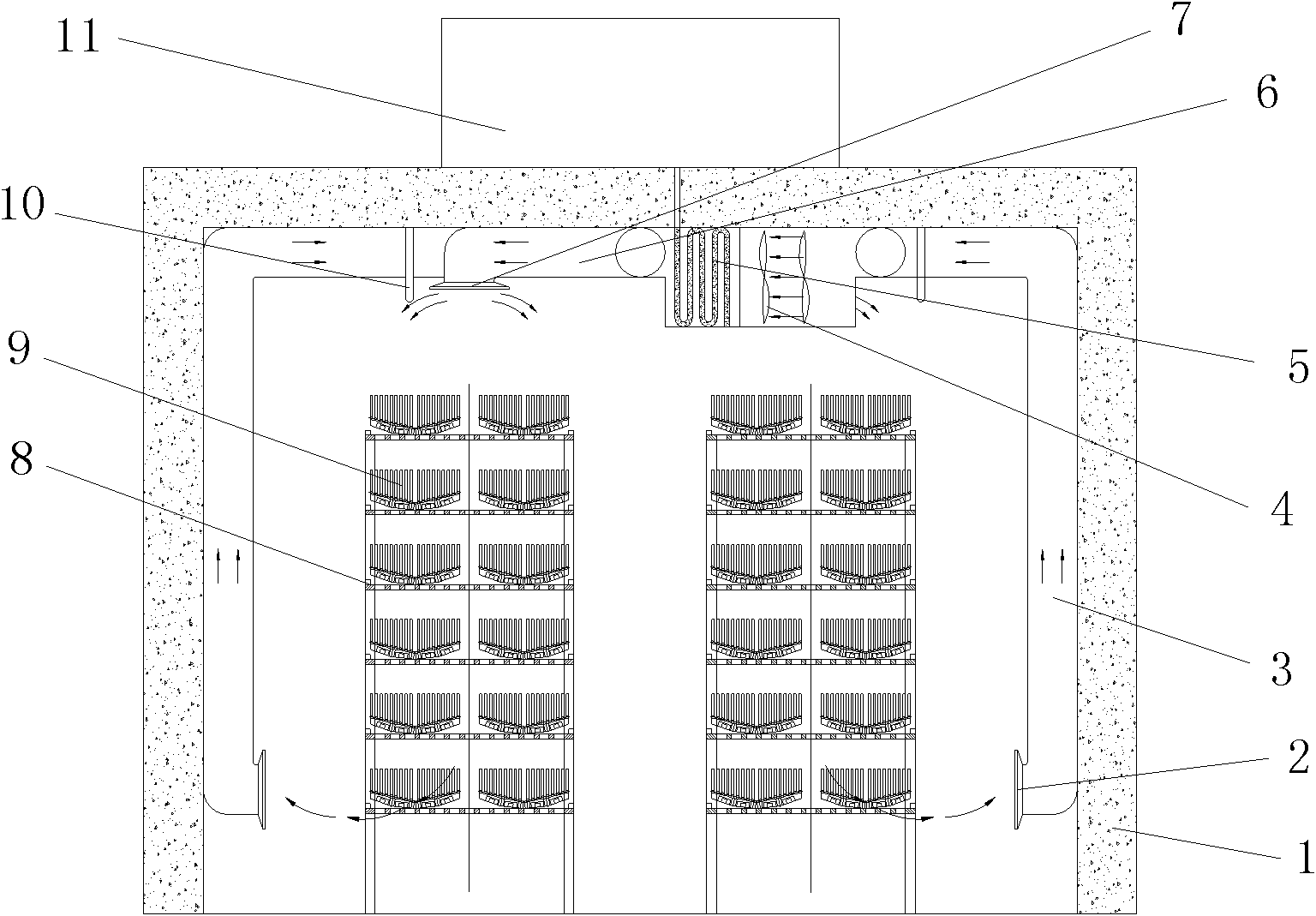

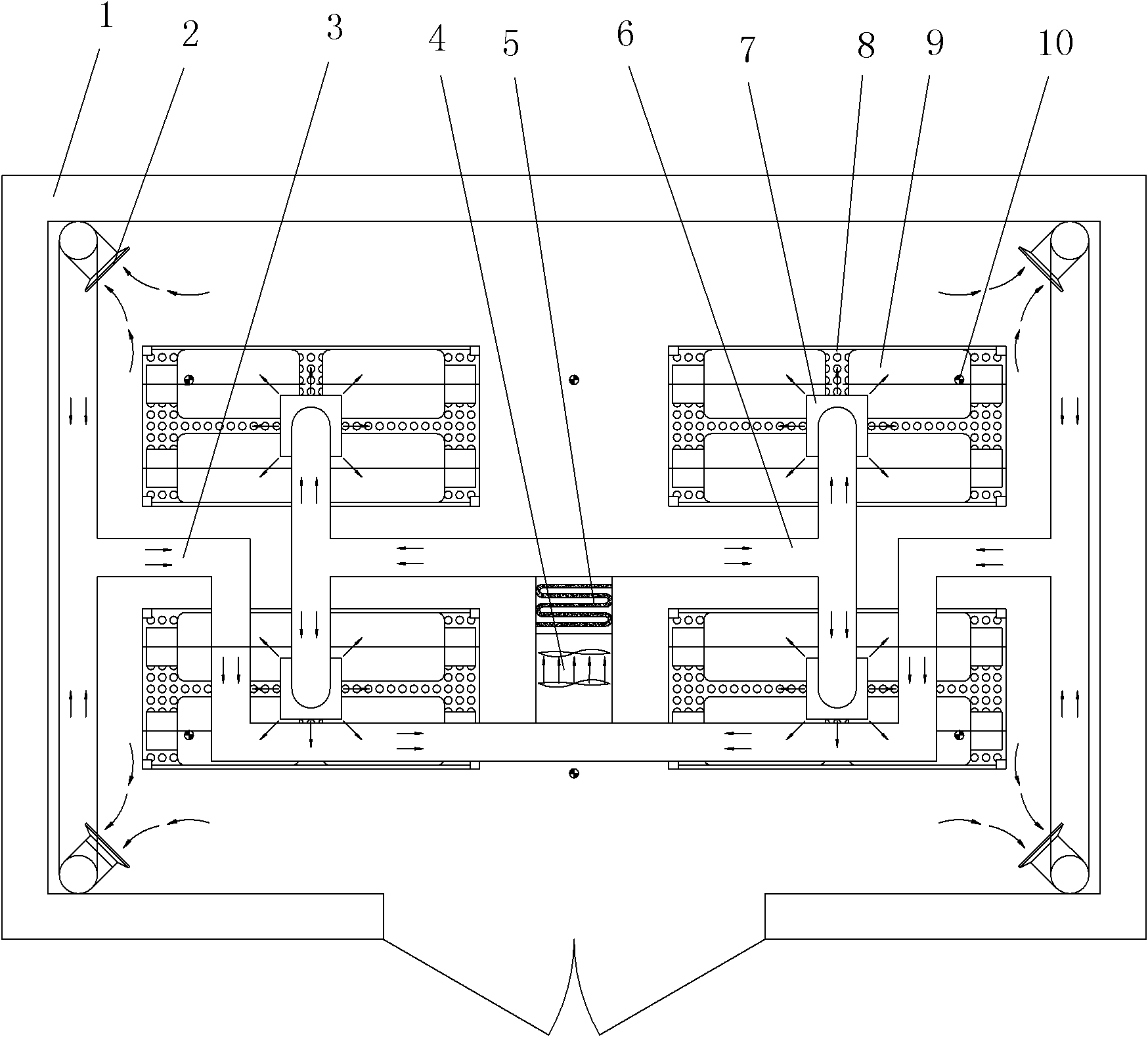

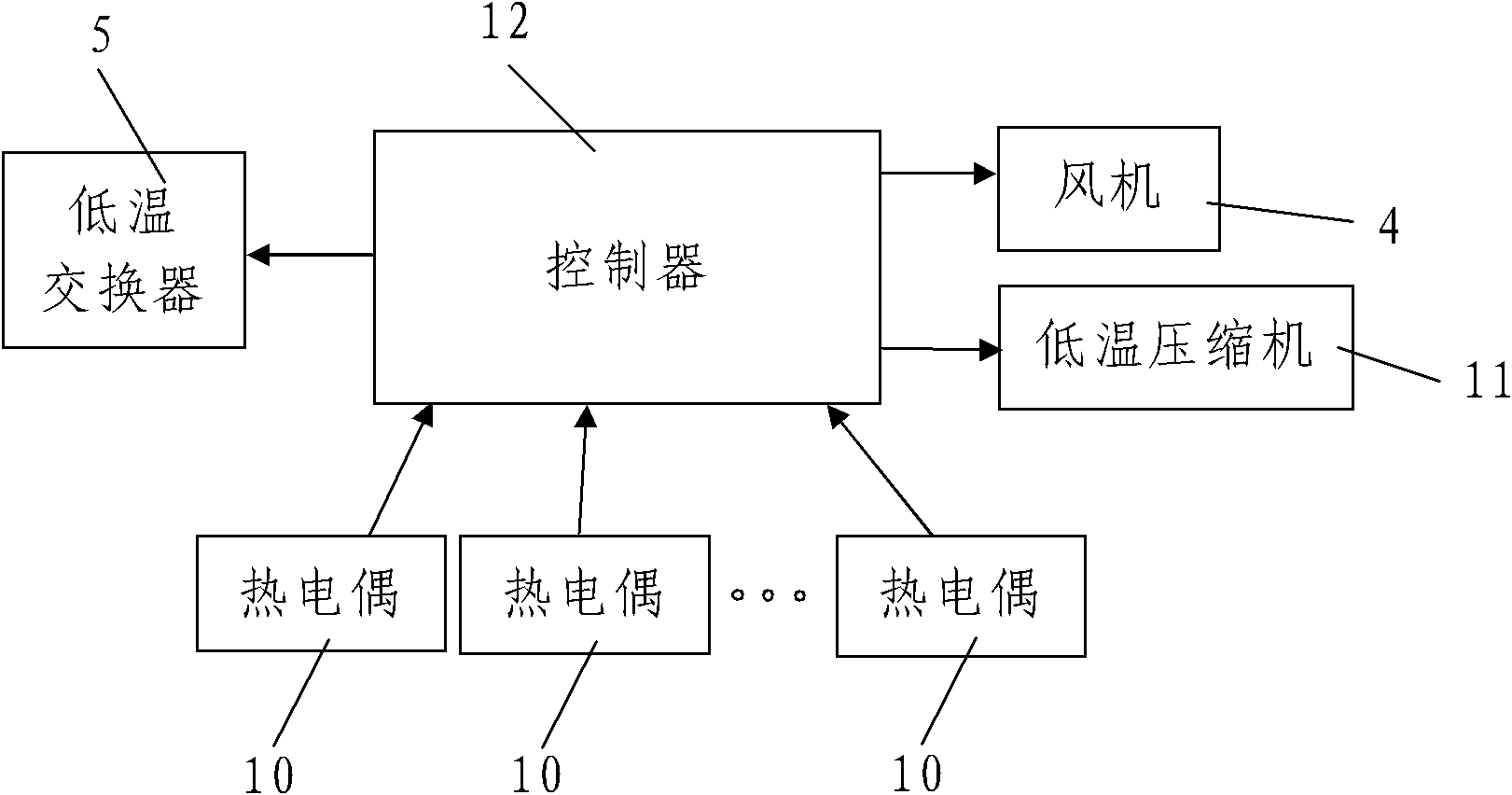

LED (light-emitting diode) street lamp low temperature environment aging room

InactiveCN102486321ASimple structureLow costDucting arrangementsSpace heating and ventilation safety systemsAirflowReturn channel

The invention discloses an LED (light-emitting diode) street lamp low temperature environment aging room. The LED street lamp low temperature environment aging room comprises an aging room body, an air-circulating channel which is used for continually circulating to introduce cold air to an aging region in the aging room body, a controller and multiple temperature-detecting devices, wherein the air-circulating channel comprises a low temperature exchanger, a low temperature compressor, a fan, a cold air inlet channel, and an air return channel, wherein the low temperature exchanger is arranged above the middle of the aging room body, the low temperature compressor is connected with a low temperature exchanger, the cold air inlet channel is used for leading cooling draft acquired by the low temperature exchanger after low temperature exchange to successively introduce the aging region through multiple cold air inlets, the air return channel is used for absorbing air in the aging region under the action of the fan to the side of the low temperature exchanger so as to carry out low temperature exchange through multiple air return ports, and the cold air inlet channel is communicated with the air return channel through a communicating pipe. The low temperature environment aging room provided by the invention has the advantages of simple structure, is easy to operate, is low in cost and has good using effects, and can be used for effectively solving a temperature maldistribution problem in the aging region through adjusting the refrigeration states of the low temperature exchanger and the low temperature compressor and the shutter states of air inlets and the air return ports.

Owner:XIAN DAYU PHOTOELECTRIC TECH

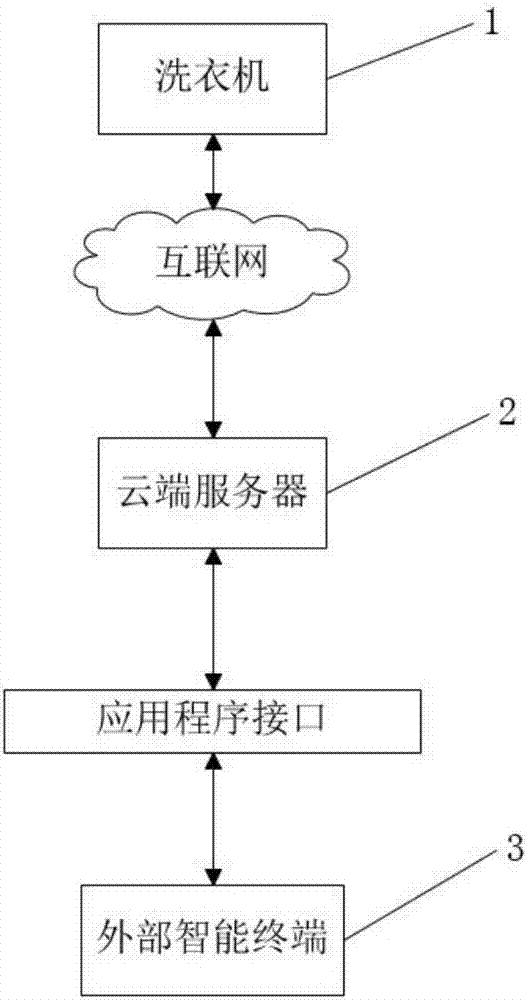

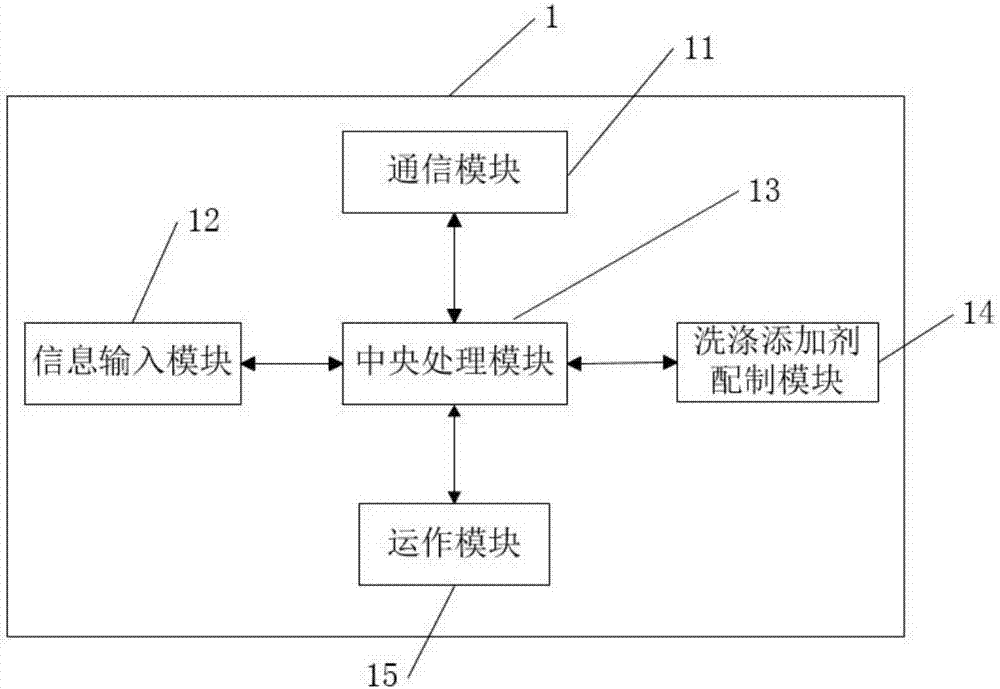

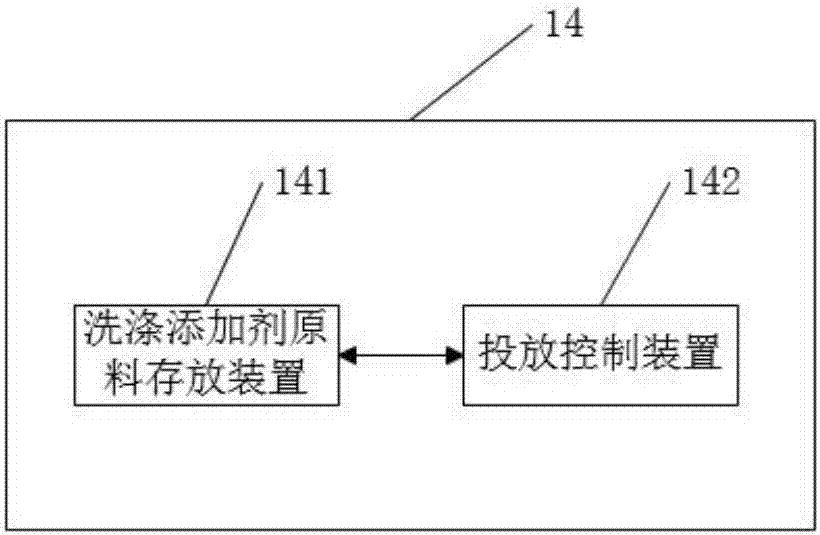

Internet of things washing machine capable of preparing washing additive

ActiveCN107964761ASolve production costOther washing machinesControl devices for washing apparatusProcess engineeringLaundry

Disclosed is an internet of things washing machine capable of preparing a washing additive. The washing machine comprises a washing machine body, a cloud server and an external intelligent terminal, the washing machine body comprises a washing additive preparation module, and the washing additive preparation module comprises a washing additive raw material storage device for storing at least one washing additive raw material and a putting control device for controlling putting of the washing additive raw materials. A method of the washing machine for preparing the washing additive comprises the steps of determining related washing information; determining a washing additive preparation scheme; putting the washing additive raw materials. According to the internet of things washing machine,through the arrangement of the washing additive preparation module and the utilization of an internet of things technology, the washing additive raw materials are prepared and put for use according tothe corresponding scheme, not only are the washing additive raw materials utilized for preparation and use of the washing additive on the internet of things washing machine, but also no finished detergent is used in the laundry process, and therefore the problem is solved that existing finished detergents are high in production cost and transportation cost.

Owner:宁波小奥家电科技有限公司

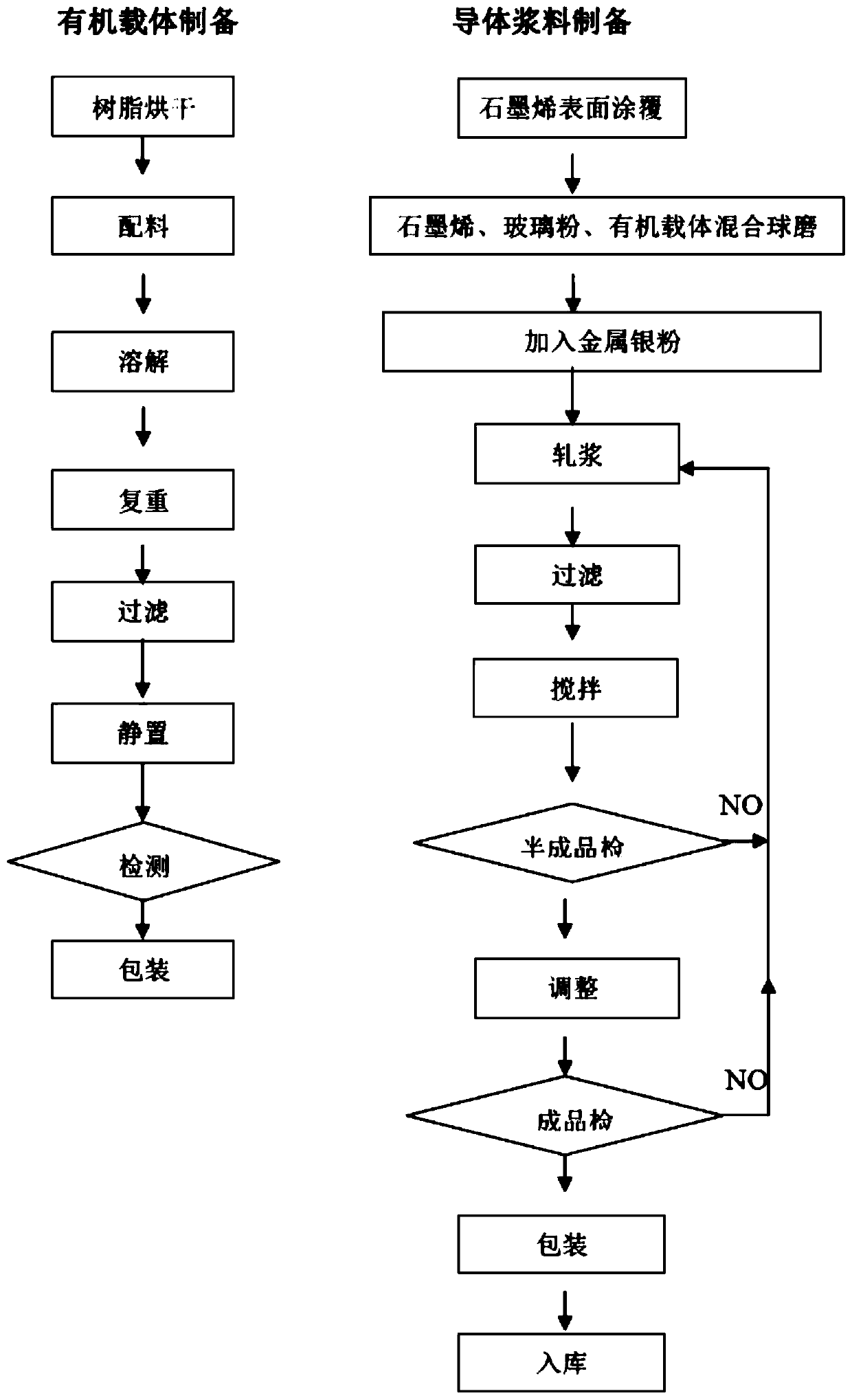

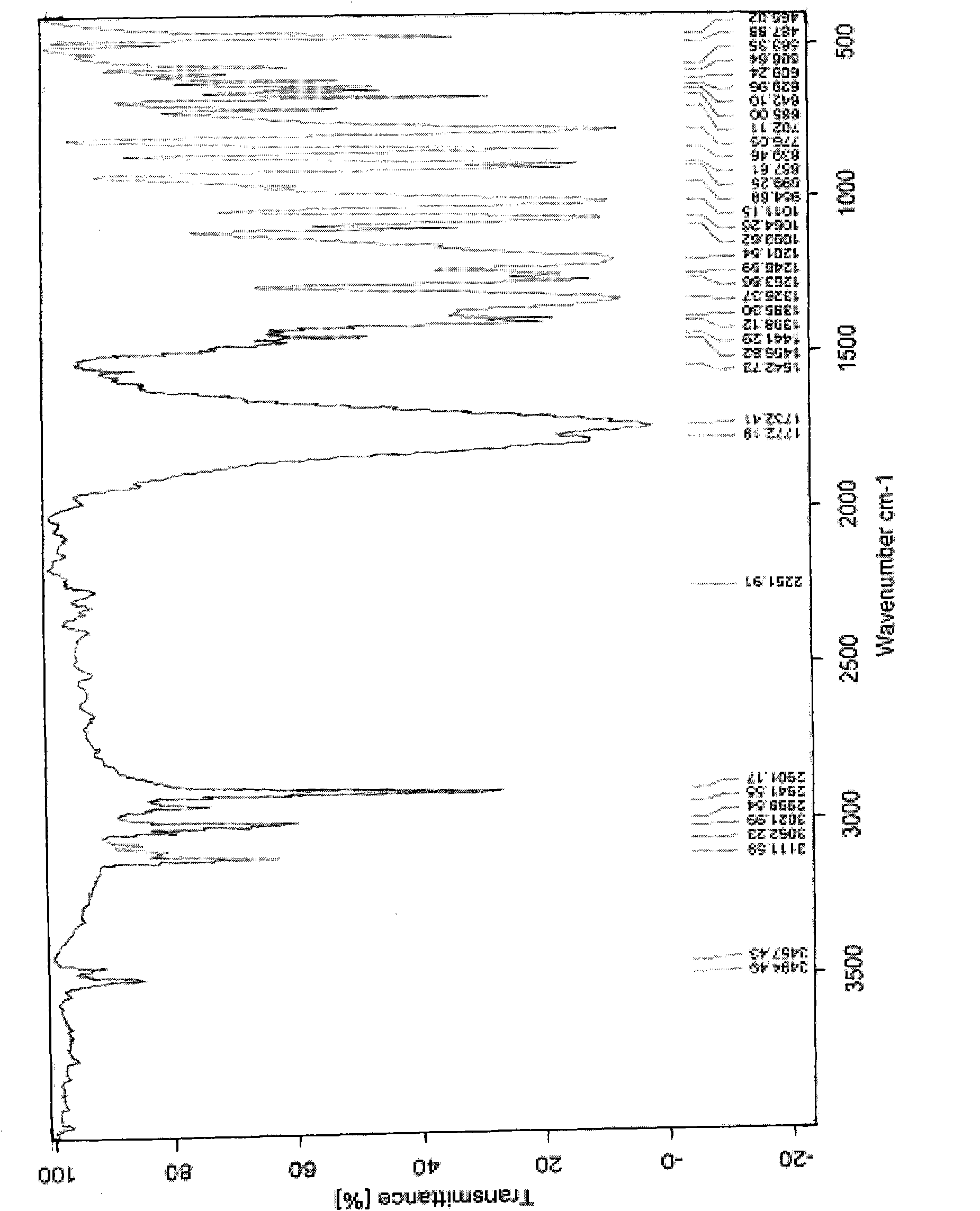

Conductor paste and conductor material

InactiveCN110942842AReduce silver contentReduce manufacturing costNon-conductive material with dispersed conductive materialCable/conductor manufactureGraphiteGraphene

The invention relates to a conductor paste and a conductor material. The conductor paste comprises the following components in percentage by weight: 20%-40% of silver powder, 0.01%-20% of graphene, 1%-8% of glass powder and 45%-70% of an organic carrier. The silver content in the conductor paste is extremely low and is only 20%-40%, so that the thinking constraint of traditional high silver and high conductivity is broken through, the conductor paste is a new breakthrough in the limit field of domestic electronic materials, the production cost can be effectively reduced for downstream enterprises, and the living space is effectively improved; Meanwhile, graphene is added into the conductor slurry, and the defects caused by silver reduction are overcome by utilizing the excellent electricalproperty of graphene.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

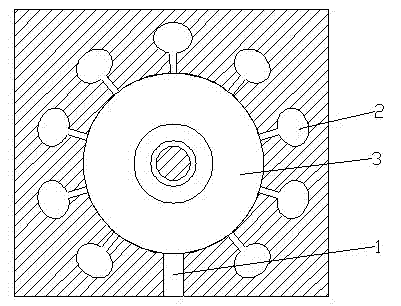

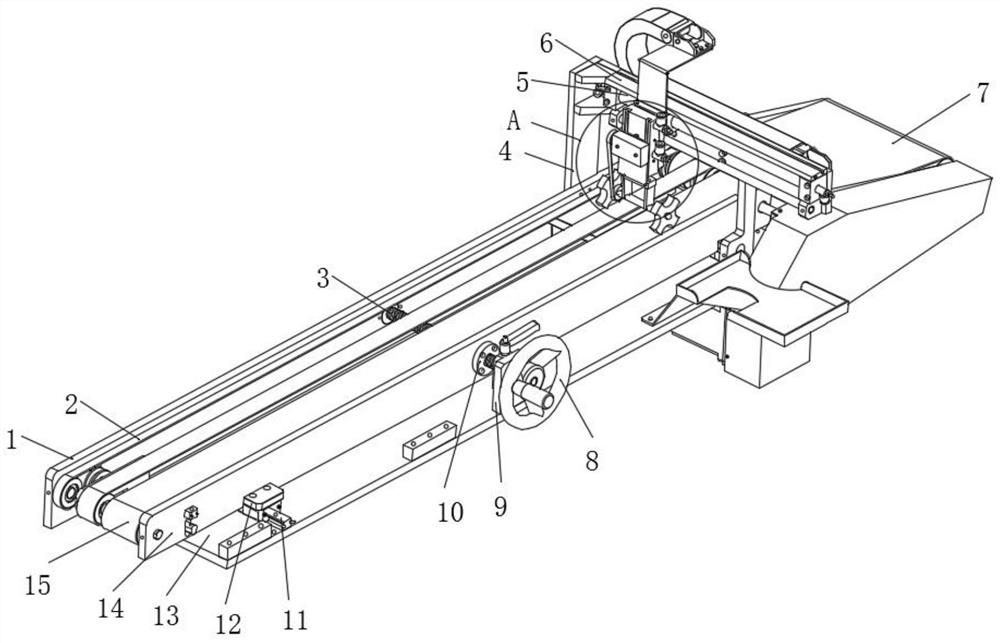

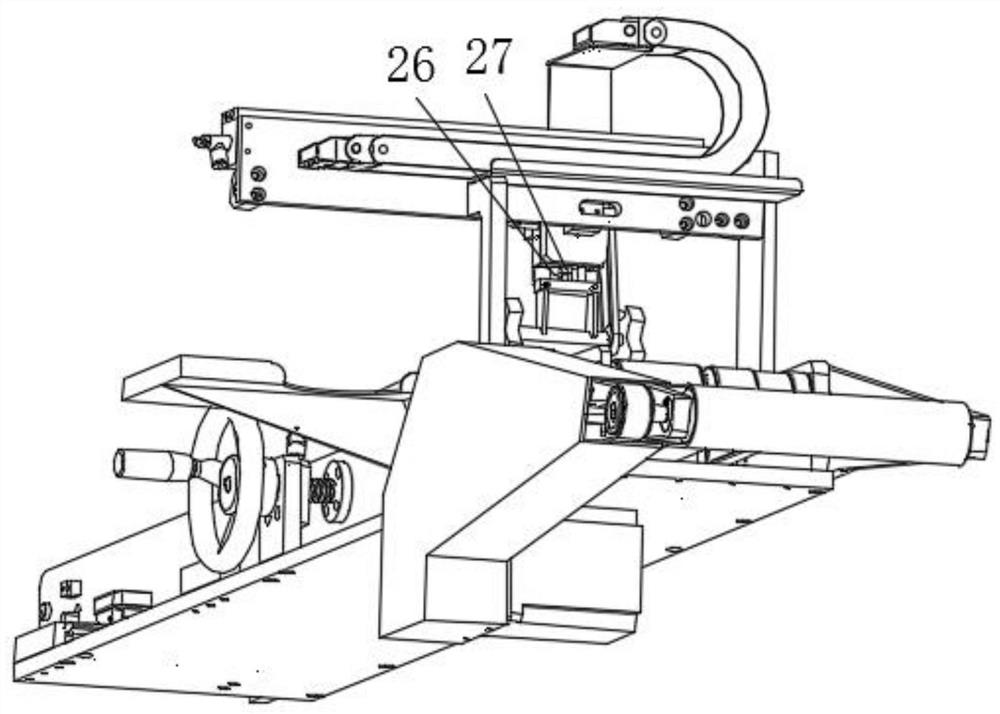

Excavator guide assembly guiding aluminum wheel mould and die casting process

InactiveCN102773456ASolve technical problemsSolve production costManufacturing engineeringAluminium alloy

The invention discloses an excavator guide assembly guiding aluminum wheel mould and a die casting process. The excavator guide assembly guiding aluminum wheel mould comprises a slit gate (1), slagging ladles (2) and a cavity (3), wherein the thickness of the slit gate (1) is 15-20mm; a sectional area of each slagging ladle (2) is 30mm*80mm-40mm*100mm, and 7-10 slgging ladles are annularly distributed around the cavity (3). In a die casting process, the injecting force used by a die-casting machine is 10-15Mpa, and the filling speed is 0.5-2m / s. According to the invention, the problems of high cost and low production cost existing when an existing thick walled casting is molded by casting through a casting molding hard mould are solved. Precise aluminum alloy casting molding is adopted to replace a large alloy piece casting molding process, so that the production cost is greatly reduced, the production efficiency is greatly improved, and the performances of produced castings reach the standard.

Owner:GUIZHOU YUGAO ELECTRONICS

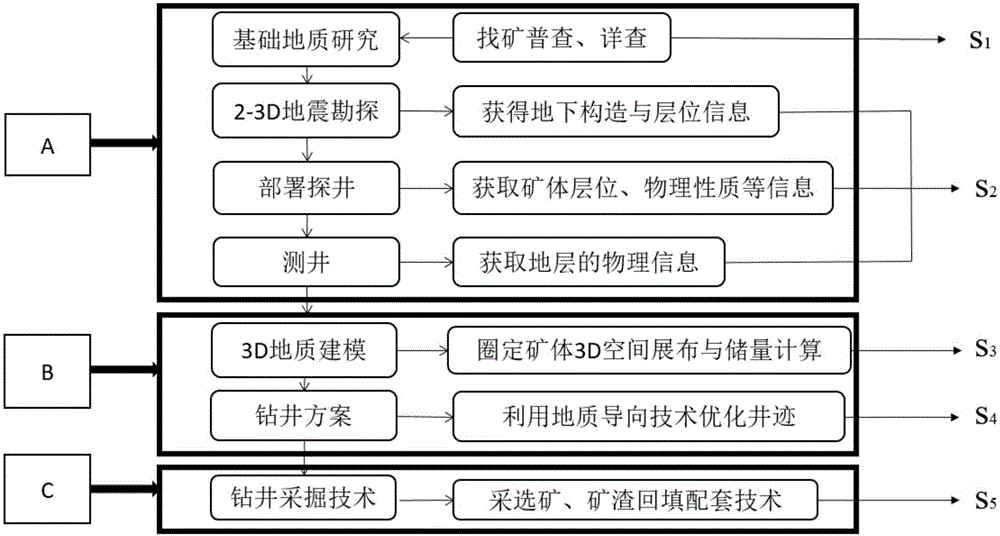

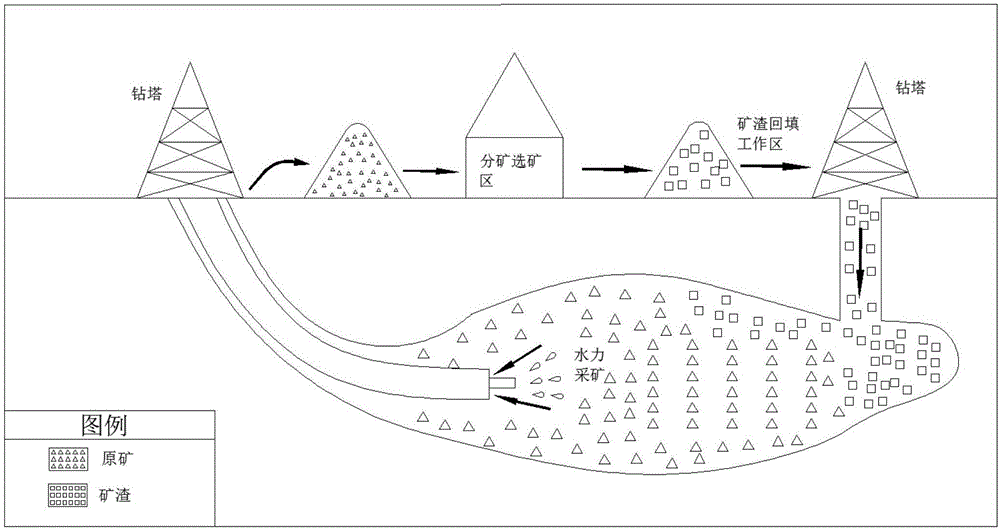

Deep intelligent coal mining method based on GGD (Geology Geophysics Drilling) concept

InactiveCN106640084AIntelligent intelligent constructionEnvironmentally friendly and intelligent constructionDetails involving processing stepsMaterial fill-upWell loggingSlurry

The invention provides a deep intelligent coal mining method based on a GGD (Geology Geophysics Drilling) concept. The deep intelligent coal mining method comprises the following steps: S1, carrying out general investigation and detailed investigation of ore prospecting according to a research theory of fundamental geology; S2, deploying well prospecting and well logging; carrying out 2D to 3D seismic prospecting to obtain physical properties and ore body position information of strata of a prospecting region; S3, carrying out 3D geological modeling, and delineating 3D space spreading of a ore body and calculating reserves; S4, designing a well drilling plan and optimizing a well track by utilizing a geology steering technology; S5, finishing an intelligent flow from mining to backfilling of whole deep ores by utilizing a well drilling and mining technology matched with mining and dressing, ore slurry reverse discharging and ore residue backfilling. According to the deep intelligent coal mining method, the drilling efficiency and quality are improved by utilizing a remote intelligent coal mining technology; meanwhile, safety accidents and environment pollution problems caused by the safety accidents are reduced and the mine exploring cost is saved; efficient, safe and environment-friendly intelligent construction of the deep ores is realized and a direction can be appointed to future development of an ore industry; upgrading of a traditional mine manufacturing industry is promoted.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

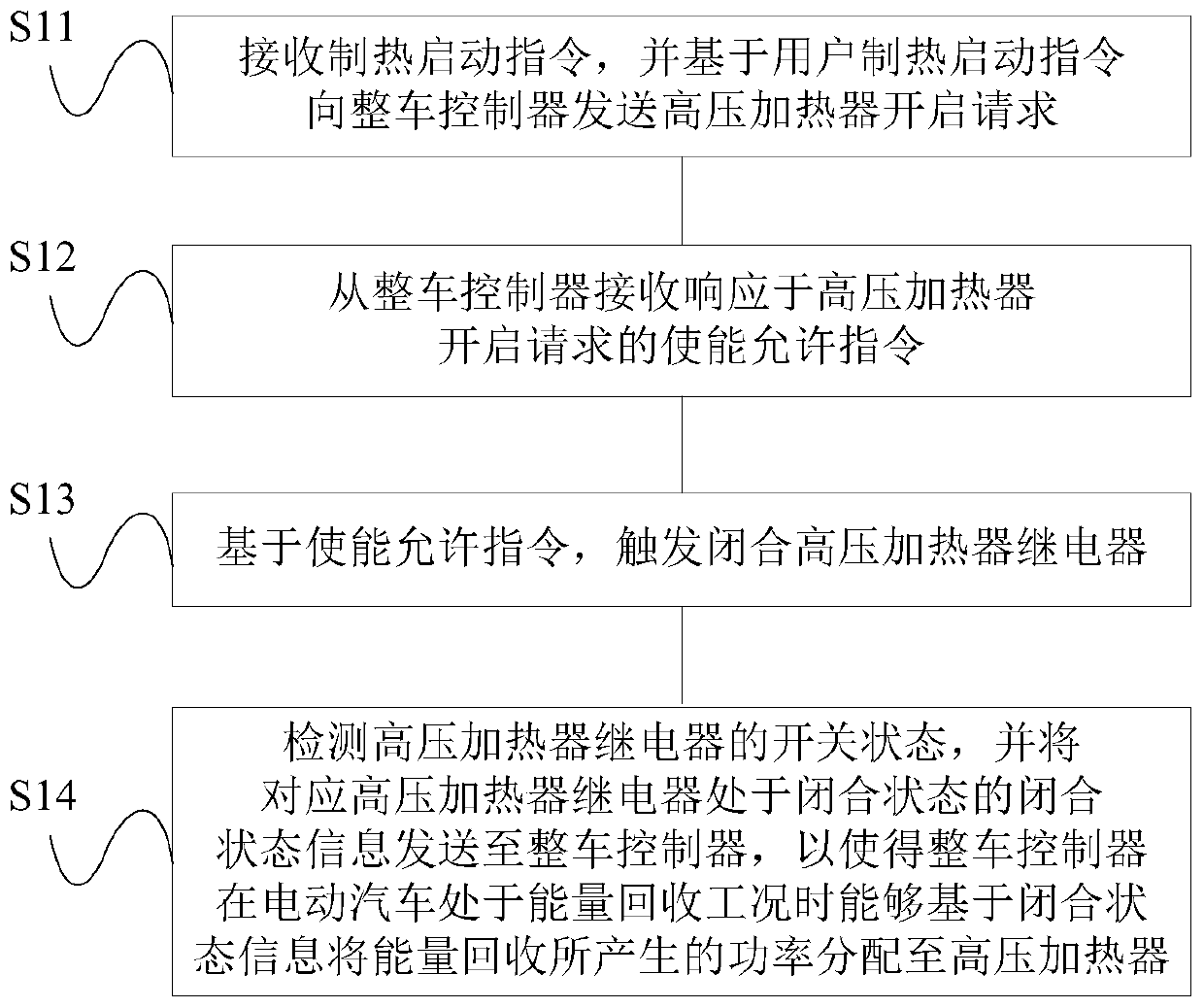

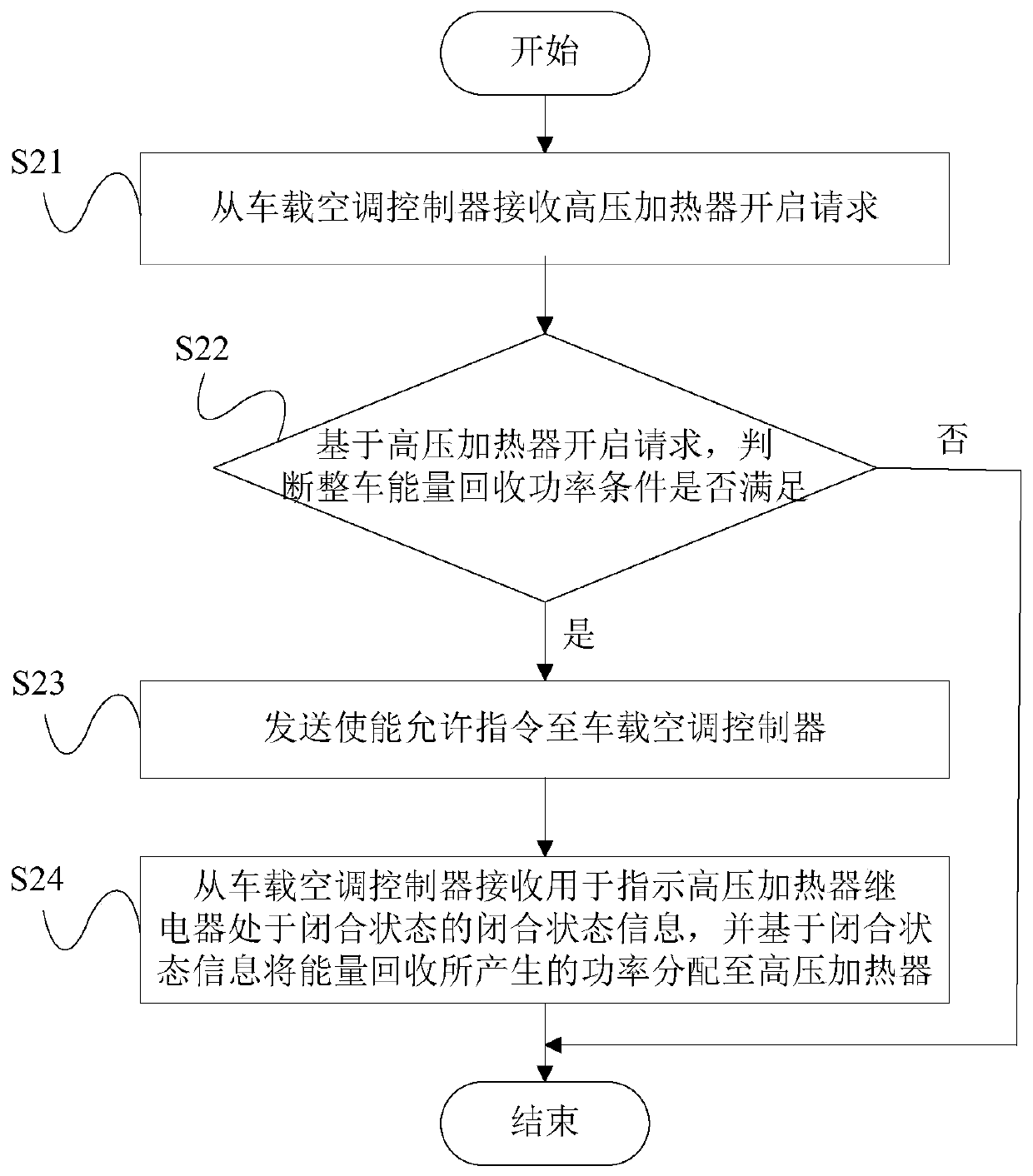

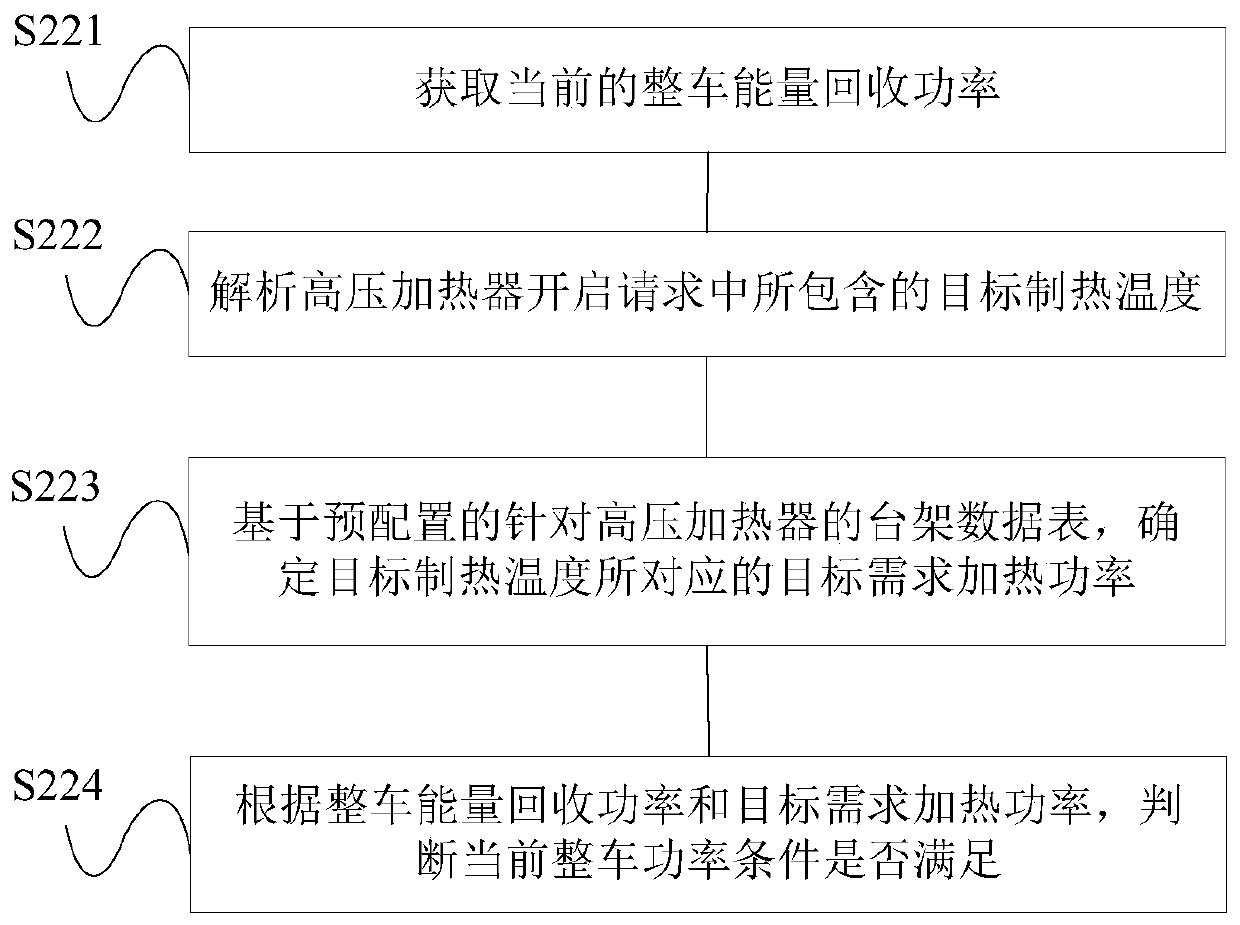

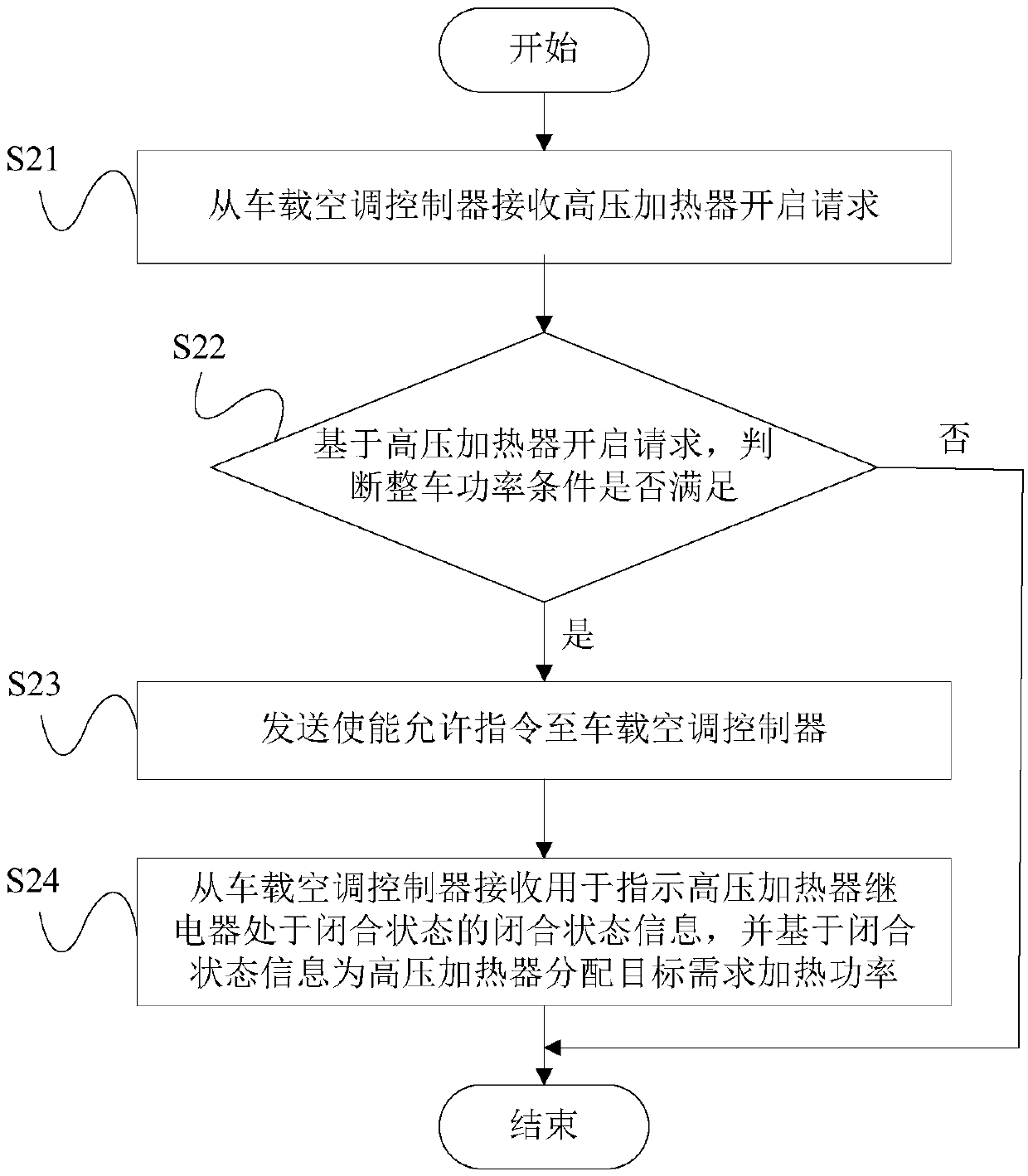

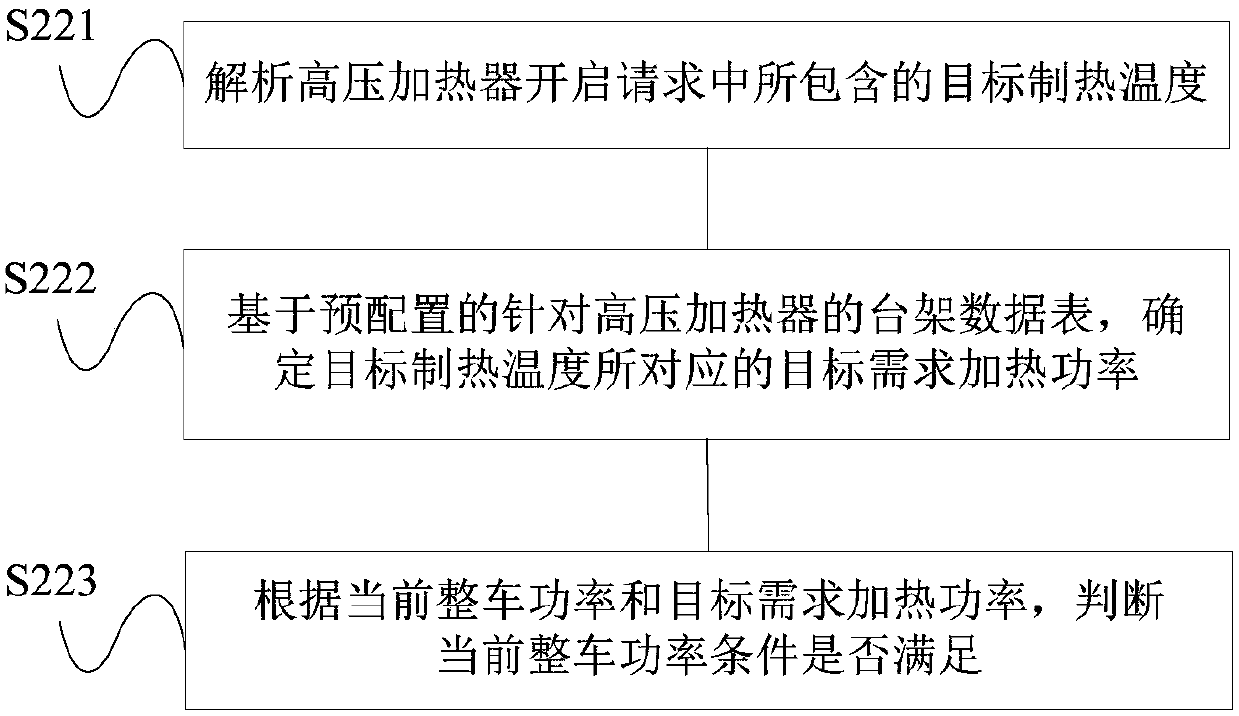

Energy recovery control method and device for electric vehicle HVH

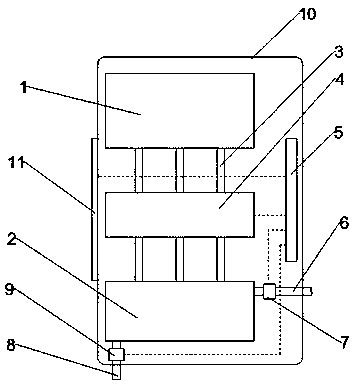

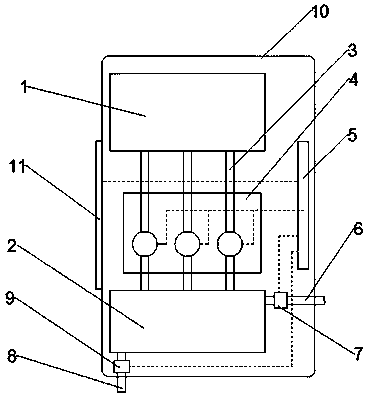

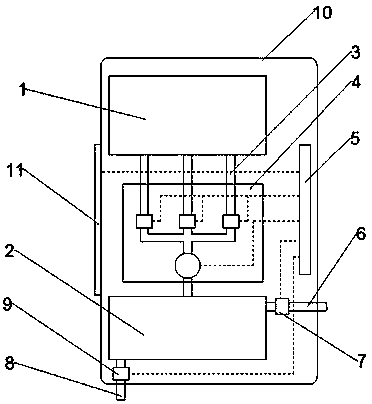

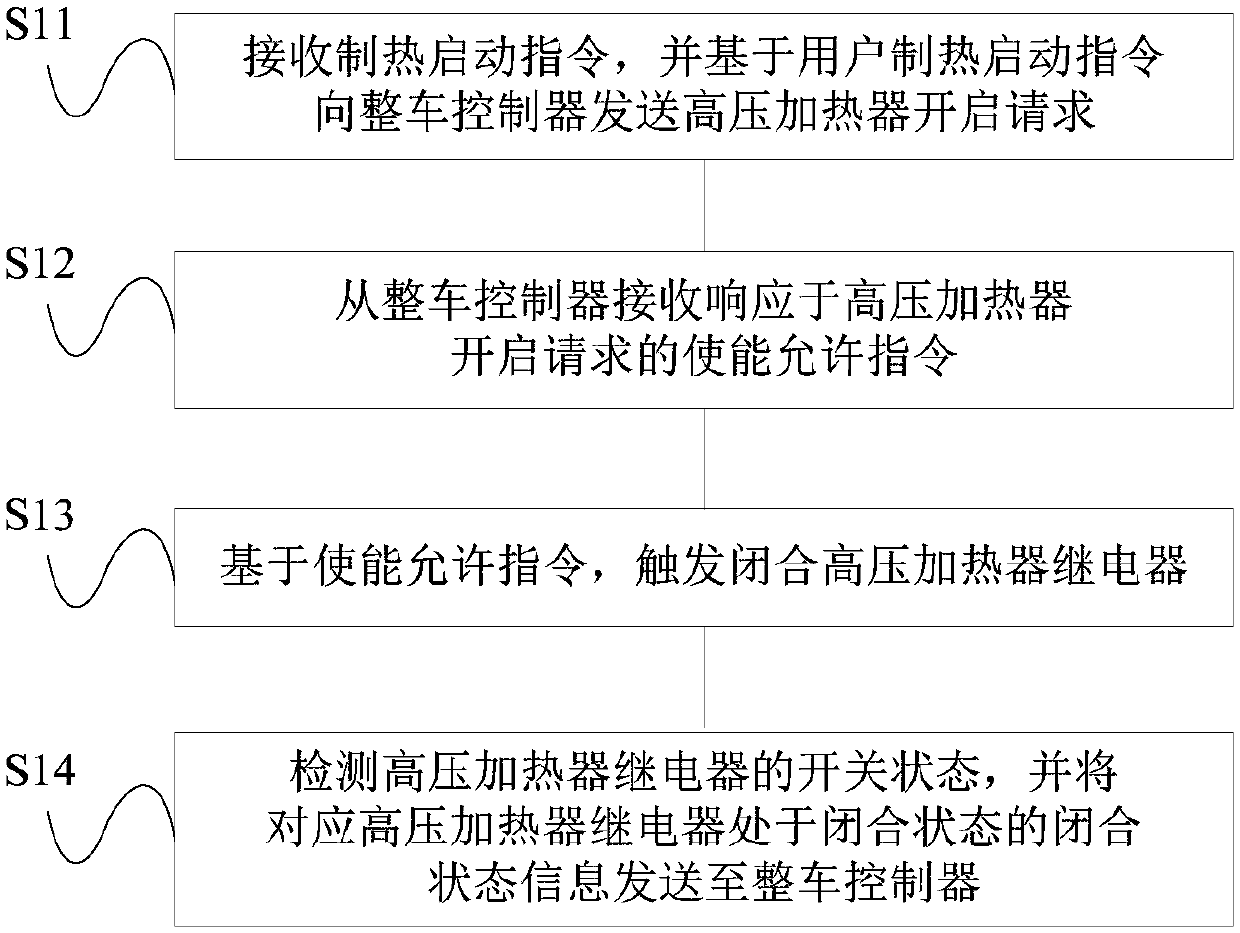

PendingCN111483287AAdvantages of recovery energy control methodAvoid the problem of overchargingAir-treating devicesVehicle heating/cooling devicesElectric vehicleControl theory

The invention relates to the field of electric vehicle control, and provides an energy recovery control method and device for the electric vehicle HVH. The method comprises the steps: receiving a heating start instruction, and transmitting a high-pressure heater start request to a vehicle control unit based on the heating start instruction; receiving an enable permission instruction in response tothe high-pressure heater starting request from the vehicle control unit; triggering closing of a high-pressure heater relay based on the enable permission instruction; and detecting the on-off stateof the high-pressure heater relay, and sending closed state information corresponding to the closed state of the high-pressure heater relay to the vehicle control unit to enable the vehicle control unit to distribute power generated by energy recovery to the high-pressure heater based on the closed state information when the electric vehicle is in an energy recovery working condition. Therefore, energy recovery power distribution is well controlled without an HVH controller, and the potential safety hazard of overcharge lithium precipitation of the battery during energy recovery heating is reduced.

Owner:GREAT WALL MOTOR CO LTD

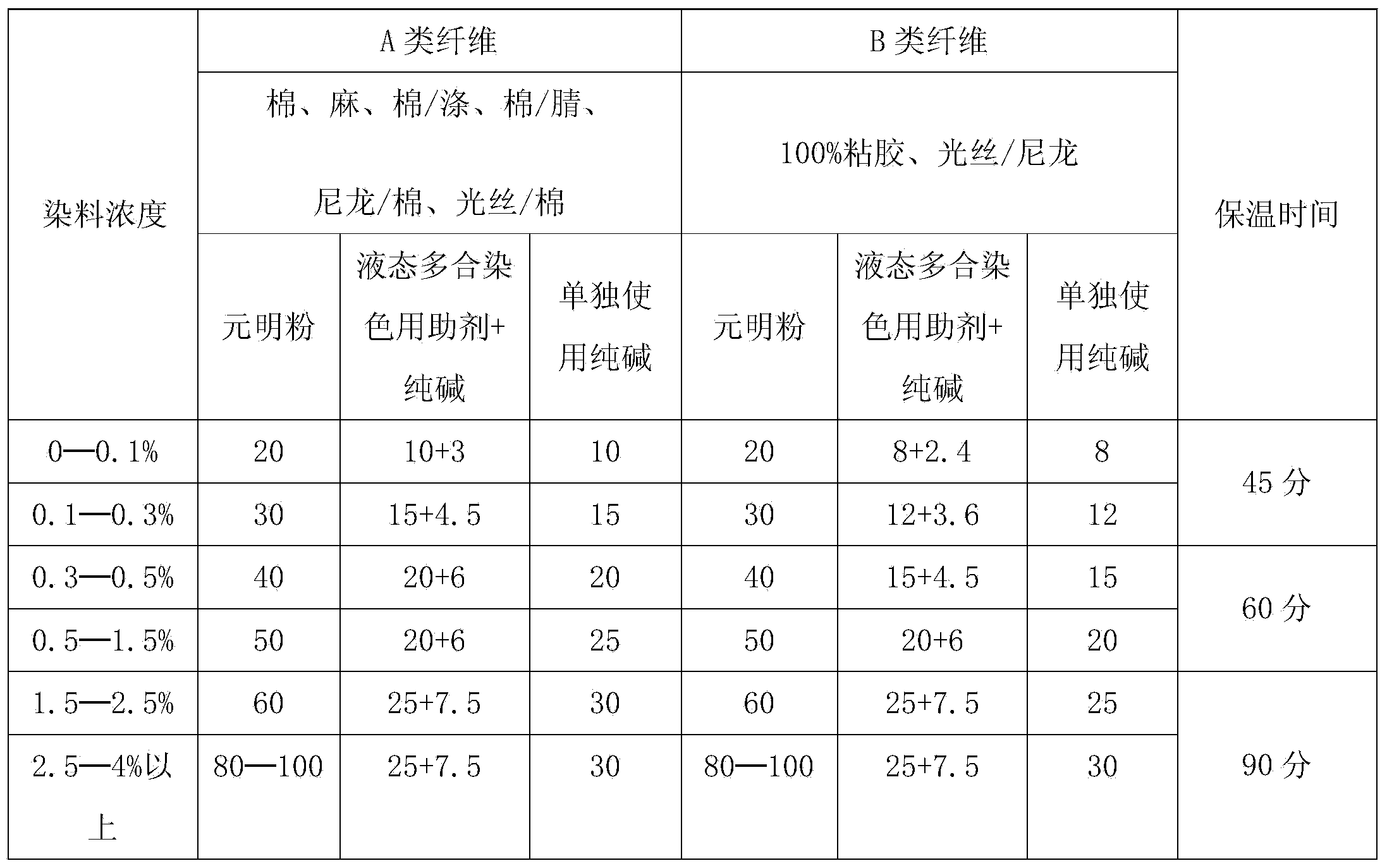

Liquid multi-dyeing auxiliary agent and using method thereof

InactiveCN104358168AAvoid cylinder differenceRapid permeation and diffusion performanceDyeing processSodium carbonateChemistry

The invention discloses a liquid multi-dyeing auxiliary agent and a using method thereof. The liquid multi-dyeing auxiliary agent is an aqueous solution of flaky sodium hydroxide, a chelating agent and sodium hexametaphosphate, including 0.5-1.5 parts of sodium hydroxide, 0.2-0.5 part of chelating agent and 0.2-1 part of sodium hexametaphosphate in part by mass; a ratio of the total mass of the sodium hydroxide, the chelating agent and the sodium hexametaphosphate to the mass of water is 2:50; the pH value of the liquid multi-dyeing auxiliary agent is 2g / L:8.5 plus or minus 1. The liquid multi-dyeing auxiliary agent can greatly reduce the using amount of conventional sodium carbonate, saves energy consumption and greatly reduces the workload; the liquid multi-dyeing auxiliary agent does not cause air pollution in the printing and dyeing process, and discharged wastewater can be easily treated; the liquid multi-dyeing auxiliary agent can prevent decline in strength of dyed and bleached fabric; the liquid multi-dyeing auxiliary agent is good in level dyeing property and can reduce the production cost.

Owner:JIANGSU MINGYANG CHEM TECH CO LTD

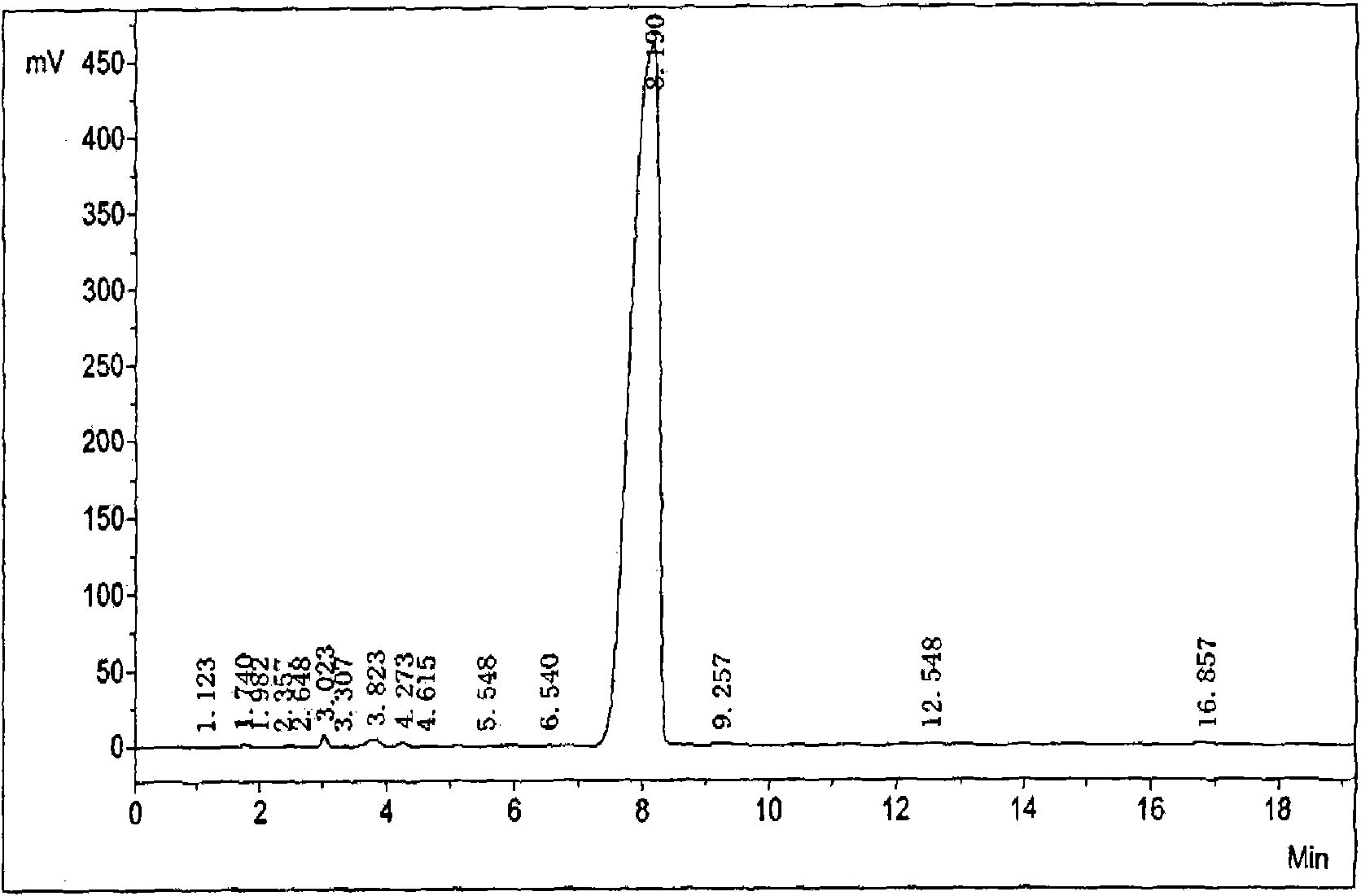

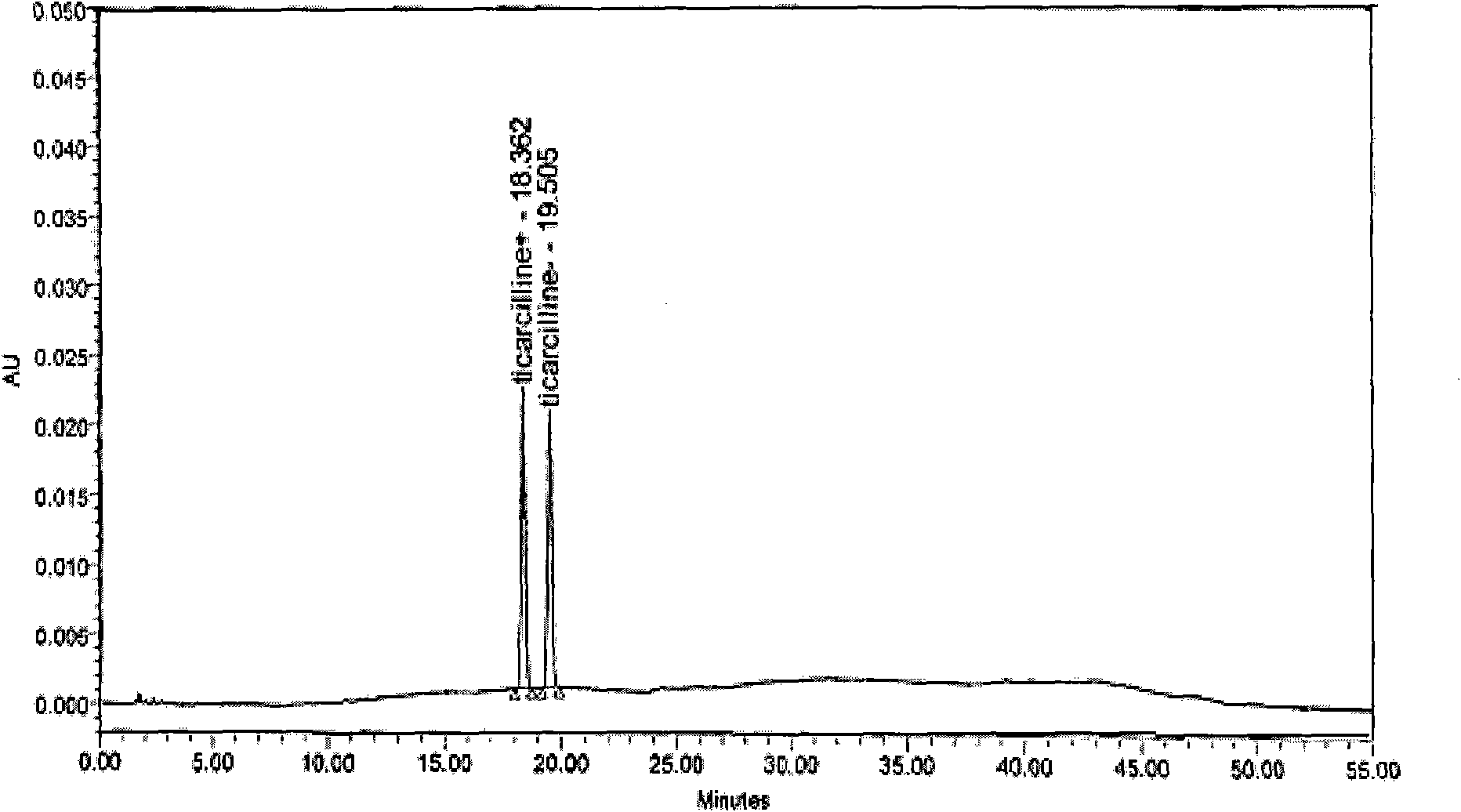

Carboxylic acid penicillin amine salt and application thereof in preparing high-purification sodium oxacillin salt

The invention relates to a carboxylic acid penicillin dibenzyl (substituting benzyl) ethylenediamine salt compound and an application thereof in preparing a high-purification sodium oxacillin salt. The carboxylic acid penicillin dibenzyl (substituting benzyl) ethylenediamine salt compound has a structure as the formula II, and carboxylic acid penicillin comprises ticacillin, carbenicillin and thelike, wherein R is thiofuran-3-group or phenyl; R1, R2 and R3 are respectively independent H, alkyls of C1-C5, halogens and nitryl; and substituent groups of the substituted alkyl are selected from the halogens and alkoxy groups of C1-C5.

Owner:QILU PHARMA HAINAN +1

Receiving equipment for nixie tube processing and working method of receiving equipment

InactiveCN113044470ASolve problems affecting the production cost of the enterpriseSolve production costConveyorsPackagingFixed bearingEngineering

The invention discloses receiving equipment for nixie tube processing and a working method of the receiving equipment , and relates to the technical field of nixie tube production equipment. A displacement conveying belt is rotatably arranged on the side wall of a vertical mounting panel, rotary connecting parts are arranged on the surfaces of a fixed support and the vertical mounting panel, a fixed bearing seat is fixedly arranged on the upper surface of a lower fixed plate, and the fixed bearing seat and the rotary connecting parts on the fixed support and the vertical mounting panel are coaxial. A rotating threaded rod is rotationally arranged in the rotary connecting part on the fixed support and the fixed bearing seat, an adjusting rotating disc is fixedly arranged at one end of the rotating threaded rod, the rotating threaded rod is in threaded connection with the interior of the rotary connecting part on the vertical mounting panel, and sliding blocks are fixedly arranged at the two ends of the interior of the vertical mounting panel correspondingly. The problem that the production cost of an enterprise is affected due to the fact that different receiving devices are adopted for nixie tubes of different specifications because the nixie tubes cannot be correspondingly adjusted according to the specifications and sizes of the nixie tubes is solved.

Owner:ANHUI MINGYANG ELECTRONICS

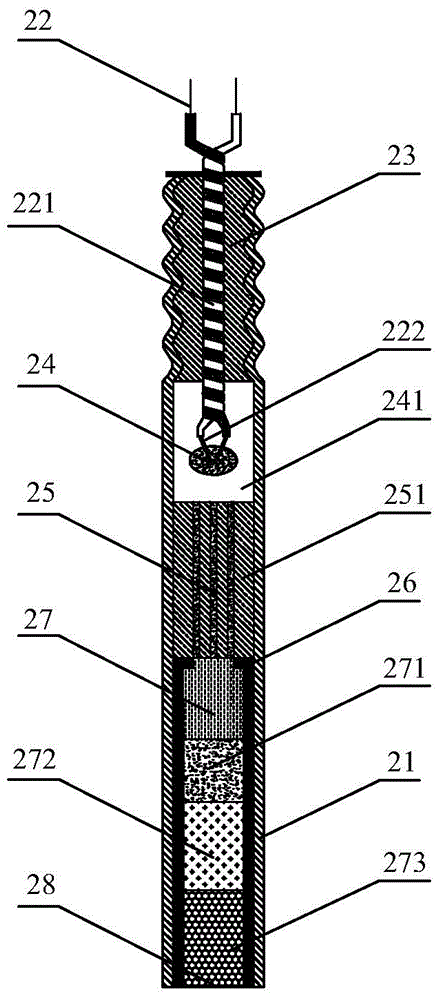

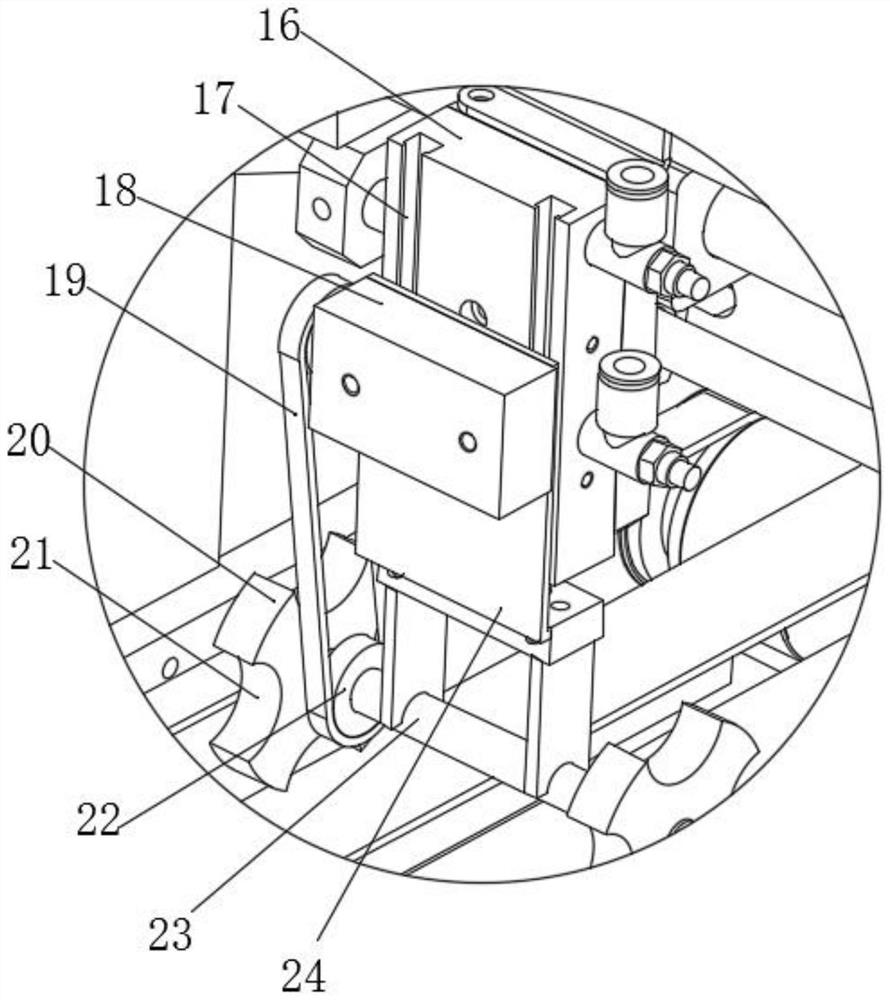

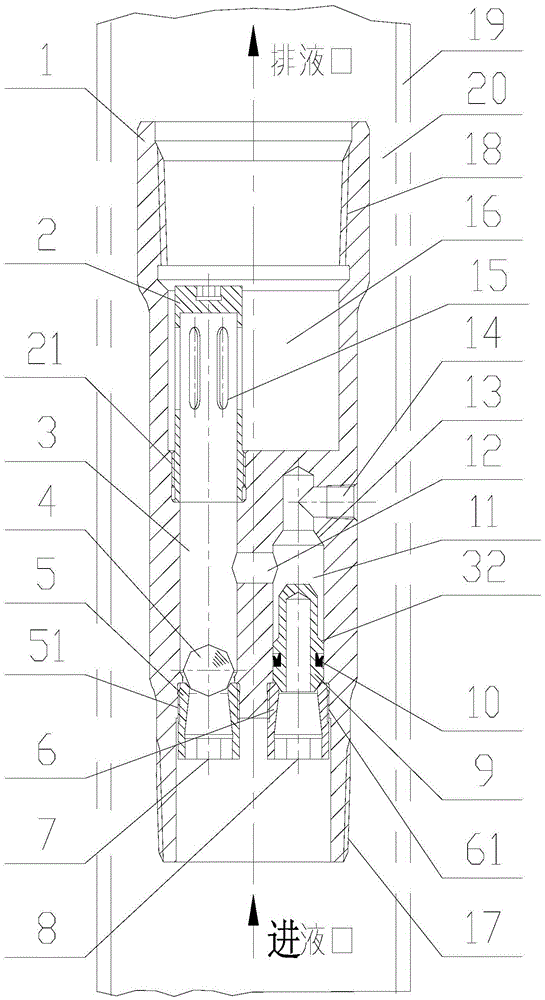

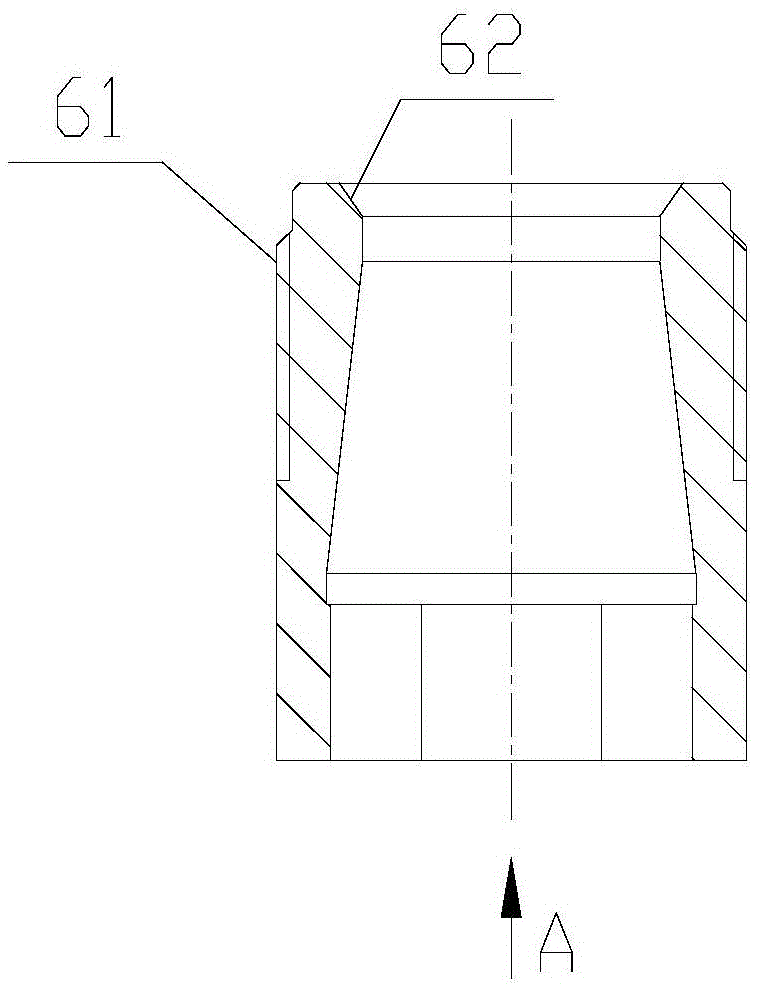

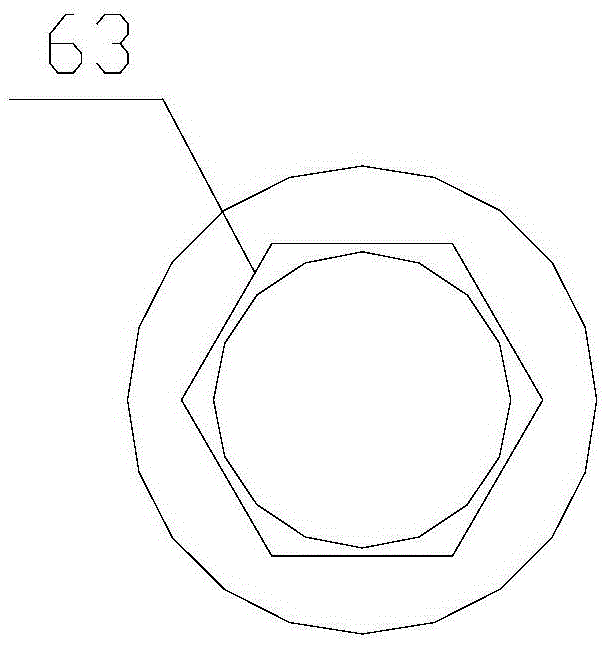

Multifunctional well washing valve for oil field electric submersible pump production oil well

ActiveCN105569607ASolve labor intensitySolve production costConstructionsWell/borehole valve arrangementsElectricityEngineering

The invention relates to a multifunctional well washing valve for an oil field electric submersible pump production oil well. The multifunctional well washing valve comprises a valve body, one end of the valve body is provided with a liquid inlet, the other end of the valve body is provided with a liquid discharge opening, and the valve body is provided with a well washing liquid opening communicated with a casing pipe annular cavity; the valve body is internally provided with a production channel and a well washing channel, and the production channel and the well washing channel are independent of each other and communicated with each other through a through hole; the production channel is internally provided with a liftable sealing part which has the one-way valve function, and the liftable sealing part can be subjected to well liquid pressure to lift and open the production channel in the production process and close the production channel in the well washing operation process; the well washing channel is internally provided with a sliding sealing part which can be ascended and descended in the well washing channel, and the sliding sealing part can be subjected to the well liquid pressure to be lifted and close the through hole and the well washing liquid opening in the production process and open the through hole and the well washing liquid opening due to drop of the well washing liquid pressure and shut off a well washing joint in the well washing process. Accordingly, cyclic well washing operation in the positive direction or the negative direction can be conducted at will, and no precedence order is required to follow.

Owner:TIANJIN YINUO SCI & TECH DEV CO LTD

Device for preparing washing addictive

ActiveCN108221287ASolve production costImprove universalityTableware washing/rinsing machine detailsOther washing machinesProcess engineeringRaw material

Provided is a device for preparing washing addictive. The device comprises a washing addictive raw material storage device, a storage device and a throw-in control device, wherein the washing addictive raw material storage device is used for storing at least one washing addictive raw material, the storage device is connected with the washing addictive raw material storage device through a throw-inpipeline and used for containing the washing addictive raw materials thrown out of the washing addictive raw material storage device, and the washing addictive raw materials are mixed to washing addictive products; the throw-in control device is arranged on the throw-in pipeline, and used for controlling the throwing-in of the washing addictive raw materials. The device directly prepares the washing addictive raw materials into the washing addictive for users to use, so that the users do not need to use the product washing addictive, and the problem that the production cost and transportationcost of the existing product washing addictive are higher is solved; the device for preparing the washing addictive can be widely applied to devices or places using the washing addictive, and achievethe universality of the application.

Owner:SHANGHAI XIAOJI INTERNET TECH CO LTD

Electric vehicle HVH driving method, vehicle-mounted air conditioner controller and whole vehicle control unit

PendingCN110696584AImprove securityGuaranteed allocated powerAir-treating devicesVehicle heating/cooling devicesIn vehicleNew energy

The invention relates to the field of new energy vehicle control, and provides an electric vehicle HVH driving method, a vehicle-mounted air conditioner controller and a whole vehicle controller. Theelectric vehicle HVH driving method comprises the steps of receiving a heating starting instruction, and sending a high-pressure heater starting request to the whole vehicle controller based on the heating starting instruction; receiving an enable permission instruction in response to the high-pressure heater starting request from the whole vehicle controller; triggering to close a high-pressure heater relay based on the enable permission instruction; and detecting the on-off state of the high-pressure heater relay, and sending the closed state information corresponding to the closed state ofthe high-pressure heater relay to the whole vehicle controller. Therefore, the problem of energy waste caused by the fact that the HVH relay does not respond to the enable permission signal to be closed is avoided, and the safety performance of the high-pressure heater in the driving process is further improved.

Owner:GREAT WALL MOTOR CO LTD

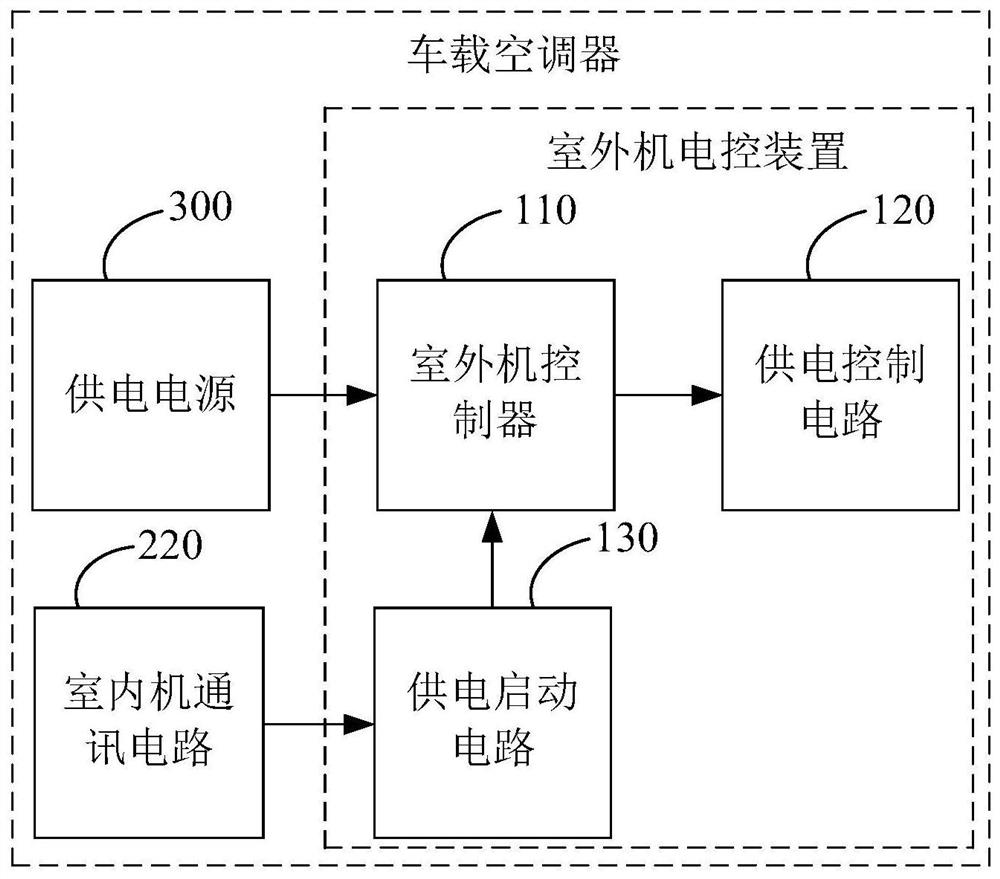

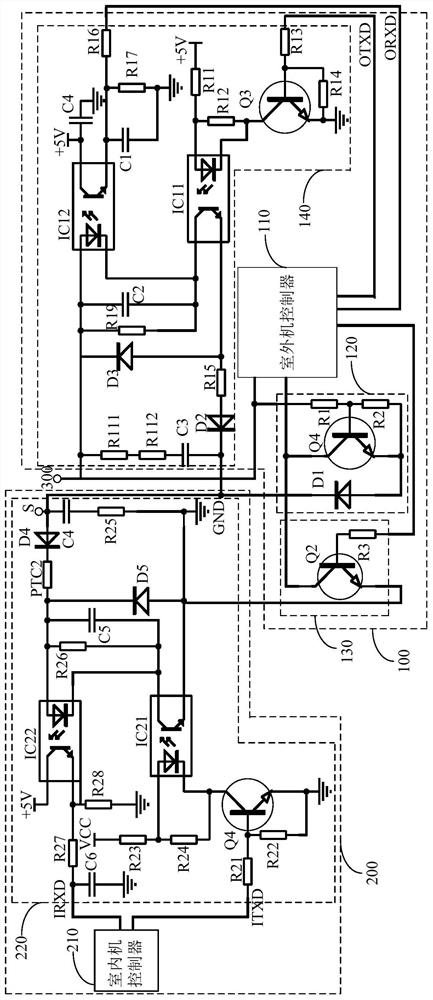

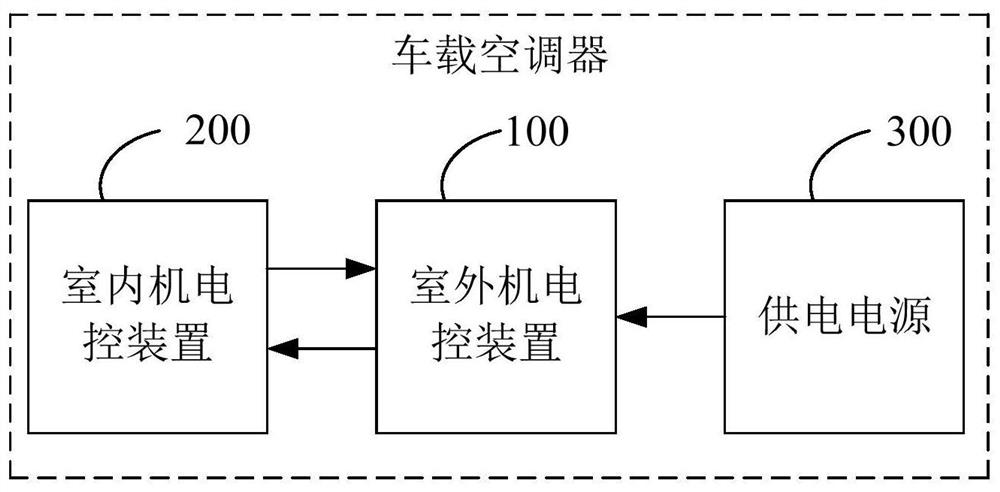

Outdoor unit electric control device and vehicle-mounted air conditioner

ActiveCN111976415AReduce standby power consumptionSolve production costAir-treating devicesVehicle heating/cooling devicesIn vehicleStandby power

The invention discloses an outdoor unit electric control device and a vehicle-mounted air conditioner. The outdoor unit electric control device comprises an outdoor unit controller, a power supply starting circuit and a power supply control circuit; the power supply end of the outdoor unit controller is used for being connected into a power supply; the power supply starting circuit is provided with a signal receiving end connected with a signal sending end of an indoor unit communication circuit and is connected with the ground terminal of the outdoor unit controller to provide a first power supply loop for the outdoor unit controller; the power supply starting circuit receives a communication signal outputted by the indoor unit through the signal receiving end and switches on the first power supply loop of the outdoor unit controller according to the communication signal; the controlled end of the power supply control circuit is connected with the outdoor unit controller and is used for providing a second power supply loop for the outdoor unit controller; and when a standby signal outputted by the outdoor unit controller is received, the second power supply loop of the outdoor unit controller is disconnected. The outdoor unit electric control device solves the problems that the standby power consumption of an air conditioner is large, and power supply of the outdoor unit is controlled by the indoor unit through additionally arranging a wire to cause communication design is complicated.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

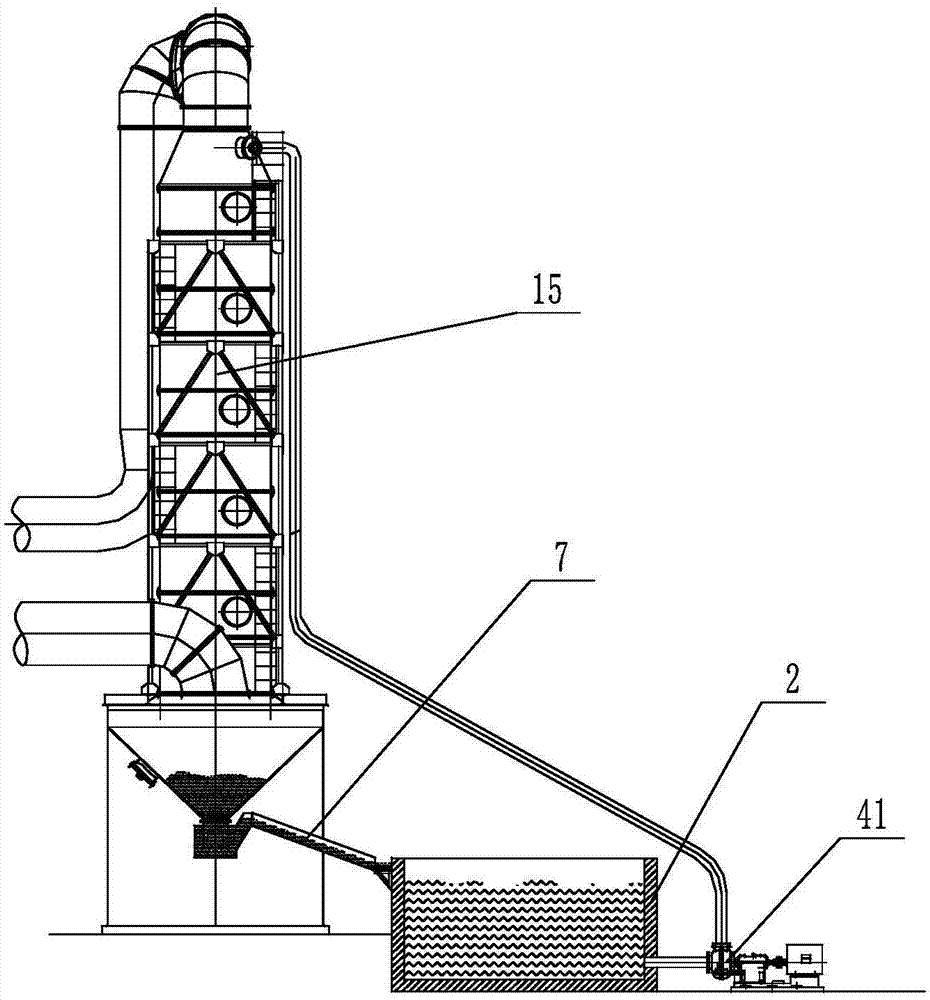

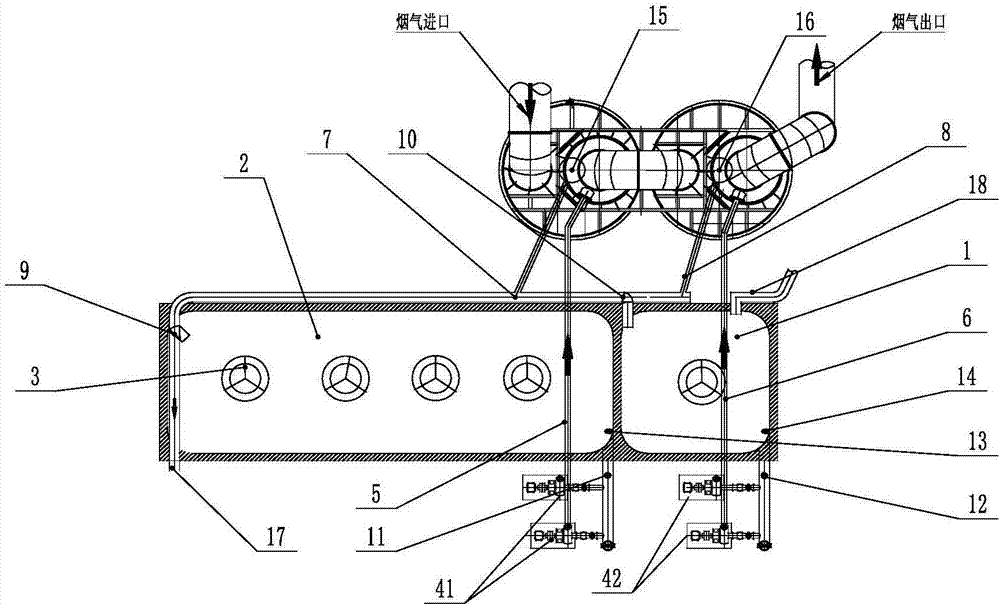

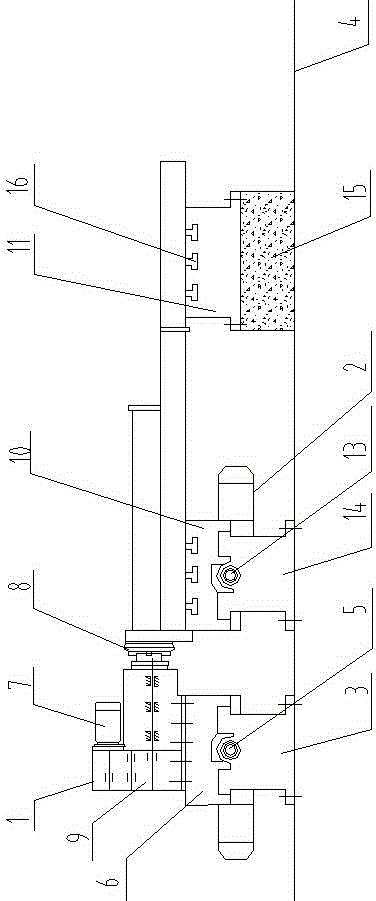

Device and method of preventing lime milk in smelting desulfurization system from scaling

ActiveCN107261799ATimed drainageSolve the problem of deposit scalingGas treatmentDispersed particle separationSlagWater level

Disclosed are a device and method of preventing lime milk in a smelting desulfurization system from scaling. The device comprises a raw slurry pond, an aeration pond, mixers, slag-slurry pumps, slag-slurry pump tubes, lime chutes, lime milk automatic splitters, automatic pH testing apparatus and water level monitors. The device and method of preventing lime milk in the smelting desulfurization system from scaling provided by the invention realize timed discharging of water and slag of lime milk in a DS multiphase reactor, solve the problem that the lime milk is deposited and scales in the raw slurry pond, the aeration pond and DS tower sections, the problem of low utilization rate of the lime milk, the problem of production cost, the problem of environmental pollution and the problem of occupational hazard.

Owner:HUAIHUA CHENZHOU MACHINERY

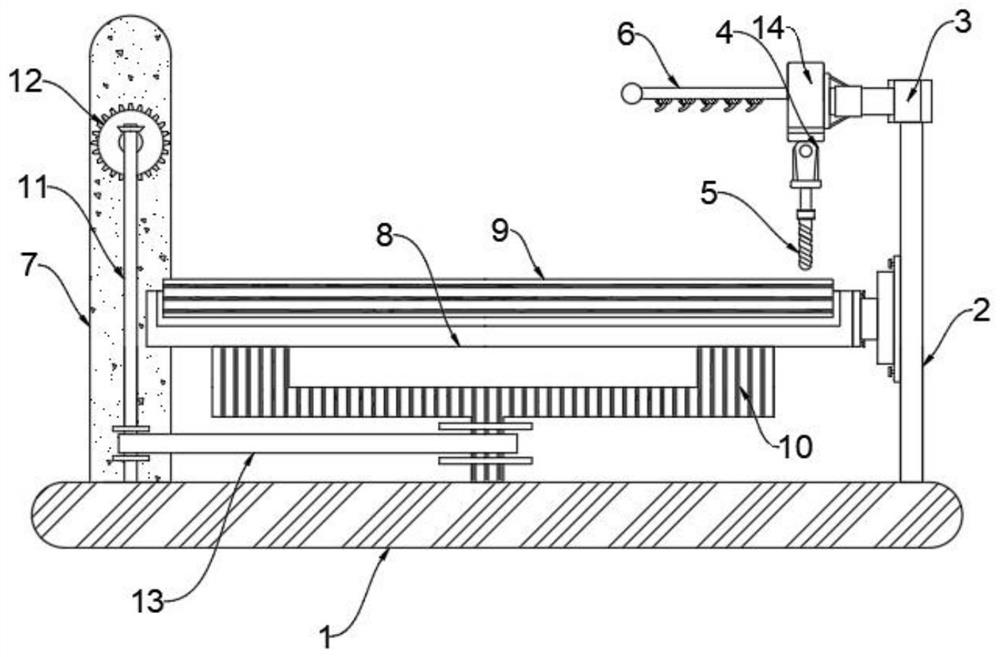

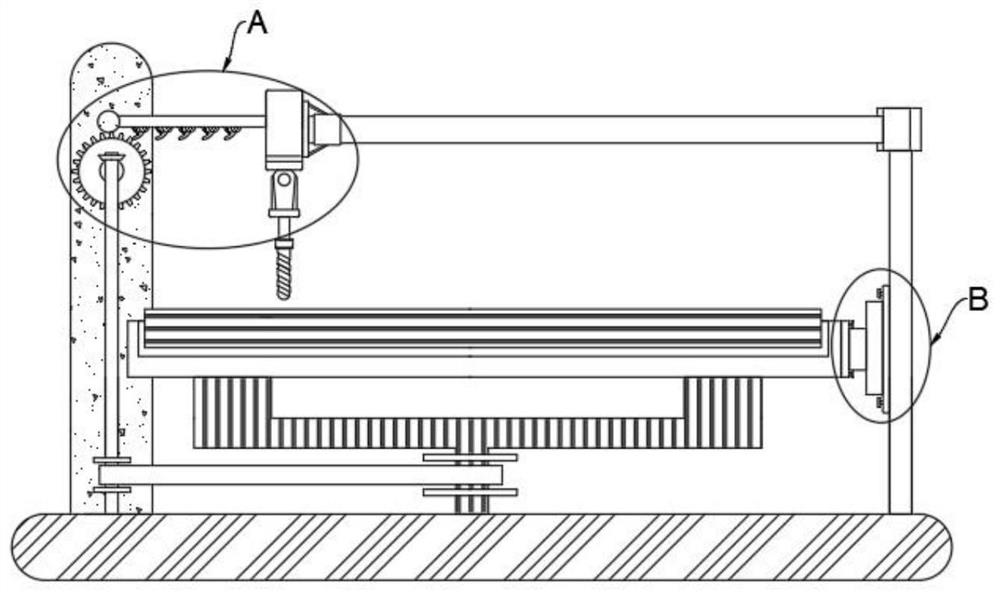

Milling machine tool device for processing fire grates

InactiveCN104400089AOvercome processing difficultiesGuaranteed normal processingLarge fixed membersMilling equipment detailsMilling cutterEngineering

The invention relates to a milling machine tool device for processing fire grates. The device comprises a milling device, and a work table group arranged on one side of the milling device, wherein the milling device comprises a milling head base; a first sliding platform is arranged above the milling head base through a first sliding screw rod in a transmission manner; a power device and a milling cutter disk are arranged on the first sliding platform and are in transmission through a gear; the work table group comprises a first work table and a second work table, wherein the first work table is arranged above a platform bracket through a second sliding screw rod in a transmission manner; the second work table is fixedly arranged above a cement boss through a bolt and the upper surface of the second work table and the upper surface of the first work table are on the same level surface; a plurality of T-shaped grooves for tooling grate processing parts are respectively formed in the upper surfaces of the first work table and the second work table. The milling machine tool device disclosed by the invention improves the production efficiency, and effectively solves the problems of high production cost and long production cycle of equipment.

Owner:JIANGSU TIANYING ENVIRONMENTAL PROTECTION ENERGY COMPLETE EQUIP CO LTD

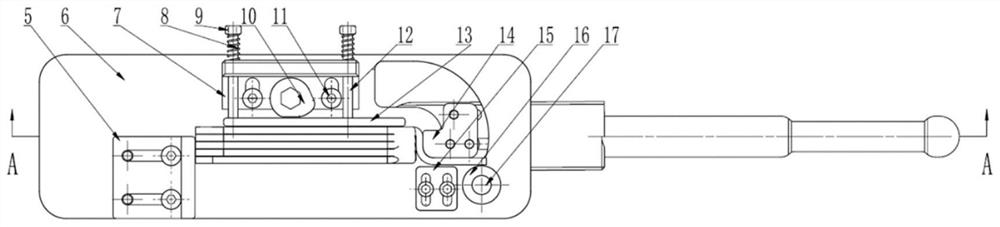

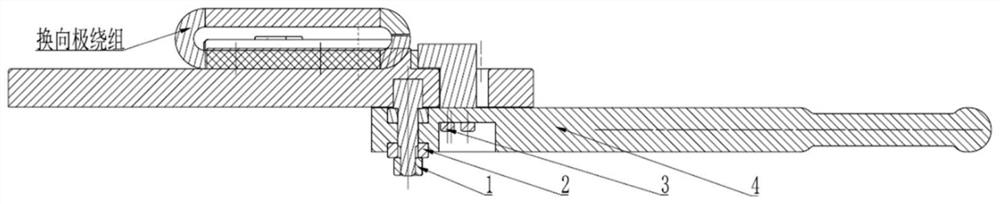

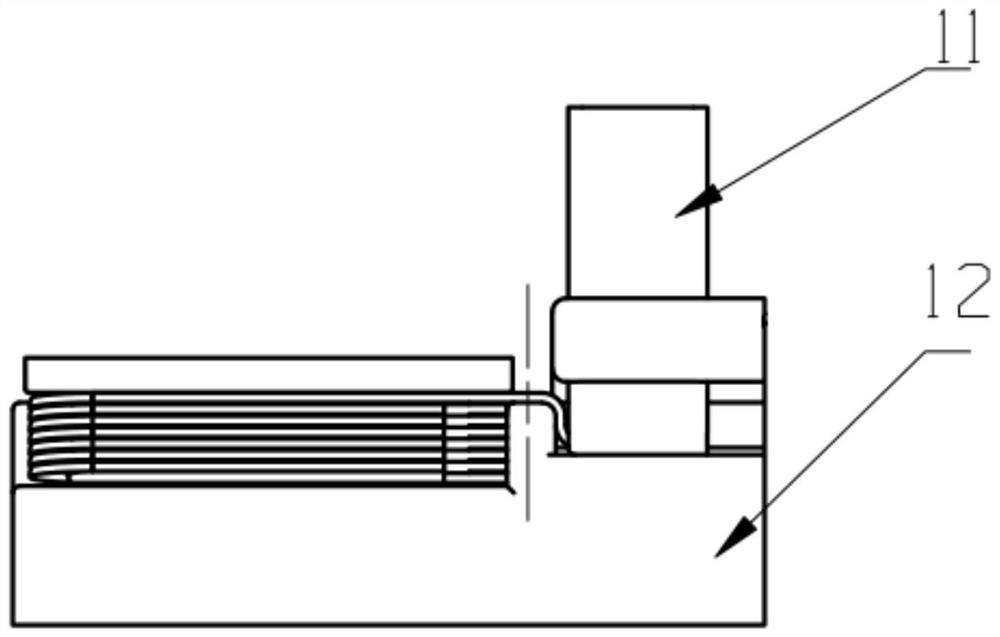

Adjustable commutation pole winding end forming device

PendingCN113284738ASolve production costReduce manufacturing costInductances/transformers/magnets manufactureControl engineeringControl theory

The invention provides an adjustable commutation pole winding end forming device. The adjustable commutation pole winding end forming device comprises a forming base. A first positioning block and a second positioning block are arranged on the front portion and the rear portion of the forming base respectively, a rotatable handle assembly is arranged at the bottom of the forming base, and a pressing plate support is arranged on one side of the forming base. According to the invention, the requirement for the space of the end bending position of the winding is low, the influence of a narrow space is avoided, one set of device can be suitable for forming windings of different models and specifications within a certain range by adjusting the positioning block and the forming block, and the universality is high. The problems of complicated operation, paint film damage and poor universality of the original structure are solved, and the problems of tool production cost, management cost and the like are reduced; and the structure is simple, operation is convenient, forming precision is high, labor intensity is low, machining efficiency is improved, and practicability and universality are wide.

Owner:GUIZHOU AEROSPACE LINQUAN MOTOR CO LTD

Stamping process of double-folded-edge back plate structure

ActiveCN112355577AReasonable and efficient processingAvoid situations where foreign objects are easily scrapedPhotovoltaic energy generationPunchingStructural engineering

The invention discloses a stamping process of a double-folded-edge back plate structure. The stamping process comprises the following steps that S1, protruding is conducted, specifically, protruding is conducted on a middle forming area of a back plate to form a convex hull structure, meanwhile, hole drawing is conducted on the back plate at the periphery, and a circle of semicircular deep drawingribs are arranged on the periphery; S2, plane shaping and partial edge cutting are conducted, specifically, a cutting device is used for conducting cutting treatment on part of the edge of the back plate; S3, edge cutting and punching are conducted, specifically, the cutting device is used for conducting cutting treatment on the outer dimension of the back plate, and then a punching device is used for conducting punching treatment on the positions of screw holes in the periphery of the back plate; and S4, bending and positioning convex point forming are conducted, specifically, a bending device is used for bending the edge of the back plate by a certain angle, and then the folded edge is bent again. According to the stamping process of the double-folded-edge back plate structure, throughimplementation of the whole process of the stamping process of the double-folded-edge back plate structure, double folded edges are used for replacing a traditional single-folded-edge structure machining process, and machining of the whole back plate is more reasonable and efficient.

Owner:冠鸿光电科技(武汉)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com