Milling machine tool device for processing fire grates

A milling device and milling technology, applied in the direction of metal processing machinery parts, milling machine equipment, milling machine equipment details, etc., can solve problems such as processing difficulties in large-scale grate workpieces, solve production costs and production cycles, improve production efficiency, overcome Difficult to process effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

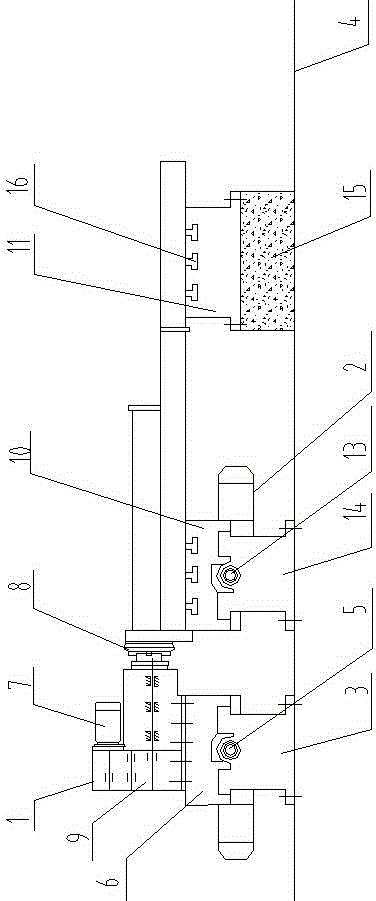

[0007] Such as figure 1 As shown, the present invention includes a milling device 1, a workbench group 2 arranged on one side of the milling device 1; the milling device 1 includes a milling head base 3, and the milling head base 3 is arranged above the foundation 4 by bolts; above the milling head base 3 The first sliding platform 6 can be set by the transmission of the first sliding screw mandrel 5; the power unit 7 and the milling cutter disc 8 are set on the first sliding platform 6, and the power unit 7 is connected with the milling cutter disc 8 and drives the milling cutter disc 8 to rotate , between the power unit 7 and the milling cutter disc 8 through gear 9 transmission; the workbench group 2 includes a first workbench 10 and a second workbench 11, and the first workbench 10 is arranged between the milling device 1 and the second workbench 11 Between, the first workbench 10, the second workbench 11 and the milling device 1 are arranged on the same axis; the first wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com