Patents

Literature

42results about How to "Overcome processing difficulties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

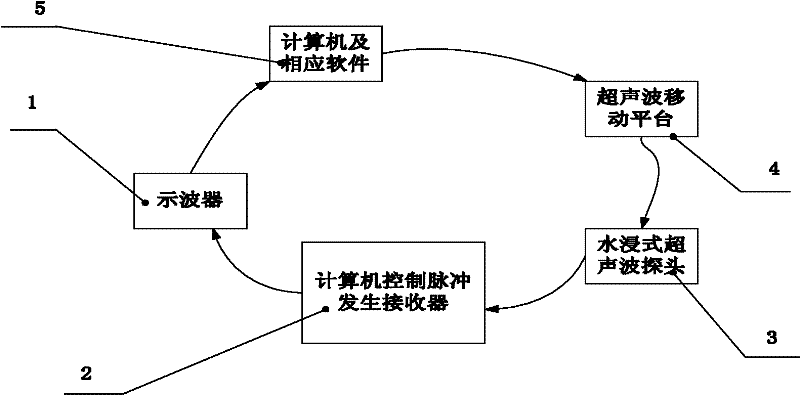

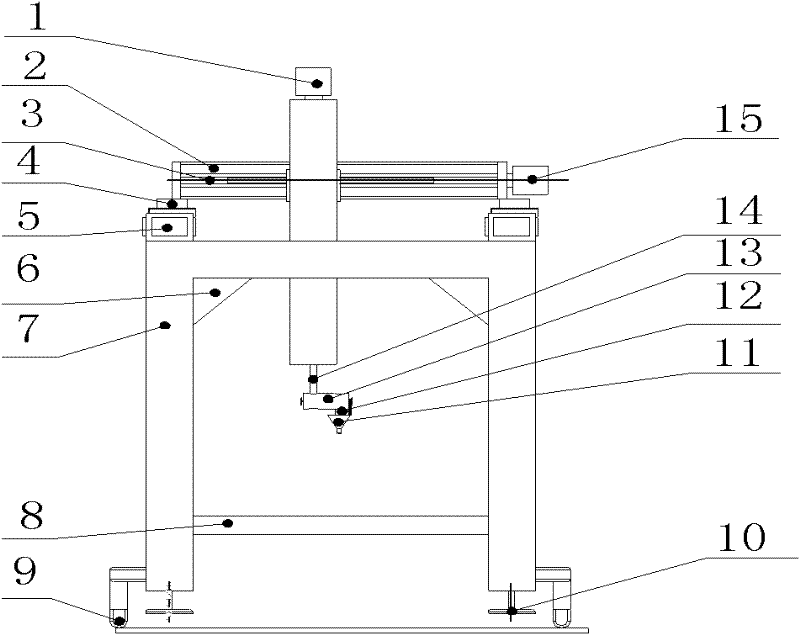

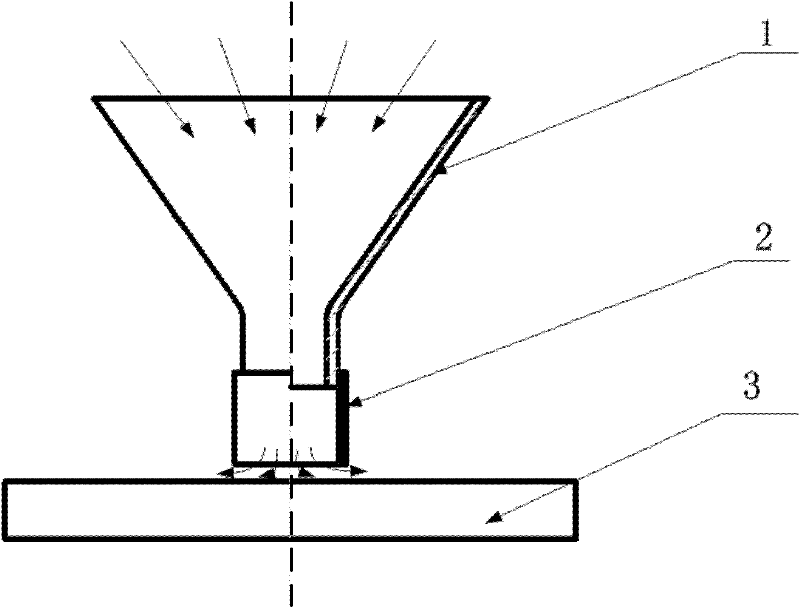

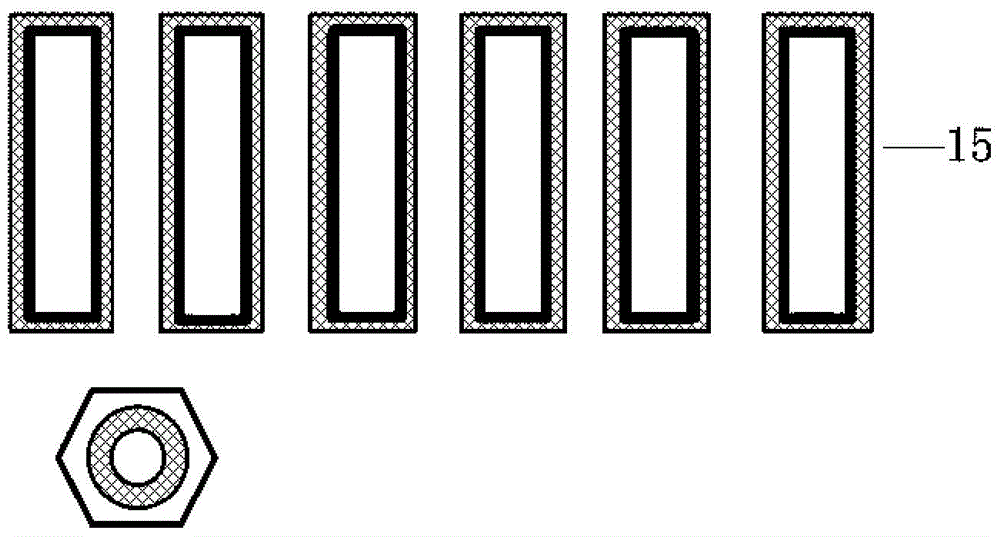

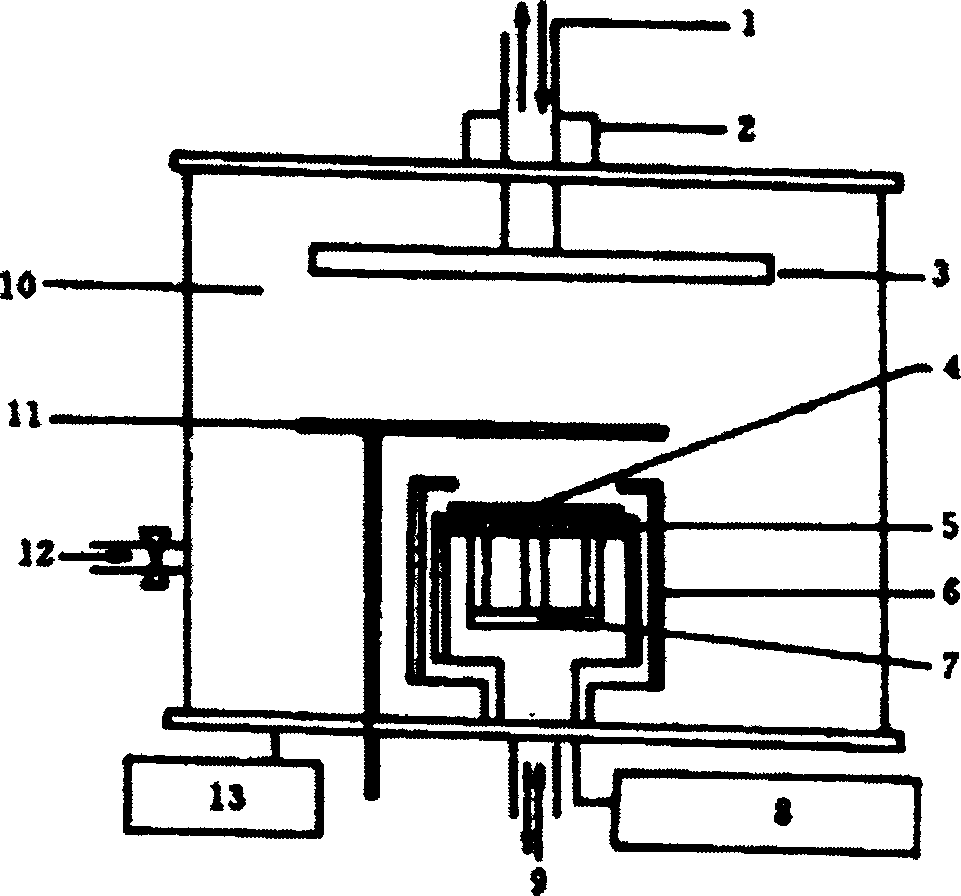

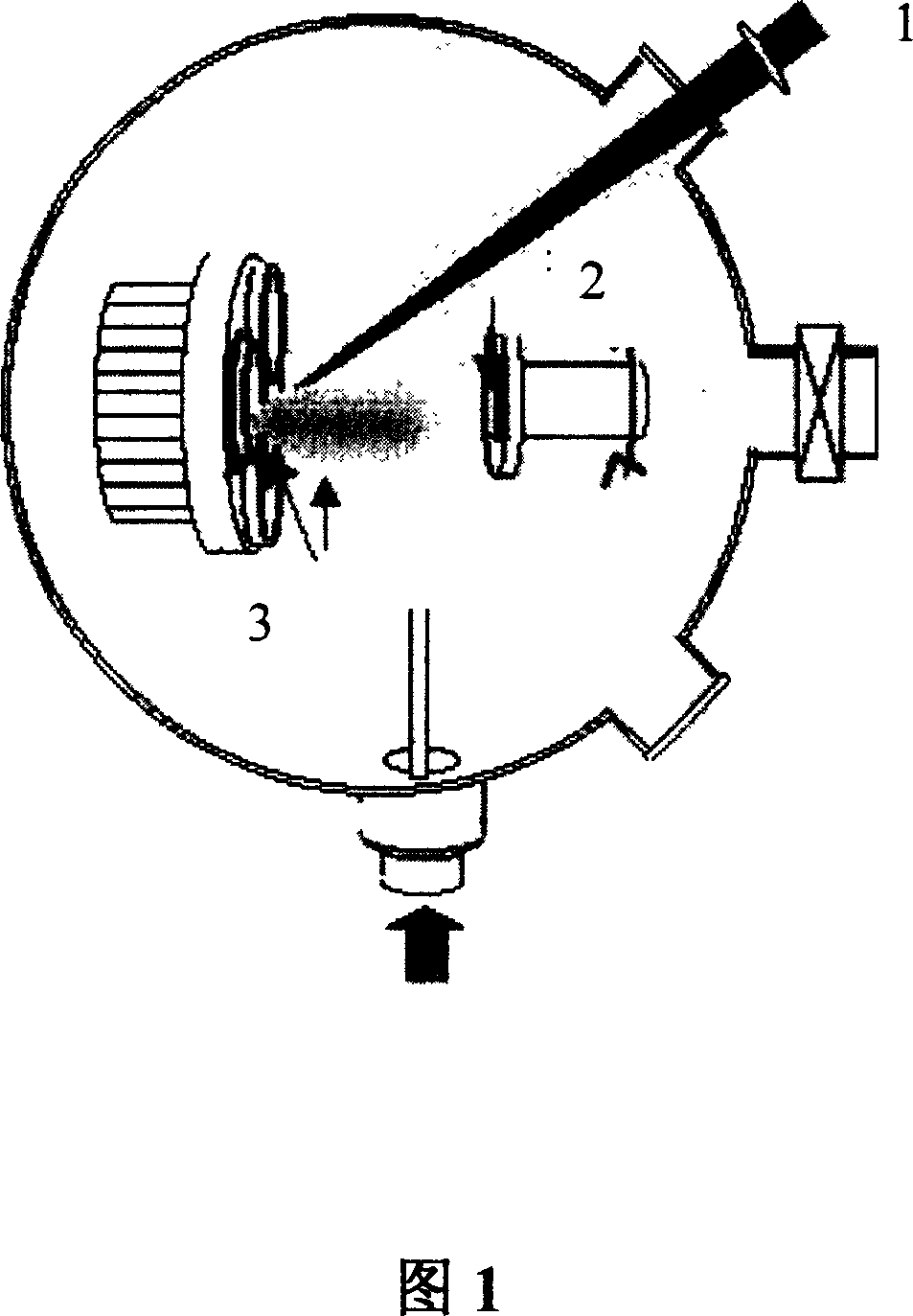

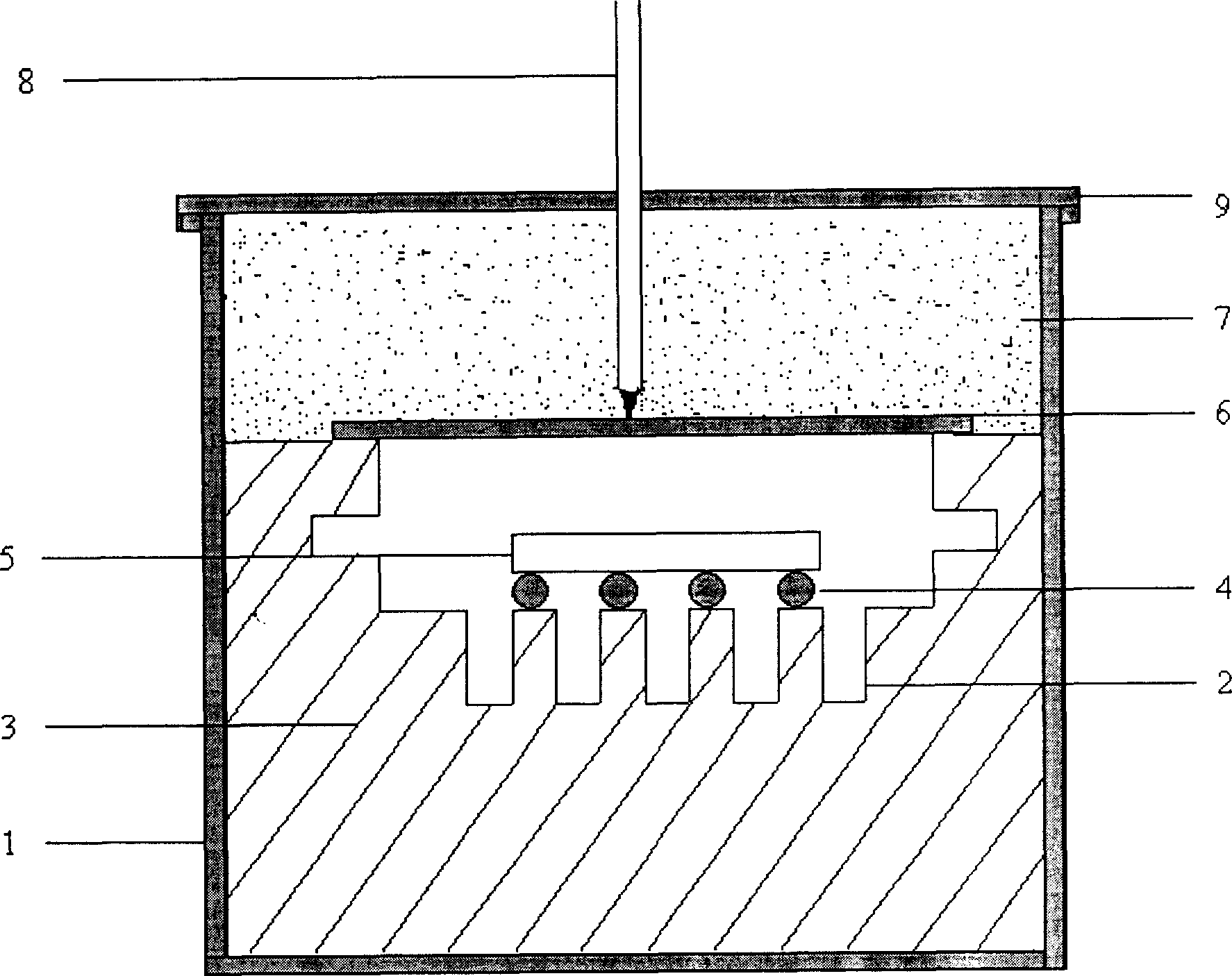

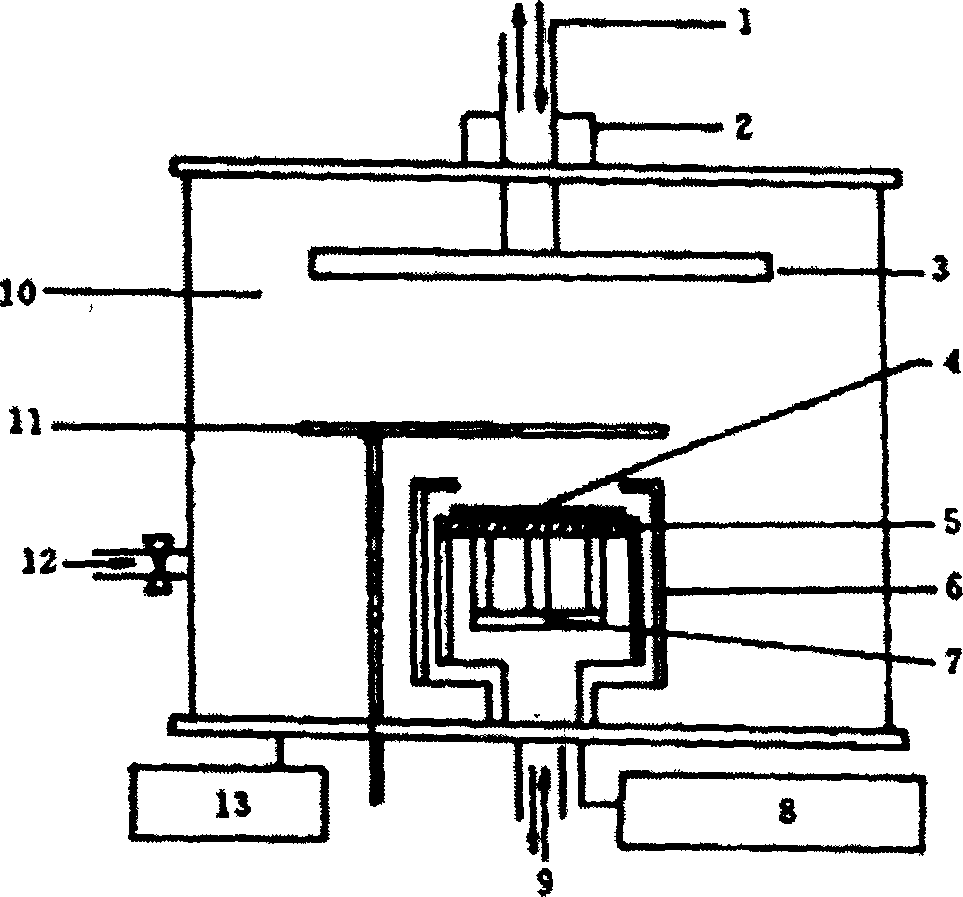

Ultrasonic detection device and data processing method for bolt joint surface

ActiveCN102297761AOvercome processing difficultiesIncrease horizontal resolutionMachine part testingAnalysing solids using sonic/ultrasonic/infrasonic wavesSupersonic wavesImage resolution

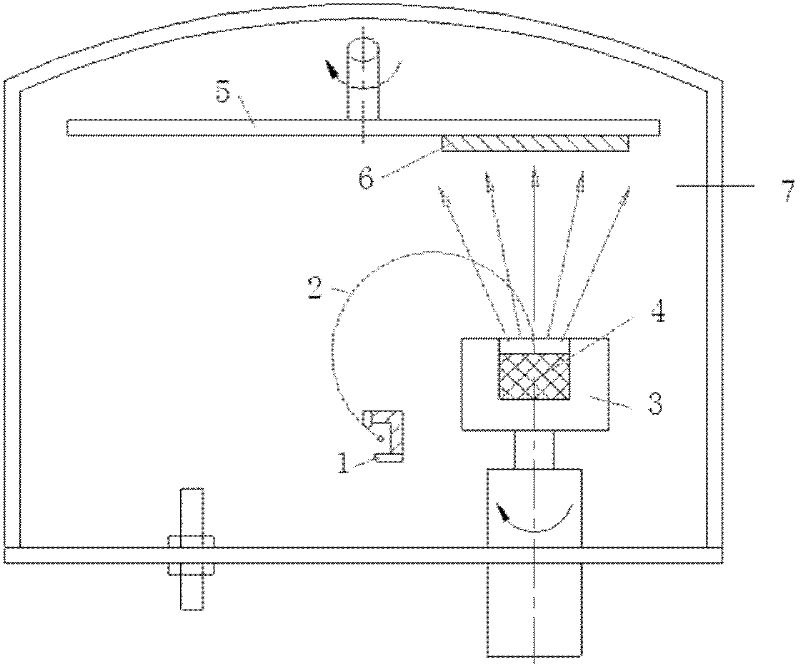

The invention discloses a bolt faying face supersonic wave detection apparatus and a data processing method thereof. The apparatus comprises a mobile platform which is composed of a mobile support and a micro-motion measuring mechanism, and is suitable for measurement of any large-scale bolt faying face. An accurate angular displacement bench in the mobile platform can adjust an angle of an ultrasonic transducer accurately, and detection precision and efficiency are raised. According to the data processing method, a problem of image processing difficulty caused by a measuring result when detecting the bolt faying face is overcome, and a problem of an unsatisfactory image restoration result by employing a traditional Wiener filtering method is solved. According to the method, lateral resolution of an ultrasonic c scanning image is greatly raised.

Owner:XI AN JIAOTONG UNIV

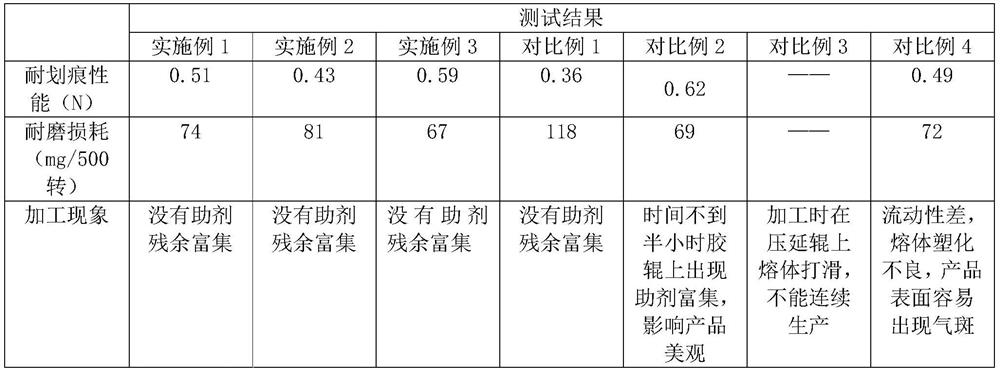

Polyformaldehyde composite material and preparation method thereof

ActiveCN102417690AOvercome processing difficultiesImprove processing efficiencyPolytetrafluoroethyleneThermoplastic polyurethane

The invention relates to a polyformaldehyde composite material, comprising 70-80 weight portions of polyformaldehyde resin, 10-15 weight portions of flexibilizer, 2-2.5 weight portions of silicone oil, 0.3-0.4 weight portions of antioxidant and 8-15 weight portions of wear-resisting agent. The polyformaldehyde composite material has the advantages of excellent wear resistance, low temperature resistance, no noise and the like. According to the invention, by adding teflon as the wear-resisting agent in molecules, the wear resistance of the product is good; by using the thermoplastic polyurethane as the flexibilizer, the low temperature toughness of the product is effectively improved at the same time the wear resistance and mechanical strength of the product are guaranteed. In addition, the invention further relates to a preparation method of the polyformaldehyde composite material.

Owner:古道尔工程塑胶(深圳)有限公司 +1

Finish machining process for cold-punching special-shaped square holes

The invention discloses a finish machining process for cold-punching a special-shaped square hole. The square hole is roughly machined, an amount of 0.5mm is left on each side of a material, a square hole-punching punch die is used for first punching off 0.3mm and then finish-punching off 0.2mm on a punch, and thereby a finished product is machined.

Owner:ZHUANGHE TIANCHENG MACHINERY

Process for preparing coated potato pieces using pregelatinized starch

InactiveUS20060045956A1Reduce brittlenessImprove sensory qualityFood coatingFood preparationViscosityHigh amylose

The invention provides methods for coating potato strips using low levels of pre-gelled modified starches characterized by a Brookfield viscosity of from 15 to 100 cp when measured on a 6% solids basis. The invention also provides methods for coating potato strips using low levels of high amylose starches.

Owner:PENFORD FOOD INGREDIENTS +1

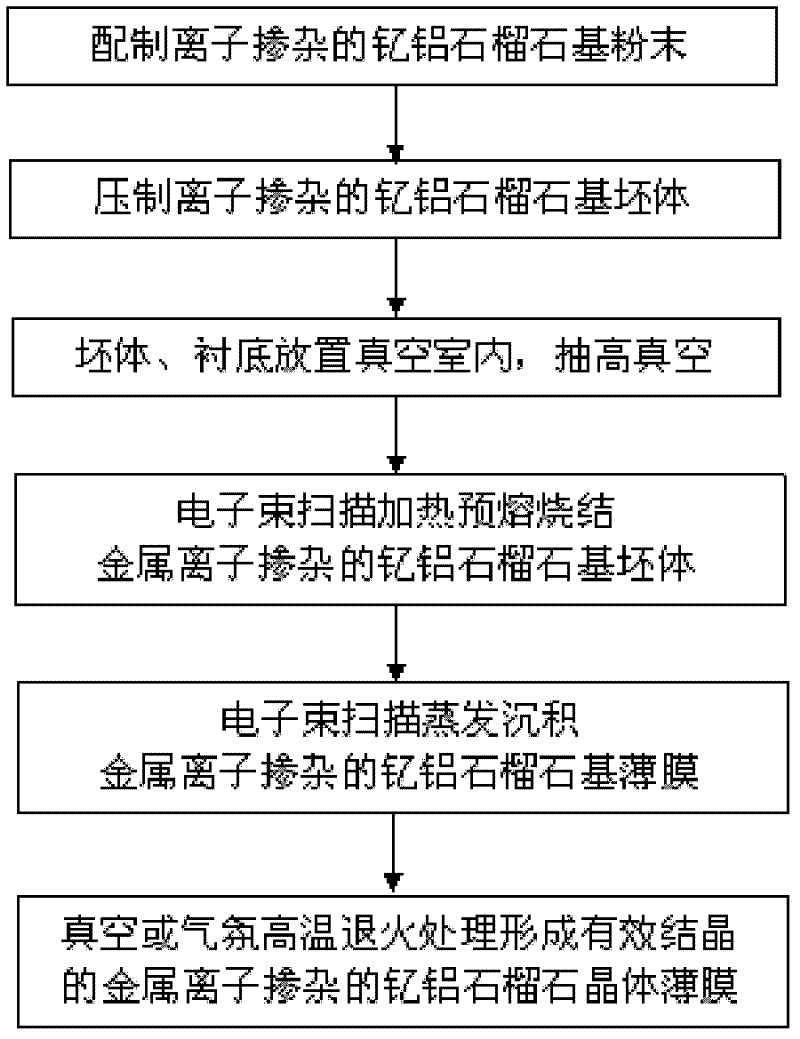

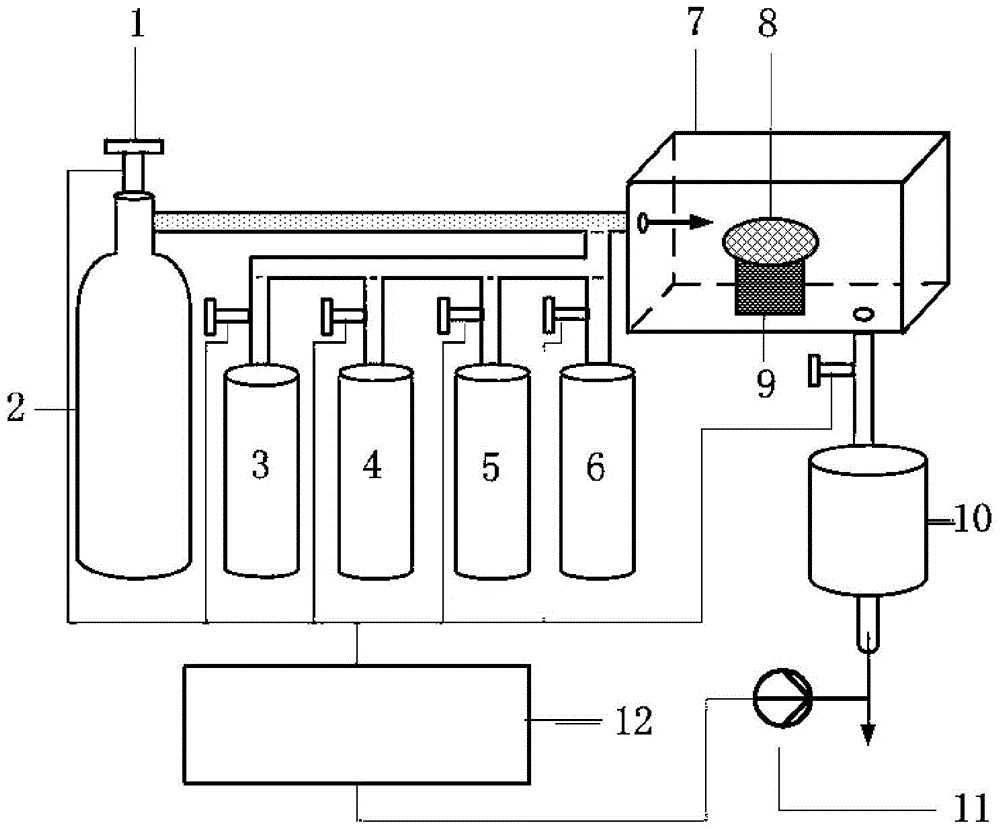

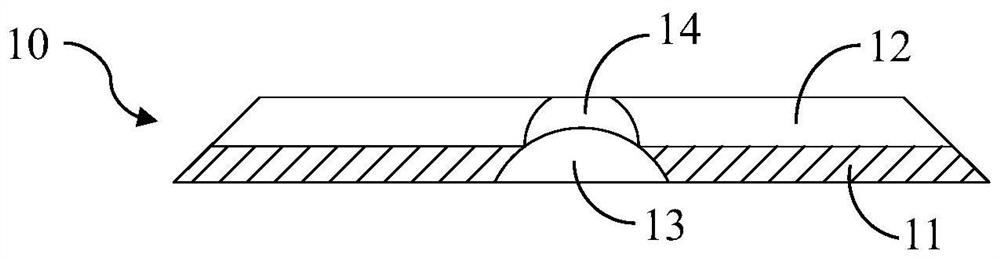

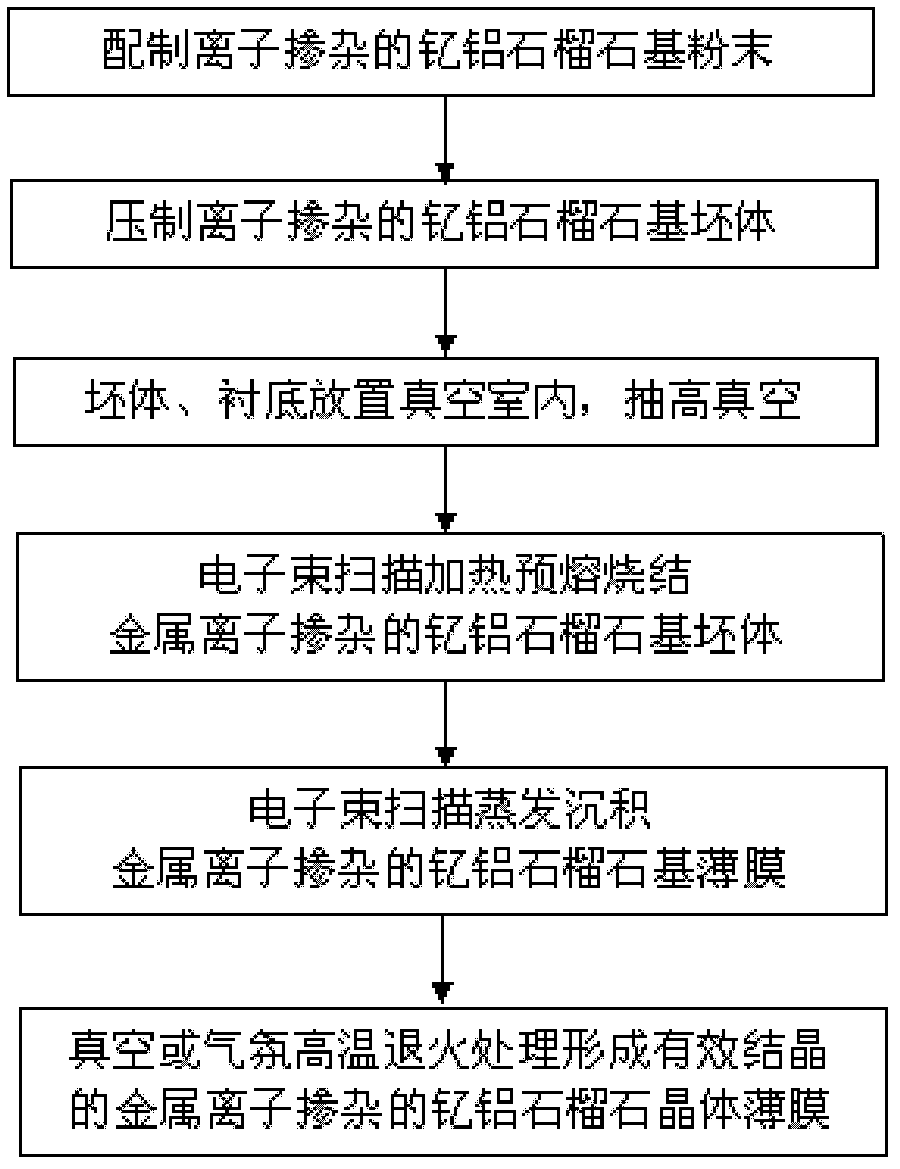

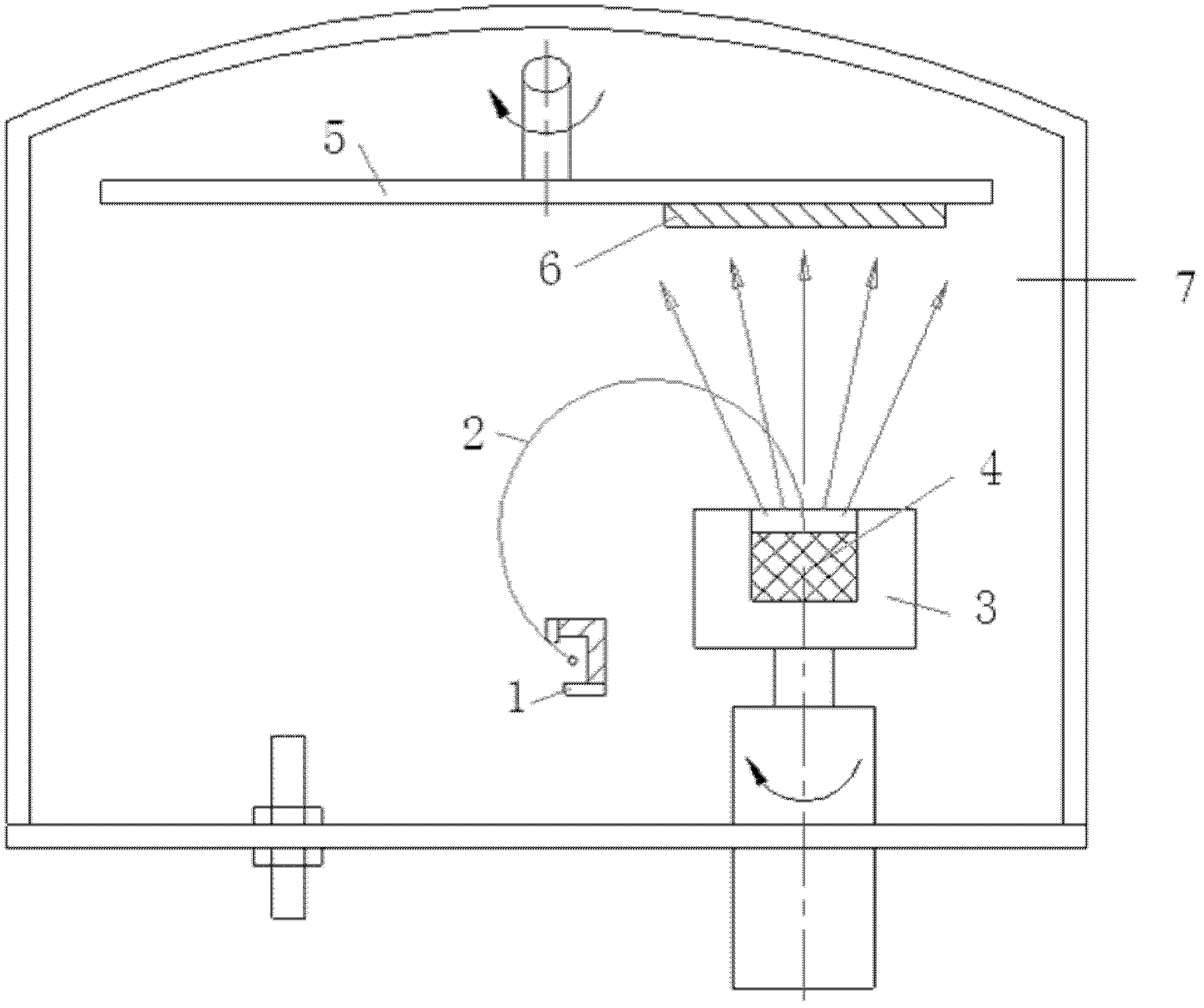

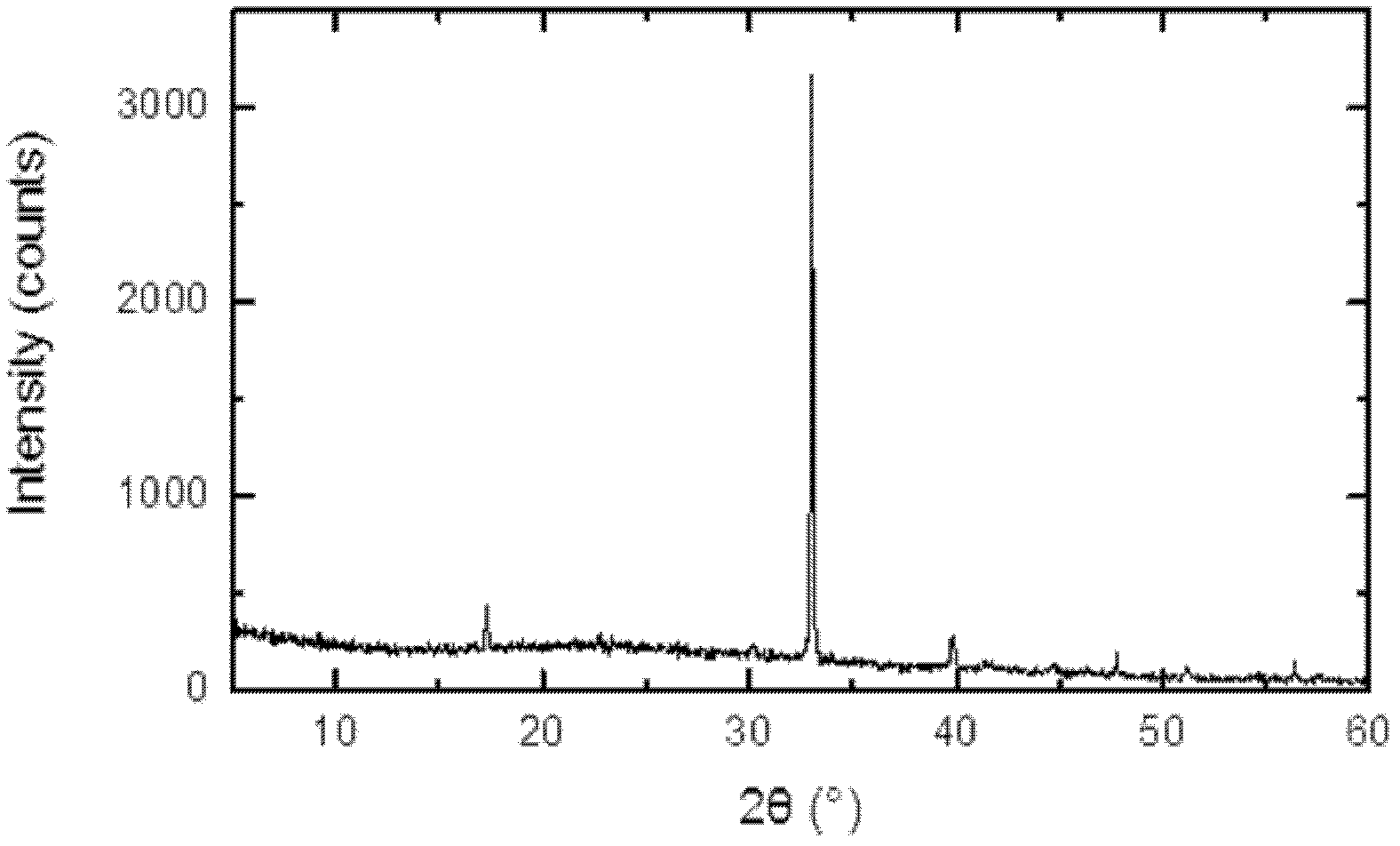

Preparation method of yttrium aluminum garnet crystal film doped with metal ions

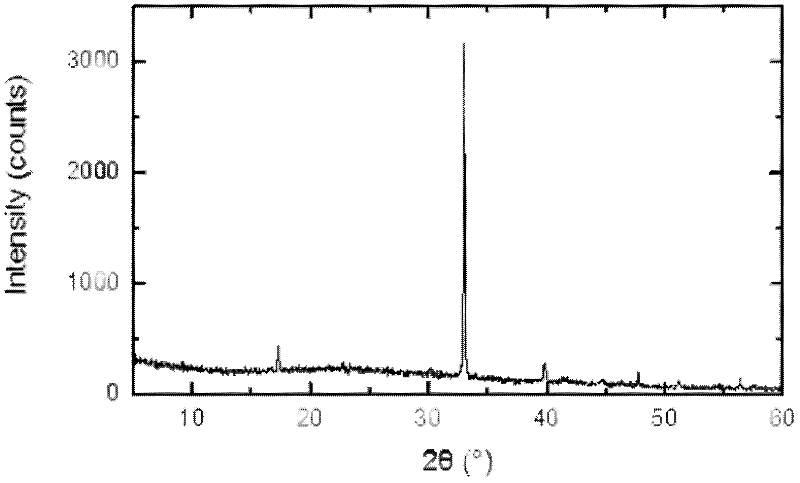

InactiveCN102392305ASimple to suppressSimple processPolycrystalline material growthFrom condensed vaporsYttriumFilm material

The invention discloses a preparation method of yttrium aluminum garnet crystal film doped with metal ions. The preparation method comprises the following steps: pressing raw material powders of yttrium aluminum garnets doped with metal ions into a green body used for a deposition coating film according to proportion, adopting electron beam evaporation-deposition process, focusing and injecting electron beams generated by an electron gun into the green body, controlling the electron beams to automatically scan and uniformly heat the pre-melted green body, primarily sintering the green body for crystallizing so as to obtain porcelain, then increasing the power of the electron gun so as to further heat the green body, thus melting, evaporating and depositing the green body on a lining substrate so as to form a film, then annealing the film under vacuum or protection atmosphere, and finally obtaining the yttrium aluminum garnet crystal film doped with metal ions, which is crystallized effectively. The method can realize the high-quality, low-cost and large-area batch production of the yttrium aluminum garnet crystal film doped with metal ions, the prepared yttrium aluminum garnet crystal film doped with metal ions can be used as novel light wave guide materials, laser work medium and functional film materials.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Process for preparing coated potato pieces using pregelatinized starch

InactiveUS20060045955A1Reduce brittlenessImprove sensory qualityFood coatingFood preparationOrganic chemistryViscosity

Owner:CAVENDISH FARMS +1

Method for manufacturing plastic electrode plate of lithium ion secondary battery

InactiveCN101132063AOvercome processing difficultiesAvoid difficultiesElectrode manufacturing processesElectrode carriers/collectorsFree coolingEngineering

This inventive lithium ion plastic battery electrode plate is made of polyethylene as base material and polyaniline and carbon-black as conductive fillings. The production procedures are: (a), drying raw materials, weighing polyethylene, carbon-black and plastifier with the total weight of 40g, proceeding torque deformation blending, being pressed by plat-vulcanizer and natural cooling to obtain product; (b), carbon-black: polyaniline=80-40%: 20-60%, being mixed, weighing the mixture 80g, being mixed, processed, natural cooling to obtain product. The inventive electrode plate has high electroconductivity, high toughness, suitable for production of secondary lithium ion battery.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Method for processing feeding gear gauge

InactiveCN104416328AImprove launch performanceEffective Quality InspectionUsing mechanical meansEngineeringMechanical engineering

The invention discloses a method for processing a feeding gear gauge, and the gauge comprises a feeding gear gauge body which is composed of a first workpiece, a second workpiece, a third workpiece and a fourth workpiece. The gauge is used for measuring the sizes of feeding gear parts, and the measuring principle thereof is that: a special gauge H / PJ17 01-136 L-2 penetrates holes with the size of phi 5.5 until two holes are passed through, the feeding gear parts are positioned by the gauges H / PJ17 01-136 L-2 and H / PJ17 01-136 L-7B, and then the special gauge H / PJ1701-136 L-22 is used for detecting whether the shape of the feeding gear is qualified. If the difference between the part shape and the gauge shape is within 0.2mm, the parts are qualified; if the difference is beyond 0.2mm, the parts are unqualified.

Owner:CHANGAN AUTOMOBILE (GRP) CO LTD

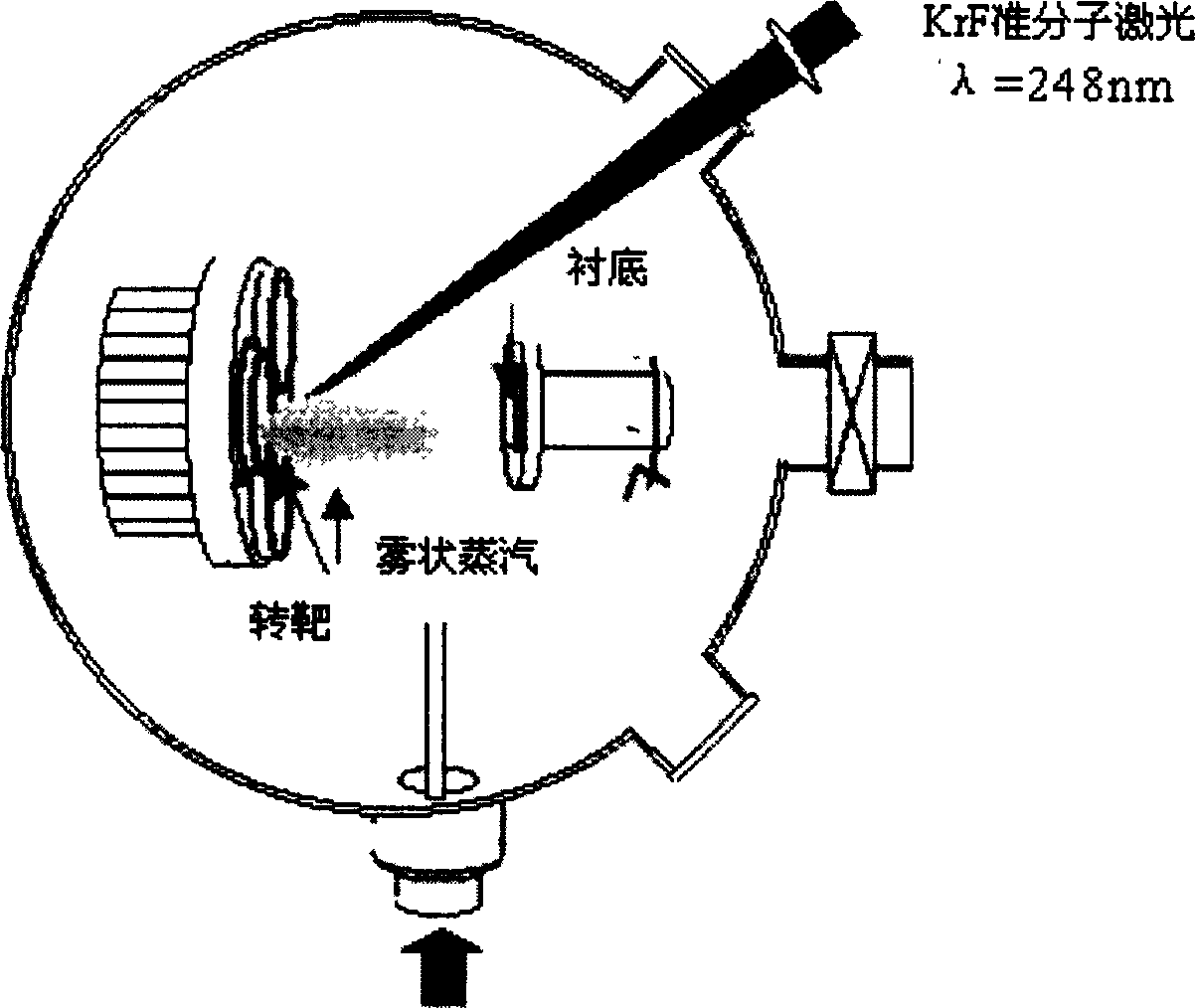

Preparation of Yb-Gd-Ga doped garnet planar optical waveguide

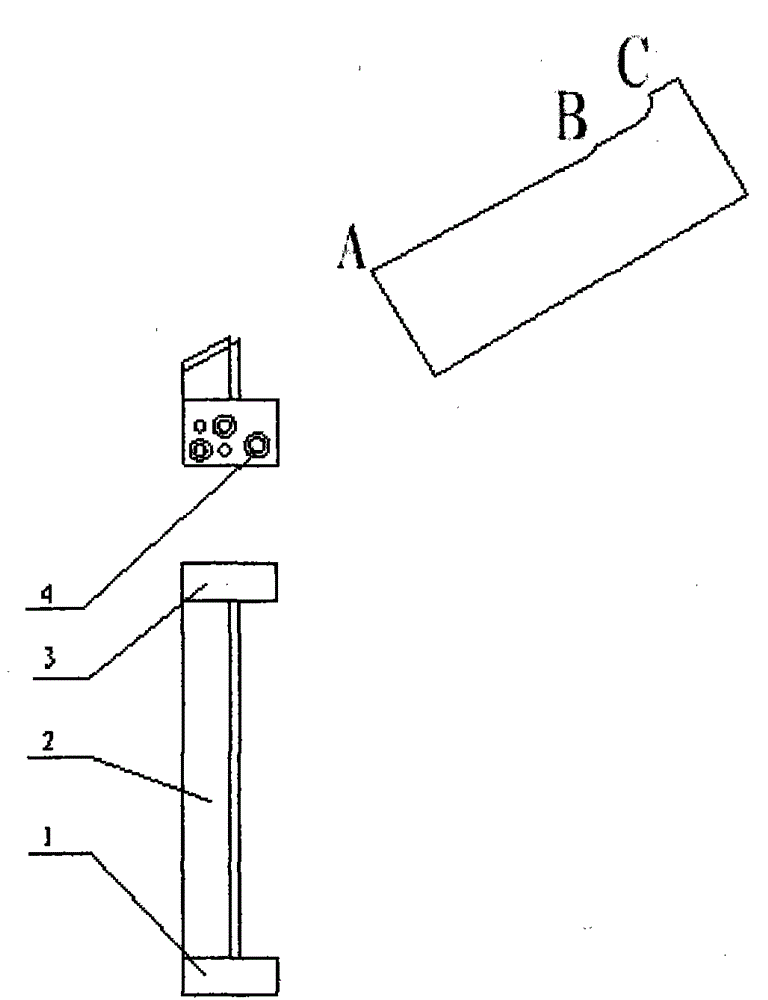

InactiveCN1614453AOvercome processing difficultiesTo satisfy the market's needsOptical waveguide light guideSurface layerOptoelectronics

A method for preparing planar optical waveguide of garnet doped with Yb-Gd-Ga applies pulse laser depositing method to fuse out surface layer molecule of Yb3+: GGG multicrystal target material and to generate Yb3+:GGG planar optical waveguide on heated pure YAG substrate. A Yb3+: GGG planar optical waveguide on the requirement in micron grade cand be growed up by utilizing the method.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

A method of making microchannel plate functional layer by atomic layer deposition technology

ActiveCN104152868BEasy to adjustMeet surface precision requirementsChemical vapor deposition coatingWorking lifeAtomic layer deposition

The invention provides a method for making a functional layer of a microchannel plate by using atomic layer deposition technology, so as to overcome the inherent defects of the functional layer prepared by the traditional hydrogen reduction technology of the microchannel plate, and solve the problem of complex manufacturing of the functional layer of the microchannel plate, unstable performance, and short lifespan. Not long and other problems, to manufacture a resistance layer and emission layer with strong adhesion, smooth surface, uniform thickness, and high purity of composition, improve the performance stability of the micro-channel plate, and prolong its working life.

Owner:东莞市中科原子精密制造科技有限公司

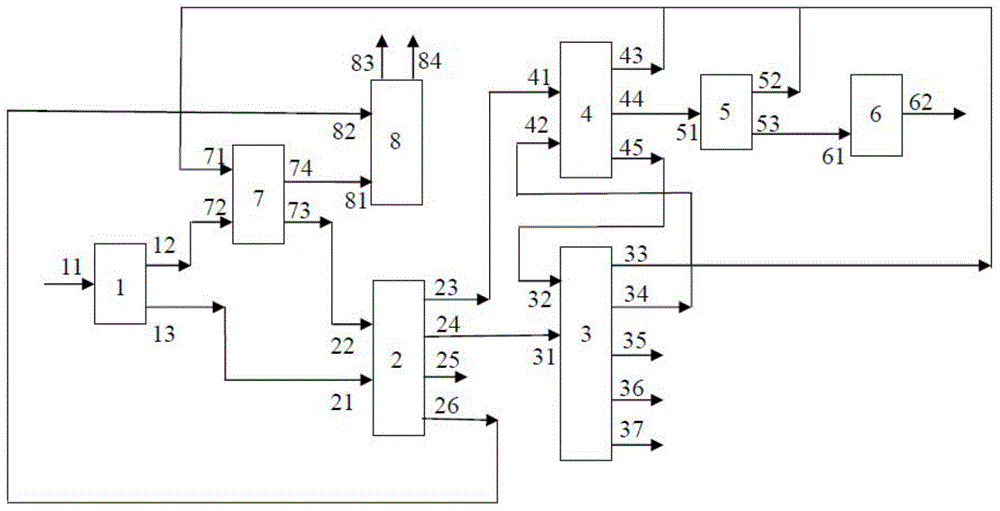

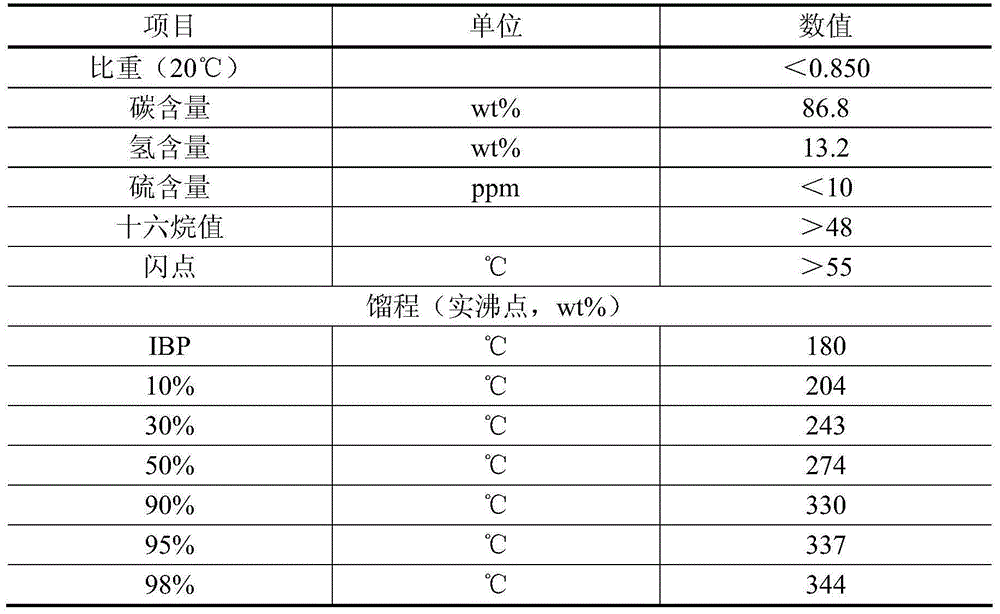

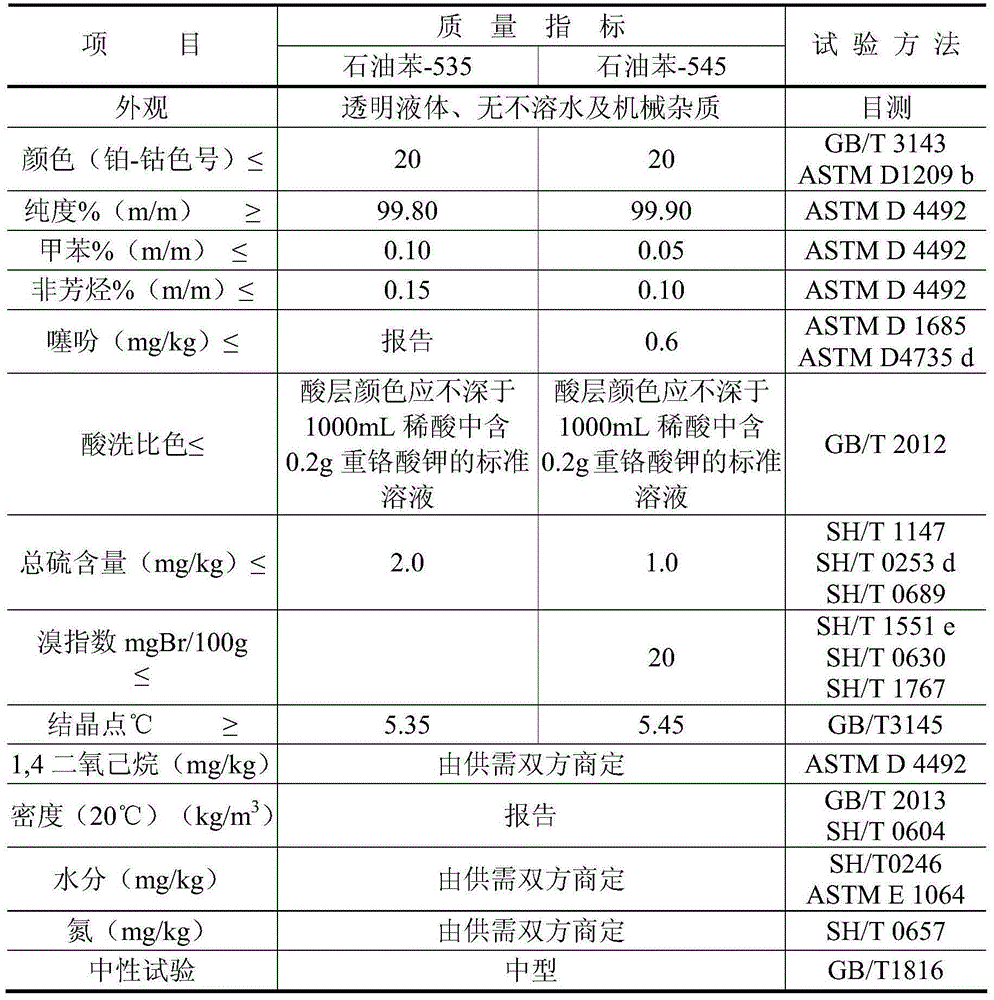

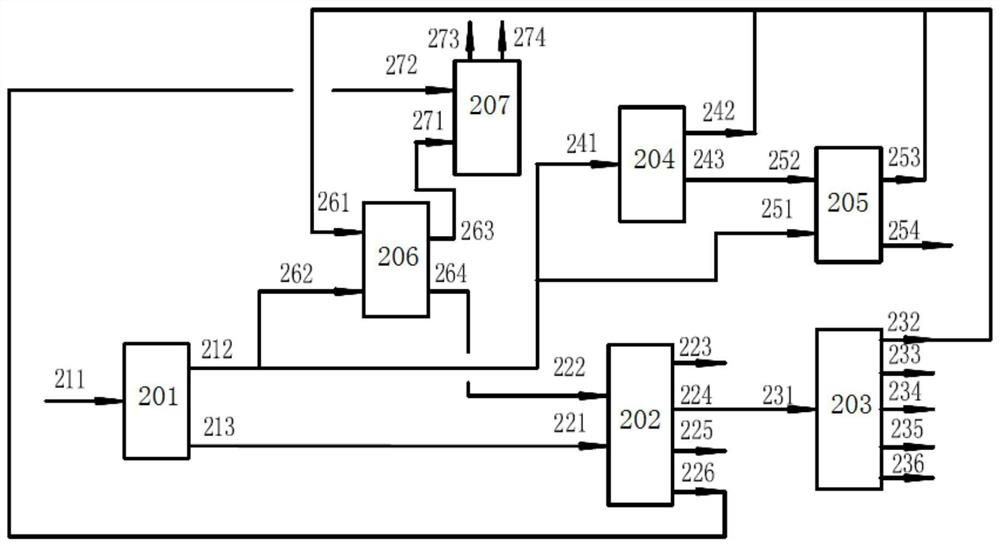

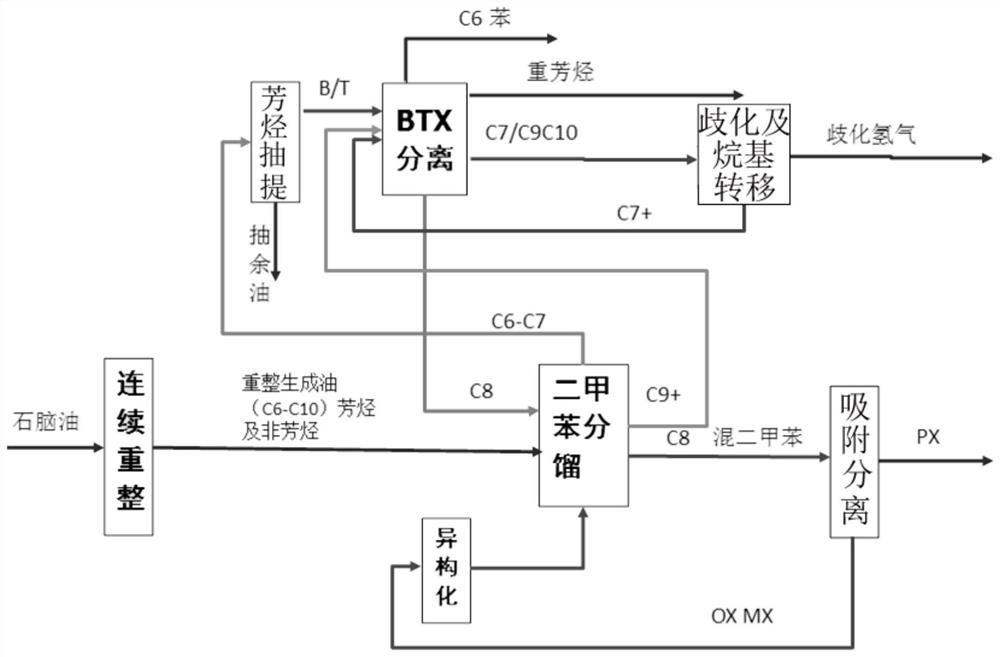

Coal processing method and system

ActiveCN104987886AImprove processingIncrease added valueHydrogenHydrocarbon by isomerisationCarbonizationDehydrogenation

The invention provides a coal processing method and system. The processing method at least comprises the steps of coal carbonization or coal gasification, coal tar hydrocracking, aromatics combination, light dydrocarbon aromatization, propane dehydrogenation, polypropylene preparation and the like. Main products include diesel oil, p-xylene, benzene, heavy aromatics, polypropylene and the like. The system at least comprises a coal carbonization or coal gasification device, a coal tar hydrocracking device, an aromatics combination device, a light dydrocarbon aromatization device, a propane dehydrogenation device, a polypropylene preparation device and the like. By means of the processing method and system, high additional value products such as diesel oil, gasoline blending components, aromatics and alkene can be produced, the problem that coal tar cannot be processed easily is solved, and the processing method and system with coal, oil, aromatics and alkene integrated are achieved.

Owner:BEIJING PETROCHEM ENG

Scratch-resistant PVC film and preparation method thereof

ActiveCN112143135AOvercome processing difficultiesReduce dosageWriting boardsPolymer chemistryPlasticizer

The invention relates to the field of polyvinyl chloride, particularly to a scratch-resistant PVC film and a preparation method thereof. The PVC film is prepared from the following raw materials in parts by weight: 100 parts of PVC powder, 2-8 parts of a scratch-resistant modifier, 0.2-1.0 part of a slipping processing aid, 5-15 parts of a plasticizer, 0.8-2 part of a wear-resistant agent, 2-4 parts of a stabilizer, 2-10 parts of an impact modifier, 0.1-0.5 part of an external lubricant, 0.1-0.5 part of a lubricant and 0.8-2.5 parts of an aid. According to the invention, by adding the wear-resistant agent, the scratch-resistant effect is achieved, the precipitation of the rubber flower roller is reduced, and the processing technology difficulty caused by adding the wear-resistant agent inthe prior art is overcome.

Owner:GUANGDONG TIANAN NEW MATERIAL

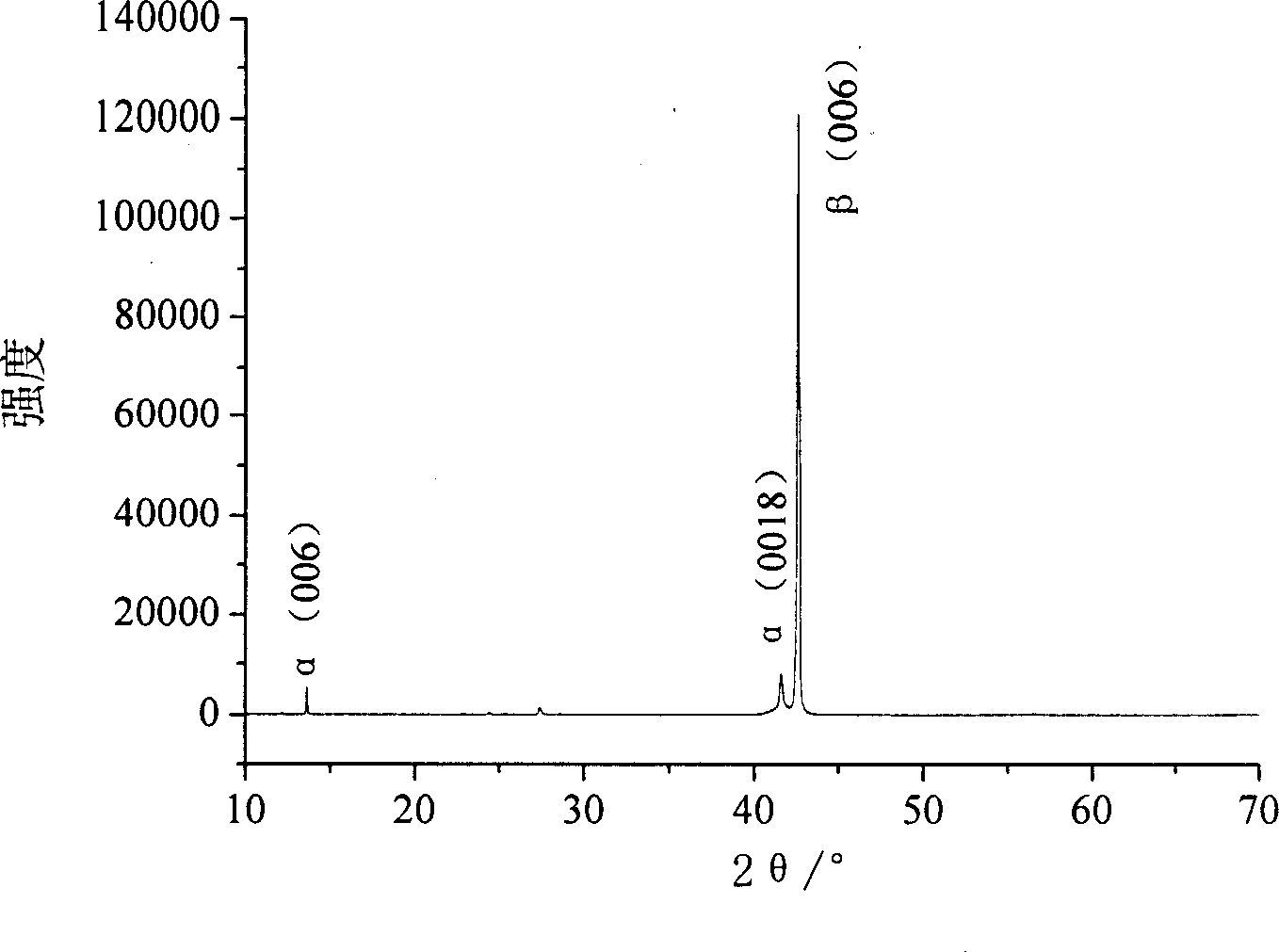

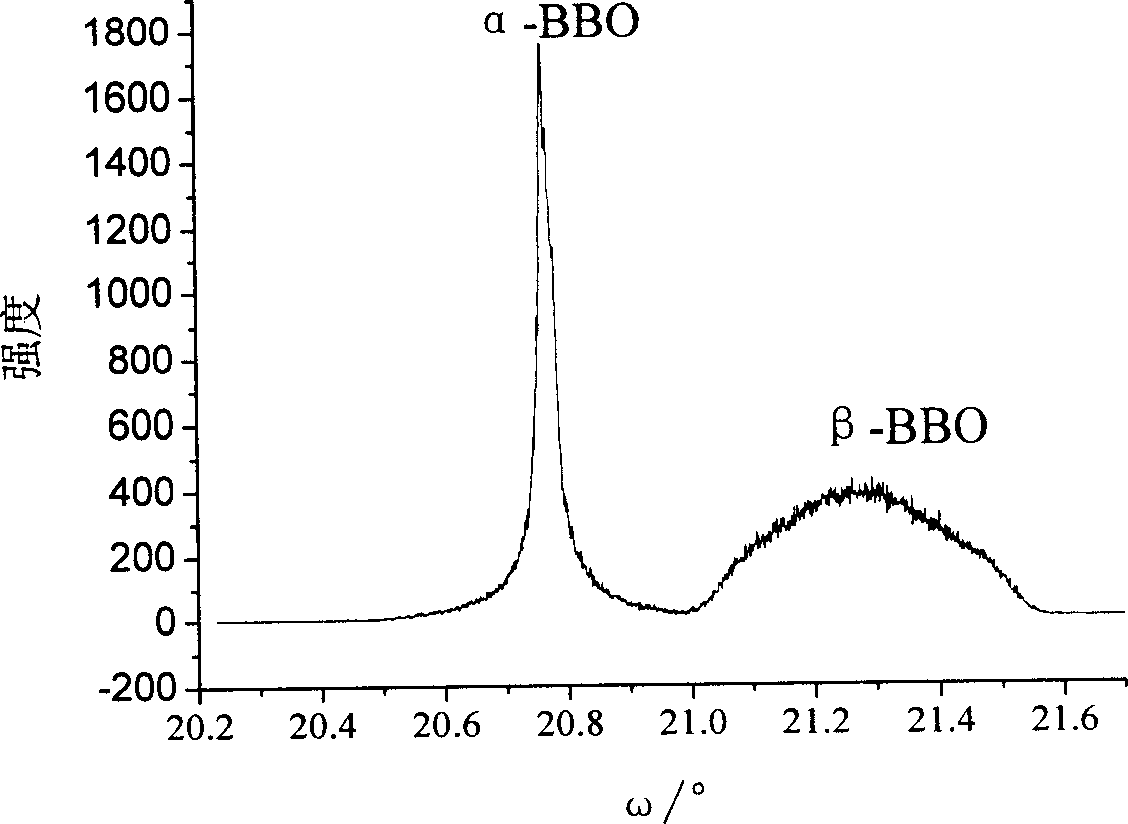

Process for preparing low-temperature phase barium metaborate monocrystalline film through magnetron sputtering

InactiveCN1632185ATo satisfy the market's needsOvercome processing difficultiesPolycrystalline material growthFrom chemically reactive gasesLaser technologySputtering

A kind of magnetron sputtering method to prepare low-temperature phase barium metaborate single crystal thin film, which is characterized in that the β-BBO ceramic target or β-BBO single crystal target is selected, and the magnetron sputtering method is used on the α-BBO single crystal substrate A layer of β-BBO / α-BBO composite single crystal thin film is formed on it. The method of the invention overcomes the problem of difficult processing of growing body single crystals in the prior art, and greatly saves materials. The invention is suitable for mass production, can meet the market demand of rapid development of laser technology, and has good economic benefits.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

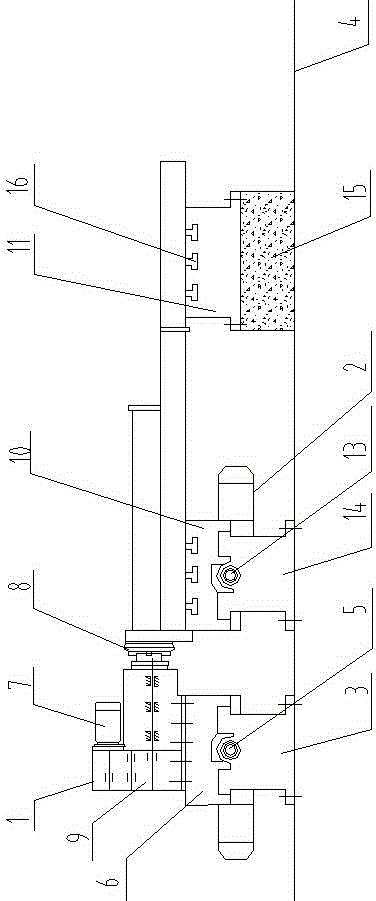

Milling machine tool device for processing fire grates

InactiveCN104400089AOvercome processing difficultiesGuaranteed normal processingLarge fixed membersMilling equipment detailsMilling cutterEngineering

The invention relates to a milling machine tool device for processing fire grates. The device comprises a milling device, and a work table group arranged on one side of the milling device, wherein the milling device comprises a milling head base; a first sliding platform is arranged above the milling head base through a first sliding screw rod in a transmission manner; a power device and a milling cutter disk are arranged on the first sliding platform and are in transmission through a gear; the work table group comprises a first work table and a second work table, wherein the first work table is arranged above a platform bracket through a second sliding screw rod in a transmission manner; the second work table is fixedly arranged above a cement boss through a bolt and the upper surface of the second work table and the upper surface of the first work table are on the same level surface; a plurality of T-shaped grooves for tooling grate processing parts are respectively formed in the upper surfaces of the first work table and the second work table. The milling machine tool device disclosed by the invention improves the production efficiency, and effectively solves the problems of high production cost and long production cycle of equipment.

Owner:JIANGSU TIANYING ENVIRONMENTAL PROTECTION ENERGY COMPLETE EQUIP CO LTD

Preparation of Yb-Gd-Ga doped garnet planar optical waveguide

InactiveCN1308715COvercome processing difficultiesTo satisfy the market's needsOptical waveguide light guideSurface layerOptoelectronics

A method for preparing planar optical waveguide of garnet doped with Yb-Gd-Ga applies pulse laser depositing method to fuse out surface layer molecule of Yb3+: GGG multicrystal target material and to generate Yb3+:GGG planar optical waveguide on heated pure YAG substrate. A Yb3+: GGG planar optical waveguide on the requirement in micron grade cand be growed up by utilizing the method.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

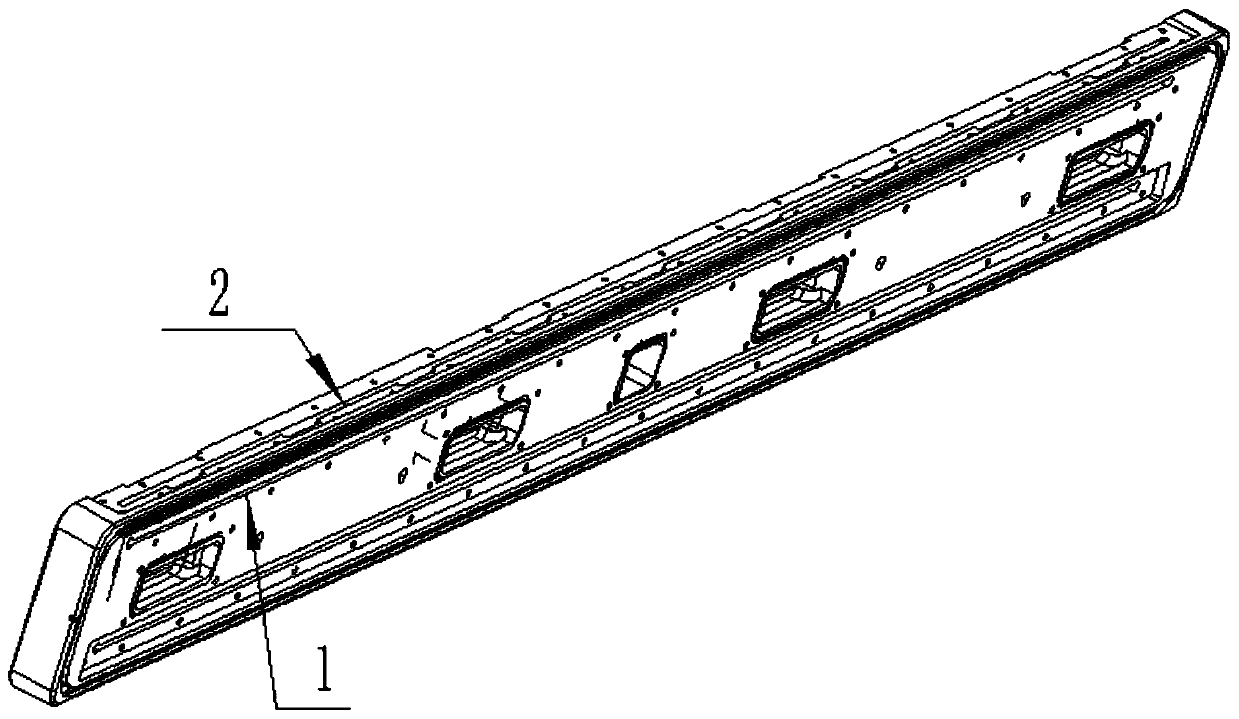

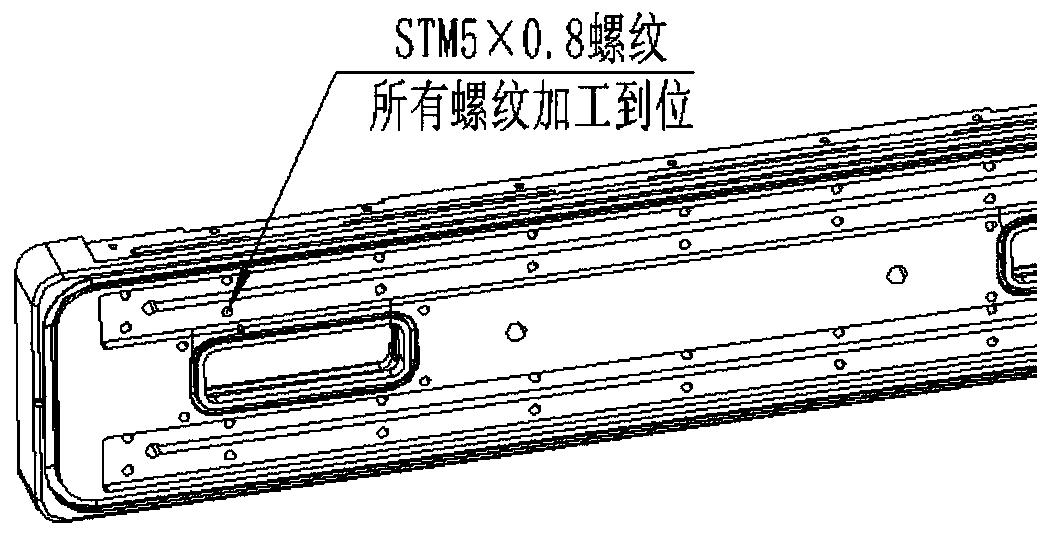

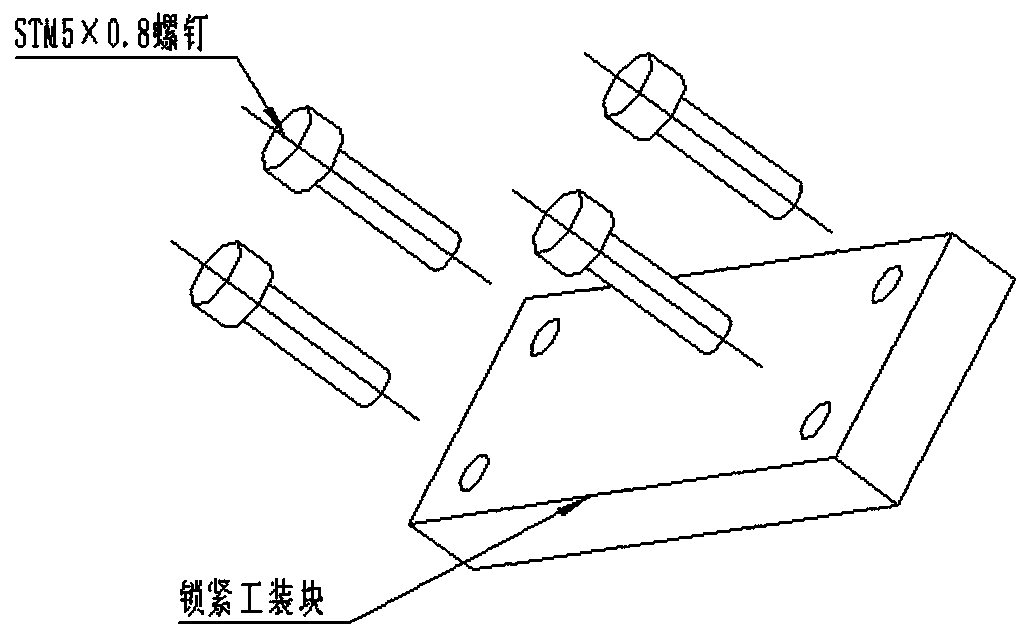

Processing Technology of 5083-o Aluminum Alloy Door

ActiveCN108672775BGuaranteed accuracyStable support functionMilling equipment detailsMachining processCooling fluid

The invention discloses a machining process of a 5083-O aluminum alloy DOOR. The machining process is characterized by comprising the following steps that (1) a machining portion is effectively supported and fixed; (2) uniform locating and locking are achieved; (3) continuous cutting is achieved in the machining process, and cutter vibration is avoided; and (4) an application tool is simple, and operation is convenient and fast. The machining portion is effectively supported and fixed in the step (1), and the situation that no supporting edge strip exists in the machining process, cutter vibration happens after machining through operation, and part overcut is caused is avoided. In the step (2), uniform locating and locking are achieved, interrupted arrangement is achieved, cooling liquid and aluminum chips are smoothly discharged out in the machining process, and the situation that chips are left in the part machining process, and parts are damaged is effectively avoided. Cutter holesare drilled in the two ends of a deep groove, direct cutting is achieved, reciprocating non-cutter-lifting machining is adopted, the deep groove is machined through a long cutter and a short cutter, and the machining speed is effectively increased. Operation is convenient, the technical requirements for overall locking work are low, and the requirements for operation workers are effectively reduced.

Owner:SHENYANG FORTUNE PRECISION EQUIP CO LTD

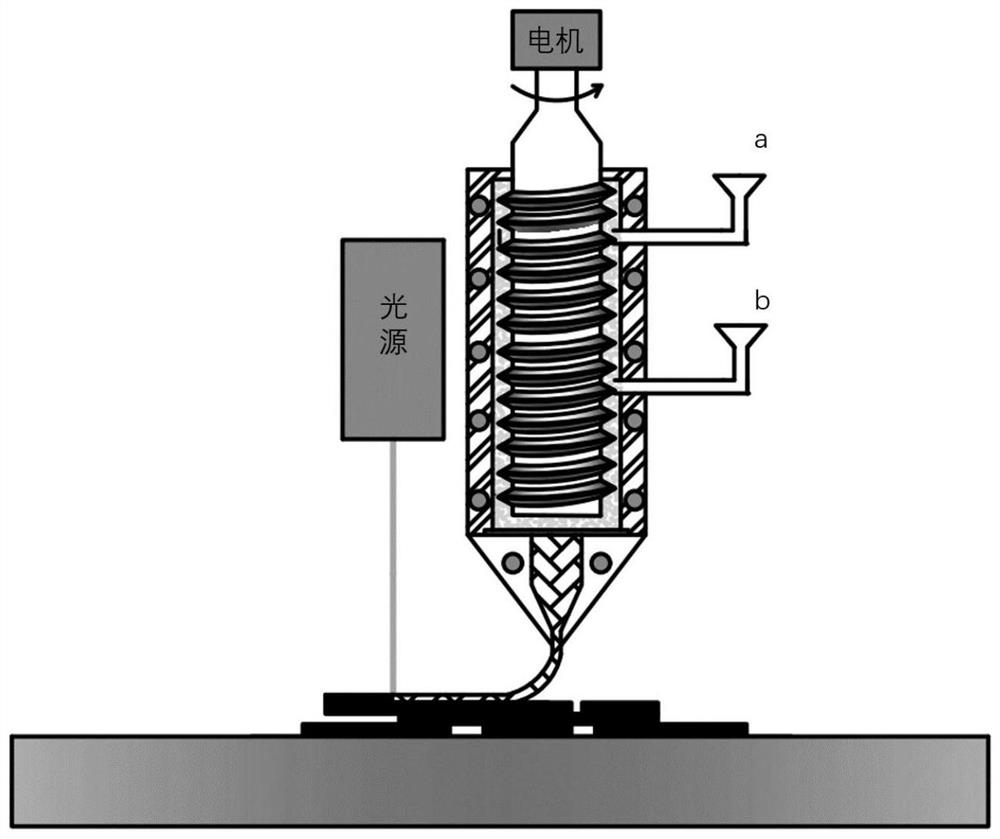

Method and device for 3D printing of thermosetting material or photosensitive material

PendingCN114474711AAvoid cloggingRealize printingAdditive manufacturing apparatus3D object support structures3d printPolymer science

The invention discloses a method and a device for 3D printing of a thermosetting material or a photosensitive material, which are used for 3D printing of thermosetting resin and comprise a thermosetting resin 3D printing device and a 3D printing material laser thermocuring method. Resin, a curing agent and other auxiliaries are evenly mixed through the screw in the charging barrel and conveyed to the front-end printer nozzle to be sprayed out, then the resin on the working platform is cured and formed through light beams, the screw and the light beams synchronously and accurately move under the control of a computer, printing is conducted layer by layer, and a thermosetting 3D printed part is formed. The thermosetting resin is used as a raw material for 3D printing, the deep development of the 3D printing technology is promoted, and the application of the thermosetting resin in 3D printed parts is expanded. According to the method, the thermal degradation risk and loss caused by repeated melting of resin in existing 3D printing technologies such as FDM are avoided, the technological method for preparing the thermosetting material 3D printed part under a common spray head is achieved, and the performance of the 3D printed part is improved.

Owner:SHANGHAI UNIV +1

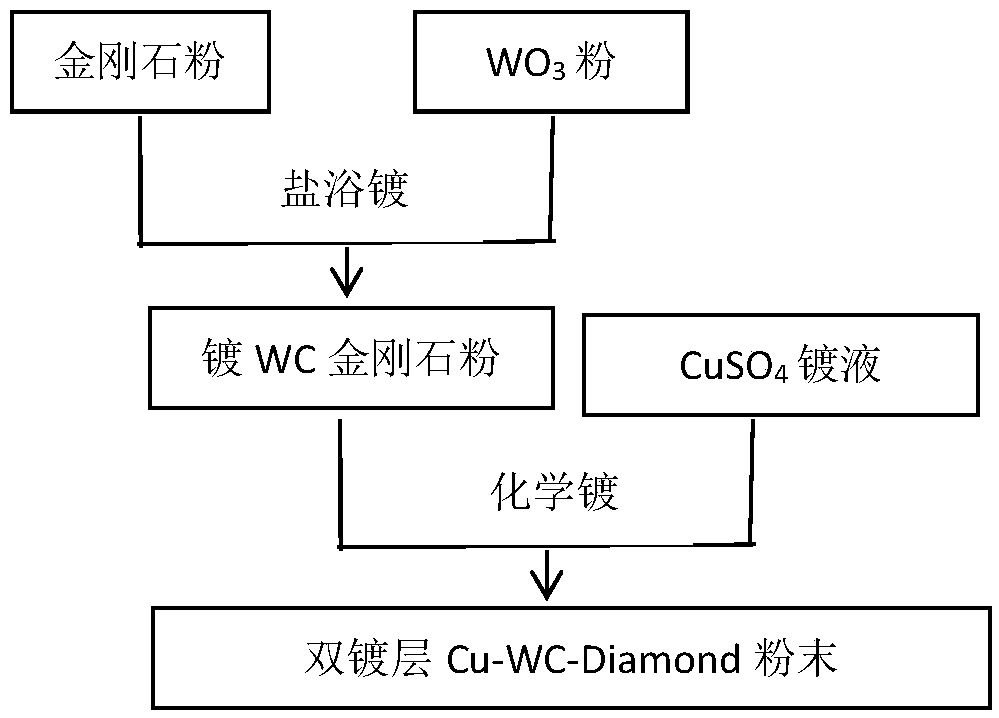

A kind of preparation method of double-coated diamond powder

ActiveCN106756906BHigh densityImprove performanceTransportation and packagingMetal-working apparatusCopper platingMetal matrix composite

The invention belongs to the technical field of powder metallurgy, and relates to a method for preparing double-coated diamond powder. A layer of uniform WC is coated on the diamond surface by salt bath plating technology to improve the wettability of diamond and copper, and then electroless plating is used. The coating method continues to plate copper on the surface of the WC layer, by controlling the Cu in the plating solution 2+ content to control the thickness of the copper plating layer, thereby preparing a double-coated Cu-WC-Diamond powder with a copper volume fraction of 30-50vol.%. The powder can be directly pressed into (Diamond / Cu) composite parts, realizing the near-net shape of metal matrix composite parts with complex shapes. The advantage of the present invention is that Cu-WC-Diamond powder can be prepared by controlling the thickness of the copper plating layer, and the copper plating amount of the prepared Cu-WC-Diamond powder is the copper content of the Diamond / Cu composite material after pressing the powder. , so the diamond distribution of the prepared composite material is uniform, the bonding strength is high, and the performance is excellent.

Owner:UNIV OF SCI & TECH BEIJING

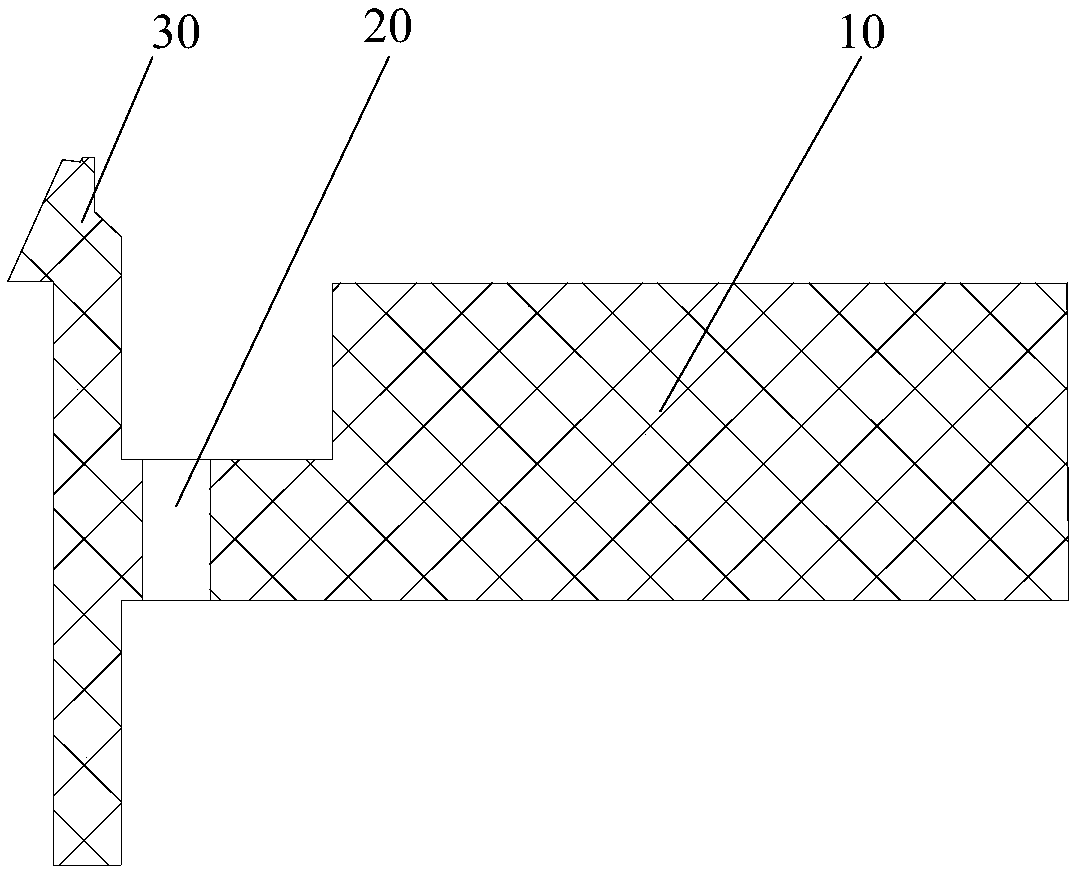

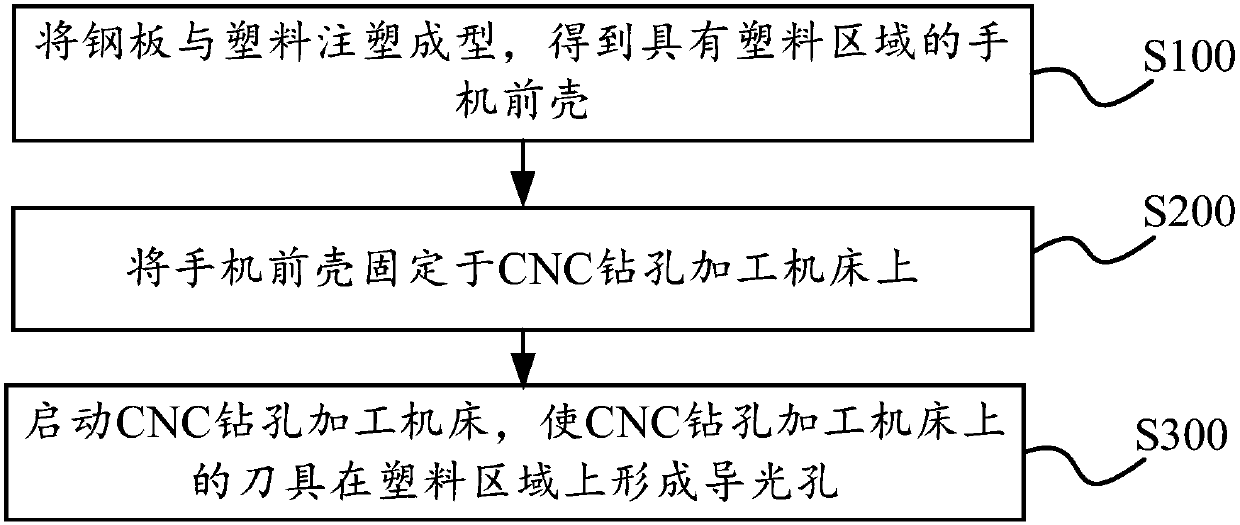

Mobile phone front shell, machining method thereof, mobile phone and machine tool

InactiveCN107813369AAchieve mass productionOvercome processing difficultiesDomestic articlesMetal working apparatusPunchingLight guide

The invention provides a mobile phone front shell, a machining method thereof, a mobile phone and a machine tool. The machining method comprises the following steps: performing injection molding on asteel plate and plastic to obtain the mobile phone front shell with a plastic area; fixing the mobile phone front shell onto a CNC drilling and machining machine tool; and starting up the CNC drillingand machining machine tool to enable a tool on the CNC drilling and machining machine tool to form a light guide hole in the plastic area. Through the technical scheme, the problem that a light guidehole of a conventional mobile phone front shell is difficult to machine on a die is solved, a pillar on the die has low probability of being broken by punching, volume production of the mobile phonefront shell can be realized, the production cost is lowered, and the machining efficiency is improved.

Owner:MEIZU TECH CO LTD

Process for preparing low-temperature phase barium metaborate monocrystalline film

InactiveCN1292100CMeet the rapidly developing market demandOvercome processing difficultiesFrom solid stateSingle crystalEngineering

A process for preparing a low-temperature phase barium metaborate monocrystalline film comprises following particular steps: arranging Li2CO3 and Al2O3 mixed feed block with ari holes in a platinum crucible; arranging or hanging an alpha-BBO wafer with two face polished on a platinum thread, adding a crucible lid covered by Li2CO3 and Al2O3 mixed powder and thermocouple, sealing a top portion of the crucible by a platinum lid, and arranging the crucible in an electric resistance furnace; heating the electric resistance furnace to lift temperature to 700-1000 DEG C, holding the temperature for 2-100 hours, diffusing Li2 to the alpha-BBO wafer to perform a solid state reaction with the alpha-BBO wafer, so that a surface layer of the alpha-BBO wafer generates phase changes to generate a beta-BBO single crystal film. The invention can grow a micron level beta-BBO single crystal film which is accorded with request on a beta-BBO substrate, thereby only only materials can be saved, but also mass-production can be performed, the invention has important significance on development of laser technic and integrated optics.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

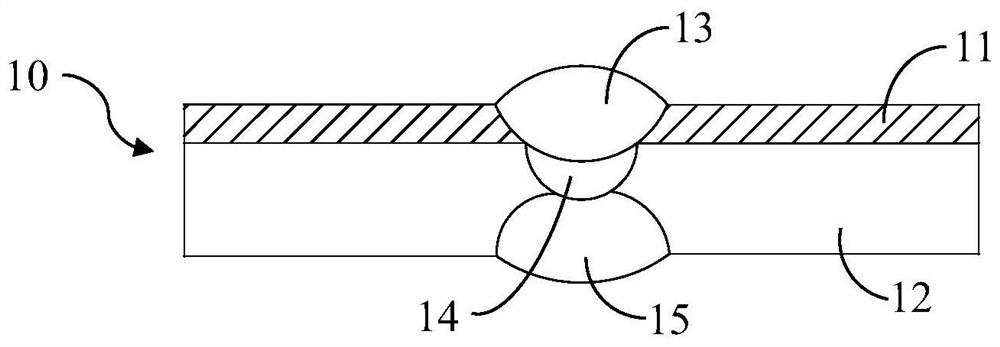

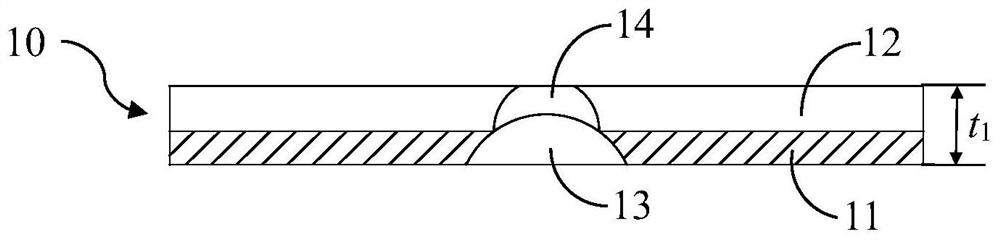

A method for preparing corrosion samples of welded joints of metal composite plates

ActiveCN110044667BGet efficientlyImprove machining accuracyPreparing sample for investigationPlanishingComposite plate

The invention discloses a method for preparing a corrosion sample of a welded joint of a metal composite plate, comprising: step 1, selecting a blank sample of a metal composite plate with a welded joint; , and smooth the surface of the cladding; Step 3, using the surface of the cladding as a reference plane, use a planer to thin the blank sample to the first thickness; Step 4, use a clamp to clamp the blank sample so that the surface of the base layer faces upward; Step 5 , the fixture is installed on the milling machine, and the blank sample is thinned to the second thickness by the milling machine; Step 6, the blank sample is thinned to the target thickness by the grinding machine, so as to obtain the blank sample whose upper and lower surfaces are cladding components; step Seventh, cut the length of the blank sample to the target length to obtain the corrosion sample. By adopting the preparation method of the invention, qualified corrosion samples can be obtained quickly and efficiently, and the processing precision is high.

Owner:BAOSHAN IRON & STEEL CO LTD

Preparation method of yttrium aluminum garnet crystal film doped with metal ions

InactiveCN102392305BSimple to suppressSimple processPolycrystalline material growthFrom condensed vaporsYttriumFilm material

The invention discloses a preparation method of yttrium aluminum garnet crystal film doped with metal ions. The preparation method comprises the following steps: pressing raw material powders of yttrium aluminum garnets doped with metal ions into a green body used for a deposition coating film according to proportion, adopting electron beam evaporation-deposition process, focusing and injecting electron beams generated by an electron gun into the green body, controlling the electron beams to automatically scan and uniformly heat the pre-melted green body, primarily sintering the green body for crystallizing so as to obtain porcelain, then increasing the power of the electron gun so as to further heat the green body, thus melting, evaporating and depositing the green body on a lining substrate so as to form a film, then annealing the film under vacuum or protection atmosphere, and finally obtaining the yttrium aluminum garnet crystal film doped with metal ions, which is crystallized effectively. The method can realize the high-quality, low-cost and large-area batch production of the yttrium aluminum garnet crystal film doped with metal ions, the prepared yttrium aluminum garnet crystal film doped with metal ions can be used as novel light wave guide materials, laser work medium and functional film materials.

Owner:SOUTH CHINA NORMAL UNIVERSITY

A method for processing high-precision metal patterns on the surface of ceramic material products

The invention discloses a method for processing a high-precision metal pattern on the surface of a ceramic material product. In the method, the ceramic material product is firstly pretreated, and a metal film with a thickness of 0.01-100 μm is plated on the surface of the ceramic material product, and then the metal film is coated on the metal film. Coating corrosion-resistant photosensitive material, exposure and development, and finally etching the metal film with etching solution, removing the cured photosensitive material after etching, exposing the pattern of the metal film layer, and further electroplating on the surface of the metal film layer as required or electroless plating treatment. The method of the present invention is used to make micro-nano level high-precision metal patterns on the surface of ceramic material products. The metal patterns produced have the characteristics of adjustable color, adjustable conductivity, and arbitrary design of patterns, which can improve the product quality of ceramic material products. It is high-grade and ornamental, and does not damage the ceramic substrate, and the cost is low.

Owner:CHAOZHOU THREE CIRCLE GRP

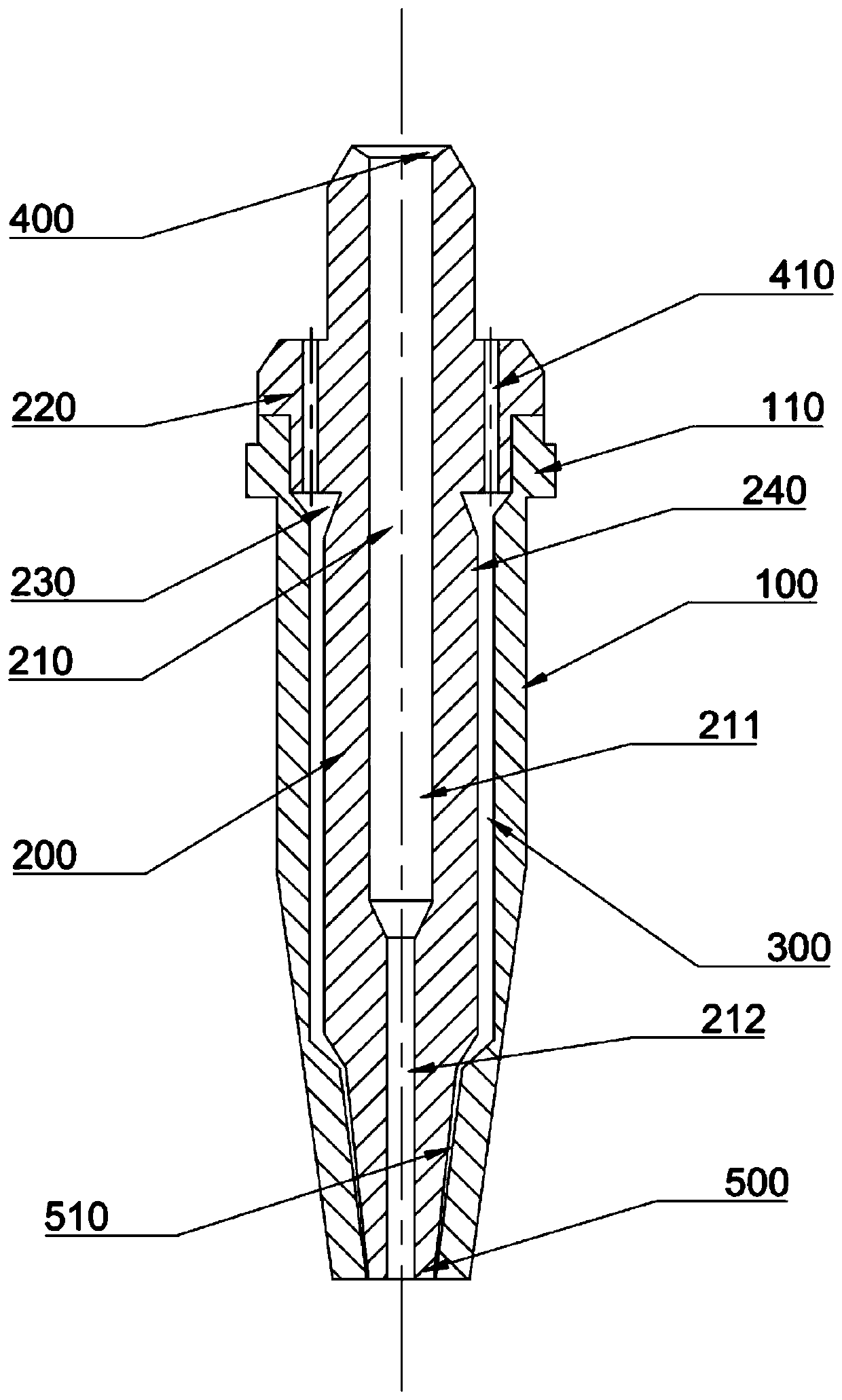

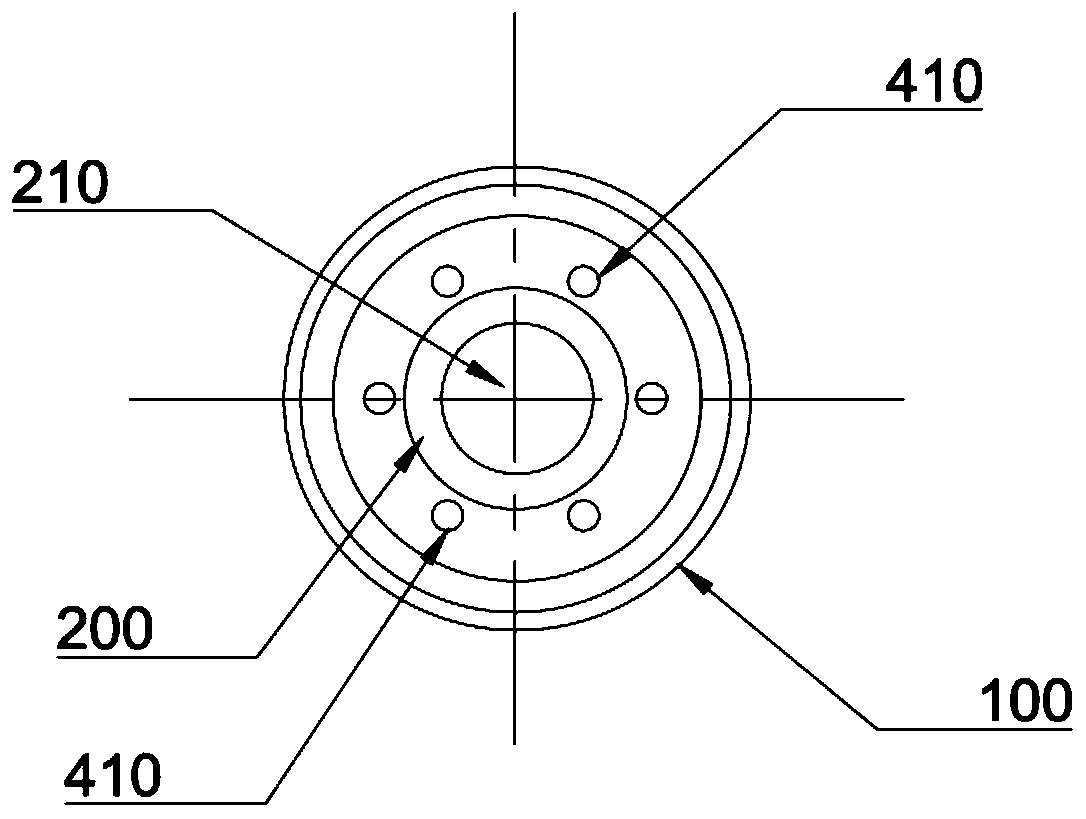

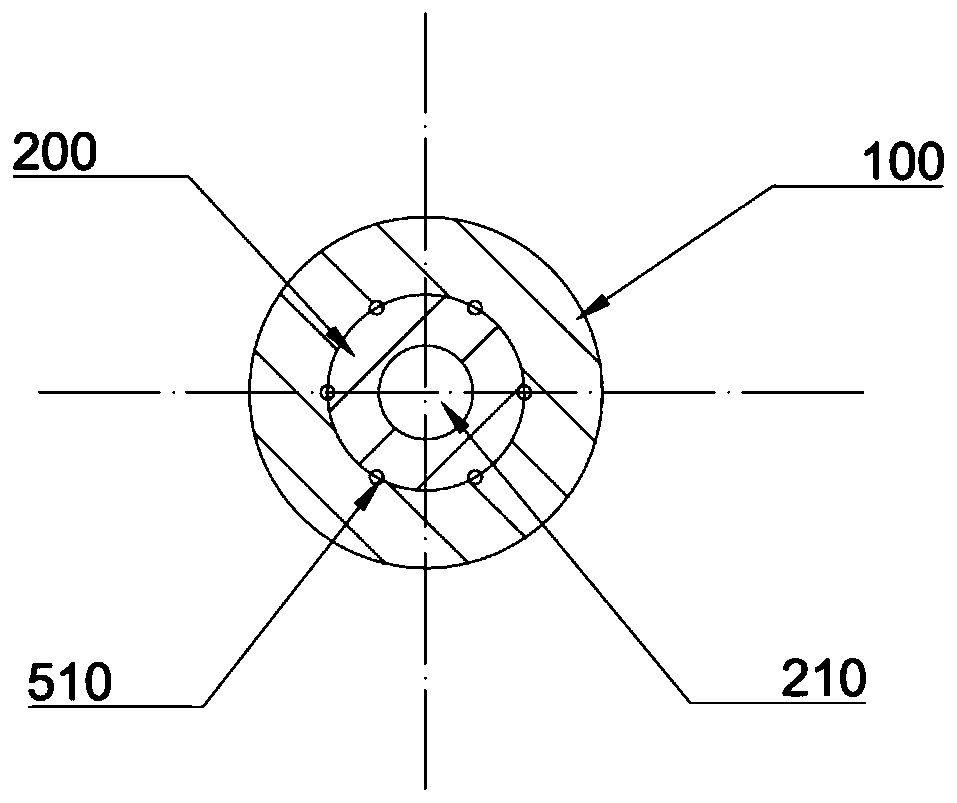

Acetylene cutting nozzle and production process thereof

PendingCN109967822AWell mixedLarge mixing chamber volumeGaseous fuel burnerGas flame welding apparatusPulp and paper industryCopper

The invention discloses an acetylene cutting nozzle. An air inlet end is arranged at one end of the cutting nozzle, an air outlet end is arranged at the other end of the cutting nozzle, the air inletend is provided with an air inlet mechanism, the air outlet end is provided with a flame spraying mechanism, the cutting nozzle further comprises an oxygen flow mechanism, and the oxygen flow mechanism communicates with the air inlet end and the air outlet end. The acetylene cutting nozzle comprises an outer nozzle body and an inner nozzle body, the outer nozzle body sleeves the inner nozzle body,a mixed gas cavity is formed between the inner nozzle body and the outer nozzle body, and the mixed gas cavity communicates with the air inlet mechanism and the flame spraying mechanism. The oxygen flow mechanism is arranged in the inner nozzle body in a penetrating mode. The outer nozzle body is matched with the inner nozzle body to form a first sealing end and a second sealing end, and the flame spraying mechanism is arranged at the second sealing end. The invention further discloses a production process of the acetylene cutting nozzle, a copper rod is taken as a raw material, cold headingmachining is carried out first to obtain prefabricated parts of the outer nozzle body and the inner nozzle body, and forging machining is carried out after sleeving the prefabricated parts of the outer nozzle body and the inner nozzle body to integrate the prefabricated parts into an integral structure. The acetylene cutting nozzle is easy to machine and can spray flame with more uniform pressure.The acetylene cutting nozzle has the characteristics of less feeding and high machining speed, and the production cost is reduced.

Owner:宁波市奉化一洲焊割工具有限公司

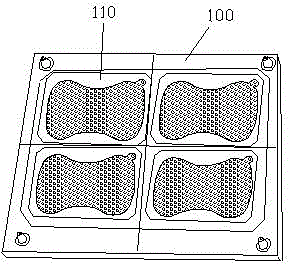

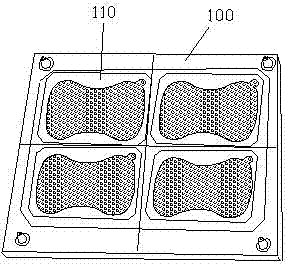

Silica gel brush and manufacturing method thereof

The invention discloses a silica gel brush manufacturing method; a silica gel brush is obtained by extruding hot melting silica gel in a molding cavity formed by upper and lower steel templates embedded with copper cores, wherein multiple taper holes for forming the brush are formed in the copper cores. Copper core are embedded in a traditional steel mold; since copper is soft and easy to cut then steel, the problem of difficult machining of dense small mold holes is overcome; the corresponding mold machining difficulty is reduced; and the mold development cost is largely reduced. Meanwhile, the taper holes in the copper core are machined in a segmented manner to prevent the problem of easy break of a cutter, so that the mold opening success rate and the mold opening efficiency are improved, and the product quality of the machined silica gel brush is improved.

Owner:FOSHAN DRAGON TECH

A kind of silicone brush and its manufacturing method

The invention discloses a method for manufacturing a silica gel brush. The silica gel brush is obtained by extruding hot-melt silica gel in a cavity formed by a steel upper and lower template embedded with a copper core, wherein the copper core is provided with A plurality of tapered holes for forming brushes. The present invention adopts the method of inlaid copper core in the traditional steel mould, utilizes the characteristics that copper is softer than steel and can be cut easily, overcomes the problem of difficult processing of small holes in dense molds, reduces the processing difficulty of corresponding molds, and the cost of mold development is correspondingly greatly increased reduce. At the same time, the taper hole on the copper core is processed in sections to avoid the problem of easy breakage of the tool, improve the success rate and efficiency of mold opening, and the product quality of the processed silicone brush is also improved.

Owner:FOSHAN DRAGON TECH

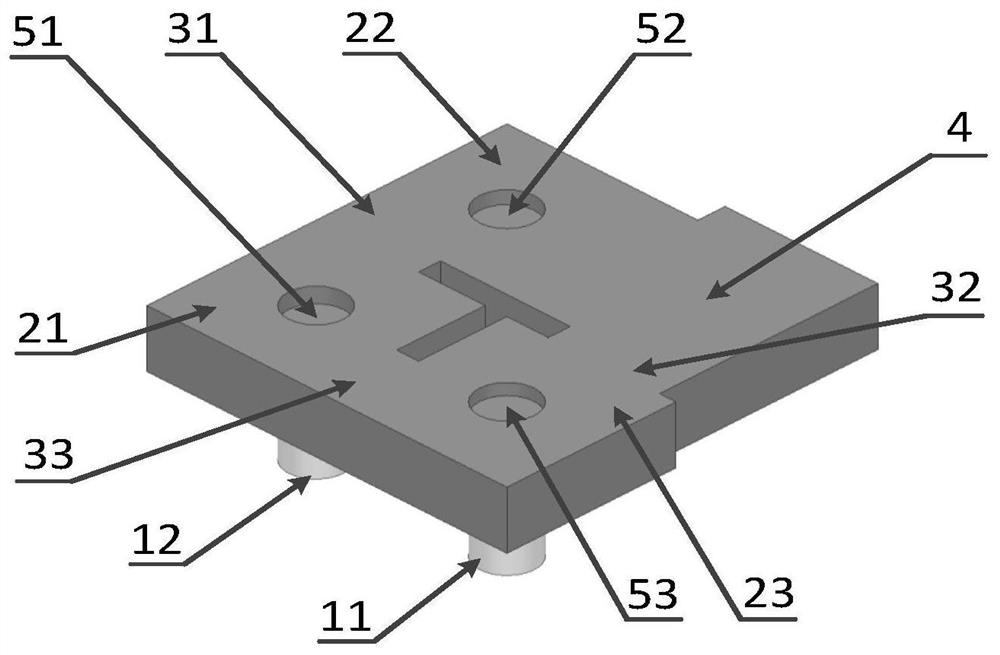

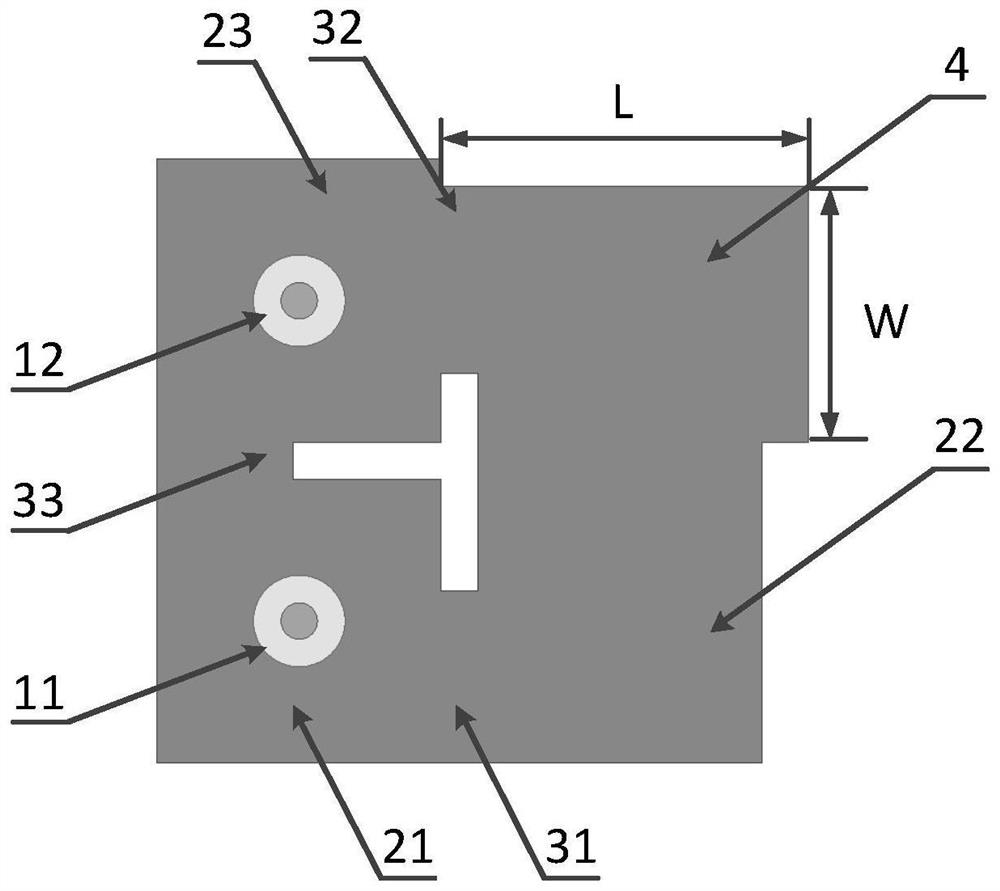

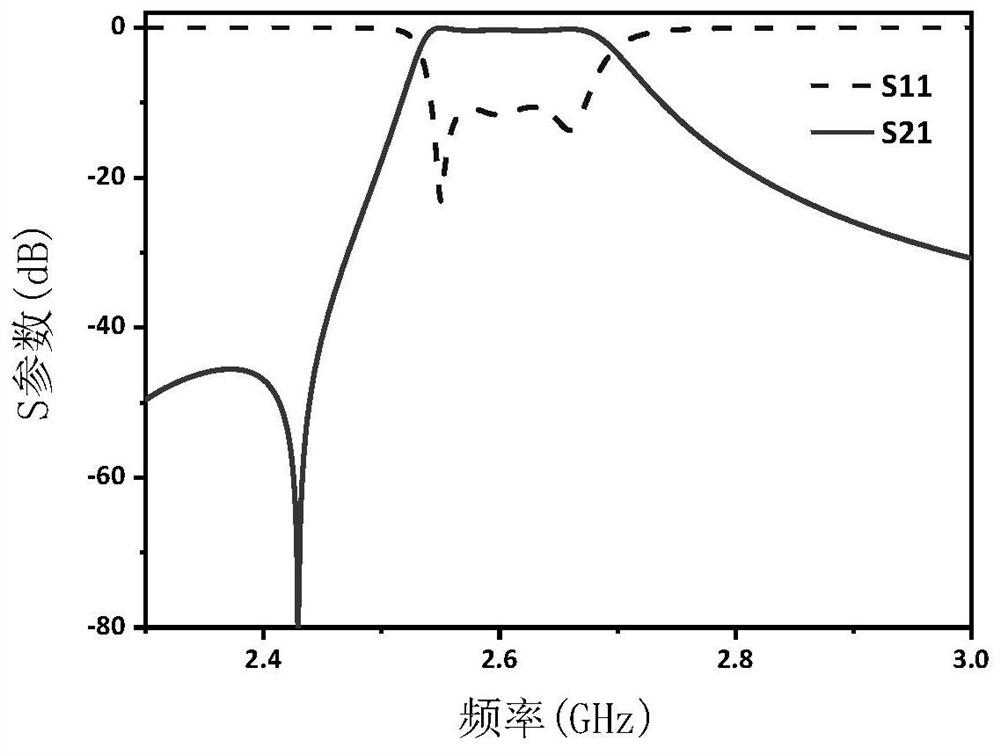

A Dielectric Filter with 180 Degree Phase Shifter

ActiveCN111900518BAchieving Cross-Coupling ResponsesOvercome processing difficultiesResonatorsCommunications systemElectrical polarity

The invention discloses a dielectric filter with a 180-degree phase shifter, which comprises a plurality of interconnected dielectric resonators and a 180-degree phase shifter; each dielectric resonator and the 180-degree phase shifter surface It is a metal conductive layer, and the inside is a medium with any dielectric constant; each dielectric resonator contains a debugging hole, which is used to adjust the resonant frequency of the resonator; the 180-degree phase shifter is a waveguide transmission line of any shape, which may not contain or Multiple debugging blind vias are included, and the included debugging blind vias are used to reduce the size of the 180-degree phase shifter, which is used to change the polarity of the original coupling to achieve filter cross-coupling response. The invention can flexibly change the polarity of the original coupling, easily realize the cross-coupling filter, has low cost and high reliability, and can be used in the filter design of the modern communication system.

Owner:人民华智通讯技术有限公司

Process for preparing low-temperature phase barium metaborate monocrystalline film through magnetron sputtering

InactiveCN1292103CTo satisfy the market's needsOvercome processing difficultiesPolycrystalline material growthFrom chemically reactive gasesSputteringEconomic benefits

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

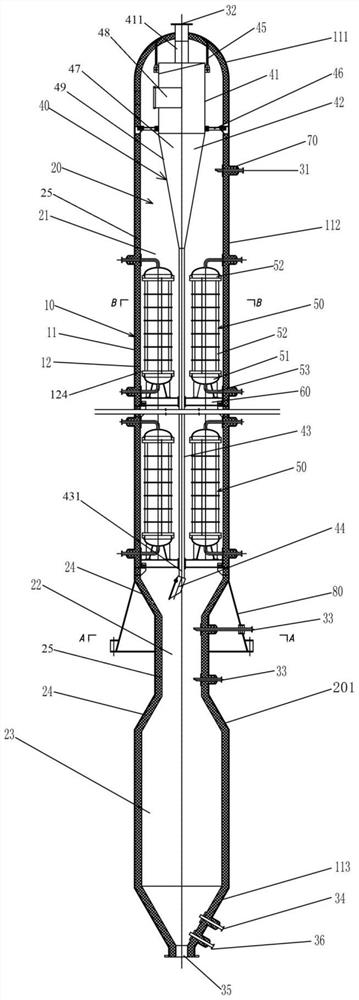

Heavy oil processing method and system

PendingCN112500891ALow priceReduce typesOrganic compound preparationHydrogen separation using solid contactOil processingGlycol synthesis

The invention provides a heavy oil processing method and system. The method at least comprises the following steps: (1) heavy oil cracking and gasification: heavy oil is subjected to heavy oil cracking and gasification, and at least cracking gas, synthesis gas and cracking oil are obtained; (2) cracking oil hydrocracking: carrying out hydrocracking on the cracking oil obtained in the step (1) to obtain a product containing dry gas, low-fraction gas, light naphtha, heavy naphtha and diesel oil; (3) aromatic hydrocarbon combination: by taking the heavy naphtha obtained in the step (2) as a raw material, performing aromatic hydrocarbon combination to obtain a product containing hydrogen, benzene and p-xylene and byproducts containing liquefied petroleum gas, pentane, raffinate oil and heavy aromatic hydrocarbon; (4) methanol synthesis: taking part of pyrolysis gas and synthesis gas obtained in the step (1) as raw materials, and performing methanol synthesis to obtain a methanol product; and (5) ethanol synthesis: taking the residual pyrolysis gas and synthesis gas obtained in the step (1) as raw materials, and carrying out ethanol synthesis to obtain an ethanol product.

Owner:北京石油化工工程研究院

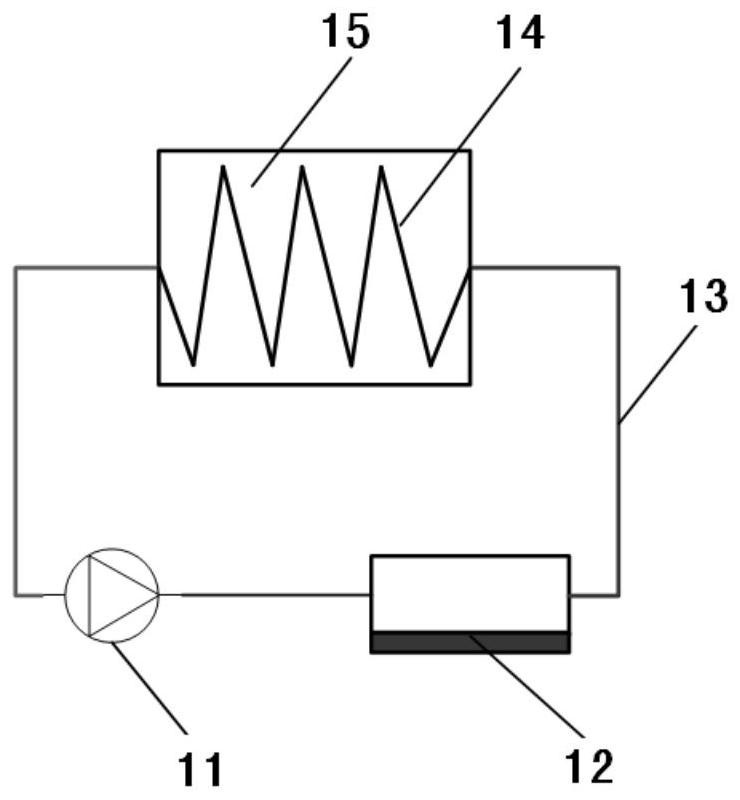

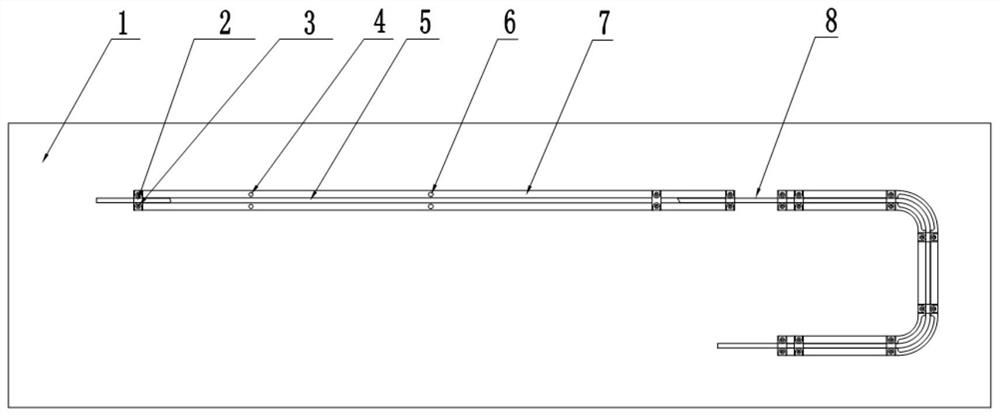

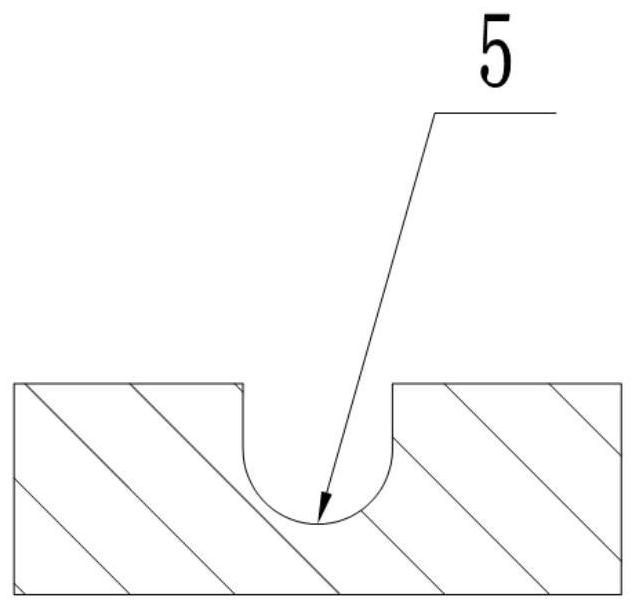

Two-phase fluid loop condenser device for spacecraft

InactiveCN112284166AOvercome processing difficultiesEasy to processIndirect heat exchangersHeat exchanger casingsEngineeringMetal sheet

The invention discloses a two-phase fluid loop condenser device for a spacecraft. The two-phase fluid loop condenser device comprises a pipeline pressing plate, a mounting plate, a pipeline, a mounting plate screw and a pressing plate screw; the mounting plate is of a plate-shaped metal structure, a pipeline channel is machined in the surface of the mounting plate and used for mounting a pipeline,the pipeline is mounted in the pipeline channel in a fastened mode through a pipeline pressing plate and the pressing plate screw, the mounting plate and a radiator are assembled in a fastened mode through the mounting plate screw, and the mounting plate and the radiator are mounted in a heat conduction mode; the pipeline pressing plate is of a narrow-strip-shaped metal sheet structure, through holes are machined in the two sides of the pipeline pressing plate and used for the pressing plate screw to penetrate through, and the contact face of the pipeline pressing plate and the pipeline is aplane; and a pressing plate mounting threaded hole and a mounting plate through hole are formed in the mounting plate, the pressing plate mounting threaded hole is used for achieving assembly of the pressing plate screw, and the mounting plate through hole is used for achieving penetration of the mounting plate screw. The device can be coupled with aerospace remote sensor structures of different structural forms, can be mounted with body-mounted radiators of different sizes and different shapes, and is low in development difficulty and low in manufacturing cost.

Owner:BEIJING RES INST OF SPATIAL MECHANICAL & ELECTRICAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com