Preparation of Yb-Gd-Ga doped garnet planar optical waveguide

A planar optical waveguide and garnet technology, applied in the direction of optical waveguide and light guide, can solve the problem that GGG crystals are difficult to process micron-scale wafers, and achieve good economic benefits and material saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

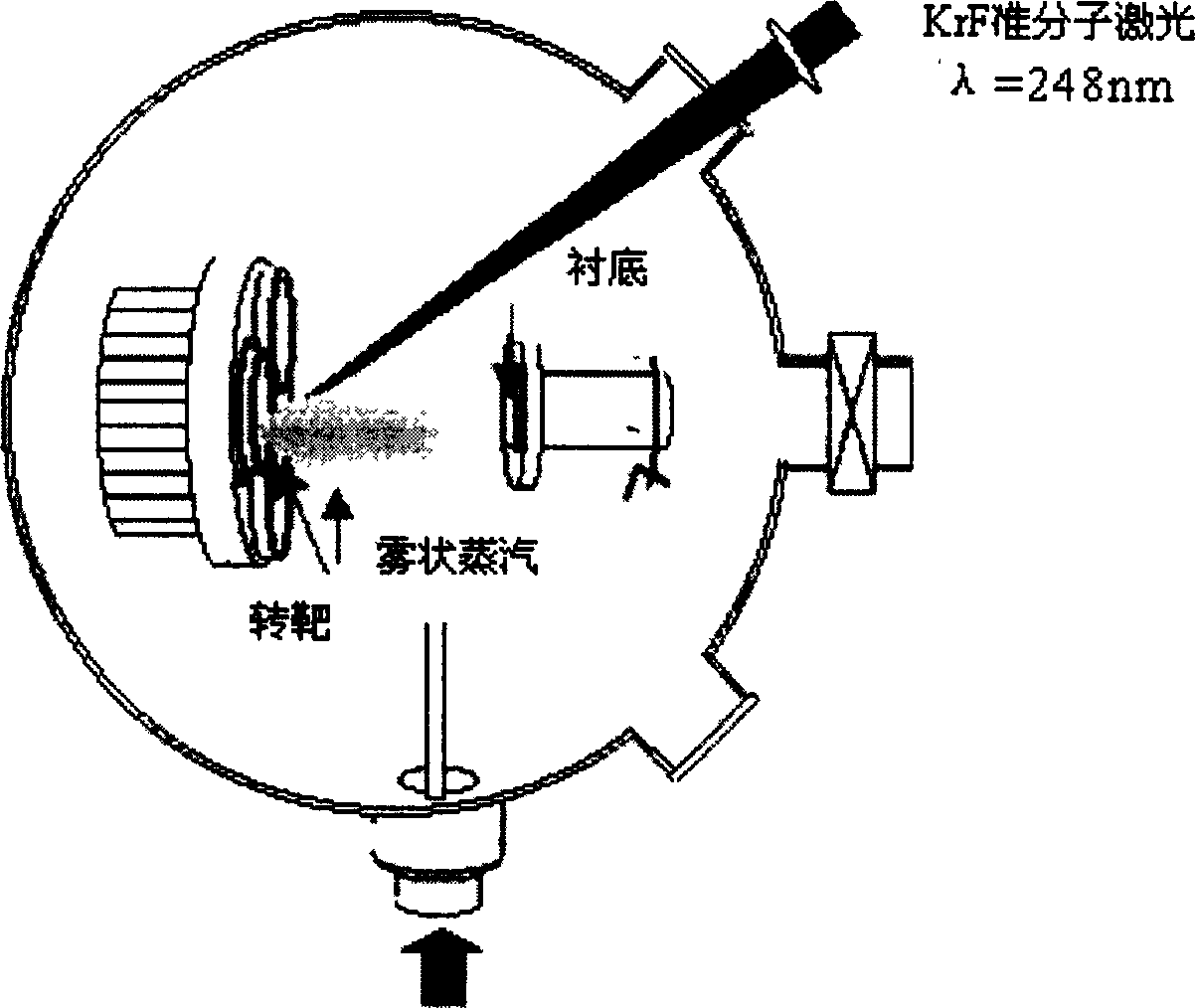

[0018] Yb was prepared by pulsed laser deposition (PLD) as described above 3+ :GGG single crystal thin film device and specific process flow:

[0019] The size to be cleaned is 10×10mm 2 , double-sided polished pure YAG substrate and Yb 3+ : The GGG polycrystalline target is sent into the pulsed laser deposition system;

[0020] Evacuate the cavity into an ultra-high vacuum, and then fill it with an oxygen atmosphere;

[0021] Heating the substrate to 600°C, passing the ArF excimer laser with a pulse width of 25ns through the lens at 10J / cm 2 The energy density of the concentrated light is irradiated to the Yb in the device through the optical window 3+ : GGG polycrystalline target, the target surface molecules are melted and evaporated to form a film on a pure YAG substrate, and high-quality Yb can be obtained after slow cooling 3+ : GGG film.

Embodiment 2

[0023] Yb was prepared by pulsed laser deposition (PLD) as described above 3+ :GGG single crystal thin film device and specific process flow:

[0024] The size to be cleaned is 10×10mm 2 , double-sided polished pure YAG substrate and Yb 3+ : The GGG polycrystalline target is sent into the pulsed laser deposition system;

[0025] Evacuate the cavity into an ultra-high vacuum, and then fill it with an oxygen atmosphere;

[0026] Heating the substrate to 900°C, passing the ArF excimer laser with a pulse width of 25ns through the lens at 10J / cm 2 The energy density of the concentrated light is irradiated to the Yb in the device through the optical window 3+ : GGG polycrystalline target, the target surface molecules are melted and evaporated to form a film on a pure YAG substrate, and high-quality Yb can be obtained after slow cooling 3+ : GGG planar optical waveguide.

Embodiment 3

[0028] Yb was prepared by pulsed laser deposition (PLD) as described above 3+ :GGG single crystal thin film device and specific process flow:

[0029] The size to be cleaned is 10×10mm 2 , double-sided polished pure YAG substrate and Yb 3+ : The GGG polycrystalline target is sent into the pulsed laser deposition system;

[0030] Evacuate the cavity into an ultra-high vacuum, and then fill it with an oxygen atmosphere;

[0031] Heating the substrate to 800°C, passing the ArF excimer laser with a pulse width of 25ns through the lens at 10J / cm 2 The energy density of the concentrated light is irradiated to the Yb in the device through the optical window 3+ : GGG polycrystalline target, the target surface molecules are melted and evaporated to form a film on a pure YAG substrate, and high-quality Yb can be obtained after slow cooling 3+ : GGG planar optical waveguide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com